Fundamentals

Your journey toward hormonal balance is deeply personal. It begins with a conversation, a series of symptoms, and the intuitive sense that your body’s internal communication system is operating with static on the line. When you and your clinician decide that a personalized, compounded hormone protocol is the right path, you are placing immense trust in a process.

You are trusting that the medicine designed specifically for your physiology is precisely what it claims to be. This trust is built upon a silent, rigorous, and non-negotiable foundation of quality control. Understanding this foundation is the first step in transforming from a passive recipient of care into an active, informed architect of your own well-being.

A compounded hormone preparation is fundamentally different from a mass-produced pharmaceutical. It is a specific formulation created by a pharmacist for an individual patient, based on a prescription from a licensed practitioner. This allows for customized dosages, unique delivery systems like topical creams or subcutaneous injections, and formulations free of allergens or irritants found in commercial products.

This bespoke approach is the power of compounding; it is also where the profound responsibility of quality assurance begins. The measures in place are designed to answer a series of critical questions. Is the preparation sterile and free from contaminants? Does it contain the exact amount of the active hormone prescribed? Is the hormone pure and unadulterated? The answers to these questions determine whether your therapy will be effective and, most importantly, safe.

The Architecture of Trust

The system of quality control for compounded hormones rests on several key pillars. The United States Pharmacopeia (USP) is a scientific nonprofit organization that sets the standards for the quality, purity, strength, and identity of medicines. These are not mere suggestions; they are detailed, science-based chapters that provide the blueprint for safe compounding.

State Boards of Pharmacy are the primary regulatory bodies that enforce these standards at the local level, inspecting pharmacies and ensuring compliance. The U.S. Food and Drug Administration (FDA) also plays a crucial role, particularly in overseeing the bulk drug substances used in compounding and regulating a special class of large-scale compounding facilities.

Think of this system as building a house. The USP provides the architectural blueprints and the building codes, detailing every requirement for a safe structure. The State Board of Pharmacy is the local inspector who visits the site, ensuring every wall is sound and every wire is placed correctly.

The FDA ensures that the raw materials, the very lumber and concrete of the house, are of high quality before they even arrive at the building site. Each component is essential to ensuring the final product is a safe and reliable home for your health protocol.

Core Quality Concepts

To appreciate the importance of these measures, it is helpful to understand the core concepts they are designed to protect. These principles are the non-negotiable attributes of any compounded preparation you receive.

- Potency ∞ This refers to the strength or concentration of the active pharmaceutical ingredient (API), which in this case is the hormone itself. If your prescription is for 20mg of testosterone, potency testing verifies that the preparation contains exactly that amount, within a very narrow and acceptable margin. A sub-potent dose will fail to produce the desired clinical effect, leaving you with unresolved symptoms. A super-potent dose can introduce significant health risks and unwanted side effects.

- Purity ∞ This ensures that the hormone API is free from contaminants or impurities. During the chemical synthesis of a hormone, other related substances can be created. Purity testing confirms that these are removed and that you are only receiving the intended molecule.

- Sterility ∞ This is an absolute requirement for any preparation that bypasses the body’s natural defenses, such as injections. Sterile compounding ensures the absence of any viable microorganisms like bacteria or fungi. A contaminated injection can lead to serious, life-threatening infections. This is why sterile compounding is performed in highly controlled environments.

The integrity of a compounded hormone is a direct reflection of the meticulous, multi-layered quality control processes that govern its creation.

These concepts form the biological and chemical promise of your prescription. When you begin a protocol, whether it is weekly Testosterone Cypionate injections to restore vitality or a topical progesterone cream to ease the transition through perimenopause, your clinical success is entirely dependent on the pharmacy’s unwavering adherence to these quality principles.

The protocols themselves, from TRT for men and women to the use of specific peptides like Sermorelin for metabolic health, are only as effective as the molecules they deliver. Therefore, a deep understanding of quality control is a vital part of your therapeutic journey, empowering you to ask the right questions and partner with providers who prioritize these uncompromising standards.

Intermediate

Having established that the safety and efficacy of your personalized hormone therapy depend on potency, purity, and sterility, we can now examine the specific operational frameworks that bring these concepts to life. These are the detailed procedures and environmental controls that a high-quality compounding pharmacy integrates into its daily workflow.

The transition from a theoretical standard to a tangible, reliable medication occurs within a system of meticulously defined processes, governed primarily by the United States Pharmacopeia (USP). For compounded hormones, two chapters are of particular importance ∞ USP General Chapter <797> for sterile preparations and USP General Chapter <795> for non-sterile preparations.

The Sterile Compounding Environment under USP 797

Injectable therapies, such as Testosterone Cypionate, Gonadorelin, or peptide protocols involving Ipamorelin, must be sterile. USP <797> provides the detailed requirements to minimize the risk of microbial contamination. This chapter is extensive, dictating everything from the physical layout of the facility to the training of the personnel.

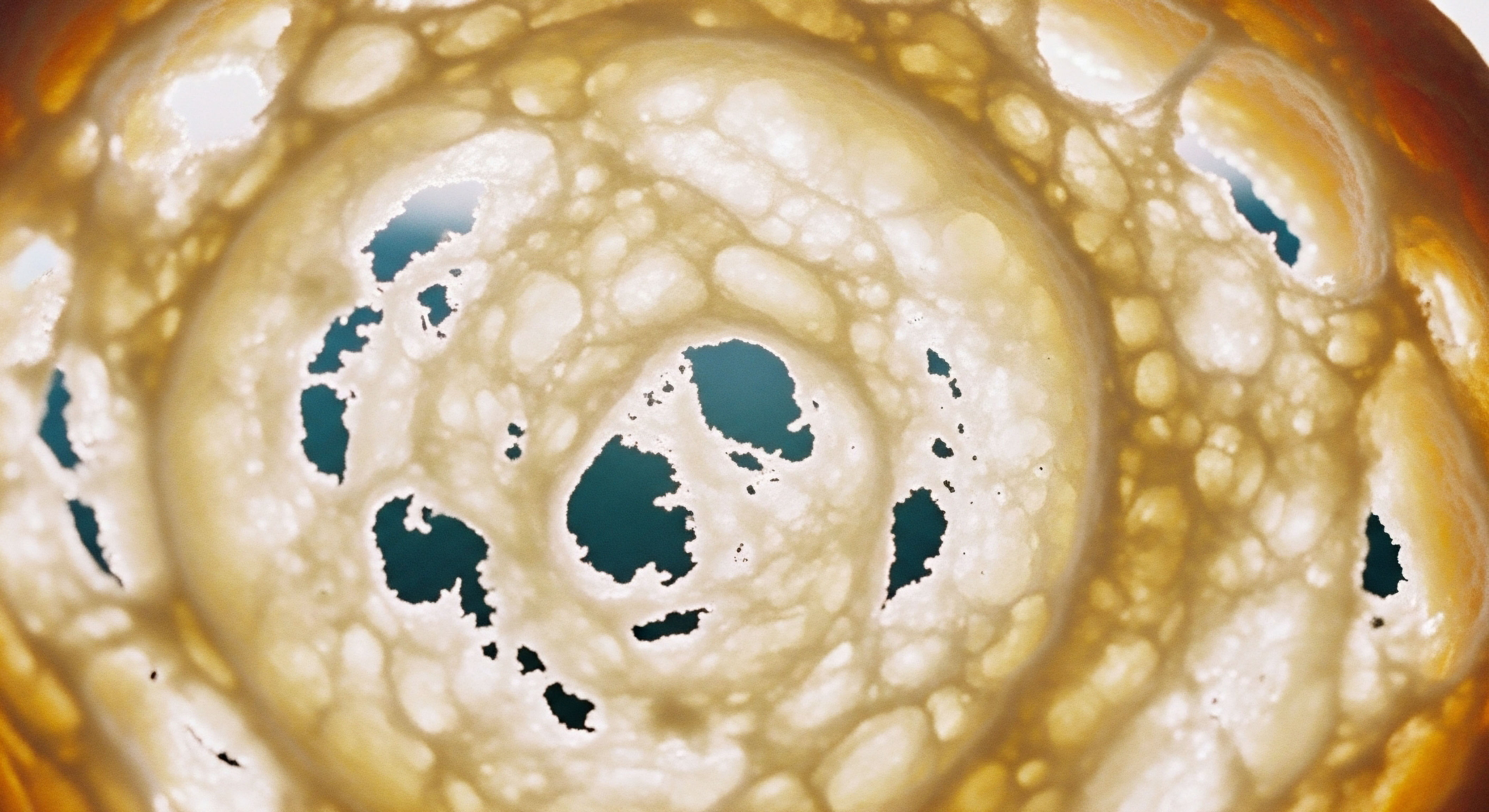

The core of USP <797> is the principle of controlled environments. Compounding of sterile preparations must occur within a Primary Engineering Control (PEC), such as a laminar airflow workbench or a biological safety cabinet. These devices create an ISO Class 5 environment, which means the air is exceptionally clean, containing no more than 3,520 particles of 0.5 microns or larger per cubic meter. To put this in perspective, the air in a typical room has millions of such particles.

The PEC itself is housed within a larger cleanroom environment. A Category 2 compounded sterile product (CSP), which allows for a longer beyond-use date, must be prepared in a PEC that is located inside a buffer room with ISO Class 7 air quality, which is adjacent to an ante-room with ISO Class 8 air quality.

This suite of rooms creates a pressure cascade, where the cleanest room has the highest pressure, so air always flows outward, preventing contaminants from entering. This controlled environment is the physical manifestation of a commitment to sterility.

Personnel Training and Aseptic Technique

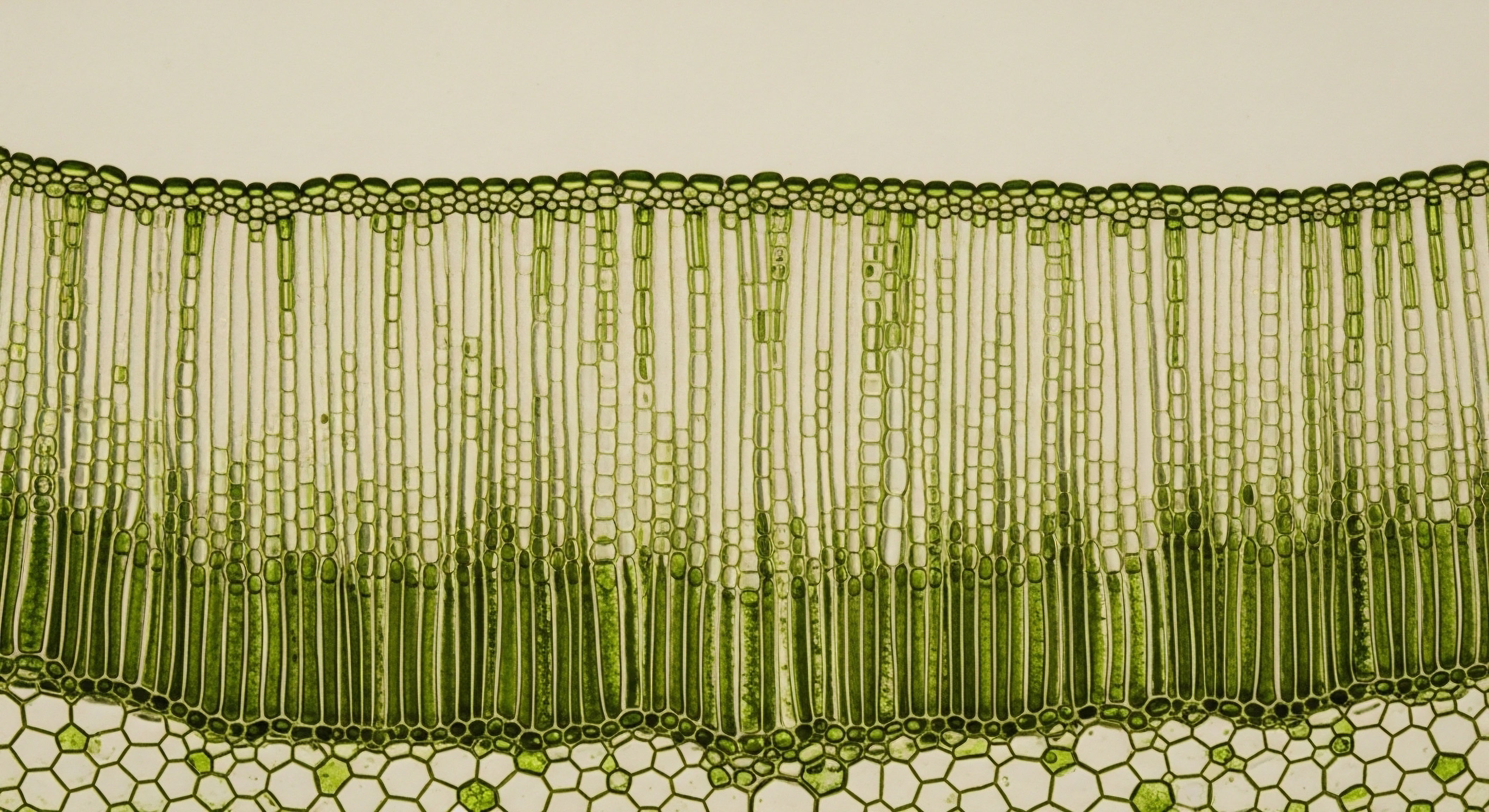

The most advanced cleanroom is only as good as the practices of the people working within it. USP <797> places enormous emphasis on personnel training and competency. Compounding staff must undergo rigorous training in aseptic technique, which is the set of practices used to prevent contamination. This includes:

- Garbing ∞ A specific, sequential process for donning sterile gloves, gowns, hair covers, masks, and shoe covers before entering the cleanroom.

- Hand Hygiene ∞ Extensive hand washing and sanitization procedures.

- Material Handling ∞ Procedures for disinfecting all vials, syringes, and other components as they are introduced into the ISO 5 environment.

- Aseptic Manipulation ∞ Performing the compounding steps in a way that never compromises the sterility of the critical sites, such as the needle hub or the vial septum.

Competency is not a one-time event. Pharmacists and technicians must pass written tests and practical evaluations, including a “media-fill test.” In this test, they compound a product using a sterile growth medium instead of a drug. The resulting preparation is then incubated to see if any microbial growth occurs, providing a direct measure of their aseptic technique proficiency.

A pharmacy’s investment in rigorous environmental controls and continuous personnel training is a direct investment in patient safety.

Verification through Testing

While process controls are essential, the final product must still be verified. This is where analytical testing becomes a critical quality control measure. High-quality compounding pharmacies will conduct routine testing on their preparations, either in-house or through a third-party analytical laboratory.

Potency and Purity Analysis

The most common and powerful tool for determining the potency of compounded hormones is High-Performance Liquid Chromatography (HPLC). This instrument separates the components of a sample and measures the precise quantity of the active hormone. This test confirms that a 10mg/mL testosterone preparation actually contains 10mg/mL. The accepted range for most compounded drugs is typically between 90% and 110% of the labeled strength. Results from HPLC provide objective, documented evidence that the pharmacy’s compounding process is accurate and reproducible.

Purity is also often assessed using HPLC or a related technique called Gas Chromatography (GC). These methods can detect and quantify any impurities or related substances, ensuring the final product meets the required specifications for the bulk drug substance.

Sterility and Endotoxin Testing

For sterile preparations, testing goes beyond chemical analysis. A sample from a batch of compounded medication may be sent for sterility testing according to USP <71>. This involves incubating the sample in growth media over a period of time to confirm the absence of microbial growth.

Furthermore, injectable drugs must be tested for bacterial endotoxins, which are fever-inducing substances released from the cell walls of certain bacteria. Even if a product is sterile, the presence of endotoxins can cause a severe reaction in a patient.

How Are Compounding Pharmacies Regulated?

The regulatory landscape for compounding pharmacies is divided into two main categories, and understanding the difference is important for any patient receiving compounded therapies. The distinction was clarified by the Drug Quality and Security Act of 2013, which created Sections 503A and 503B of the Food, Drug, and Cosmetic Act.

The table below outlines the key differences between these two types of facilities.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Prescription Requirement | Requires a valid, patient-specific prescription before compounding (can prepare limited quantities in anticipation of prescriptions). | Can produce large batches with or without prescriptions for “office use” by healthcare facilities. |

| Primary Oversight | Regulated primarily by State Boards of Pharmacy. | Must register with the FDA and is subject to federal oversight. |

| Manufacturing Standards | Must comply with USP <795> and <797> standards for compounding practices. | Must comply with full Current Good Manufacturing Practices (CGMP), the same standards required for pharmaceutical manufacturers. |

| Adverse Event Reporting | Not required to report adverse events to the FDA. | Must report adverse events to the FDA. |

| Scale of Production | Typically smaller-scale, focused on individual patient needs. | Large-scale production, functioning as a hybrid between a traditional pharmacy and a drug manufacturer. |

Choosing a pharmacy, whether a 503A or 503B facility, that can provide documentation of its compliance with USP standards, its personnel training protocols, and its third-party testing results is a critical step in ensuring you receive a high-quality, safe, and effective medication. This level of transparency is the hallmark of a pharmacy dedicated to excellence in personalized medicine.

Academic

The clinical success of hormonal optimization protocols is predicated on a principle of biochemical precision. The therapeutic window for hormones like testosterone, estradiol, and progesterone is often narrow, and achieving a desired physiological response while minimizing adverse effects requires accurate and consistent dosing.

While USP chapters provide the procedural framework for safe compounding, a deeper, academic inquiry reveals that the analytical validation of the final preparation is the ultimate guarantor of this precision. The intersection of analytical chemistry and clinical endocrinology is where the true quality of a compounded hormone is defined.

A deviation of 15% in potency is not merely a number on a lab report; it is a clinically significant event that can alter the delicate feedback loops of the hypothalamic-pituitary-gonadal (HPG) axis and undermine the entire therapeutic goal.

The Analytical Science of Potency Validation

Potency testing is the quantitative confirmation of a compounded preparation’s strength. While several analytical techniques exist, High-Performance Liquid Chromatography (HPLC) is the gold standard for the analysis of steroid hormones due to its specificity, precision, and accuracy. An HPLC system separates molecules based on their physicochemical properties as they are passed through a column under high pressure.

A detector at the end of the column quantifies the amount of the target molecule (the hormone) by comparing its signal to that of a certified reference standard of known concentration.

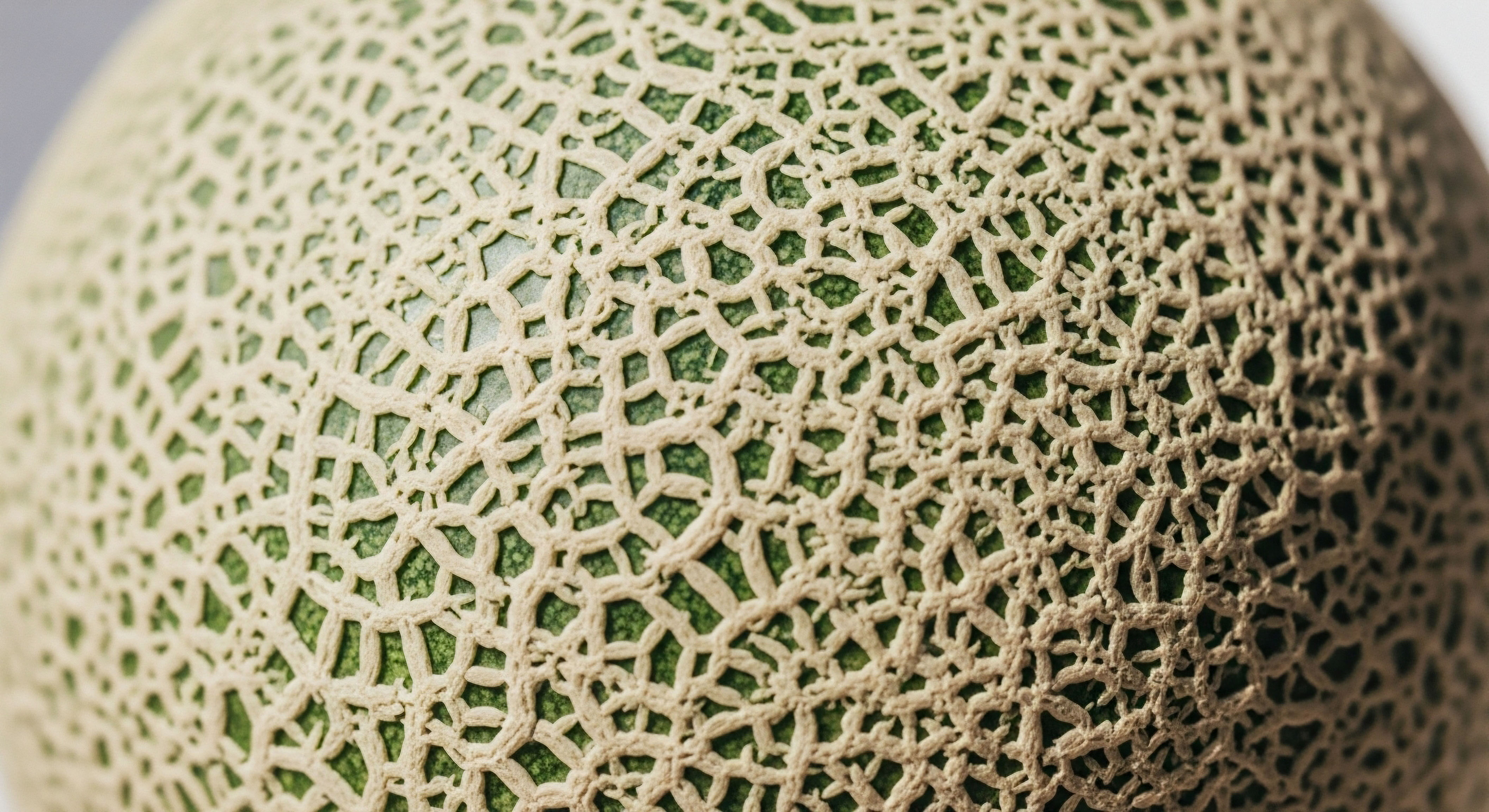

A critical, and often overlooked, aspect of this process is method validation. A laboratory cannot simply use a generic HPLC method. The method must be validated for the specific hormone in the specific base, or “matrix,” in which it is compounded.

For example, the method for testing testosterone cypionate in grapeseed oil will be different from the method for testing testosterone in a pluronic lecithin organogel (PLO) cream. Method validation, as guided by USP Chapter <1225>, establishes and documents that the analytical procedure is suitable for its intended purpose. This involves demonstrating:

- Specificity ∞ The ability of the method to unequivocally assess the analyte in the presence of components that may be expected to be present, such as other ingredients in the base, or potential degradation products.

- Accuracy ∞ The closeness of the test results obtained by the method to the true value. This is often determined by “spiking” a blank matrix with a known amount of the hormone and measuring the recovery.

- Precision ∞ The degree of agreement among individual test results when the method is applied repeatedly to multiple samplings of a homogeneous sample. This demonstrates the reproducibility of the test.

- Linearity ∞ The ability of the method to produce test results that are directly proportional to the concentration of the analyte within a given range.

Without this rigorous validation, a potency result is scientifically meaningless. An advanced compounding pharmacy will partner with an analytical lab that can provide data from validated, stability-indicating methods. A stability-indicating method is one that can also detect and quantify any degradation products that may form over time, which is essential for establishing a scientifically sound Beyond-Use Date (BUD).

What Are the Clinical Consequences of Potency Deviations?

The clinical importance of this analytical rigor becomes clear when we consider the physiological impact of potency deviations. Let us examine a standard male TRT protocol ∞ 100mg of Testosterone Cypionate injected weekly. If a compounded preparation is super-potent by 20% (120mg), the patient is receiving an additional 80mg of testosterone per month.

This can lead to supraphysiologic serum levels, increasing the rate of aromatization to estradiol and the conversion to dihydrotestosterone (DHT). The clinical result is a greater likelihood of side effects such as gynecomastia, fluid retention, and potentially adverse effects on the prostate, requiring higher doses of anastrozole to manage.

Conversely, a sub-potent preparation at 80mg per week may fail to elevate serum testosterone into the therapeutic range, leaving the patient with persistent symptoms of hypogonadism and a mistaken belief that the therapy is ineffective.

The precision of an analytical instrument in a laboratory directly translates to the predictability of a clinical outcome in a patient.

This principle extends to all hormonal therapies. In female hormone protocols, the ratio of estradiol to progesterone is critical. A sub-potent progesterone cream can result in unopposed estrogen, increasing the risk of endometrial hyperplasia. The lack of reliable pharmacokinetic and bioavailability data for many compounded preparations already presents a clinical challenge; adding the variable of uncertain potency makes rational dose adjustments nearly impossible.

The Challenge of Sterility Assurance and Pyrogenicity

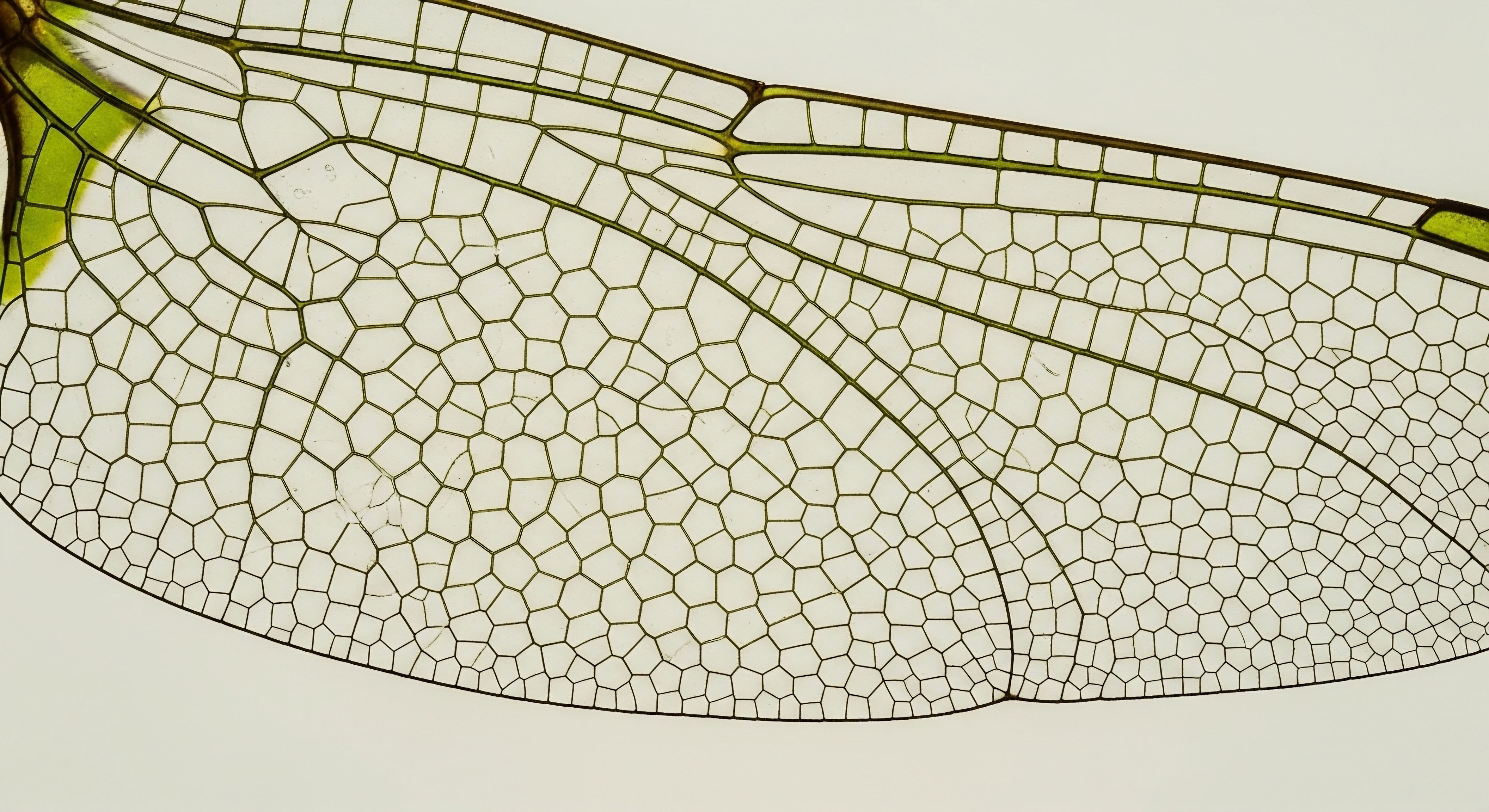

For injectable hormones, sterility is an absolute. While USP <797> provides the framework for minimizing contamination risk, terminal sterilization methods or aseptic filtration must be validated. For example, when using a 0.22-micron sterilizing filter, the pharmacy must perform a bubble point test on the filter after use. This test confirms that the filter’s membrane integrity was maintained during the filtration process. A failure of this test means the sterility of the entire batch is compromised.

Furthermore, the absence of viable microorganisms does not guarantee the absence of pyrogens. Bacterial endotoxins are lipopolysaccharides from the cell walls of Gram-negative bacteria that can cause a severe inflammatory response, including fever, chills, and hypotension, even in microscopic quantities. They are not removed by sterilizing filters.

Therefore, all sterile injectables must be tested for endotoxins, typically using the Limulus Amebocyte Lysate (LAL) test as described in USP <85>. The bulk drug substances and all excipients used must also be low in endotoxins. This is a critical quality attribute that separates pharmaceutical-grade ingredients from lower-grade materials.

The table below details some of the advanced quality control tests that underpin the safety and efficacy of compounded sterile hormones.

| Quality Attribute | Test/Method | Purpose and Clinical Significance |

|---|---|---|

| Identity | FTIR / HPLC / Mass Spectrometry | Confirms the active pharmaceutical ingredient is the correct molecule. Prevents administration of the wrong hormone. |

| Potency | Validated, Stability-Indicating HPLC | Ensures the dose is accurate, preventing sub-therapeutic outcomes or increased risk of side effects from super-potent doses. |

| Purity | HPLC / GC | Ensures the absence of impurities from the synthesis process or degradation, minimizing exposure to unknown substances. |

| Sterility | USP <71> Sterility Testing | Confirms the absence of viable microbial contamination to prevent serious infections from injectable therapies. |

| Endotoxins | USP <85> Bacterial Endotoxins Test (LAL) | Detects fever-inducing pyrogens to prevent severe inflammatory reactions following injection. |

| Particulate Matter | USP <788> Particulate Matter in Injections | Measures sub-visible particles that can cause vascular occlusion and other adverse events. |

In conclusion, the quality control of compounded hormones is a domain of applied science where procedural compliance meets analytical verification. For the clinician and the patient, partnering with a compounding pharmacy that not only adheres to the letter of USP standards but also embraces a culture of analytical validation is paramount.

This commitment to quality, demonstrated through transparent documentation of training, environmental monitoring, and rigorous, matrix-specific analytical testing, is what transforms a personalized prescription from a theoretical concept into a reliable and powerful therapeutic tool.

References

- National Academies of Sciences, Engineering, and Medicine. “The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of the Evidence.” The National Academies Press, 2020.

- United States Pharmacopeial Convention. “General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations.” United States Pharmacopeia and National Formulary (USP-NF), 2023.

- United States Pharmacopeial Convention. “General Chapter <795> Pharmaceutical Compounding ∞ Nonsterile Preparations.” United States Pharmacopeia and National Formulary (USP-NF), 2022.

- Food and Drug Administration. “Current Good Manufacturing Practice ∞ Guidance for Human Drug Compounding Outsourcing Facilities Under Section 503B of the FD&C Act.” U.S. Department of Health and Human Services, 2020.

- ARL Bio Pharma. “Potency Testing Benefits and Requirements.” ARL Bio Pharma, Inc. Accessed July 2025.

- American College of Obstetricians and Gynecologists. “Committee Opinion No. 532 ∞ Compounded Bioidentical Menopausal Hormone Therapy.” Obstetrics & Gynecology, vol. 120, no. 2, pt. 1, 2012, pp. 411-415.

- Tsiligiannis, Themos, et al. “The Standardization of Nonsterile Compounding ∞ A Study in Quality Control and Assessment for Hormone Compounding.” International Journal of Pharmaceutical Compounding, vol. 19, no. 5, 2015, pp. 426-431.

- McDermott Will & Emery. “FDA Publishes Proposed Rule on 503A and 503B Compounding.” JDSupra, 5 Apr. 2024.

- European Pharmacopoeia Commission. “Hormone Potency Assays.” European Pharmacopoeia (Ph. Eur.), 10th ed. 2020.

- Kastango, Eric S. and Douglas S. Scheckelhoff. “The Revised USP Sterile Compounding Standards and the Role of the Designated Person.” American Journal of Health-System Pharmacy, vol. 78, no. 18, 2021, pp. 1678-1686.

Reflection

Calibrating Your Therapeutic Alliance

The information presented here is more than a technical overview. It is a framework for a new kind of conversation about your health. The biological systems that govern your vitality are intricate, and the therapies designed to support them must be crafted with an equal measure of precision and care.

Your body does not distinguish between a hormone molecule from a large manufacturer and one from a compounding pharmacy; it only recognizes the signal the molecule provides. The integrity of that signal is everything.

As you move forward, this knowledge becomes a tool for empowerment. It equips you to engage with your clinical team on a deeper level. The quality of a compounded preparation is a direct extension of the pharmacy’s philosophy and commitment to excellence.

A willingness to discuss their USP compliance, to share their environmental monitoring data, or to provide certificates of analysis for their products are all indicators of a culture of transparency. Your path to optimized health is a partnership, a therapeutic alliance built on shared knowledge and mutual trust.

Understanding the science of quality control allows you to be an active, discerning partner in that alliance, ensuring the foundation of your therapy is as strong and reliable as the health you seek to build upon it.

Glossary

quality control

united states pharmacopeia

compounded hormones

food and drug administration

potency testing

sterile compounding

testosterone cypionate

compounding pharmacy

sterile preparations

beyond-use date

high-performance liquid chromatography

this test confirms that