Fundamentals

The conversation around personal wellness and hormonal optimization often centers on the therapeutic agents themselves ∞ the peptides like Sermorelin or Ipamorelin that signal your body to heal, regenerate, and reclaim its vitality. You may have heard these names in discussions about improving sleep, accelerating recovery, or sharpening cognitive function.

Your focus, understandably, is on the outcome. You feel the fatigue, the slowed recovery, or the mental fog, and you seek a biological solution. This is a completely valid and personal starting point on a journey toward profound well-being.

The therapies are designed to interact with your body’s most intricate signaling systems, a delicate biological conversation between the peptide and your cells. For this conversation to be productive and safe, the integrity of the messenger ∞ the peptide itself ∞ is paramount.

This brings us to a foundational concept that underpins the entire world of therapeutic peptides Good Manufacturing Practice, or GMP. It is the rigorous, scientifically mandated system of controls that ensures a peptide is precisely what it claims to be, free from contaminants, and consistent in every single dose.

When you consider a protocol designed to optimize your endocrine system, you are placing immense trust in the purity and identity of the molecules you introduce to your body. GMP is the framework that honors that trust.

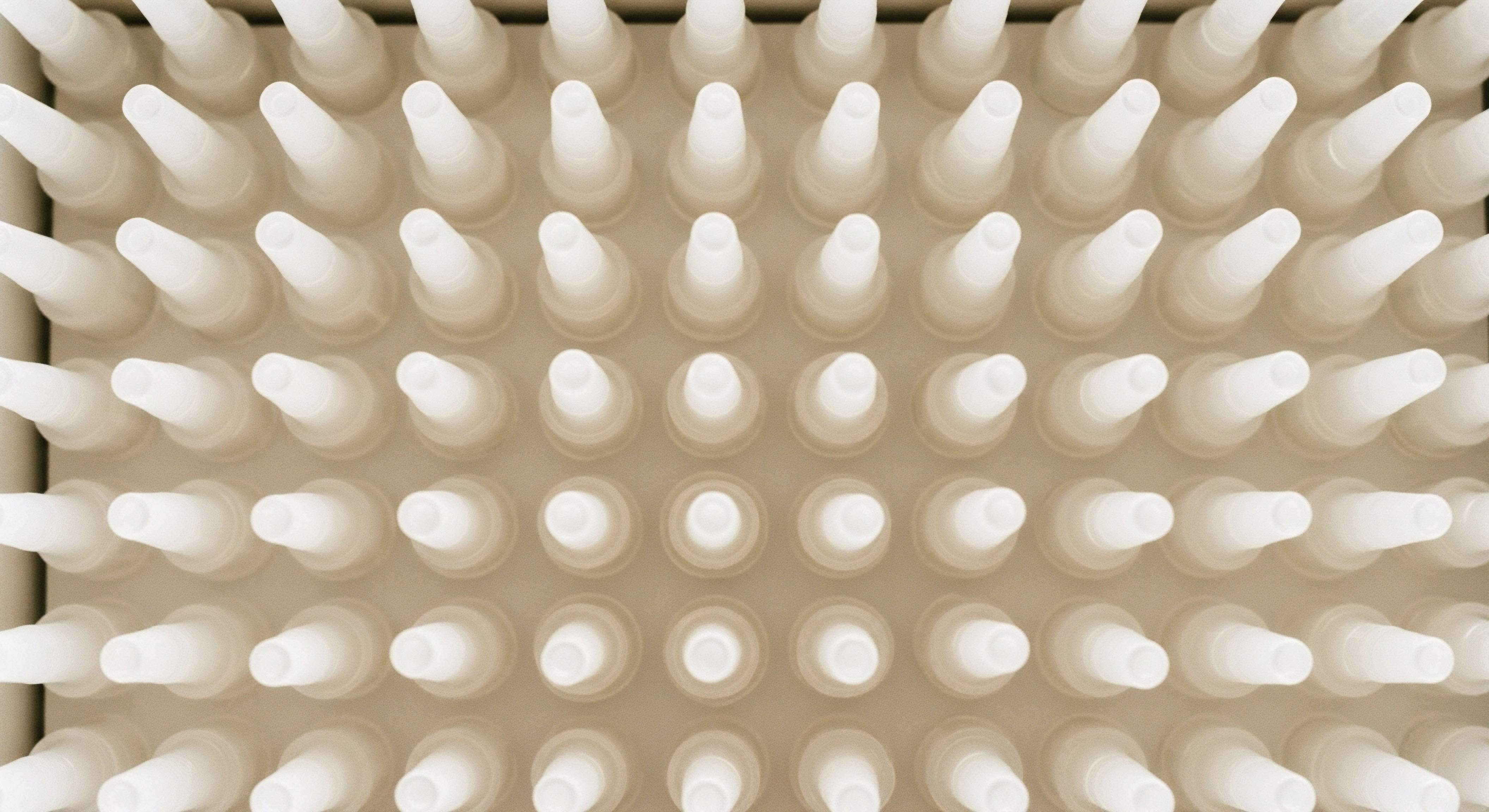

It dictates that every stage of a peptide’s creation, from the initial raw materials to the final sterile vial, is governed by exacting standards of quality and safety. This system is designed to produce a product that is not only effective but fundamentally safe for clinical use.

The quality of a therapeutic peptide is not an abstract benchmark; it is a direct determinant of its safety and its ability to effectively communicate with your body’s cellular architecture.

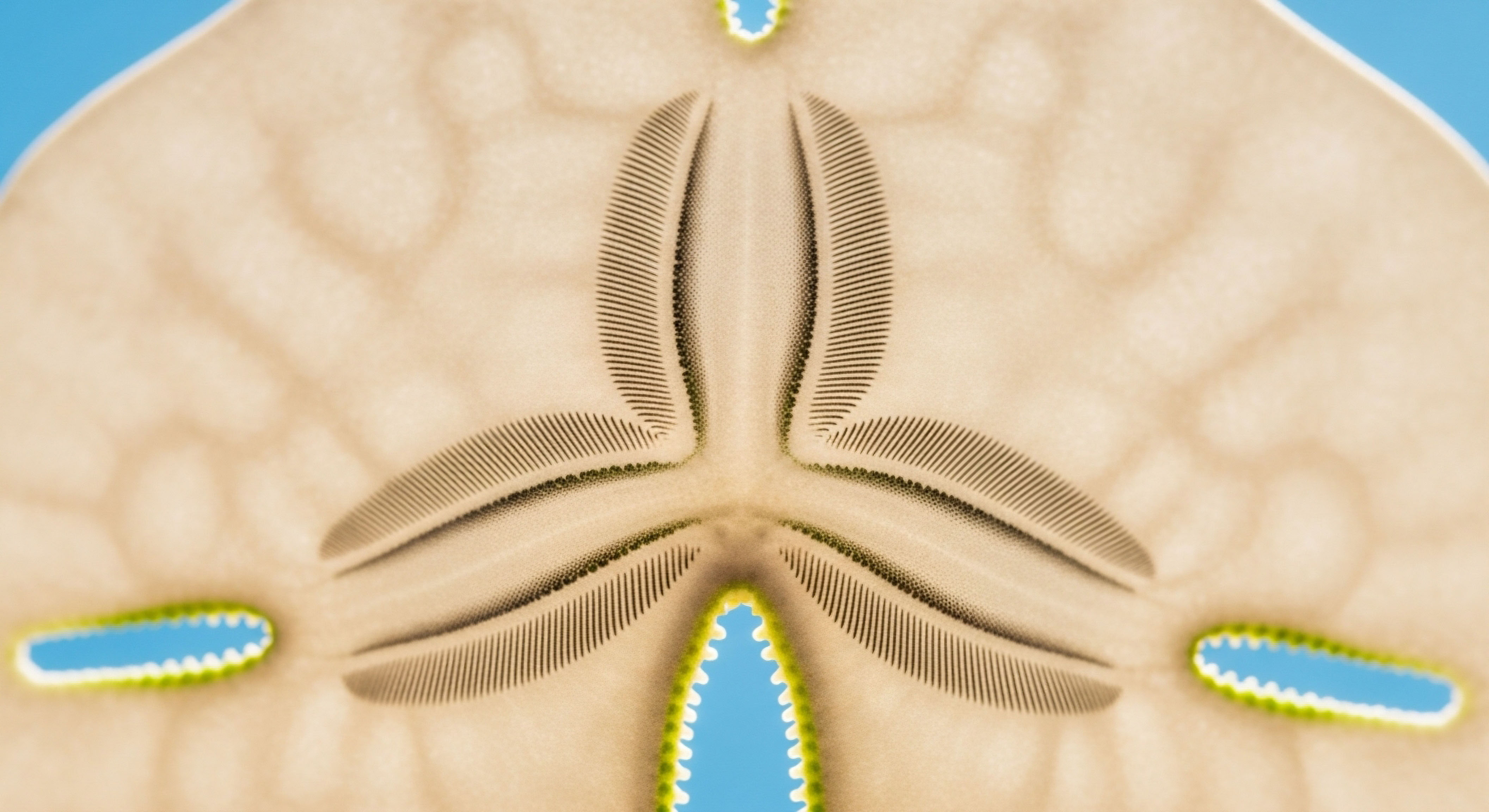

The journey of a peptide from a sequence on a screen to a therapeutic tool is a testament to precision chemistry. Peptides are synthesized by linking amino acids together in a specific, predetermined order. A slight deviation in this sequence, an unintended modification, or the presence of residual chemicals from the manufacturing process can alter the peptide’s structure.

A structurally compromised peptide may fail to bind to its target receptor, rendering it ineffective. Worse, it could be recognized by your immune system as a foreign entity, triggering an unwanted reaction. Therefore, the quality control measures mandated by GMP are not merely bureaucratic hurdles; they are the essential guardians of your biological well-being, ensuring that the molecule intended to support your health does exactly that.

At its heart, GMP is about control and documentation. Every step is defined by a Standard Operating Procedure (SOP), and every action is recorded. This creates a complete, traceable history for every batch of peptides produced. This meticulous record-keeping ensures that if any deviation occurs, it can be immediately identified, investigated, and corrected.

The environment in which peptides are made is also strictly controlled, using clean rooms with filtered air and regulated temperature and humidity to prevent contamination. For anyone embarking on a journey of personalized wellness that includes peptide therapy, understanding the significance of GMP is the first step toward becoming an informed and empowered participant in your own health narrative.

It is the assurance that the science you are leveraging for your vitality is as pure and reliable as the biological systems you are seeking to support.

Intermediate

When we move beyond the conceptual importance of quality and into the practical application of Good Manufacturing Practice (GMP) for peptide manufacturing, we enter a world of rigorous analytical chemistry and validated processes. The system is built to answer several critical questions about a peptide with verifiable data Is it the correct molecule?

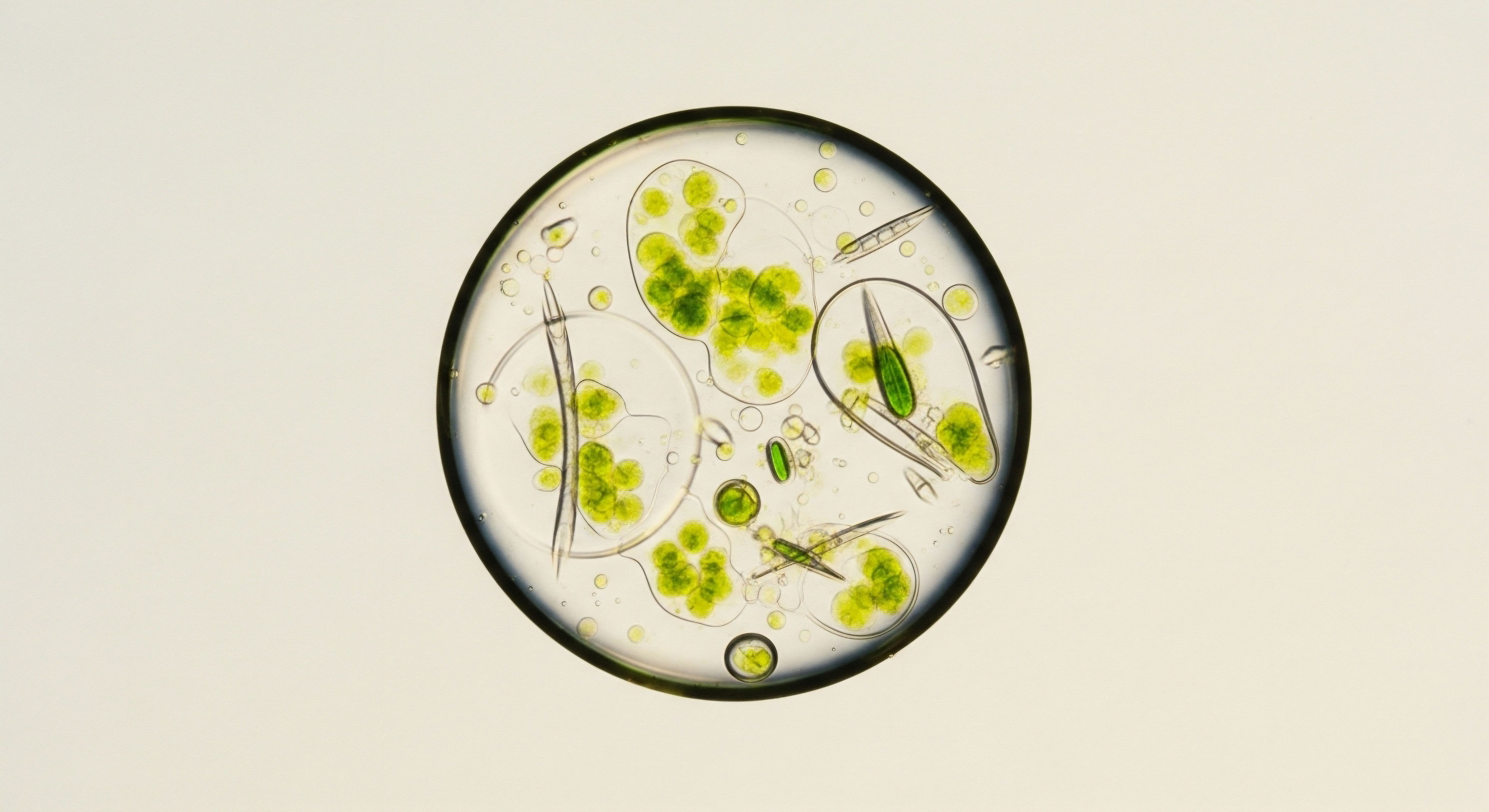

How pure is it? Is it stable? And is it free from harmful substances? These questions are answered through a multi-stage quality control (QC) process that scrutinizes the peptide at every phase of its lifecycle, from raw materials to the final packaged product. This ensures that the therapeutic signals sent by the peptide are clear, consistent, and safe.

Characterizing the Peptide Identity and Purity

The foundational analysis in peptide QC is confirming the molecule’s identity and assessing its purity. The primary tool for this is High-Performance Liquid Chromatography (HPLC), a powerful technique that separates the target peptide from any impurities. In a typical GMP process, a specification for HPLC purity is set, often requiring greater than 97% purity, with no single impurity exceeding 1%.

This is not a simple pass/fail test. The HPLC method must be sophisticated enough to detect and quantify various potential impurities that can arise during synthesis, such as deletion sequences (where an amino acid is missing), truncated sequences, or products of chemical side reactions like deamidation or oxidation.

To confirm that the primary peak on the HPLC chromatogram is indeed the correct peptide, its molecular weight is verified using Mass Spectrometry (MS). This technique provides a precise measurement of the molecule’s mass, which is then compared against the theoretical mass calculated from its amino acid sequence.

A match provides high confidence in the peptide’s identity. Further characterization is achieved through Amino Acid Analysis (AAA), which involves breaking the peptide down into its constituent amino acids and quantifying each one. This confirms that the correct amino acids are present in the correct ratios, providing another layer of assurance about the peptide’s composition.

What Are the Mandated Tests for Safety and Consistency?

Beyond confirming the peptide’s structure, GMP mandates a battery of tests to ensure its safety and suitability for clinical use. These tests are designed to detect and quantify substances that could cause harm or compromise the product’s effectiveness.

- Bioburden and Endotoxin Testing ∞ Since most peptides are administered via injection, they must be tested for microbial contamination (bioburden) and bacterial endotoxins. Endotoxins are substances found in the cell walls of certain bacteria that can cause a severe inflammatory response, including fever and shock, if injected. GMP requires stringent limits on these contaminants to ensure patient safety.

- Residual Solvent Analysis ∞ The chemical synthesis of peptides often involves organic solvents. While these are removed during purification, trace amounts may remain. Gas Chromatography (GC) is typically used to test for residual solvents, ensuring they are below predefined safety limits set by regulatory bodies.

- Potency and Strength Assays ∞ It is essential to know the exact amount of active peptide in the final product. This is often determined by measuring the peptide content, which accounts for the peptide, any counter-ions (from the purification process), and water content. This ensures accurate and consistent dosing for the end-user.

A peptide’s efficacy is directly tied to its verified purity and potency, which are established through a rigorous and multi-faceted analytical testing process.

The Role of Stability and Documentation

A peptide’s quality must be maintained over time. GMP requires robust stability testing programs to determine the product’s shelf-life and appropriate storage conditions. This involves storing the peptide under various temperature and humidity conditions and testing it at regular intervals to see if its purity, potency, or physical appearance changes. This data is what informs the expiration date on the product label.

The entire manufacturing and testing process is governed by a Quality Assurance (QA) system, which emphasizes documentation and traceability. Every action, from the qualification of a raw material supplier to the calibration of an analytical instrument, is documented. This creates a comprehensive batch record that provides a complete history of the product, ensuring accountability and facilitating investigation if any issues arise.

| Test Parameter | Analytical Method | Purpose |

|---|---|---|

| Purity & Impurity Profile | High-Performance Liquid Chromatography (HPLC) | To separate and quantify the target peptide from synthesis-related impurities. |

| Identity Confirmation | Mass Spectrometry (MS) | To verify the molecular weight of the peptide, confirming the correct sequence. |

| Composition Analysis | Amino Acid Analysis (AAA) | To confirm the correct ratio of constituent amino acids in the peptide structure. |

| Bacterial Endotoxins | Limulus Amebocyte Lysate (LAL) Test | To ensure the product is free from harmful bacterial toxins that can cause fever. |

| Peptide Content (Potency) | HPLC or AAA | To determine the exact amount of active peptide versus non-peptide components (e.g. water). |

Academic

The regulatory framework of Good Manufacturing Practice (GMP) provides the operational skeleton for ensuring pharmaceutical quality. For synthetic peptides, however, the complexity of the molecule itself demands a far deeper analytical commitment than for traditional small-molecule drugs. The potential for subtle structural heterogeneity introduces significant challenges that are addressed through the development and validation of highly specific analytical methods.

The core scientific objective of GMP quality control in this context is the comprehensive characterization of the peptide product, which includes the unambiguous identification of the target sequence and the rigorous detection, identification, and quantification of all process-related and degradation-related impurities.

How Is Analytical Method Validation Performed under GMP?

The analytical methods themselves are subject to intense scrutiny under GMP. A method used for release testing, such as a purity HPLC assay, must undergo a formal validation process to prove it is fit for its intended purpose. This validation, guided by directives from bodies like the International Council for Harmonisation (ICH), establishes the method’s performance characteristics. Key validation parameters include:

- Specificity ∞ The ability of the method to unequivocally assess the analyte in the presence of components that may be expected to be present. For a peptide purity assay, this means demonstrating that impurity peaks do not co-elute with the main peptide peak and that the method can distinguish the target peptide from closely related structures.

- Linearity and Range ∞ Establishing that the method’s response is directly proportional to the concentration of the analyte over a specified range. This is critical for accurately quantifying both the main peptide and any impurities.

- Accuracy and Precision ∞ Accuracy refers to the closeness of the test results to the true value, while precision measures the degree of scatter between a series of measurements. Both are assessed to ensure the method is reliable and reproducible.

- Detection and Quantitation Limits ∞ The Limit of Detection (LOD) is the lowest concentration of an analyte that can be detected, while the Limit of Quantitation (LOQ) is the lowest concentration that can be measured with acceptable precision and accuracy. These are vital for controlling impurities at very low levels.

The validation of these methods is a resource-intensive process that generates a substantial data package, forming a core part of the product’s regulatory submission. It provides regulators with the confidence that the manufacturer can reliably assess the quality of each batch produced.

Deep Dive into Impurity Profiling

A significant focus of academic and industrial research in peptide manufacturing is impurity profiling. Impurities can arise from the raw materials, the synthesis process itself, or degradation of the peptide over time. Their control is a central tenet of GMP.

- Synthesis-Related Impurities ∞ Solid-phase peptide synthesis (SPPS), the dominant manufacturing method, can generate a predictable family of impurities. These include deletion sequences (failure of an amino acid to couple), truncated sequences (premature termination of the chain), and products of side-chain reactions. Advanced chromatographic techniques, often coupled with mass spectrometry (LC-MS), are employed to identify these structures.

- Enantiomeric Purity ∞ Amino acids (except glycine) are chiral molecules, existing as L- and D-enantiomers. Peptides in humans are composed almost exclusively of L-amino acids. During synthesis, some amino acids can undergo racemization, converting from the L-form to the D-form. This creates a diastereomeric impurity that can have different biological activity and must be controlled. Chiral chromatography is the specialized technique used to separate and quantify these enantiomeric impurities.

- Degradation Products ∞ Peptides can degrade through specific chemical pathways, most notably deamidation (of asparagine and glutamine residues) and oxidation (of methionine and cysteine residues). Forced degradation studies, where the peptide is intentionally exposed to stress conditions like heat, light, and extreme pH, are a mandatory part of GMP development. These studies help identify likely degradation products and inform the development of stability-indicating analytical methods.

The scientific rigor of GMP is most apparent in its demand for validated, stability-indicating analytical methods capable of separating and quantifying structurally similar impurities.

The data gathered from these advanced analytical techniques feeds back into the process development, allowing for the optimization of synthesis and purification steps to minimize the formation of impurities. This iterative cycle of analysis and process improvement is a hallmark of a mature GMP manufacturing operation. It ensures that the final peptide product is not just a molecule, but a well-characterized, highly pure, and stable active pharmaceutical ingredient suitable for its intended clinical purpose.

| Analytical Challenge | Primary Technology | GMP Objective |

|---|---|---|

| Identification of Co-eluting Impurities | LC-MS/MS (Tandem Mass Spectrometry) | To structurally elucidate impurities that cannot be separated chromatographically. |

| Quantification of Stereoisomers | Chiral Chromatography | To control levels of D-enantiomers that may affect biological activity or safety. |

| Assessment of Higher Order Structure | Circular Dichroism (CD) Spectroscopy | To confirm the correct secondary structure (e.g. alpha-helix, beta-sheet) of the peptide. |

| Detection of Aggregates | Size-Exclusion Chromatography (SEC) | To identify and quantify peptide dimers and larger aggregates that can be immunogenic. |

References

- Crest C, Millipore. “Quality Control and Assurance in GMP Peptide Production.” Peptide Manufacturing, 2023.

- NEX Bio. “Understanding GMP Standards in Peptide Manufacturing.” NEX Bio Insights, 2025.

- ScinoPharm. “Ensure Safe & Effective Peptide Drugs ∞ Mastering GMP Compliance for Quality Control.” ScinoPharm News, 2024.

- GenScript ProBio. “Introduction to GMP and Its Importance in Peptide Production.” GenScript ProBio Resources, 2023.

- Polypeptide Group. “Quality control in peptide manufacturing ∞ specifications for GMP peptides.” Polypeptide Laboratories Technical Bulletin, 2005.

Reflection

You began this exploration seeking to understand the tools that might help you reclaim a state of optimal function. The journey through the exacting standards of Good Manufacturing Practice reveals that the foundation of any effective therapeutic protocol is an unwavering commitment to quality.

The science of peptide synthesis and the art of medicine converge at this point of precision. The knowledge of what it takes to produce a pure, potent, and safe peptide empowers you to ask more informed questions. It shifts your perspective from being a passive recipient of a therapy to an active, knowledgeable partner in your own health journey.

Your path forward is now illuminated not just by the potential of what these molecules can do, but by the understanding of the scientific integrity required to let them do it safely.

Glossary

good manufacturing practice

amino acids

quality control

peptide manufacturing

high-performance liquid chromatography

target peptide from

mass spectrometry

amino acid analysis

endotoxin testing

stability testing

quality assurance

analytical methods

peptide purity

impurity profiling