Fundamentals

The feeling of being unheard, of knowing something within your own body is misaligned, is a profound and often isolating experience. You sense a shift in your energy, your mood, or your physical vitality, yet translating that internal reality into a clinical conversation can be challenging.

When you embark on a path of hormonal optimization, you are seeking a protocol that acknowledges your unique biochemistry. The compounded hormones Meaning ∞ Compounded hormones are pharmaceutical preparations custom-made for an individual patient by a licensed compounding pharmacy. you receive are the tangible result of that personalized approach. This is why the question of their quality control is so deeply personal. It connects directly to the trust you place in a treatment designed specifically for you.

Understanding the quality control measures Meaning ∞ Quality control measures are systematic procedures implemented to uphold the accuracy, reliability, and integrity of clinical processes, laboratory analyses, and therapeutic interventions within healthcare settings. for these preparations is an act of self-advocacy. It provides a framework for comprehending the precision and care that must go into creating a formulation that aligns with your body’s specific needs. The process begins with the raw ingredients.

Every hormone, whether it’s Testosterone Cypionate, Progesterone, or Estradiol, must be sourced from reliable suppliers who can provide a Certificate of Analysis Meaning ∞ A Certificate of Analysis, often abbreviated as CoA, represents an official document issued by a manufacturer or third-party laboratory, detailing the specific test results and quality control parameters for a particular batch of a product. (COA). This document is a detailed report verifying the identity, purity, and potency of the chemical. It is the first checkpoint, ensuring the foundational materials meet stringent scientific standards before they are even considered for your preparation.

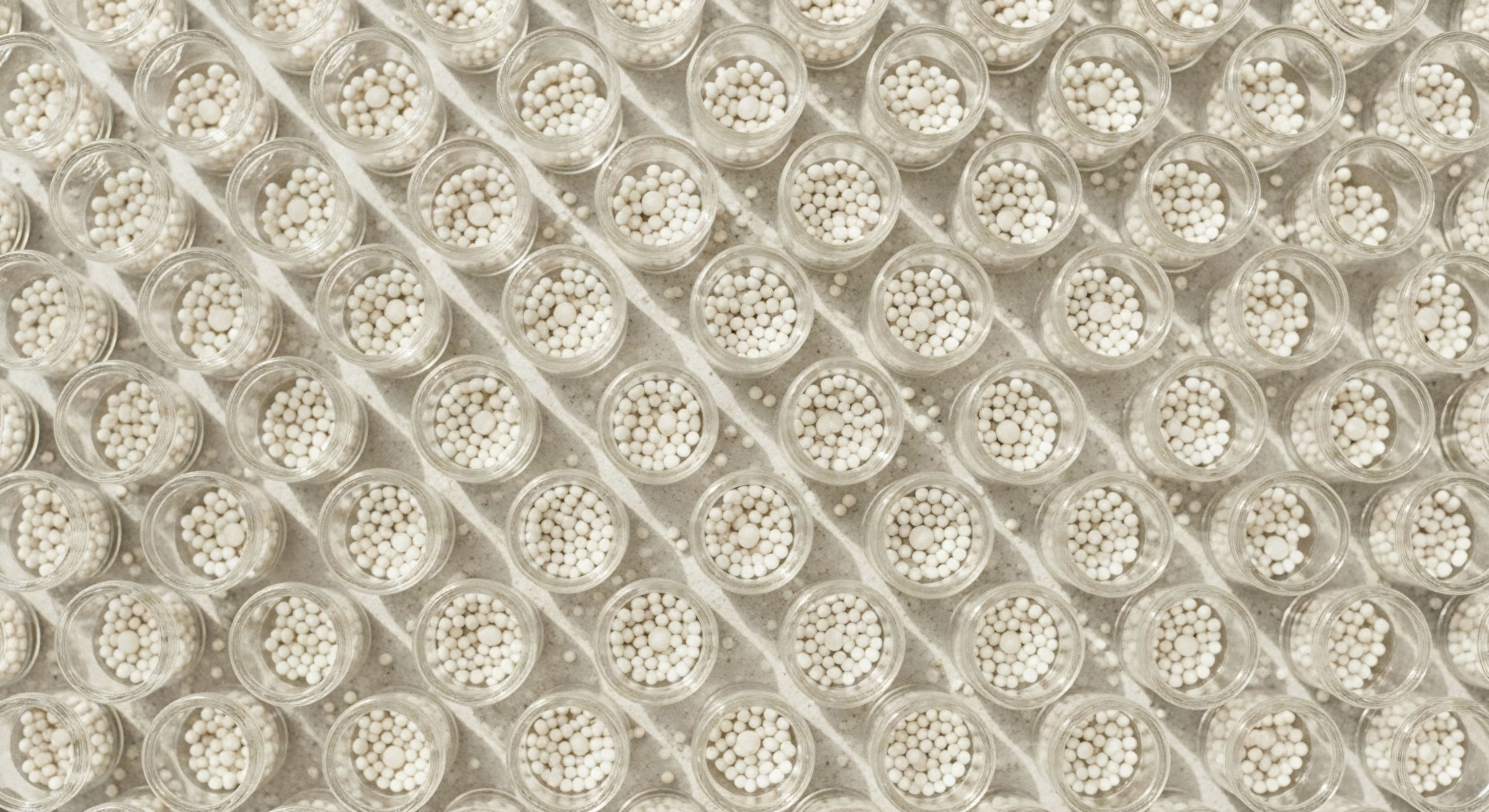

A compounded hormone preparation’s quality is verified through a series of tests that confirm its potency, purity, and stability.

Once the active ingredients are verified, the compounding pharmacy itself operates under a comprehensive set of guidelines. These are primarily established by the United States Pharmacopeia Meaning ∞ The United States Pharmacopeia (USP) is an independent, scientific, non-profit organization establishing public standards for identity, strength, quality, and purity of medicines, food ingredients, and dietary supplements. (USP), a scientific organization that sets standards for the identity, strength, quality, and purity of medicines.

Two chapters are particularly relevant here ∞ USP 795 Meaning ∞ USP 795 designates a critical chapter within the United States Pharmacopeia, delineating comprehensive standards for the preparation of nonsterile compounded pharmaceutical products. for non-sterile preparations (like creams or capsules) and USP 797 for sterile preparations Meaning ∞ Sterile preparations are pharmaceutical products meticulously compounded or manufactured in an environment free from viable microorganisms, particulate matter, and pyrogens. (like injections). These are not mere suggestions; they are robust frameworks that dictate everything from the training of the pharmacy staff to the environmental conditions of the compounding area. Personnel must undergo specific training and demonstrate their competency, and the environment must be controlled to prevent contamination.

The final preparation itself undergoes a series of checks. At a minimum, this includes a visual inspection to ensure the physical properties of the compound ∞ such as color, consistency, and clarity ∞ are correct. For many formulations, especially sterile ones, further testing is required. This can involve checks for microbial contamination to ensure safety and sterility.

The goal of this multi-layered process is to build quality into the formulation from the very beginning, ensuring that the personalized therapy you receive is not only effective but, above all, safe.

Intermediate

When you progress from understanding the need for quality control Meaning ∞ Quality Control, in a clinical and scientific context, denotes the systematic processes implemented to ensure that products, services, or data consistently meet predefined standards of excellence and reliability. to examining the specific tests involved, you are moving toward a deeper appreciation of the science behind your personalized therapy. The quality control process for compounded hormones is a system of procedures designed to ensure that the final preparation consistently meets the required standards for safety and efficacy.

This system can be broken down into three key areas ∞ ensuring the quality of the starting materials, controlling the compounding process, and verifying the integrity of the final product.

The first stage, as mentioned, involves the rigorous qualification of all ingredients. Beyond simply accepting a Certificate of Analysis, a compounding pharmacy may perform its own identity and potency testing Meaning ∞ Potency testing refers to the analytical process of quantifying the active pharmaceutical ingredient within a medication to ascertain its precise strength and biological activity. on incoming raw materials. This provides an independent verification that the active pharmaceutical ingredients (APIs) and excipients (the inactive ingredients) meet the necessary specifications. This step is critical because the quality of the final preparation is entirely dependent on the quality of its components.

How Are Formulations Standardized?

The compounding process itself is guided by a Master Formulation Record Meaning ∞ The Master Formulation Record represents the definitive blueprint for preparing a specific drug product in pharmaceutical compounding. (MFR). This document is like a detailed recipe for your specific preparation. It outlines every step of the compounding process, including the specific ingredients to be used, the quantities of each, the equipment required, and the precise instructions for mixing and packaging. For each batch of a compounded medication that is prepared, a corresponding Compounding Record is created, which documents that the steps in the MFR were followed correctly.

Environmental monitoring is another critical component of process control, particularly for sterile compounds governed by USP 797. This involves regularly testing the air and surfaces within the compounding area for microbial contamination. This ensures that the environment in which your sterile medications are prepared is maintained in a state of control, minimizing the risk of introducing contaminants.

The integrity of a compounded sterile preparation is confirmed through bubble point testing of the filter used during its formulation.

Finally, the finished preparation undergoes a series of quality control tests before it is dispensed. These tests are designed to verify that the compounding process was successful and that the final product meets all specifications. The specific tests performed depend on the type of preparation.

- Visual Inspection ∞ All compounded preparations are visually inspected for clarity, color, and the absence of particulate matter.

- pH Testing ∞ For aqueous (water-based) solutions, the pH is tested to ensure it falls within the specified range for stability and patient comfort.

- Sterility Testing ∞ For sterile preparations, especially those prepared in batches, sterility testing is performed to ensure the absence of microbial contamination.

- Endotoxin Testing ∞ Injectable medications must be tested for bacterial endotoxins, which are substances that can cause fever and other adverse reactions.

- Potency Testing ∞ This involves sending a sample of the compounded preparation to an independent analytical laboratory to verify that it contains the correct concentration of the active hormone.

Understanding Risk Levels in Sterile Compounding

USP 797 categorizes compounded sterile preparations (CSPs) into different risk levels, which dictates the stringency of the required quality control measures. These categories help to ensure that the level of quality control is appropriate for the potential risk to the patient.

| Risk Level | Description | Typical Quality Control Measures |

|---|---|---|

| Category 1 | CSPs with shorter beyond-use dates (BUDs), typically prepared in a segregated compounding area. | Visual inspection, personnel competency verification. |

| Category 2 | CSPs with longer BUDs, prepared in a cleanroom suite, which may be prepared for multiple patients. | Sterility testing, endotoxin testing, environmental monitoring. |

| Category 3 | CSPs with the longest BUDs, requiring the most stringent controls, including sterility and stability data. | Batch-specific sterility testing, endotoxin testing, potency testing, antimicrobial effectiveness testing for multi-dose vials. |

Academic

A sophisticated understanding of quality control in pharmaceutical compounding Meaning ∞ Pharmaceutical compounding involves the specialized creation of a medication tailored to an individual patient’s specific therapeutic needs, diverging from commercially available drug formulations. requires an appreciation for the interplay between regulatory standards, analytical chemistry, and risk management. The framework provided by USP General Chapters 795 and 797 establishes the minimum standards for quality, but the practical application of these standards involves a complex series of scientific validation and verification processes. The ultimate goal is to ensure that every compounded preparation has the identity, strength, quality, and purity it purports to possess.

From a pharmacopeial perspective, quality is not something that can be tested into a product at the end; it must be built into the entire process. This principle, known as Quality by Design (QbD), is central to modern pharmaceutical manufacturing and is increasingly relevant to compounding. It involves a systematic approach to development that begins with predefined objectives and emphasizes product and process understanding and process control, based on sound science and quality risk management.

What Is the Role of Analytical Testing?

Potency testing, or assay, is perhaps the most critical analytical test for compounded hormones. It confirms that the concentration of the active pharmaceutical ingredient (API) is within an acceptable range of the prescribed dose. High-performance liquid chromatography Meaning ∞ High-Performance Liquid Chromatography, commonly known as HPLC, is an advanced analytical chemistry technique used to separate, identify, and quantify individual components within a complex liquid mixture. (HPLC) is the most common analytical method used for this purpose.

HPLC separates the components of a mixture and provides a quantitative analysis of each component. For a potency test to be meaningful, the analytical method itself must be validated to ensure it is accurate, precise, specific, and robust for the particular formulation being tested.

Beyond potency, other analytical tests may be necessary depending on the formulation. For example, content uniformity testing is important for solid dosage forms like capsules to ensure that each capsule contains the same amount of the API. For sterile preparations, the bubble point test is a simple yet effective way to verify the integrity of the sterilizing filter used during compounding.

This test uses pressure to determine the largest pore size of the filter, confirming that it was not compromised during the filtration process.

The Science of Stability and beyond Use Dates

A key aspect of quality control is establishing an appropriate beyond-use date Meaning ∞ The Beyond-Use Date (BUD) marks the final time a compounded pharmaceutical preparation is suitable for use. (BUD). A BUD is the date after which a compounded preparation should not be used. It is determined based on the stability of the specific formulation. Stability refers to the extent to which a product retains, within specified limits, and throughout its period of storage and use, the same properties and characteristics that it possessed at the time of its compounding.

Establishing a scientifically valid BUD requires stability-indicating analytical methods. These are validated methods that can detect any degradation of the API over time. A stability study involves assaying samples of the compounded preparation at various time points under specific storage conditions to determine how long the preparation remains potent and stable. For aqueous multi-dose sterile preparations, antimicrobial effectiveness testing (AET) according to USP 51 is also required to ensure the preservative system remains effective throughout the BUD.

| Test Parameter | Methodology | Purpose in Hormonal Compounding |

|---|---|---|

| Potency | High-Performance Liquid Chromatography (HPLC) | Quantifies the concentration of the active hormone to ensure accurate dosing. |

| Sterility | Direct Inoculation or Membrane Filtration (per USP 71) | Detects the presence of viable microorganisms in sterile preparations. |

| Endotoxins | Limulus Amebocyte Lysate (LAL) Test | Detects bacterial endotoxins in injectable preparations to prevent pyrogenic reactions. |

| Stability | Stability-Indicating HPLC | Determines the rate of degradation of the API to establish a valid beyond-use date. |

The complexity of these testing requirements underscores the high level of scientific expertise required to operate a compounding pharmacy that produces high-quality, reliable preparations. The integration of robust quality assurance systems with validated analytical testing provides the necessary framework to ensure that personalized hormonal therapies are both safe and effective for the patient.

References

- United States Pharmacopeial Convention. Pharmaceutical Compounding ∞ Nonsterile Preparations. In ∞ United States Pharmacopeia and National Formulary (USP 43-NF 38). Rockville, MD ∞ United States Pharmacopeial Convention; 2020.

- United States Pharmacopeial Convention. Pharmaceutical Compounding ∞ Sterile Preparations. In ∞ United States Pharmacopeia and National Formulary (USP 43-NF 38). Rockville, MD ∞ United States Pharmacopeial Convention; 2020.

- National Academies of Sciences, Engineering, and Medicine. The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of the Evidence. Washington, DC ∞ The National Academies Press; 2020.

- Kastango, E. S. & Bradshaw, B. D. (2019). USP and Answered. CriticalPoint, LLC.

- Allen, L. V. Jr. (2016). The Art, Science, and Technology of Pharmaceutical Compounding (5th ed.). American Pharmacists Association.

Reflection

The journey to understand the intricate quality control measures behind your personalized hormonal therapy is, in itself, a powerful step toward reclaiming agency over your health. This knowledge transforms you from a passive recipient of care into an active, informed participant.

The science of potency assays, sterility testing, and stability studies provides a reassuring foundation of precision and safety. Yet, this clinical framework is only one part of the equation. The other, more personal part, involves your own lived experience, your unique physiology, and the continuous dialogue between you and your healthcare provider.

How does this deeper understanding of the meticulous processes involved in creating your therapy change your perspective on your own path to wellness? Consider how this knowledge empowers you to ask more specific questions, to better articulate your needs, and to move forward with a renewed sense of confidence in the choices you are making for your body and your future.