Fundamentals

You have arrived at a pivotal point in your health journey. The generalized advice and one-size-fits-all solutions have proven insufficient. You feel the subtle, persistent signs of a system operating out of sync ∞ the fatigue that sleep does not resolve, the shifts in mood and cognitive clarity, the changes in your body’s composition and energy utilization.

Your pursuit of a solution has led you to personalized wellness protocols, specifically those involving hormonal optimization or metabolic recalibration. These protocols often depend on medications prepared by a compounding pharmacy, tailored to your unique biological requirements as indicated by your lab results and clinical presentation.

The promise of this approach is profound ∞ a therapeutic agent designed specifically for your body. The Testosterone Cypionate for your hormone replacement therapy, the Anastrozole to maintain your delicate estrogen balance, or the Ipamorelin peptide to support your body’s natural regenerative processes are all prepared to a precise dosage that your clinician has determined for you.

Herein lies a critical junction. The efficacy and safety of your entire protocol rest upon the molecular integrity of these compounded preparations. Your body’s endocrine system is a vast, interconnected communication network, operating with exquisite sensitivity. Hormones and peptides are the chemical messengers, the keys designed to fit specific cellular locks.

Federal oversight of the pharmacies that create these keys is the mechanism that ensures the key is cut correctly, is made of the right material, and is free from any contaminants that could jam the lock or damage the entire system.

The integrity of a personalized therapeutic protocol is directly dependent on the verifiable quality and precision of the compounded medication itself.

The Biological Stakes of Pharmaceutical Compounding

Your body functions through a series of intricate feedback loops. The Hypothalamic-Pituitary-Gonadal (HPG) axis, for instance, is the master regulator of your reproductive and metabolic health. When you introduce an external hormone like testosterone, you are intentionally influencing this system. The goal is to restore balance and optimal function.

A compounded medication that is dosed imprecisely, however, introduces chaos into this system. Too low a dose may fail to produce a therapeutic effect, leaving you with persistent symptoms and the mistaken belief that the protocol itself has failed. A dose that is too high can overwhelm the system, leading to unwanted side effects and shutting down your body’s own natural hormone production more than intended.

The concern extends beyond simple dosage. The sterility of injectable medications is a foundational pillar of patient safety. Your weekly subcutaneous or intramuscular injections bypass many of the body’s primary defense barriers. A sterile preparation is one that is free from living microbes, such as bacteria or fungi.

When a sterile injectable is contaminated, it introduces these organisms directly into your muscle tissue or bloodstream. The consequences can range from localized infections to systemic, life-threatening conditions. This is the precise reason why federal bodies like the Food and Drug Administration (FDA) and standard-setting organizations like the United States Pharmacopeia (USP) have established stringent guidelines for sterile compounding.

Who Guards the Guardians of Your Health?

The regulatory structure governing compounding pharmacies in the United States involves both state and federal agencies, creating a multi-layered system of oversight. Historically, state boards of pharmacy were the primary regulators of compounding practices. They are responsible for licensing pharmacists and pharmacies, conducting inspections, and ensuring compliance with state-specific laws. These boards remain the frontline defense in patient safety, particularly for traditional pharmacies preparing medications for individual patients.

Following a tragic public health crisis in 2012 involving contaminated sterile injections, the role of the federal government was significantly clarified and expanded. The FDA now plays a direct and active role in overseeing compounding pharmacies, especially those that produce larger quantities of sterile medications.

The agency conducts its own inspections, investigates reports of adverse events, and can take enforcement action against facilities that fail to meet federal quality standards. This dual system of state and federal oversight provides a safety net, with federal standards creating a baseline of quality and safety that applies across the country, ensuring that your personalized medications are prepared with the highest degree of care, regardless of where the pharmacy is located.

The Role of the United States Pharmacopeia

A third critical entity in this safety framework is the United States Pharmacopeia (USP). The USP is a non-governmental, scientific organization that sets quality standards for medicines. These standards are published in chapters that define the required procedures for different types of compounding. Two of the most important chapters for personalized wellness protocols are:

- USP General Chapter <797> ∞ This chapter provides detailed standards for sterile compounding. It dictates everything from the air quality in the cleanroom and the proper sterilization of equipment to the specific training and garb that personnel must use to prevent microbial contamination of injectable medications.

- USP General Chapter <795> ∞ This chapter governs non-sterile compounding, such as the preparation of capsules, creams, or oral solutions. It ensures that these medications are prepared with correct calculations, ingredients, and procedures to maintain potency and stability.

Compliance with these USP standards is a cornerstone of safe compounding. Federal and state regulators often enforce these standards during their inspections. For you, the person relying on these medications, these chapters represent the detailed instruction manual that a pharmacy must follow to ensure the product you receive is both safe and effective. It is the tangible expression of the commitment to quality that underpins the entire practice of personalized medicine.

Intermediate

Understanding the fundamental need for oversight is the first step. The next is to appreciate the specific legal and operational frameworks that were constructed to prevent catastrophic failures and ensure the reliability of your therapeutic protocols. The modern landscape of compounding regulation was forged by tragedy.

The 2012 fungal meningitis outbreak, traced back to contaminated steroid injections from the New England Compounding Center (NECC), resulted in over 750 cases of infection and 64 deaths. This event exposed critical gaps in the existing oversight structure and served as the catalyst for landmark federal legislation.

In 2013, the U.S. Congress passed the Drug Quality and Security Act (DQSA). This law fundamentally altered the FDA’s authority over compounding pharmacies. It created a new, distinct category of compounder and established clearer lines of authority, moving beyond the patchwork of state-level regulations that had previously defined the landscape.

For anyone engaged in a hormone optimization or peptide therapy protocol, understanding the DQSA is essential to becoming an informed partner in your own healthcare. The law directly impacts the source, quality, and reliability of the injectable medications that form the basis of many of these advanced wellness strategies.

How Does the DQSA Differentiate between Pharmacy Types?

The DQSA established two distinct classes of compounding pharmacies under federal law, each with different requirements and levels of oversight. Your clinician’s choice of where to source your compounded medications is influenced by these classifications. The two types are known as 503A facilities and 503B facilities, named after the sections of the Food, Drug, and Cosmetic Act that the DQSA amended.

A 503A facility is a traditional compounding pharmacy. These are the pharmacies most people are familiar with. They must be licensed by a state board of pharmacy and are primarily regulated at the state level. Under the DQSA, 503A facilities can only compound medications based on the receipt of a valid, patient-specific prescription.

They can compound in limited quantities in anticipation of receiving prescriptions, but they are prohibited from functioning as large-scale manufacturers. While they are expected to comply with USP standards for quality, they are not required to adhere to the more rigorous federal standards known as Current Good Manufacturing Practices (cGMP).

A 503B facility, also known as an “outsourcing facility,” is a new category created by the DQSA. These facilities voluntarily register with the FDA and are subject to direct federal oversight. Unlike 503A pharmacies, 503B facilities can produce large batches of compounded medications with or without patient-specific prescriptions, which they can then sell to healthcare providers and hospitals.

This is particularly relevant for common protocols, such as standardized concentrations of Testosterone Cypionate or Sermorelin. In exchange for this ability to produce at scale, 503B facilities must adhere to a much higher standard of quality. They are required to comply fully with the FDA’s cGMP regulations, which are the same standards that large pharmaceutical manufacturers must follow.

The Drug Quality and Security Act created a tiered system of oversight, distinguishing between traditional patient-specific compounding and large-scale outsourcing facilities to apply appropriate quality standards.

The table below outlines the key distinctions between these two types of facilities, which directly relate to the safety and consistency of your medications.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Regulator | State Boards of Pharmacy | U.S. Food and Drug Administration (FDA) |

| Prescription Requirement | Must have a patient-specific prescription to compound and dispense. | Can compound without patient-specific prescriptions for “office use”. |

| Quality Standard | Expected to follow USP <795> and <797> standards. | Must comply with Current Good Manufacturing Practices (cGMP). |

| Production Volume | Limited to small batches for specific patients. | Permitted to produce large batches of sterile drugs. |

| Federal Registration | Not required to register with the FDA. | Must voluntarily register with the FDA and is subject to routine inspections. |

The Clinical Importance of Current Good Manufacturing Practices

The requirement for 503B facilities to adhere to cGMP is a defining feature of the post-DQSA regulatory environment. For a patient on a long-term injectable protocol, this is a critical quality assurance measure. cGMP regulations are a comprehensive set of rules that govern the design, monitoring, and control of manufacturing processes and facilities. They ensure that drugs are produced with consistent identity, strength, quality, and purity.

What does this mean for your weekly Testosterone Cypionate or CJC-1295/Ipamorelin injection? It means the facility producing it must follow exacting procedures for every step of the process:

- Facility Design and Maintenance ∞ The physical plant must be designed to prevent contamination. This includes validated systems for air filtration (HEPA filters), strict separation between sterile and non-sterile areas, and surfaces that are smooth, non-porous, and easily sanitized.

- Raw Material Testing ∞ Every batch of active pharmaceutical ingredient (API), such as the raw testosterone powder, must be tested for identity, purity, and potency before it is used in a formulation. The facility must verify that the API is not degraded or contaminated.

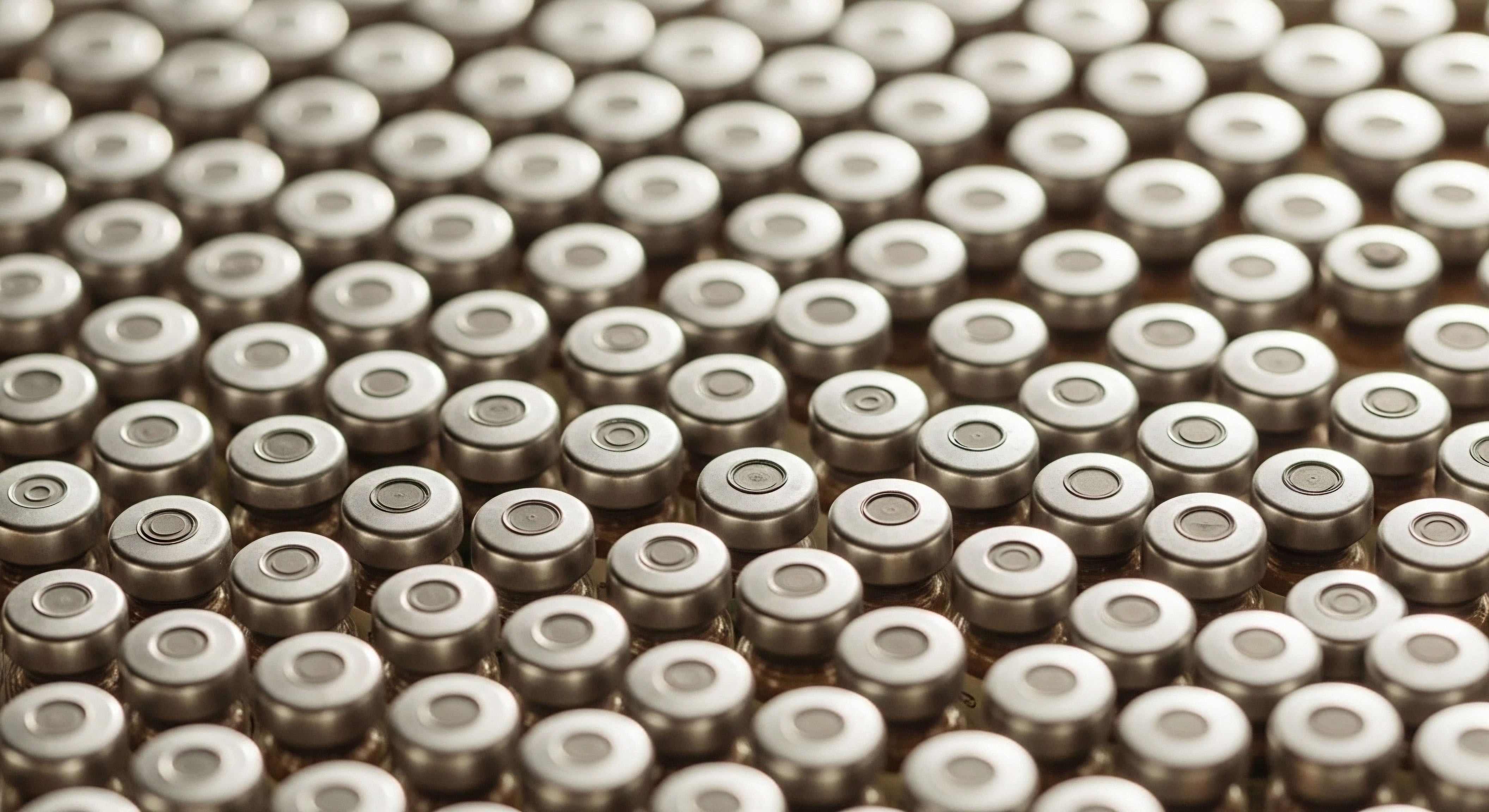

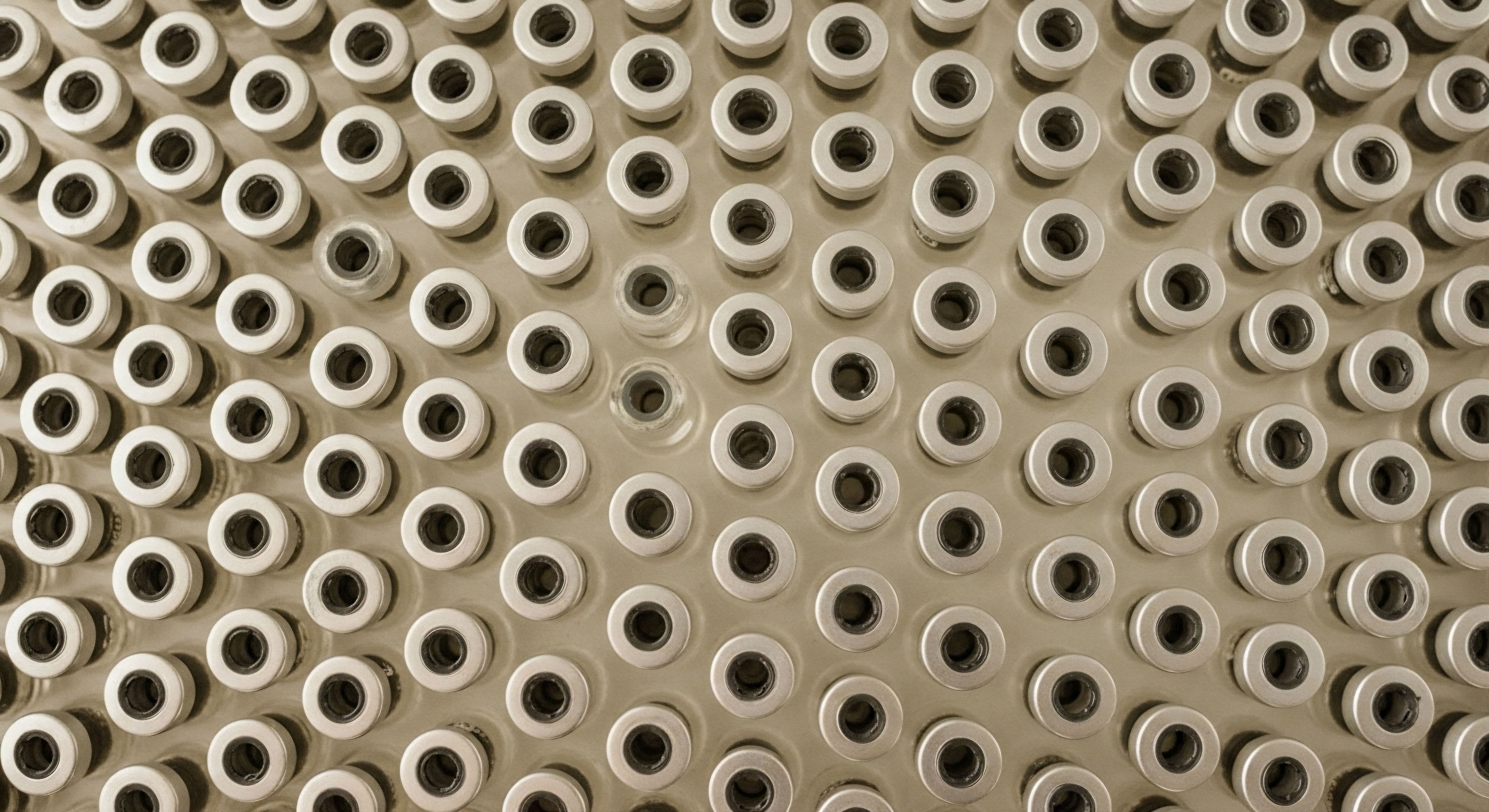

- Process Validation ∞ The exact process for mixing, filtering, and filling vials must be validated to prove that it consistently produces a sterile product at the correct concentration. This involves rigorous testing of finished products.

- Environmental Monitoring ∞ The air and surfaces within the cleanroom must be regularly tested for microbial contamination. Personnel must also be tested to ensure their garbing and aseptic techniques are effective.

- Finished Product Testing ∞ A statistically significant number of vials from every batch must be tested for sterility and potency before the batch can be released for distribution. This provides a final verification that the process was successful.

This level of process control provides a high degree of confidence that every vial from a 503B facility is what it claims to be. It minimizes the risk of receiving a product that is contaminated, under-dosed, or over-dosed, thereby protecting the integrity of your personalized wellness protocol and safeguarding your health from the systemic risks of a compromised medication.

Academic

A sophisticated appreciation of federal oversight requires a granular analysis of the potential failure points within the compounding process and their cascading biological consequences. The conversation moves from the general principle of safety to the specific pharmacokinetics of contamination and the subtle yet profound endocrine disruption caused by dose variability.

The NECC tragedy serves as a stark case study in catastrophic failure, where contaminated lots of preservative-free methylprednisolone acetate led to a national outbreak of fungal meningitis caused by the organism Exserohilum rostratum. This event underscores a critical vulnerability ∞ the administration of sterile preparations into privileged anatomical sites, such as the epidural space, bypasses innate immune defenses, making the absolute sterility of the compound a life-or-death variable.

Federal oversight, particularly the cGMP framework applied to 503B outsourcing facilities, is a systemic response designed to mitigate these risks at every stage of production. The cGMP requirements are predicated on the scientific understanding that quality cannot be tested into a product; it must be built into the process itself.

For the patient engaged in hormonal optimization, the implications are twofold. First is the prevention of infectious sequelae from contaminated injectables. Second, and just as significant for the efficacy of the protocol, is the assurance of potency and purity, which protects the delicate balance of the neuroendocrine axes.

What Are the Systemic Consequences of a Compounded Drug Failure?

The failure of a compounded medication can manifest in ways that are either acute and dramatic, as with microbial contamination, or chronic and insidious, as with dose variability. Both represent significant threats to a patient’s health and the success of their therapeutic regimen.

From a microbiological perspective, the introduction of a pathogen via a contaminated injectable initiates a complex host-pathogen interaction. The type of organism, the site of injection, and the immune status of the host determine the clinical outcome.

In the context of hormone replacement, many individuals may be in a state of relative immune senescence or metabolic dysregulation, potentially increasing their susceptibility. A localized abscess at the injection site is a best-case scenario. A systemic infection, or sepsis, represents a life-threatening dysregulated host response to the infection. In the NECC case, direct injection into the central nervous system provided the fungus a direct pathway to the meninges, leading to a devastating and difficult-to-treat infection.

From an endocrinological perspective, the consequences of inconsistent dosing are equally disruptive, albeit less immediately apparent. Consider a male patient on a Testosterone Replacement Therapy (TRT) protocol that includes weekly injections of Testosterone Cypionate and twice-weekly oral Anastrozole to manage aromatization. The protocol is designed to maintain serum testosterone within a specific therapeutic window while keeping estradiol levels controlled to prevent side effects like gynecomastia and fluid retention. The entire system is a carefully managed equilibrium.

Inconsistent potency in compounded hormones introduces chaotic signaling into the neuroendocrine system, undermining the very stability that therapeutic protocols aim to achieve.

Now, introduce a compounding error. If a batch of Testosterone Cypionate is prepared at 80% of its stated potency, the patient will experience a sub-therapeutic trough level, leading to the re-emergence of hypogonadal symptoms ∞ fatigue, low libido, and cognitive fog.

Conversely, if the Anastrozole is compounded with insufficient potency, the patient’s estradiol levels may rise unchecked, producing significant side effects even with a correct testosterone dose. If the testosterone is super-potent, it can lead to excessive erythrocytosis, polycythemia, and a more profound suppression of the endogenous HPG axis.

These variations transform a therapeutic intervention into a source of biological noise, making it impossible for the clinician to titrate doses effectively and for the patient to achieve a stable physiological state. The table below details some of these potential systemic effects.

| Compounding Failure | Intended Mechanism | Potential Biological Consequence |

|---|---|---|

| Sub-potent Testosterone Cypionate | Maintain serum testosterone in the optimal range (e.g. 600-900 ng/dL). | Failure to resolve hypogonadal symptoms. Patient experiences continued fatigue, depression, and low libido. Erroneous conclusion that TRT is ineffective. |

| Super-potent Testosterone Cypionate | Maintain serum testosterone in the optimal range. | Supraphysiological testosterone levels. Increased risk of polycythemia, potential for adverse cardiovascular events, and excessive aromatization to estradiol. Deeper HPG axis suppression. |

| Sub-potent Anastrozole | Inhibit the aromatase enzyme to control the conversion of testosterone to estradiol. | Uncontrolled rise in serum estradiol. Increased risk of gynecomastia, edema, mood volatility, and potential for prostate stimulation. |

| Super-potent Anastrozole | Inhibit the aromatase enzyme to control estradiol. | Suppression of estradiol to excessively low levels (“crashed E2”). Leads to joint pain, low libido, anxiety, and negative impacts on bone mineral density and lipid profiles. |

| Microbial Contamination | Deliver a sterile therapeutic agent. | Localized abscess, cellulitis, or systemic bacteremia/fungemia. High risk of sepsis and life-threatening infection, particularly with intramuscular or intravenous administration. |

The Regulatory Science of Ensuring Quality

Federal oversight through cGMP is the application of regulatory science to prevent these outcomes. It mandates a system of controls that are scientifically validated to ensure predictability and consistency. For example, a 503B outsourcing facility must use a validated High-Performance Liquid Chromatography (HPLC) method to confirm the potency of every batch of finished product.

They must perform sterility testing according to the methods outlined in USP <71>, which involves incubating samples of the product in growth media for a specified period to detect any potential microbial contamination. They must also test for bacterial endotoxins, which are fever-inducing substances shed from the cell walls of certain bacteria, using the methods in USP <85>.

These requirements for quantitative, validated testing provide an objective assurance of quality that is absent in less-regulated environments. The establishment of the 503B category under the DQSA was a direct acknowledgment that when compounding moves from a patient-specific practice to a larger-scale manufacturing operation, the potential for widespread harm increases exponentially.

Therefore, the level of regulatory scrutiny must increase commensurately. For the individual whose vitality and well-being depend on these therapies, this framework of federal oversight is the silent, essential partner ensuring that the pursuit of personalized health is built on a foundation of safety and molecular certainty.

References

- Kauffman, G. L. & Gudeman, J. (2014). Sterile Compounding ∞ Clinical, Legal, and Regulatory Implications for Patient Safety. Journal of Managed Care & Specialty Pharmacy, 20(12), 1254 ∞ 1261.

- United States Pharmacopeia. (2019). USP General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations. In United States Pharmacopeia and National Formulary (USP 42-NF 37). United States Pharmacopeial Convention.

- American Society of Health-System Pharmacists. (2020). ASHP Comments on FDA Compounding Guidances. Retrieved from ASHP official publications.

- The Pew Charitable Trusts. (2016). State Oversight of Drug Compounding. The Pew Charitable Trusts and the National Association of Boards of Pharmacy.

- U.S. Food and Drug Administration. (2013). Drug Quality and Security Act (DQSA). Public Law 113-54.

- National Academies of Sciences, Engineering, and Medicine. (2020). Compounded Topical Pain Creams ∞ Review of Select Ingredients for Safety, Effectiveness, and Use. The National Academies Press.

- U.S. Food and Drug Administration. (2018). Insanitary Conditions at Compounding Facilities ∞ Guidance for Industry. Center for Drug Evaluation and Research.

Reflection

You have now traversed the landscape of compounding pharmacy oversight, from the personal stakes in your own health protocol to the intricate legal and scientific frameworks designed to protect you. This knowledge serves a distinct purpose. It transforms you from a passive recipient of care into an informed advocate for your own biological sovereignty.

The journey toward optimal health is deeply personal, yet it relies on a system of external quality controls that function invisibly in the background. Understanding this system allows you to ask more precise questions and make more discerning choices.

As you move forward, consider the dialogue you have with your clinical team. The source of your therapeutic compounds is a valid and important topic of conversation. The knowledge of terms like ‘503B outsourcing facility’ and ‘cGMP’ provides you with the vocabulary to engage in that discussion with confidence.

This exploration of oversight is a foundational piece of your wellness education. The ultimate goal is to build a resilient, responsive, and vibrant biological system. Achieving that requires a partnership between your own commitment, your clinician’s expertise, and a pharmaceutical supply chain that operates with the highest degree of integrity. The path forward is one of continued learning and proactive engagement with every variable that influences your health.

Glossary

compounding pharmacy

hormone replacement therapy

testosterone cypionate

endocrine system

federal oversight

patient safety

food and drug administration

united states pharmacopeia

compounding pharmacies

microbial contamination

sterile compounding

drug quality

peptide therapy

compounded medications

503b facilities

current good manufacturing practices

outsourcing facility

503b outsourcing

maintain serum testosterone

anastrozole

hpg axis