Fundamentals

Your experience of wellness is a dynamic conversation within your body. The fatigue you feel, the subtle shifts in mood, or the frustrating plateaus in your physical progress are tangible signals from an intricate communication network. This network, the endocrine system, relies on precise messengers called peptides and hormones to transmit instructions that govern everything from your energy levels to your metabolic rate.

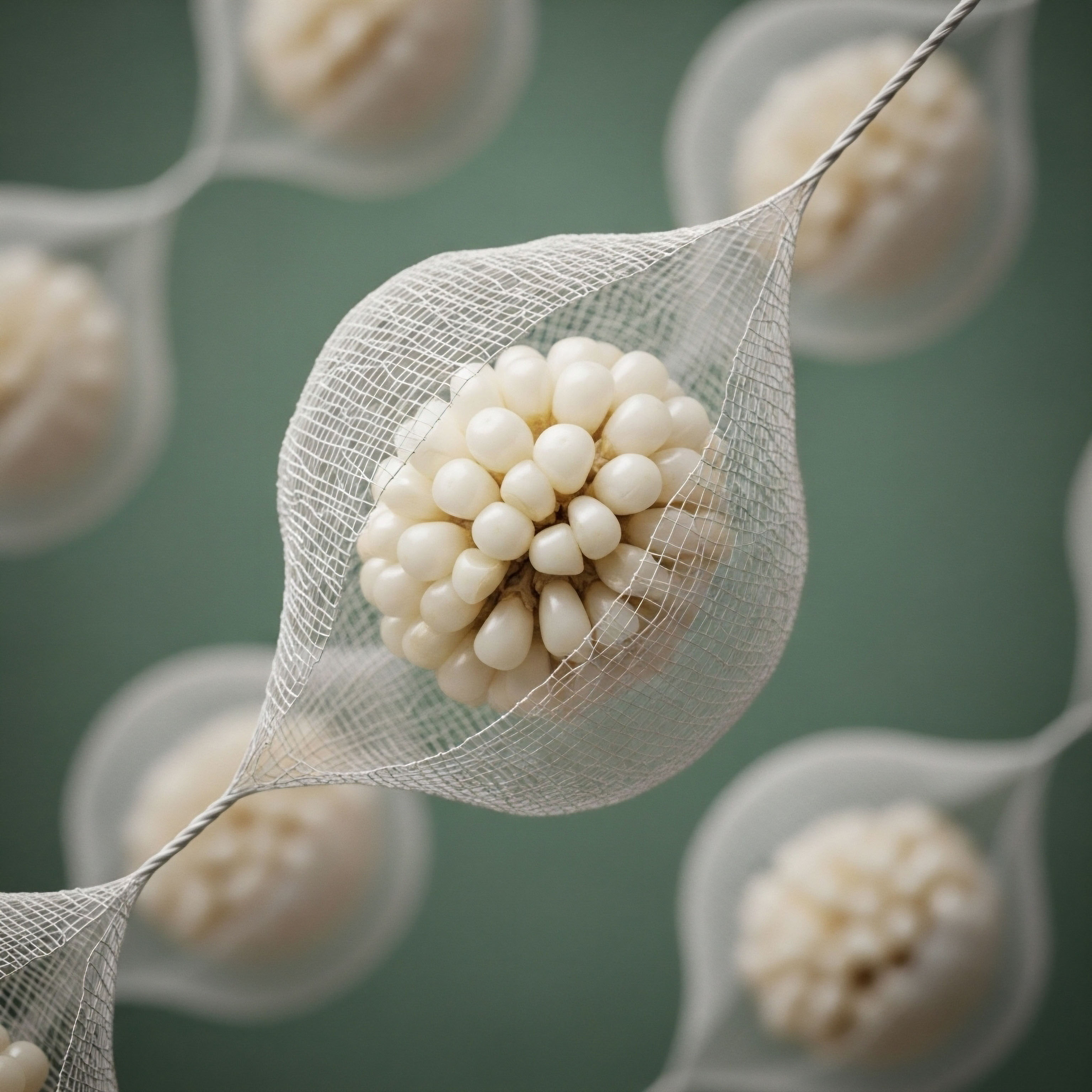

When you administer a therapeutic peptide, the goal is to join this conversation, providing a clear, consistent signal that helps restore your system’s intended function. The challenge arises because this biological dialogue is nuanced, occurring in specific rhythms and volumes. A simple injection delivers the message in a flood, a method that is effective yet biologically unsophisticated. The lived reality of managing a protocol with frequent injections, with its peaks and troughs, is a direct reflection of this mismatch.

The pursuit of novel peptide delivery systems stems from a fundamental need to speak the body’s language more fluently. We seek methods that can replicate the body’s own elegant signaling ∞ a steady release, a pulsatile rhythm, or a targeted delivery to specific tissues. This is the clinical aspiration.

A transdermal patch that releases a peptide steadily over 24 hours, a microneedle array that provides a painless and efficient delivery, or an implantable device that offers months of stability are all technological attempts to mimic physiological precision. These innovations are born from a deep respect for the body’s innate intelligence and a desire to support it with greater fidelity.

The journey of these technologies from a brilliant concept to a tool you can use is a long one, defined by a series of rigorous scientific and regulatory checkpoints.

The core challenge for any new peptide delivery system is to prove it can safely and reliably replicate a natural biological signal.

Every advanced delivery system must undergo an exhaustive evaluation to confirm its safety and effectiveness. This process is overseen by regulatory bodies like the U.S. Food and Drug Administration (FDA), whose mandate is to ensure that any new therapeutic product is both safe for patients and performs its intended function reliably.

The central question these agencies ask is not just whether the peptide is effective, but whether the new delivery system ∞ the patch, the pump, the implant ∞ releases the peptide in a predictable and controlled manner. They scrutinize the materials used for biocompatibility, ensuring they will not cause harm or irritation.

They examine the engineering of the device for consistency, confirming that each unit will perform exactly as designed. This meticulous process ensures that innovation serves the ultimate goal of patient well-being, translating a scientific advancement into a trustworthy therapeutic reality.

Why Is the Delivery Method so Important?

The method of delivery dictates a peptide’s pharmacokinetic and pharmacodynamic profile ∞ scientific terms for how a substance travels through the body and the effects it produces. A weekly intramuscular injection of Testosterone Cypionate, for example, creates a distinct peak in blood concentration followed by a gradual decline.

This pattern is understood and clinically managed. A new delivery system, perhaps a subcutaneous implant, must demonstrate how its own unique release profile achieves the desired clinical outcome. Regulators require extensive data comparing the new system to existing standards, proving that it is not just different, but therapeutically sound. This involves detailed studies that map the concentration of the peptide in the bloodstream over time, linking these levels to tangible physiological effects and confirming the absence of unintended consequences.

This validation process extends to the very materials that make up the delivery system. An implantable pellet or a transdermal patch is a foreign object to the body. Therefore, developers must provide exhaustive proof of biocompatibility.

This involves testing to ensure the materials do not degrade into harmful byproducts, trigger an inflammatory or allergic response, or cause damage to surrounding tissues over the intended duration of use. The regulatory hurdle here is to demonstrate long-term safety and stability, proving that the delivery vehicle is a passive and benign partner to the active therapeutic peptide it carries. The integrity of the delivery system is just as important as the integrity of the peptide itself.

Intermediate

The journey of a novel peptide delivery system through the regulatory landscape is a multi-stage process governed by stringent criteria. The primary domains of scrutiny are Chemistry, Manufacturing, and Controls (CMC); nonclinical toxicology; and clinical trial data. Each of these pillars must be constructed with meticulous evidence to support the final application for approval.

Regulatory agencies like the FDA do not simply approve a peptide; they approve a complete product, which includes the active pharmaceutical ingredient (API), the delivery device, and the entire manufacturing process that ensures its consistency and purity. Disparities in how existing guidelines are interpreted for innovative products can create challenges for both the developers and the regulators tasked with evaluating them.

CMC represents the foundational blueprint of the therapeutic product. For a product combining a peptide with a novel delivery system, this section of a regulatory submission is profoundly complex. It requires a complete characterization of the peptide itself, including its amino acid sequence, purity, and stability.

Simultaneously, it demands an exhaustive breakdown of the delivery device. For a microneedle patch, this would include the composition of the needles, the adhesive used, and the materials of the backing. For a subcutaneous pump, it involves the mechanical specifications, the software, and the materials of the reservoir and tubing. Developers must then demonstrate that the manufacturing process for this combination product is consistent, scalable, and capable of producing the exact same product, batch after batch, within very tight specifications.

Regulatory approval hinges on demonstrating consistent manufacturing, predictable drug release, and long-term biocompatibility of the delivery system.

The interaction between the peptide and its delivery system is a key area of investigation. Regulators require data proving that the peptide remains stable and active while housed within the device.

For instance, developers must show that the materials of a pump do not cause the peptide to degrade over time or that the process of loading the peptide into a transdermal patch does not alter its chemical structure. This involves sophisticated stability studies under various conditions of temperature and humidity, simulating the product’s entire lifecycle from factory to patient.

Any impurities that arise from the peptide itself or from its interaction with the device must be identified, quantified, and proven to be within safe limits.

What Are the Key Preclinical Hurdles?

Before any novel delivery system can be tested in humans, it must undergo rigorous nonclinical testing, often in animal models. The primary goal of this stage is to establish a safety profile. A central concern for any peptide therapeutic is immunogenicity ∞ the potential for the body to recognize the peptide as a foreign invader and mount an immune response against it.

A new delivery system can alter a peptide’s immunogenic potential. The slow, continuous release from an implant, for example, might expose the immune system to the peptide in a way that is different from a bolus injection, and this difference must be thoroughly investigated. Studies are designed to detect the formation of anti-drug antibodies (ADAs) and to determine if these antibodies neutralize the peptide’s therapeutic effect or cause adverse reactions.

Another critical preclinical hurdle is demonstrating the biocompatibility of the device component. This involves a series of standardized tests to assess how the body reacts to the materials of the device. These studies evaluate for:

- Cytotoxicity The potential for the material to kill cells.

- Sensitization The potential for the material to cause an allergic reaction after repeated exposure.

- Irritation The potential for the material to cause localized redness, swelling, or inflammation at the site of contact or implantation.

- Systemic Toxicity The potential for any substances that might leach from the device to cause toxicity throughout the body.

For long-term implants or devices, additional studies may be required to assess genotoxicity (the potential to damage DNA) and carcinogenicity (the potential to cause cancer). Passing this battery of tests is a prerequisite for gaining approval to begin clinical trials in humans.

Comparing Delivery Systems and Their Regulatory Focus

Different delivery systems present unique regulatory challenges. The specific concerns that regulators will focus on are directly tied to the technology’s design and mechanism of action. Understanding these distinctions clarifies why the development pathway can vary so significantly between different innovative products.

| Delivery System | Primary Regulatory Focus | Key Challenges |

|---|---|---|

| Transdermal Patches | Adhesion, Skin Irritation, Dose Consistency | Ensuring the patch adheres properly for the full duration and that the peptide penetrates the skin at a consistent rate without causing sensitization. |

| Subcutaneous Implants | Biocompatibility, Long-Term Stability, Removal Procedure | Proving the materials are safe for long-term implantation, that the peptide remains stable for months or years, and that the implant can be safely and completely removed. |

| Microneedle Arrays | Needle Integrity, Penetration Depth, Skin Healing | Demonstrating that the microneedles are strong enough to penetrate the skin without breaking and that the micro-channels created in the skin heal properly. |

| Oral Formulations | Bioavailability, Proteolytic Degradation, Permeation Enhancers | Protecting the peptide from degradation by stomach acid and digestive enzymes and proving that any enhancers used to get the peptide absorbed are safe. |

| Implantable Pumps | Mechanical Reliability, Software Validation, Dose Accuracy | Ensuring the pump mechanism is fail-safe, that the controlling software is secure and reliable, and that the delivered dose is precise over the device’s lifetime. |

Academic

The regulatory evaluation of novel peptide delivery systems, particularly those classified as drug-device combination products, represents a sophisticated intersection of pharmacology, biomedical engineering, and materials science. The central challenge from a regulatory science perspective is the characterization and control of variability.

Whereas a simple injectable solution has a well-understood and relatively simple risk profile, a combination product introduces multiple new sources of potential variability. These include the manufacturing tolerances of the device, the long-term physicochemical stability of the drug-device interface, and the interaction between the device and the patient’s unique biological environment. The regulatory framework, therefore, requires a comprehensive risk assessment that anticipates potential failure modes and their clinical implications.

A primary area of academic and regulatory focus is the science of pharmacokinetics (PK) and pharmacodynamics (PD). For a novel delivery system, establishing bioequivalence to an existing product is often a complex undertaking. A new transdermal system for testosterone, for instance, will not produce the same PK curve as an intramuscular injection.

Regulators do not expect it to. Instead, the developer must define a new therapeutic window and demonstrate through rigorous clinical trials that maintaining peptide concentrations within this window produces the desired therapeutic effect and avoids adverse outcomes. This requires sophisticated PK/PD modeling to predict how the release profile will translate into clinical efficacy and to justify the proposed dosing regimen.

The FDA’s 2023 draft guidance on peptide drugs underscores the importance of these clinical pharmacology considerations, including the assessment of renal or hepatic impairment on the drug’s disposition.

The highest regulatory barrier involves drug-device combinations, where the device’s engineering and software are as critical as the peptide’s pharmacology.

Immunogenicity presents another layer of profound complexity. The presentation of a peptide to the immune system via a novel delivery route can fundamentally alter its immunogenic profile. Continuous low-dose exposure from an implantable device, for example, could potentially induce immune tolerance in some cases or, conversely, act as a hapten and trigger an immune response by binding to host proteins.

The regulatory expectation is that sponsors will conduct a thorough immunogenicity risk assessment, which considers not only the peptide’s sequence but also factors related to the delivery system. These factors include the potential for impurities or aggregates to form at the drug-device interface and the presence of device materials that could act as adjuvants, amplifying the immune response.

How Do Regulators Classify Combination Products?

The classification of a product as a drug-device combination product triggers a specific and more complex regulatory pathway. The FDA’s Office of Combination Products (OCP) determines which of the agency’s centers ∞ the Center for Drug Evaluation and Research (CDER) or the Center for Device and Radiological Health (CDRH) ∞ will take the lead in reviewing the product.

This decision is based on the product’s “primary mode of action” (PMOA). If the primary purpose is therapeutic action from the peptide, CDER will likely lead. However, CDRH will be heavily involved in reviewing all aspects of the device component.

This dual-review process means the sponsor must satisfy the requirements of both drug and device regulations. This includes:

- Quality System Regulation (QSR) The device component must be manufactured in compliance with the QSR (also known as 21 CFR Part 820), which governs device design, manufacturing, and quality control.

- Human Factors Engineering For devices that involve patient interaction, such as an auto-injector or an infusion pump, extensive human factors and usability testing is required to demonstrate that patients can use the device safely and effectively.

- Software Validation If the device includes software, as an implantable pump does, the software must be rigorously validated to ensure its reliability and security against cyber threats.

The integration of these disparate regulatory requirements into a single, coherent development program is one of the most significant hurdles for innovators in this space.

The Challenge of Post-Market Surveillance

Regulatory oversight does not end upon product approval. For novel peptide delivery systems, especially long-term implants, post-market surveillance is a critical requirement. Sponsors are often required to conduct Phase 4 studies to monitor for long-term adverse events that may not have been apparent in the shorter, pre-market clinical trials.

This is particularly important for assessing the long-term biocompatibility of device materials and detecting rare but serious adverse events, such as device migration or failure. The data collected during the post-market phase are essential for continuously updating the product’s safety profile and ensuring its benefits continue to outweigh its risks over its entire lifecycle in the patient population.

| Clinical Trial Phase | Primary Objective for a Drug-Device Combination Product | Key Regulatory Question |

|---|---|---|

| Phase 1 | Safety, Tolerability, and Pharmacokinetics (PK) | Does the system deliver the peptide safely in a small group of healthy volunteers? What does the initial PK profile look like? |

| Phase 2 | Dose-Ranging and Preliminary Efficacy | What is the optimal dose and release rate to achieve the desired therapeutic effect in patients with the condition? |

| Phase 3 | Confirmatory Efficacy and Safety in a Large Population | Is the product statistically superior to a placebo or non-inferior to the standard of care in a large, pivotal trial? |

| Phase 4 (Post-Market) | Long-Term Safety and Real-World Effectiveness | Are there any rare or long-term adverse events associated with the device or drug? How does it perform in the general patient population? |

References

- Bhatt, Parth, et al. “Development and Regulatory Challenges for Peptide Therapeutics.” International Journal of Toxicology, vol. 40, no. 1, 2021, pp. 16-26, doi:10.1177/1091581820977846.

- U.S. Food and Drug Administration. “Draft Guidance on Clinical Pharmacology Considerations for Peptide Drug Products.” FDA.gov, Dec. 2023.

- Fosgerau, K. and T. Hoffmann. “Peptide therapeutics ∞ current status and future directions.” Drug discovery today, vol. 20, no. 1, 2015, pp. 122-128.

- Ramesh, S. et al. “Design and development of peptide-based therapeutics.” Current medicinal chemistry, vol. 23, no. 38, 2016, pp. 4350-4375.

- Gottlieb, S. “FDA Encourages Development of Novel Drug Delivery Systems.” Applied Clinical Trials, 2 May 2006.

Reflection

The scientific journey from a simple injection to a sophisticated, bio-responsive delivery system is a testament to our deepening understanding of human physiology. Each regulatory hurdle, while formidable, serves as a critical checkpoint to ensure that our technological capabilities remain aligned with the primary mandate of medicine to support the body’s own intricate systems.

The knowledge presented here is a framework for understanding the process. Your own health is a unique and personal application of these principles. As you consider your path forward, the most valuable tool is the understanding of your own biological systems, a process of inquiry that transforms clinical data into personal wisdom and empowers you to reclaim vitality on your own terms.