Fundamentals

Your journey toward hormonal and metabolic wellness begins with a deeply personal set of symptoms. It could be a persistent fatigue that sleep does not resolve, a subtle shift in mood or cognitive clarity, or changes in your body’s physical function and appearance. These experiences are data points.

They are your body’s method of communicating a change in its intricate internal environment. When you and your clinician decide on a personalized therapeutic protocol, such as Testosterone Replacement Therapy (TRT) or a specific peptide regimen, you are initiating a process of biochemical recalibration. The prescription written is a precise instruction, a blueprint for restoring a specific molecular balance within your system. This blueprint is then handed to a specialized partner in your care ∞ the compounding pharmacy.

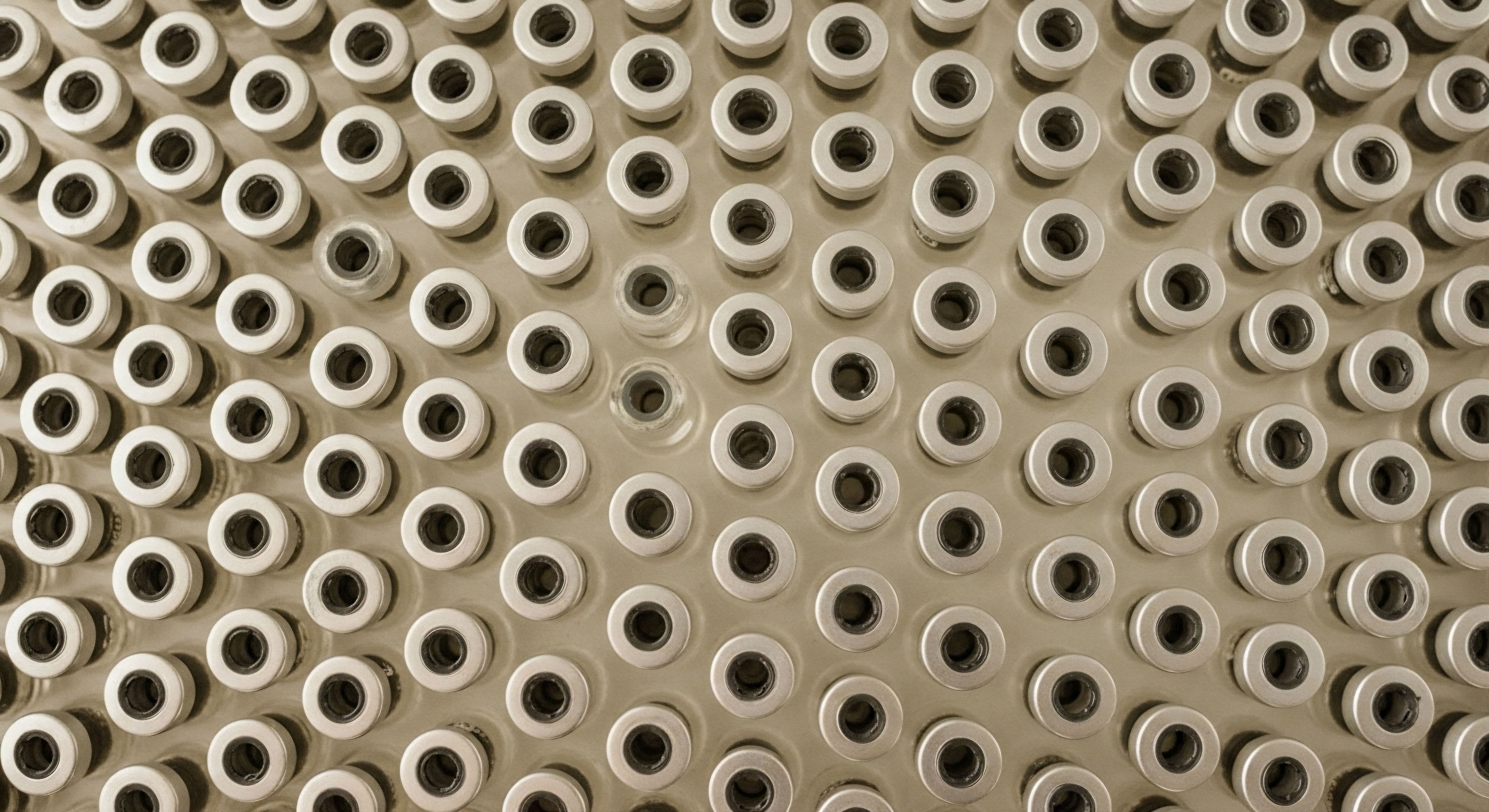

A compounding pharmacy is a specialized facility where pharmacists meticulously combine or alter ingredients to create custom-dosed medications. This process is fundamentally different from the mass production of commercial pharmaceuticals. A commercial drug is manufactured in enormous batches, with every pill or vial being identical.

A compounded medication, conversely, is created specifically for you. It might be a topical testosterone cream formulated at a precise percentage, a sterile injectable peptide solution without certain preservatives you are allergic to, or a progesterone capsule at a dose unavailable from a large manufacturer. This bespoke nature of compounded medicine is what makes it such a powerful tool in personalized health. It also introduces a profound need for an entirely different, more rigorous layer of quality oversight.

The trust you place in your hormonal protocol is ultimately trust in the molecules you introduce into your body. You trust that the 10 units of Testosterone Cypionate you administer are exactly that concentration, or that the Sermorelin peptide for growth hormone support is pure and correctly formulated.

The quality control measures implemented by a compounding pharmacy are the very foundation of this trust. These are the systems that ensure the blueprint from your doctor is translated into a final product with absolute fidelity, safeguarding your health and ensuring the therapeutic protocol can achieve its intended biological effect.

The Foundational Pillars of Safety and Purity

At the core of compounding quality are standards set by the United States Pharmacopeia (USP). The USP is a scientific, non-profit organization that establishes public standards for medicines. These standards are not suggestions; they are enforceable regulations in many states and are recognized in federal law, forming the bedrock of safe compounding practices. For the medications central to hormonal and metabolic health, two chapters are of primary importance.

- USP General Chapter <795> governs the compounding of non-sterile preparations. This includes the topical creams, gels, and oral capsules that are common in hormone therapy, such as bioidentical estrogen or progesterone creams. The chapter details requirements for personnel training, facility cleanliness, ingredient sourcing, and documentation to ensure that each preparation is the correct strength and purity, free from cross-contamination.

- USP General Chapter <797> provides the standards for sterile preparations. This is of utmost importance for therapies like TRT injections, peptide injectables (such as Ipamorelin or CJC-1295), and intravenous nutrient therapies. The focus here is on preventing harm from microbial contamination, bacterial endotoxins, and other impurities that could be dangerous if introduced directly into the bloodstream or muscle tissue.

These chapters provide a comprehensive framework that a reputable compounding pharmacy uses to build its quality management system. This system touches every aspect of the pharmacy’s operation, from the moment raw ingredients arrive at the facility to the final labeling of your specific prescription. It is a system designed to protect you, ensuring that the personalized medicine you receive is both safe and effective.

A compounding pharmacy translates a physician’s precise therapeutic blueprint into a safe and effective personalized medication through rigorous quality control.

What Does This Mean for Your Personal Protocol?

When you receive a compounded medication, you are holding the result of a meticulous, multi-step process. The quality control measures are what guarantee its integrity. For a woman using a custom-dosed topical progesterone cream, the pharmacy’s adherence to USP <795> ensures the hormone is evenly distributed throughout the base cream, so each application delivers a consistent dose.

It also ensures the active ingredient is pure and that no contaminants were introduced during mixing. For a man on a weekly TRT protocol, the pharmacy’s compliance with USP <797> is even more critical. It ensures the testosterone solution was prepared in an ultra-clean environment, filtered to remove any potential bacteria, and tested to be sterile, preventing a dangerous infection.

Understanding the existence of these measures is the first step in becoming an empowered participant in your health journey. It allows you to appreciate the distinction between pharmacies and to understand the value that a high-quality compounding facility brings to your therapeutic team. The questions of quality, purity, and potency are central to the success of any hormonal or metabolic protocol. The answers are found in the disciplined, daily execution of these foundational quality control systems.

Intermediate

As you move deeper into your understanding of personalized medicine, it becomes clear that the term “compounding pharmacy” describes a category of practice with important internal distinctions. The regulatory landscape, primarily defined by the Federal Food, Drug, and Cosmetic Act (FD&C Act), creates two main types of compounding pharmacies ∞ 503A facilities and 503B outsourcing facilities.

Recognizing the difference is essential for any patient receiving compounded therapies, as the designation dictates the scale of production, the regulatory oversight, and the specific quality systems in place.

Your typical neighborhood compounding pharmacy, which prepares a medication based on a prescription for a specific, named patient, operates as a 503A facility. These pharmacies are licensed by state boards of pharmacy and are held to the quality standards of the USP chapters, such as <795> and <797>.

Their role is to serve the unique needs of individual patients as determined by their practitioners. For example, when your doctor prescribes a 20mg weekly subcutaneous injection of Testosterone Cypionate, a 503A pharmacy compounds that single prescription for you.

A 503B outsourcing facility operates on a different model. These facilities can manufacture large batches of compounded drugs without patient-specific prescriptions, which can then be sold to healthcare facilities for office use. Because they function more like a manufacturer, 503B facilities must register with the FDA and adhere to a more stringent set of quality standards known as Current Good Manufacturing Practices (cGMP).

This is the same quality system that large pharmaceutical companies must follow. A hospital might purchase sterile injectable solutions from a 503B facility to have on hand for patients as needed.

Comparing Regulatory and Quality Frameworks

The choice between using a 503A or a 503B facility often depends on the clinical need. Both play vital roles in the healthcare system. The following table outlines the key distinctions that influence how quality is managed at each type of facility.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Regulation |

Licensed and regulated by State Boards of Pharmacy. Must comply with USP standards (e.g. <795>, <797>). |

Registered with and inspected by the FDA. Must comply with Current Good Manufacturing Practices (cGMP). |

| Prescription Requirement |

Required to obtain a valid, patient-specific prescription before compounding and dispensing. |

Can compound without patient-specific prescriptions and sell stock to healthcare facilities for office administration. |

| Scale of Production |

Small-scale, based on individual prescriptions. Prohibited from compounding large batches to sell for office stock. |

Large-scale batch production is permitted, allowing for wider distribution and potentially lower costs per unit. |

| Adverse Event Reporting |

Not required to report adverse events to the FDA, though they are tracked at the state level. |

Mandatory adverse event reporting to the FDA, similar to commercial drug manufacturers. |

A Deeper Look into Core Quality Control Processes

Regardless of the regulatory designation, a high-quality compounding pharmacy builds its operations around a core set of quality control processes designed to ensure patient safety. These processes are dictated by USP standards and are a hallmark of a facility dedicated to excellence. They represent a systematic approach to preventing errors before they happen.

- Personnel Qualification and Training ∞ The most sophisticated equipment is useless without highly skilled personnel. Pharmacists and technicians undergo extensive training in aseptic techniques for sterile compounding. This is not a one-time event. Their skills are regularly tested through processes like glove fingertip testing (to ensure they can garb without contaminating their gloves) and media-fill tests, where they compound a sterile solution using a growth medium instead of a drug. The sample is then incubated to see if any bacteria grow, providing a direct measure of their aseptic technique proficiency.

- Environmental Control and Monitoring ∞ For sterile compounding, the environment is a critical control point. Injections are prepared inside a Primary Engineering Control (PEC), such as a laminar airflow hood, which provides an ultra-clean ISO Class 5 environment. This PEC is located within a larger cleanroom, or buffer room, which also has a controlled level of air cleanliness. The pharmacy must continuously monitor parameters like air particle counts, differential pressure between rooms (to prevent dirty air from flowing into clean areas), temperature, and humidity. Regular surface sampling is also performed to test for microbial contamination on work surfaces.

- Ingredient Verification and Sourcing ∞ The quality of the final product can be no better than the quality of its starting ingredients. Reputable pharmacies source their Active Pharmaceutical Ingredients (APIs), like testosterone or progesterone powder, from FDA-registered facilities. Each API arrives with a Certificate of Analysis (COA), a document that details the identity, purity, and potency testing results for that specific batch of the chemical. The pharmacy must verify this COA and quarantine the ingredient until it is formally approved for use by the quality assurance team.

- Procedural Standardization ∞ Consistency is key to quality. For every unique formulation a pharmacy makes, it must create a Master Formulation Record. This document is the master recipe, detailing the ingredients, quantities, equipment to be used, and step-by-step compounding instructions. Each time a batch is made, a corresponding Compounding Record is created to document every action taken, including the specific lot numbers of the ingredients used and the personnel involved. This creates a complete, auditable trail for every single prescription.

- Finished Product Testing ∞ Before a compounded medication is dispensed, it undergoes final quality checks. This always includes a visual inspection for clarity, color, and particulates. For sterile preparations, certain high-risk batches may be quarantined until they pass sterility and endotoxin testing. Crucially, reputable pharmacies also conduct routine potency testing on samples of their preparations. They send samples to an independent analytical laboratory to verify that the concentration of the active ingredient is correct. This final step confirms that all other quality systems have worked as intended and that the patient will receive the exact dose prescribed by their clinician.

The distinction between 503A and 503B facilities defines the regulatory framework, but the unwavering commitment to personnel, environmental, and procedural controls is what truly ensures medication safety.

This multi-layered system of control is what separates a high-quality compounding pharmacy from a standard dispensary. It is an active, continuous process of verification, documentation, and testing. When your clinician partners with a pharmacy that rigorously implements these measures, they are ensuring that your personalized protocol is built on a foundation of quantifiable quality, giving you the best possible chance of achieving your desired health outcomes.

Academic

The clinical success of personalized hormonal therapies is contingent upon the molecular fidelity of the compounded preparation. While procedural and environmental controls defined in USP chapters establish the foundation for quality, the ultimate verification of a compounded product’s integrity lies in analytical chemistry.

Specifically, the tandem disciplines of potency testing and stability assessment provide the objective, quantitative data that confirms a preparation’s therapeutic value. This analysis moves beyond procedural compliance to the direct measurement of the active pharmaceutical ingredient (API), ensuring its concentration and chemical integrity from the moment of compounding to its final administration.

The primary analytical technique employed for this purpose is High-Performance Liquid Chromatography (HPLC). HPLC is a powerful method used to separate, identify, and quantify each component in a mixture. In the context of a compounded hormone cream or injectable solution, an HPLC system can precisely measure the concentration of the API (e.g.

Testosterone Cypionate) and separate it from excipients (the inactive ingredients) and, most critically, from any potential degradation products. The accepted range for potency in most compounded preparations is typically 90.0% to 110.0% of the labeled concentration, a standard that requires highly accurate and precise analytical methods to verify.

The Criticality of Stability-Indicating Methods

A common misconception is that any potency test is sufficient. A more sophisticated level of quality assurance requires the use of a stability-indicating method (SIM). A SIM is an analytical procedure that can accurately quantify the active ingredient in the presence of its potential degradation products, impurities, and excipients. This distinction is paramount for patient safety and therapeutic efficacy.

Consider a vial of a peptide, like CJC-1295. Over time or if exposed to improper storage conditions, the complex peptide molecule can break down into smaller, inactive fragments. A simple, non-stability-indicating HPLC method might fail to separate the intact peptide from these fragments.

The resulting chromatogram would show a single, large peak, leading to the false conclusion that the product is still at full potency. In reality, the therapeutic molecule has degraded, and the patient would be administering an ineffective solution. A validated SIM, however, is designed through forced degradation studies.

The API is intentionally exposed to harsh conditions (heat, light, acid, oxidation) to generate its likely degradation products. The analytical chemist then develops the HPLC method to achieve baseline separation between the peak for the intact API and the peaks for all the degradation products. This ensures that the potency measurement reflects only the active, therapeutically relevant molecule.

A validated stability-indicating analytical method is the only way to ensure that a potency test accurately reflects the true concentration of the active, intact drug molecule.

Systematic Points of Failure and Corresponding QC Verifications

A robust quality management system in a compounding pharmacy functions as a network of controls designed to prevent errors at every stage of the production lifecycle. The analytical testing of the final product serves as the ultimate verification of this system’s effectiveness. The following table illustrates potential points of failure in the compounding process and the specific quality control measures, particularly analytical tests, designed to mitigate these risks.

| Potential Point of Failure | Primary Risk to Patient | Key Quality Control Verification |

|---|---|---|

| Incorrect API Weighing |

Supratherapeutic or subtherapeutic dose, leading to adverse effects or lack of efficacy. |

Finished Product Potency Testing (HPLC) ∞ Directly measures the final concentration of the API to confirm it is within the 90-110% specification. |

| API Degradation (Pre-Compounding) |

Subtherapeutic dose due to use of compromised raw material. |

Certificate of Analysis (COA) Review ∞ Verifies the purity and potency of the raw material batch. Some facilities may perform identity and purity testing on incoming APIs. |

| Non-Homogeneous Mixing (e.g. Creams) |

Inconsistent dosing with each application, leading to unpredictable clinical response. |

Content Uniformity Testing ∞ Involves assaying multiple samples from different locations within a single container or batch to ensure the API is evenly distributed. |

| Microbial Contamination (Sterile Products) |

Systemic infection, sepsis, or localized abscess. This is a critical risk with injectables. |

Sterility Testing (USP <71>) ∞ Samples are incubated in growth media to detect the presence of viable microorganisms. No growth indicates a sterile product. |

| Bacterial Endotoxin Contamination |

Fever, inflammation, and potentially fatal endotoxic shock. |

Bacterial Endotoxins Test (BET) (USP <85>) ∞ Uses Limulus Amebocyte Lysate (LAL) to detect endotoxins from gram-negative bacteria. |

| Chemical Degradation Post-Compounding |

Loss of efficacy over the intended use period of the medication. |

Stability Studies & Beyond-Use Dating (BUD) ∞ The product is tested at various time points under specified storage conditions using a SIM to determine the date beyond which it should not be used. |

What Is the Impact of Endotoxin Testing on Injectable Hormones and Peptides?

For any sterile compounded preparation intended for injection, such as TRT, hCG, or peptide therapies, the absence of microbial contamination is insufficient. An equally critical parameter is the level of bacterial endotoxins. Endotoxins are lipopolysaccharides found in the outer membrane of gram-negative bacteria.

These molecules can remain in a solution even after the bacteria themselves have been killed and removed by sterilization or filtration. If injected, endotoxins can trigger a severe inflammatory response in the body, leading to fever, chills, and in high concentrations, septic shock.

Therefore, a comprehensive quality control program for sterile compounds must include a Bacterial Endotoxins Test (BET), as specified in USP <85>. This test provides a quantitative measure of the endotoxin load in the preparation, ensuring it is below the safe limit for parenteral administration.

For a patient self-administering a weekly injection, this test is an invisible but essential safeguard. It ensures that the physiological response they experience is from the therapeutic action of the hormone or peptide, not from a pro-inflammatory reaction to bacterial remnants. The combination of sterility testing and endotoxin testing provides a dual assurance of microbiological safety for all injectable compounded medications.

References

- United States Pharmacopeial Convention. “General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations.” United States Pharmacopeia and National Formulary (USP-NF), 2023.

- United States Pharmacopeial Convention. “General Chapter <795> Pharmaceutical Compounding ∞ Nonsterile Preparations.” United States Pharmacopeia and National Formulary (USP-NF), 2023.

- U.S. Food and Drug Administration. “FD&C Act Provisions that Apply to Human Drug Compounding.” FDA.gov, August 2021.

- Gudeman, J. Jozwiakowski, M. Chollet, J. & Randell, M. “Potential Risks of Pharmacy Compounding.” Drugs in R&D, vol. 13, no. 1, 2013, pp. 1-8.

- National Academies of Sciences, Engineering, and Medicine. “The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of the Evidence.” The National Academies Press, 2020.

- Kelesidis, T. & Canseco, E. “The standardization of nonsterile compounding ∞ a study in quality control and assessment for hormone compounding.” International Journal of Pharmaceutical Compounding, vol. 18, no. 2, 2014, pp. 155-61.

- Tella, S. H. & Jick, S. S. “Compounded bioidentical hormone products, a path forward.” Journal of the Endocrine Society, vol. 5, no. 1, 2021, p. bvaa187.

- U.S. Food and Drug Administration. “Compounding and the FDA ∞ Questions and Answers.” FDA.gov, April 2021.

- Allen, Loyd V. “Potency versus Stability Testing.” International Journal of Pharmaceutical Compounding, vol. 17, no. 2, 2013, pp. 108-110.

- U.S. Food and Drug Administration. “Insanitary Conditions at Compounding Facilities ∞ Guidance for Industry.” FDA.gov, November 2020.

Reflection

You have now explored the intricate systems that stand behind the personalized medications designed to restore your body’s equilibrium. This knowledge of quality control, from the cleanroom environment to the precision of an analytical test, serves a purpose beyond intellectual curiosity. It transforms your role in your own healthcare.

You are now equipped to think about your therapeutic protocols with a new layer of awareness. The conversation is no longer just about the type of hormone or the prescribed dose; it extends to the quality and integrity of the very molecules you are entrusting with your well-being.

This understanding empowers you to engage with your clinical team in a more meaningful dialogue. It allows you to ask informed questions about the compounding pharmacy they partner with, not from a place of suspicion, but from a position of shared commitment to achieving the best possible outcome.

Consider your own health journey. Think about the symptoms that prompted you to seek care and the goals you wish to achieve. The path from your current biological state to your desired state of vitality is paved with these precise, quality-assured molecules. The knowledge you have gained is a tool, enabling you to ensure that path is built on a foundation of safety, purity, and potency. Your proactive engagement is a vital component of your own success.