Fundamentals

Your journey toward hormonal balance often leads to a crucial conversation about personalized medicine. When a standard-dose medication does not align with your body’s specific needs, your clinician may prescribe a compounded therapy, such as a tailored dose of testosterone or a bioidentical hormone cream.

This decision introduces you into the world of compounding pharmacies, a specialized area of healthcare where your vitality is the primary focus. Understanding the regulations that govern these pharmacies is not an abstract legal exercise; it is a direct confirmation of the safety and integrity of the treatments designed for you.

The feeling that your unique physiology requires a unique solution is valid, and the regulatory framework is built to ensure that solution is prepared with the highest standards of care.

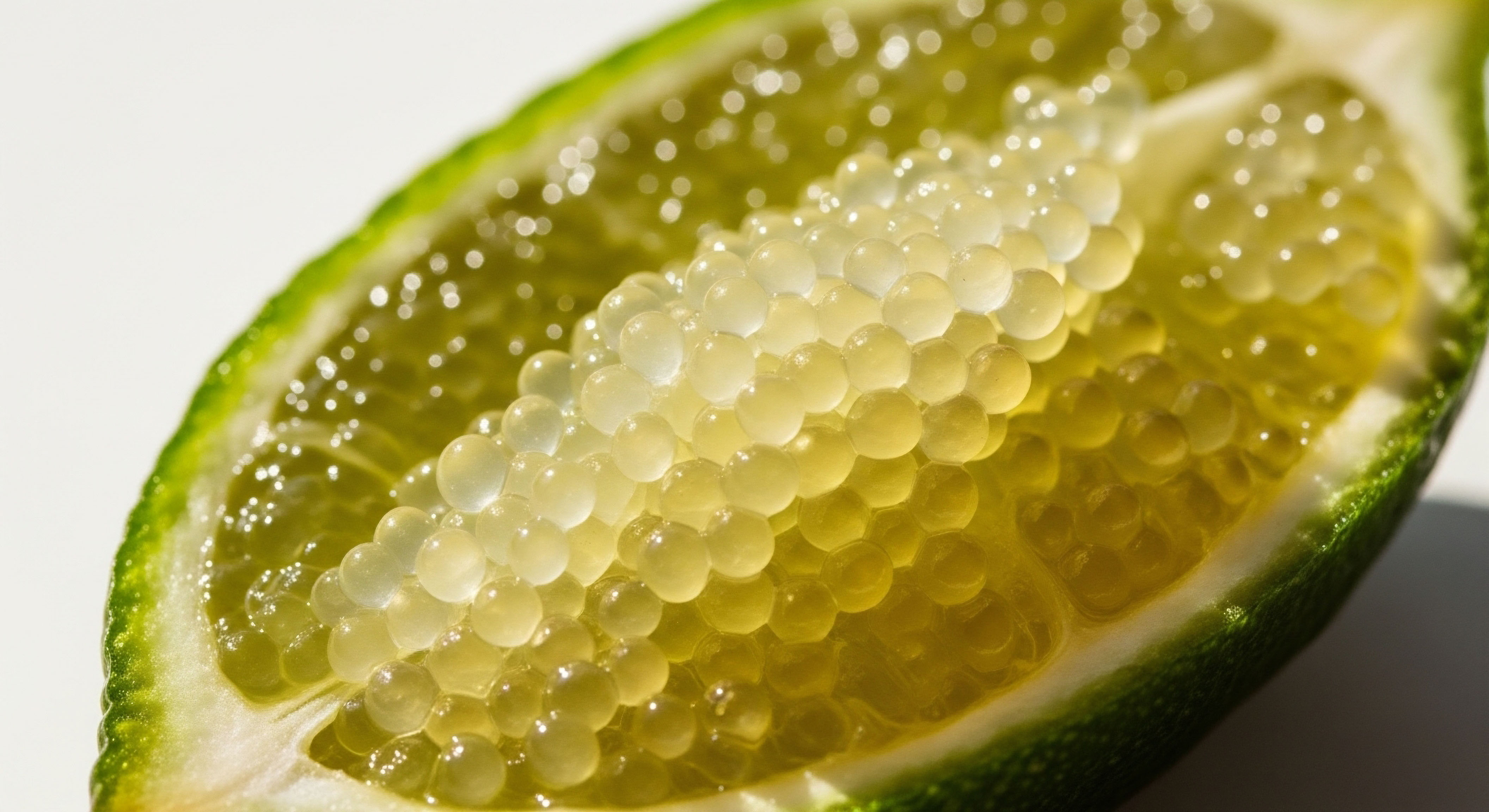

At its core, pharmaceutical compounding is the art and science of creating a personalized medication. A licensed pharmacist combines, mixes, or alters ingredients in response to a prescription to create a therapy tailored to an individual patient’s needs.

This becomes necessary when, for instance, a patient requires a specific strength of a hormone that is not commercially available, needs a formulation free of a particular allergen, or requires a different delivery method, such as a topical cream instead of an injection. The entire system is built upon a foundational principle ∞ you are not a statistic. Your treatment should be as individual as your own biology.

A Dual System of Oversight

To ensure safety and quality, compounding pharmacies in the United States operate under a dual regulatory structure, with oversight from both state and federal authorities. This layered system is designed to protect patients at every level of the process. The primary regulators are the State Boards of Pharmacy.

These bodies are responsible for licensing pharmacists and pharmacies, conducting routine inspections, and enforcing the day-to-day rules of pharmacy practice within their jurisdiction. They ensure that pharmacies adhere to established standards for quality and safety.

Complementing state oversight is the federal role of the U.S. Food and Drug Administration (FDA). While the FDA does not approve compounded drugs in the same way it approves mass-manufactured medications, its authority is critical. The FDA steps in to address issues that cross state lines, to regulate the bulk substances used in compounding, and to oversee a special class of large-scale compounding facilities. This dual system ensures both local accountability and national safety standards are met.

The Two Paths of Compounding Regulation

Following the passage of the Drug Quality and Security Act (DQSA), the federal government clarified the regulatory pathways for compounding pharmacies, dividing them into two distinct categories. This distinction is vital for understanding where and how your personalized medications are prepared.

- Section 503A Pharmacies ∞ This represents the traditional model of a compounding pharmacy. These pharmacies prepare medications based on a valid prescription for a specific, identified patient. They are primarily regulated by their state board of pharmacy but must comply with certain federal standards, including the quality benchmarks set by the United States Pharmacopeia (USP). A 503A pharmacy is exempt from certain federal requirements that apply to large drug manufacturers, such as the lengthy new drug approval process, because the medication is created for you and you alone.

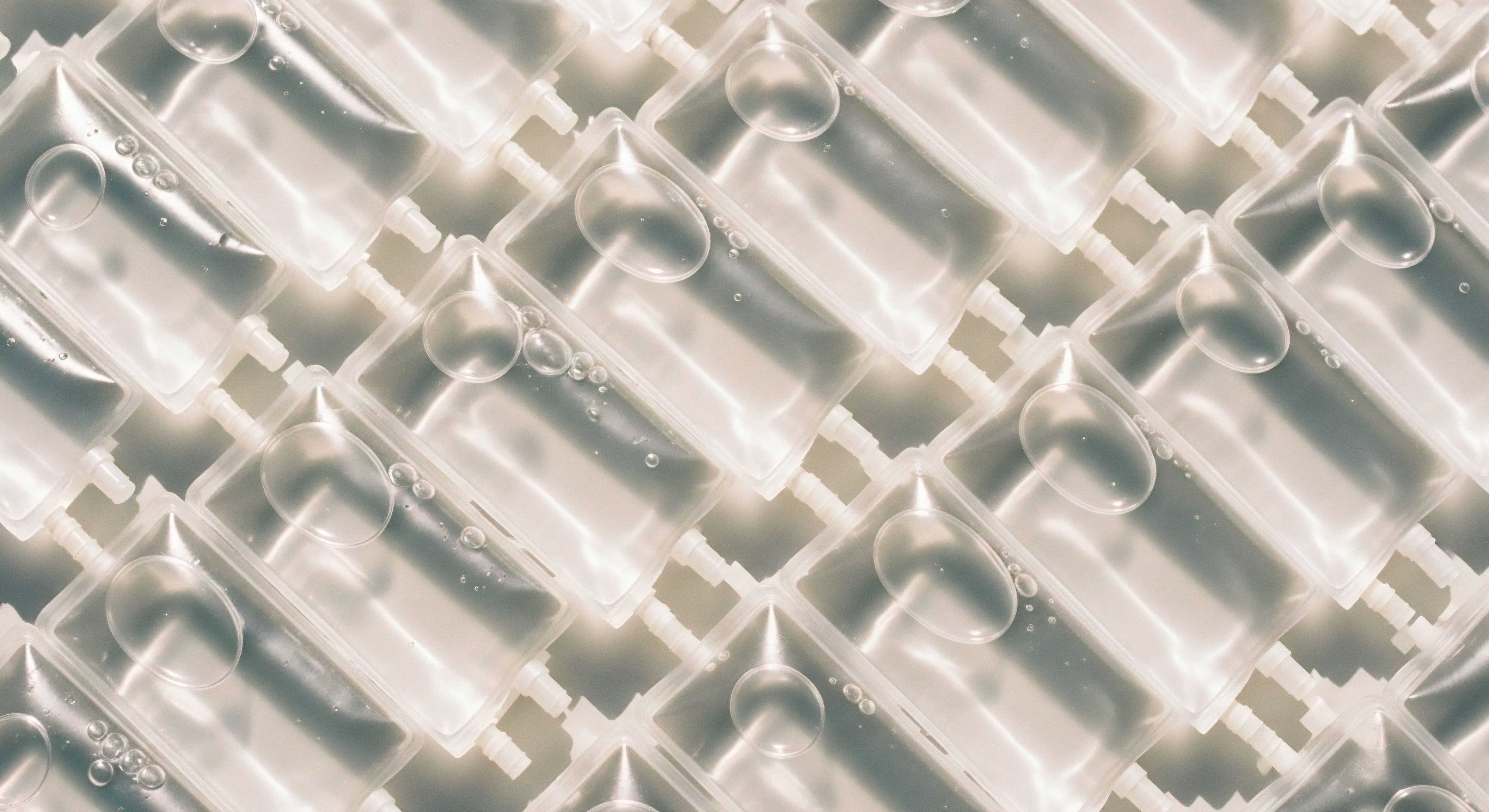

- Section 503B Outsourcing Facilities ∞ These facilities were created to fill a need for larger quantities of compounded medications, often for use in hospitals or clinics, without patient-specific prescriptions. An outsourcing facility must voluntarily register with the FDA and is held to a higher federal standard ∞ it must comply with Current Good Manufacturing Practices (CGMP). CGMP regulations are the same rigorous standards that large pharmaceutical manufacturers must follow, ensuring a high degree of quality control for medications prepared in larger batches.

The regulatory framework for compounding pharmacies is a partnership between state boards of pharmacy and the FDA, designed to ensure patient safety for personalized medications.

This division allows for both highly individualized, small-scale compounding and larger-scale production of commonly needed compounded drugs under strict federal supervision. For your personal hormonal health journey, whether it involves weekly Testosterone Cypionate injections or a daily progesterone cream, the medication will almost certainly originate from one of these two types of regulated facilities, each with specific rules designed to protect your well-being.

Intermediate

When your protocol involves a compounded medication, such as injectable testosterone for hormonal optimization or a non-sterile topical cream, you are relying on the pharmacy to execute that formulation with precision. The regulations governing this process are not just bureaucratic hurdles; they are the detailed blueprints for ensuring the stability, purity, and potency of your therapy.

The United States Pharmacopeia (USP), a non-governmental scientific organization, develops the specific, enforceable standards that 503A compounding pharmacies must follow. These standards translate the broad goal of “patient safety” into a series of meticulous, actionable procedures.

Two of the most important chapters in the USP guidelines are USP General Chapter <795> for non-sterile preparations and USP General Chapter <797> for sterile preparations. These chapters provide the minimum standards for the compounding process, from the moment raw ingredients enter the pharmacy to the final labeling of your prescription.

Adherence to these chapters is not optional; state boards of pharmacy adopt them into their regulations, giving them the force of law. For you, this means that the testosterone cream (a non-sterile preparation) and the Testosterone Cypionate injection (a sterile preparation) you use are prepared under two different but equally rigorous sets of rules.

What Are the Core Requirements of USP 795 and 797?

These USP chapters create a comprehensive framework for quality control, focusing on the environment, personnel, and processes involved in compounding. They are the operational heart of a safe compounding pharmacy.

USP for Non-Sterile Preparations

This chapter governs the compounding of medications like capsules, oral liquids, and topical creams or gels. The primary goal is to ensure that these preparations are made correctly and are not contaminated. Key requirements include:

- Personnel Training ∞ Every person involved in compounding must be thoroughly trained and demonstrate competency in the specific types of compounding they perform. This training must be documented.

- The Compounding Environment ∞ The area used for non-sterile compounding must be clean, well-maintained, and separate from other pharmacy activities to prevent cross-contamination.

- Beyond-Use Dates (BUDs) ∞ The pharmacy must assign a scientifically sound expiration date, known as a BUD, to each preparation. Revisions to USP <795> in 2023 established stricter guidelines for determining BUDs, now based on factors like the preparation’s water activity (aw), which influences its susceptibility to microbial growth.

- Documentation ∞ The pharmacy must maintain a Master Formulation Record for each unique compounded product it makes, as well as a specific Compounding Record for every prescription filled. This ensures reproducibility and traceability.

USP for Sterile Preparations

Sterile compounding requires a much higher level of control because the resulting medications, such as injections or intravenous (IV) solutions, bypass the body’s natural defense barriers. The consequences of contamination are far more severe. USP <797> is designed to prevent harm from microbial contamination, bacterial endotoxins, and other impurities. Key requirements include:

- Aseptic Technique and Garbing ∞ Personnel must be proficient in aseptic technique ∞ a set of practices that prevent contamination. This includes rigorous hand hygiene and wearing sterile gloves, gowns, and masks (a process known as garbing).

- Controlled Environments ∞ Sterile compounding must occur in a “cleanroom,” a highly controlled environment. This includes a Primary Engineering Control (PEC), such as a laminar airflow workbench, located within a Secondary Engineering Control (SEC), or buffer room. These rooms have specialized air handling systems to maintain extreme cleanliness.

- Environmental Monitoring ∞ The pharmacy must regularly test the air and surfaces within the cleanroom to ensure that microbial levels remain below established limits.

- Sterility and Endotoxin Testing ∞ For certain categories of compounded sterile products, especially those prepared in batches or assigned extended BUDs, the pharmacy must perform tests to confirm the preparation is sterile and free of fever-causing endotoxins.

The specific rules within USP chapters 795 and 797 directly govern the safety and quality of non-sterile creams and sterile injections used in hormone therapy.

How Do These Regulations Impact Your Hormonal Therapy?

The table below illustrates how these distinct regulations apply to common compounded hormone replacement therapies, ensuring the safety and integrity of your personalized treatment plan.

| Therapy Type | Compounding Category | Governing USP Chapter | Key Regulatory Focus |

|---|---|---|---|

| Topical Testosterone or Progesterone Cream | Non-Sterile | USP <795> | Preventing cross-contamination, ensuring correct potency, assigning appropriate Beyond-Use Dates (BUDs), and maintaining proper documentation. |

| Testosterone Cypionate Injections | Sterile | USP <797> | Ensuring absolute sterility through aseptic technique, use of a controlled cleanroom environment, rigorous personnel garbing, and environmental monitoring to prevent microbial contamination. |

| Sermorelin or Ipamorelin Injections | Sterile | USP <797> | The same stringent sterility requirements as other injectables, focusing on preventing patient harm from contamination in therapies that are self-administered subcutaneously. |

| Oral Progesterone Capsules | Non-Sterile | USP <795> | Focus on ingredient quality, accurate weighing and mixing of the active pharmaceutical ingredient, and ensuring the final dosage form is stable for its intended duration of use. |

Understanding these intermediate-level details should provide reassurance. The protocols you follow, from weekly injections to daily cream applications, are supported by a deep and specific regulatory structure. Each rule is a safeguard, translating clinical science into a reliable therapy that helps you reclaim your vitality.

Academic

The modern regulatory architecture governing compounding pharmacies was not the product of abstract foresight but was forged in the crucible of a public health crisis. For decades, compounding existed in a state of regulatory ambiguity, occupying a space between small-scale pharmacy practice, overseen by states, and large-scale drug manufacturing, overseen by the FDA.

This “murky regulatory space” allowed some compounders to produce medications at an industrial scale without adhering to the stringent safety standards required of manufacturers. The system’s vulnerability was tragically exposed in 2012, leading to a fundamental recalibration of federal law and the relationship between compounders, states, and the FDA.

The New England Compounding Center and the Catalyst for Change

In the fall of 2012, a multistate outbreak of fungal meningitis began to unfold. The source was traced to contaminated vials of preservative-free methylprednisolone acetate, a steroid injection prepared by the New England Compounding Center (NECC) in Massachusetts. The facility’s cleanrooms were contaminated with fungus, and the tainted injections were shipped to clinics in 20 states.

The resulting outbreak led to over 750 cases of illness and 64 deaths. The NECC was operating as a de facto drug manufacturer, producing thousands of doses in bulk, yet it was regulated primarily as a state-level pharmacy. Investigations revealed that despite prior warnings from the FDA about sterility violations, jurisdictional confusion prevented effective enforcement action.

The NECC crisis laid bare the systemic risks of the existing framework. It demonstrated that the line between traditional compounding and manufacturing had blurred to a dangerous degree and that the regulatory system was ill-equipped to manage the hybrid entities that had emerged. The event galvanized Congress to act, culminating in the passage of the Drug Quality and Security Act (DQSA) in 2013.

How Did the DQSA Restructure the Regulatory Ecosystem?

The DQSA was a landmark piece of legislation that fundamentally restructured the oversight of pharmaceutical compounding in the United States. It did not simply add more rules; it redefined the players and their responsibilities, creating clear legal categories to replace the previous ambiguity. The act’s primary innovation was Title I, the Compounding Quality Act, which established a clear, two-path system for compounders.

- Solidification of Section 503A ∞ The DQSA reaffirmed the legitimacy of traditional compounding under Section 503A of the Food, Drug, and Cosmetic Act. It clarified the law by removing previously contested language related to advertising, thereby providing a secure legal “safe harbor” for pharmacists compounding medications for specific patients pursuant to a prescription. This act preserved the essential role of the community pharmacist in preparing personalized medicines while keeping primary oversight with the state boards of pharmacy.

- Creation of Section 503B ∞ The most significant architectural change was the creation of a new entity ∞ the “outsourcing facility” under Section 503B. This was a direct response to the NECC failure. This section established a voluntary pathway for facilities that compound sterile drugs in bulk to register with the FDA. By registering, a 503B facility subjects itself to federal oversight, including routine FDA inspections and mandatory compliance with Current Good Manufacturing Practices (CGMP). This created a legal and operational framework for large-scale compounders to exist, but only under the same rigorous quality standards as conventional drug manufacturers.

The 2012 NECC tragedy was the direct impetus for the Drug Quality and Security Act, which fundamentally reshaped the industry by creating a clear, two-tiered regulatory system.

A Systems-Biology Approach to Regulation

From a systems perspective, the DQSA can be viewed as an intervention designed to restore homeostasis to the pharmaceutical ecosystem. Before the act, the system was in a state of dysregulation. High-volume compounders were operating outside their expected biological niche, creating systemic risk. The DQSA introduced new feedback loops and control mechanisms to restore balance and safety.

The table below analyzes the pre- and post-DQSA regulatory environment from a systems perspective.

| System Component | Pre-DQSA State (Dysregulated) | Post-DQSA State (Regulated) |

|---|---|---|

| Oversight Authority | Ambiguous and contested jurisdiction between FDA and state boards for large-scale compounders. | Clearly delineated roles ∞ states primarily oversee 503A pharmacies; FDA directly oversees 503B outsourcing facilities. |

| Quality Standards | Inconsistent application. Large compounders could avoid CGMP, leading to variable quality and risk of contamination. | Standardized requirements. 503B facilities are mandated to follow CGMP, while 503A pharmacies must adhere to USP standards. |

| Information Flow | Poor transparency. The FDA did not have a comprehensive list of all compounding pharmacies or what they were producing. | Improved transparency. 503B facilities must register with the FDA and report on the products they compound. |

| Systemic Risk | High. A single point of failure (like NECC) could introduce contaminated products into the national supply chain with devastating consequences. | Mitigated. The 503B framework provides a mechanism for ensuring large-scale production meets high safety standards, reducing the risk of widespread outbreaks. |

The DQSA, therefore, was more than a set of new rules. It was a structural redesign intended to ensure that the regulatory oversight applied to a pharmacy is proportional to the scale and risk of its operations.

This risk-based, systems-level approach ensures that whether you receive a single prescription from a local 503A pharmacy or a sterile injection prepared by a national 503B facility, the process is governed by a framework designed to prevent a recurrence of the failures that made reform an absolute necessity.

References

- Glassgold, J. “The 2012 Fungal Meningitis Outbreak ∞ A Public Health and Regulatory Perspective.” Clinical Infectious Diseases, vol. 57, no. 5, 2013, pp. 727-732.

- Gudeman, J. et al. “Pharmaceutical Compounding ∞ A History, Regulatory Overview, and Systematic Review of Compounding Errors.” Journal of Patient Safety, vol. 19, no. 3, 2020, pp. 195-202.

- United States Food and Drug Administration. “Drug Quality and Security Act (DQSA).” FDA.gov, 2013.

- The Pew Charitable Trusts. “National Assessment of State Oversight of Compounding Pharmacies.” 2016.

- Gabay, Michael. “The Drug Quality and Security Act.” Hospital Pharmacy, vol. 49, no. 7, 2014, pp. 613-614.

- United States Pharmacopeia. USP General Chapter <795> Pharmaceutical Compounding ∞ Nonsterile Preparations. 2022.

- United States Pharmacopeia. USP General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations. 2022.

- Kim, J. “Regulating Compounded Drugs ∞ A Legal and Historical Analysis.” Journal of Health Politics, Policy and Law, vol. 42, no. 5, 2017, pp. 845-875.

- Outterson, K. “Regulating Compounding Pharmacies After NECC.” New England Journal of Medicine, vol. 367, no. 21, 2012, pp. 1969-1972.

- Food and Drug Administration Modernization Act of 1997, Pub. L. No. 105-115, 111 Stat. 2296.

Reflection

You began this exploration seeking to understand the rules that protect you. Now, you can see the intricate system of safeguards that stands behind every personalized prescription. This knowledge of the ‘why’ ∞ the history, the science, and the structure ∞ transforms your role in your own health journey.

It shifts you from a passive recipient of care to an informed participant. The regulations governing compounding pharmacies are not merely about compliance; they are about confidence. They exist so that you can trust the process, allowing you to focus on the true goal ∞ the profound work of recalibrating your own biological systems to restore function and reclaim the feeling of being fully, vibrantly alive.

What Is Your Next Step?

This understanding is a powerful tool. It equips you to ask more precise questions of your clinical team and to feel a deeper sense of security in the protocols you undertake. Your path is unique, and the knowledge you have gained is the foundation upon which you can build a more collaborative and empowered relationship with those who guide your care. The journey forward is one of continued learning and proactive engagement with your own well-being.