Fundamentals

The arrival of a carefully packed, temperature-controlled parcel at your doorstep marks a significant moment. It represents the tangible beginning of a protocol designed to recalibrate your body’s internal communication systems. Inside, resting within a precisely chilled environment, are molecules engineered to restore a language your cells understand ∞ the language of hormones and peptides.

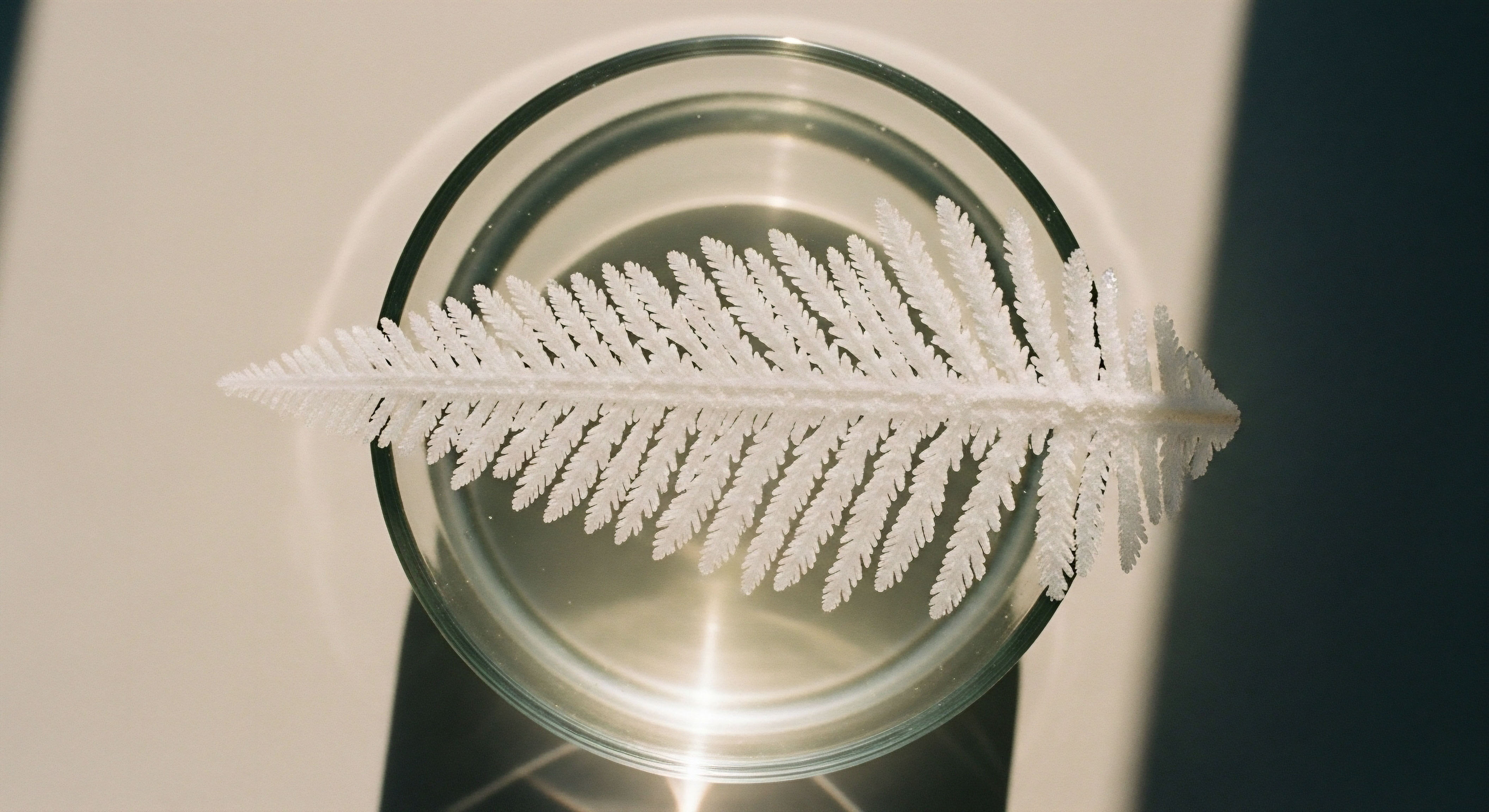

These are not inert substances; they are intricate biological keys, each folded into a specific three-dimensional shape designed to fit perfectly into the locks of your cellular receptors. The entire purpose of a therapeutic protocol hinges on this precise molecular fit. When a hormone like testosterone or a peptide like Sermorelin binds to its receptor, it initiates a cascade of events, a cellular conversation that can lead to renewed energy, improved metabolic function, and a restored sense of vitality.

The structural integrity of these molecules is paramount. A slight deviation in temperature, a moment of excessive heat, can act like a physical force, bending the key out of shape. A denatured molecule, its delicate architecture compromised, can no longer bind effectively to its receptor.

The message is lost, the cellular lock remains unturned, and the intended biological effect fails to materialize. This inherent fragility is the central reason for the existence of the pharmaceutical cold chain.

It is a continuous, unbroken series of refrigerated environments, a logistical and engineering marvel designed with a single purpose ∞ to preserve the exact molecular structure of a therapeutic agent from the moment of its creation to the moment of its administration. It is the silent guardian of your protocol’s potential.

The cold chain exists to protect the precise molecular architecture that determines a therapeutic’s biological function.

The Core Components of Protection

At its heart, the cold chain is a system of systems, a coordinated effort to combat thermal energy and preserve biochemical stability. For the sensitive biologics used in hormonal optimization, this system relies on several key elements working in concert. Understanding these components allows you to appreciate the science safeguarding your investment in your health. Each element addresses a specific threat to the stability of the molecules within the package, ensuring they arrive with their therapeutic promise intact.

The primary defense is the packaging itself. This involves more than a simple cooler; it is an engineered thermal buffer. High-density foam or advanced vacuum-insulated panels create a barrier that dramatically slows the transfer of heat from the outside world. Inside this protective shell, refrigerants provide the cooling power.

These are often specialized gel packs or phase-change materials designed to absorb heat and maintain a specific, narrow temperature range, such as 2°C to 8°C, for an extended period. The final piece is a temperature monitoring device, a silent witness that records the thermal history of the shipment, confirming that the contents were never exposed to damaging temperatures during their transit.

Why Is This so Important for Hormonal Therapies?

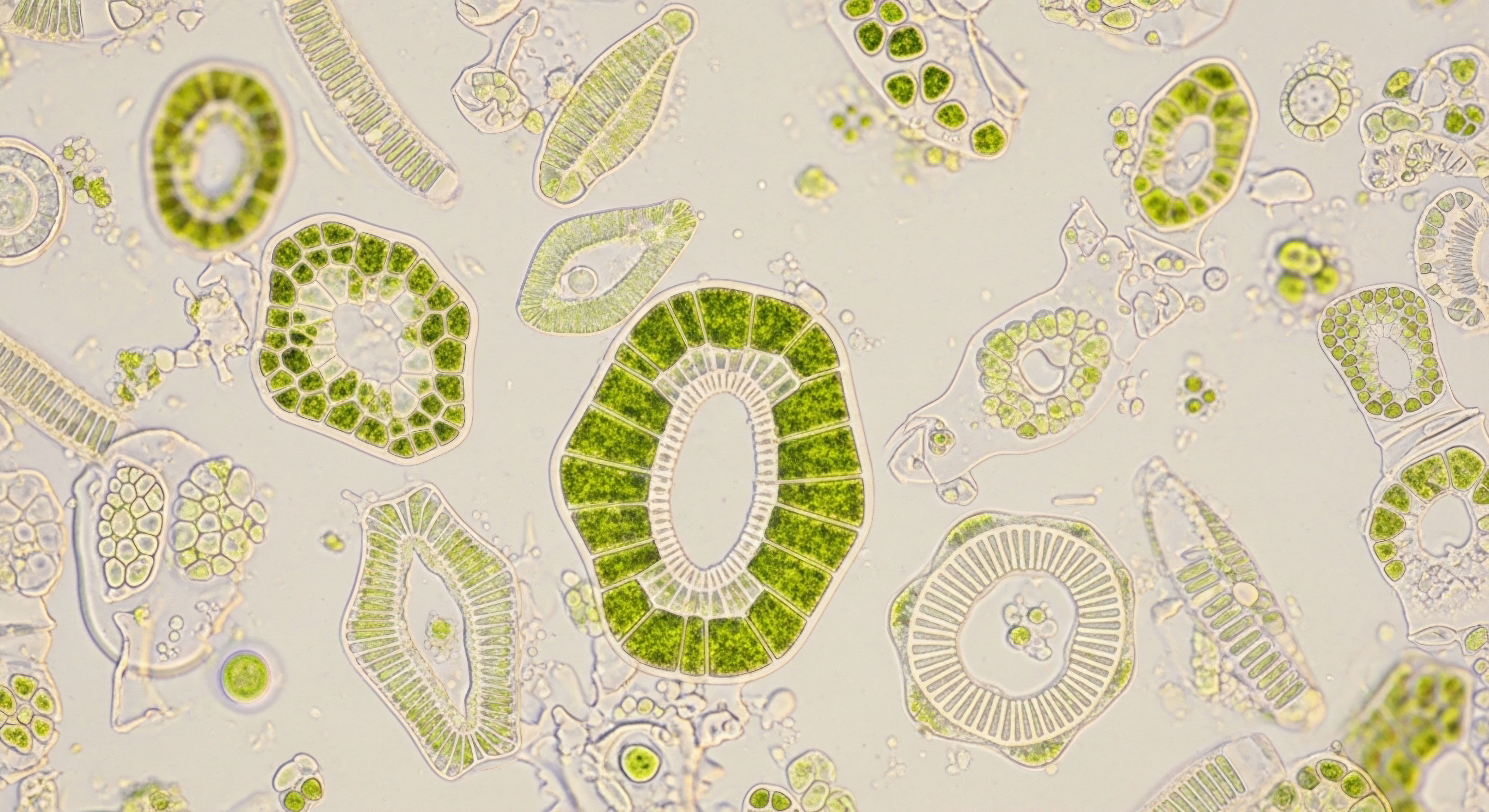

The molecules central to hormonal and metabolic recalibration possess a unique vulnerability. Testosterone Cypionate, while relatively stable, still requires controlled temperatures to prevent degradation of its carrier oil and ensure its long-term potency. Peptide therapies, such as Ipamorelin or CJC-1295, exist on another level of fragility.

These are chains of amino acids, and their biological activity is a direct function of their folded shape. Once reconstituted from a freeze-dried powder into a liquid, they become highly susceptible to heat-induced degradation. A break in the cold chain for these compounds can render a vial of potent signaling molecules into a solution of ineffective fragments.

The consequence is a protocol that produces no results, leading to confusion and the incorrect assumption that the therapy itself is ineffective, when the failure actually occurred within the supply line.

Intermediate

A deeper examination of the cold chain reveals a sophisticated interplay of materials science and data management. The system is designed to create a self-contained, stable microenvironment that can withstand the unpredictable conditions of global logistics. For a person on a wellness protocol, the technologies inside their shipment are as vital as the therapeutics themselves.

They are the guarantors of bio-availability, ensuring the molecule’s potential energy is delivered to the cellular level without compromise. This requires a move beyond basic cooling to systems that can adapt, monitor, and verify the conditions of transit with a high degree of precision.

The two primary pillars of this technological ecosystem are advanced passive protection and active monitoring. Passive systems are engineered to maintain temperature without an external power source, relying on the physical properties of their materials. Active monitoring involves electronic devices that record and sometimes transmit data, providing a detailed history of the shipment’s environment. The synergy between these two pillars creates the robust security required for high-value, temperature-sensitive biologics.

Advanced cold chain integrity is achieved through the integration of sophisticated materials science and active data monitoring systems.

Advanced Passive Thermal Regulation

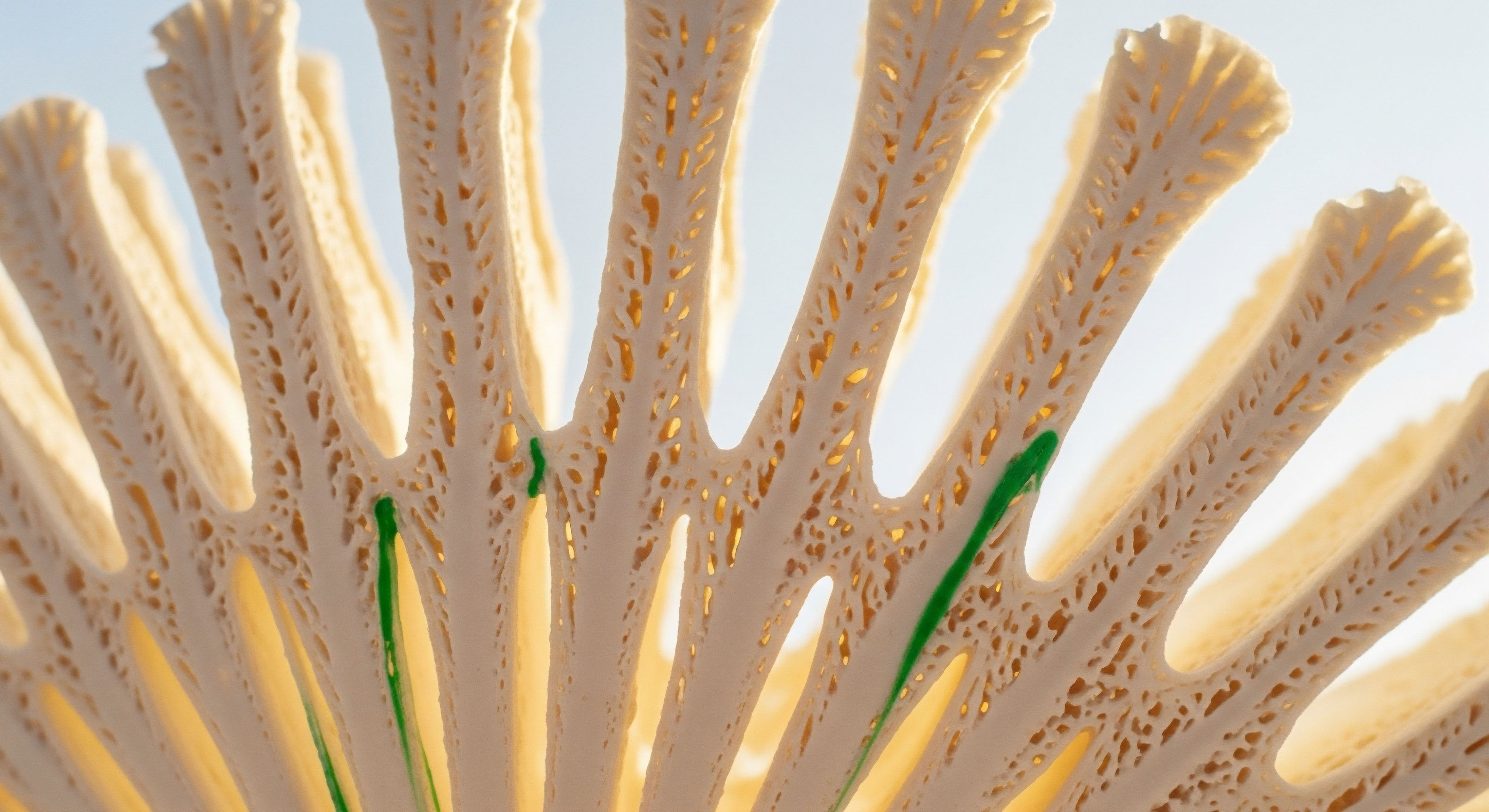

The effectiveness of a pharmaceutical shipper is determined by its ability to resist thermal transfer and maintain a stable interior temperature. Modern systems achieve this through two key innovations ∞ vacuum-insulated panels (VIPs) and phase-change materials (PCMs).

- Vacuum Insulated Panels (VIPs) These are rigid, board-like structures with a microporous core from which nearly all air has been evacuated and sealed within a gas-impermeable barrier. This vacuum drastically reduces thermal conduction and convection, giving VIPs an insulating capability many times greater than that of traditional materials like expanded polystyrene foam of the same thickness. Their use allows for smaller, lighter packages that can maintain temperature for longer durations.

- Phase Change Materials (PCMs) These are substances engineered to melt and solidify at a specific temperature. As a PCM transitions from solid to liquid, it absorbs a large amount of thermal energy without its own temperature increasing. This process, known as latent heat absorption, holds the internal environment of the shipper at a stable temperature for an extended period. PCMs are formulated for specific temperature ranges, such as maintaining a 2-8°C environment for refrigerated biologics or a -20°C environment for frozen materials.

Together, VIPs and PCMs form a powerful passive defense. The VIPs minimize the intrusion of external heat, while the PCMs actively absorb any heat that does penetrate the barrier, creating a stable thermal plateau that protects the therapeutic payload during long transit times or unexpected delays.

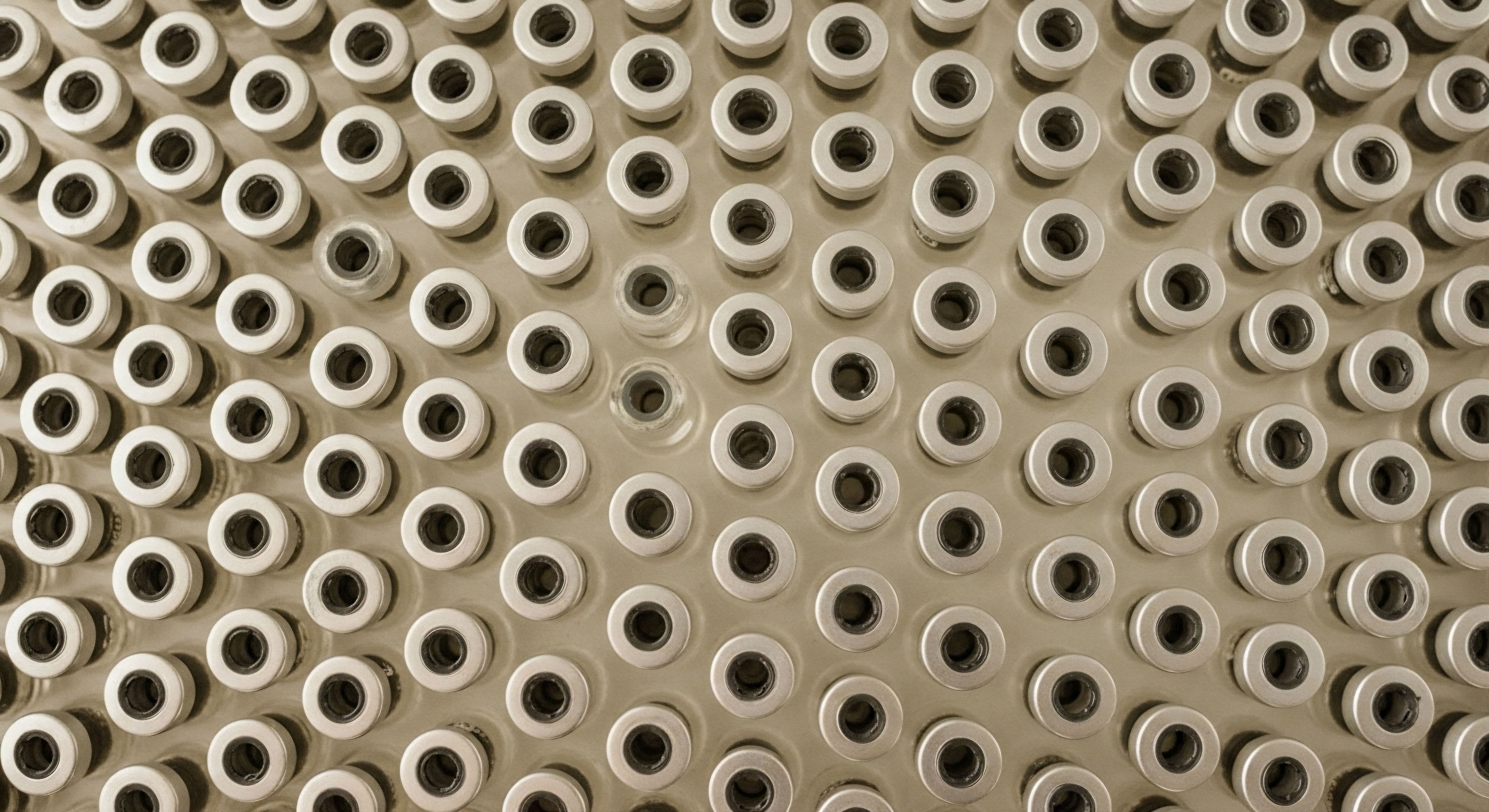

The Role of Active Data Logging

While passive systems provide physical protection, active data logging supplies the critical element of verification. A data logger is a small electronic device that measures and records temperature at predetermined intervals. This information creates an auditable record of the shipment’s journey, proving that the cold chain remained unbroken. The sophistication of these devices varies, offering different levels of insight and security.

| Technology Type | Mechanism Of Action | Data Provided | Primary Application |

|---|---|---|---|

| Chemical Indicators | A temperature-sensitive chemical undergoes an irreversible color change when a specific temperature threshold is breached. | A simple, visual go/no-go indication of a temperature excursion. | Low-cost screening for individual product packages or small shipments. |

| Digital Data Loggers (USB) | An electronic sensor records temperature data to internal memory. The device is plugged into a computer via USB at the destination to download a full time-temperature report. | A complete thermal history of the shipment, including the time and duration of any deviations. | Standard for most clinical and pharmaceutical shipments, providing detailed quality assurance data. |

| Real-Time Cellular Monitors | An integrated sensor suite (temperature, humidity, GPS) transmits data to the cloud in real-time using cellular networks. | Live visibility of a shipment’s condition and location, with automated alerts for any deviations. | High-value, critical shipments where immediate intervention in response to an excursion is necessary. |

For a patient receiving a shipment of peptides, the presence of a data logger is a mark of quality and assurance. It transforms the question of the product’s integrity from an assumption into a verifiable fact. It confirms that the delicate molecules within have been protected throughout their journey, ready to perform their intended function within your body’s intricate systems.

Academic

The integrity of the pharmaceutical cold chain is fundamentally a problem of applied thermodynamics and information science. The objective is to mitigate the kinetic processes of molecular degradation for biologics by maintaining a state of low thermal energy. For complex molecules like peptides and monoclonal antibodies, biological efficacy is an emergent property of their precise, three-dimensional conformational structure.

Any temperature excursion provides the activation energy necessary to initiate denaturation, aggregation, or proteolysis, irreversibly compromising the molecule’s function. Therefore, the technologies employed represent a sophisticated defense against entropy, ensuring the therapeutic message encoded in the molecule’s structure is delivered with fidelity.

What Does the Future of Biologic Security Look Like?

The next generation of cold chain technologies is moving from a reactive, data-recording posture to a proactive, data-driven, and fully integrated ecosystem. This evolution is powered by the confluence of the Internet of Things (IoT), blockchain technology, and predictive analytics. This new paradigm treats the entire supply chain as a single, observable entity, securing the therapeutic not just against thermal damage, but against all potential vectors of compromise, including counterfeiting and diversion.

IoT-enabled sensors form the nervous system of this modern cold chain. These are no longer simple temperature recorders; they are multi-modal sensor packages that can monitor temperature, humidity, shock, vibration, and light exposure in real-time. Using low-energy wireless protocols, these sensors transmit a constant stream of data to a centralized cloud platform.

This creates a “digital twin” of the physical shipment, a virtual representation that allows for unprecedented visibility and control. Stakeholders can be alerted to a potential temperature deviation on an airport tarmac and intervene before the product is compromised.

The integration of IoT and blockchain is transforming cold chain logistics from a system of record into a system of real-time assurance and verifiable truth.

Blockchain for an Immutable Chain of Custody

While IoT provides real-time visibility, blockchain technology provides an immutable record of truth. Blockchain is a distributed, cryptographically secured ledger that records every transaction or handoff in a product’s journey. Each entry, or “block,” is linked to the previous one, creating a chain that is computationally infeasible to alter retroactively. In the pharmaceutical context, this creates an unforgeable digital pedigree for a specific vial of medicine.

This has profound implications for patient safety and protocol efficacy. It guarantees the authenticity of the product, eliminating the risk of counterfeit therapeutics entering the supply chain. When combined with IoT data, the blockchain can record not just the chain of custody, but the chain of condition.

A smart contract could automatically verify that a shipment never deviated from its required temperature range before accepting it at a pharmacy or clinic. This creates a level of trust and verification that is mathematically enforced.

Predictive Analytics and Risk Mitigation

The vast datasets generated by IoT sensors are a fertile ground for machine learning and artificial intelligence. Predictive analytics platforms can analyze historical shipping data, weather patterns, flight schedules, and carrier performance to model the risk of a temperature excursion before a shipment even leaves the warehouse.

This allows for intelligent route planning and the selection of the most appropriate packaging and refrigerant configuration for a specific journey. For example, an algorithm might determine that a shipment from Arizona to Maine in July requires a packaging solution with an additional 24 hours of thermal buffering to account for a high probability of tarmac delays at a specific transit hub. This shifts the posture from risk monitoring to proactive risk elimination.

| Stage Of Transit | Potential Risk Vector | Integrated Technological Solution |

|---|---|---|

| Manufacturing & Packaging | Incorrect packaging selection or refrigerant loading. | Digital payload calculators and AI-driven packaging recommendations based on route risk analysis. |

| Ground & Air Transit | Unexpected delays (e.g. weather, customs, tarmac holds). | Real-time IoT monitoring with automated alerts sent to logistics managers for immediate intervention. |

| The “Last Mile” Delivery | Package left on a hot porch or in a mailbox. | GPS tracking with patient-facing delivery notifications and time-stamped delivery confirmation. |

| Patient Storage | Improper home refrigeration or storage of reconstituted peptides. | Patient education materials and time-out-of-refrigeration indicators on product vials. |

| Supply Chain Integrity | Introduction of counterfeit or diverted products. | Blockchain-based serialization, creating a verifiable and immutable digital identity for each product unit. |

For the individual engaged in a sophisticated wellness protocol, these academic advancements have a direct and personal impact. They represent the ultimate expression of quality control, a system-wide commitment to ensuring that the potent, fragile molecules they rely on are delivered with their biological promise fully intact. The convergence of these technologies ensures that the science in the syringe is precisely the science that was intended.

References

- Yi, Jizu, et al. “Degradation and Stabilization of Peptide Hormones in Human Blood Specimens.” PLoS ONE, vol. 10, no. 7, 2015, e0134427.

- Tower Cold Chain. “Maintaining pharmaceutical integrity through digitalisation.” Logistics Manager, June 2023.

- Verified Market Research. “Technological Innovations Transforming Cold Chain Monitoring.” Verified Market Research Blog, 28 June 2024.

- IPC. “Best Practices for Handling Pharmaceuticals in the Cold Chain.” Insulated Products Corporation Blog, 18 Dec. 2024.

- GMP Insiders. “Cold Chain Management In The Pharmaceutical Industry.” gmpinsiders.com, 2024.

- Fankhauser, David B. “Strategies for overcoming protein and peptide instability in biodegradable drug delivery systems.” Journal of Controlled Release, vol. 361, 2023, pp. 39-53.

Reflection

The knowledge of the systems that protect your therapeutic protocols is itself a form of empowerment. It shifts the focus from passive receipt to active awareness. When your next temperature-controlled shipment arrives, you can view it through a different lens.

You can recognize the materials science in the insulated walls, the data science in the small monitor nestled inside, and the logistical precision that brought it to you. This understanding invites a deeper engagement with your own health journey.

It prompts you to consider the integrity of your supply, to ask informed questions, and to become a more discerning partner in your own care. The stability of a molecule in a vial is a direct precursor to the stability you seek to build within your own biological systems. The journey to wellness is built upon such details.