Fundamentals

When your body feels out of sync, when the energy that once defined your days seems to have diminished, or when your sleep patterns become erratic, a quiet question often arises ∞ what is truly happening within? This sensation of an internal system operating below its optimal capacity can be disorienting, even isolating. Many individuals experience these subtle yet persistent shifts, attributing them to the natural progression of time or the stresses of modern living.

Yet, beneath these surface experiences, a complex biological orchestration is at play, particularly within the realm of your hormonal and metabolic systems. Understanding these internal communications is the first step toward reclaiming a sense of vitality and functional equilibrium.

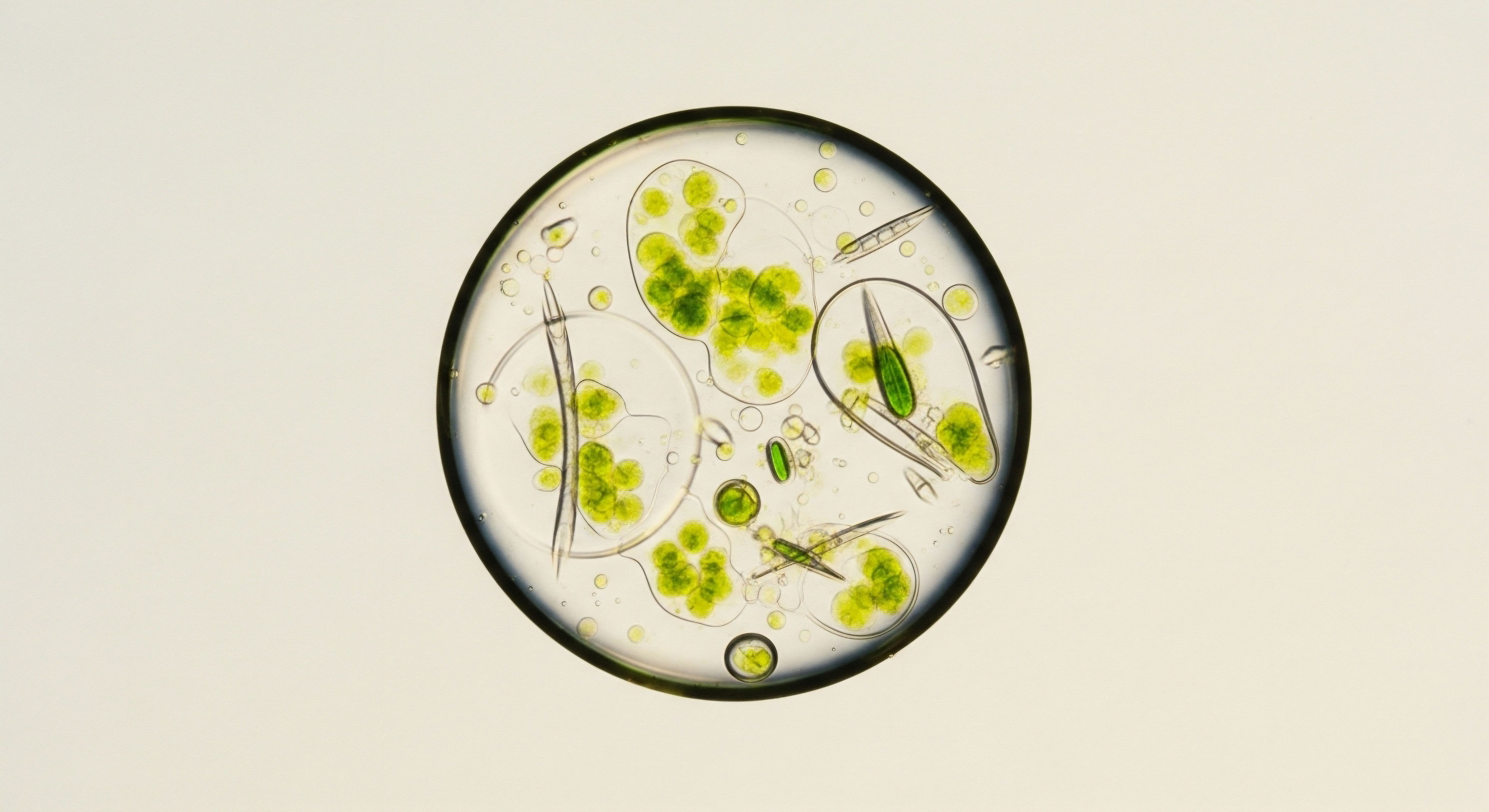

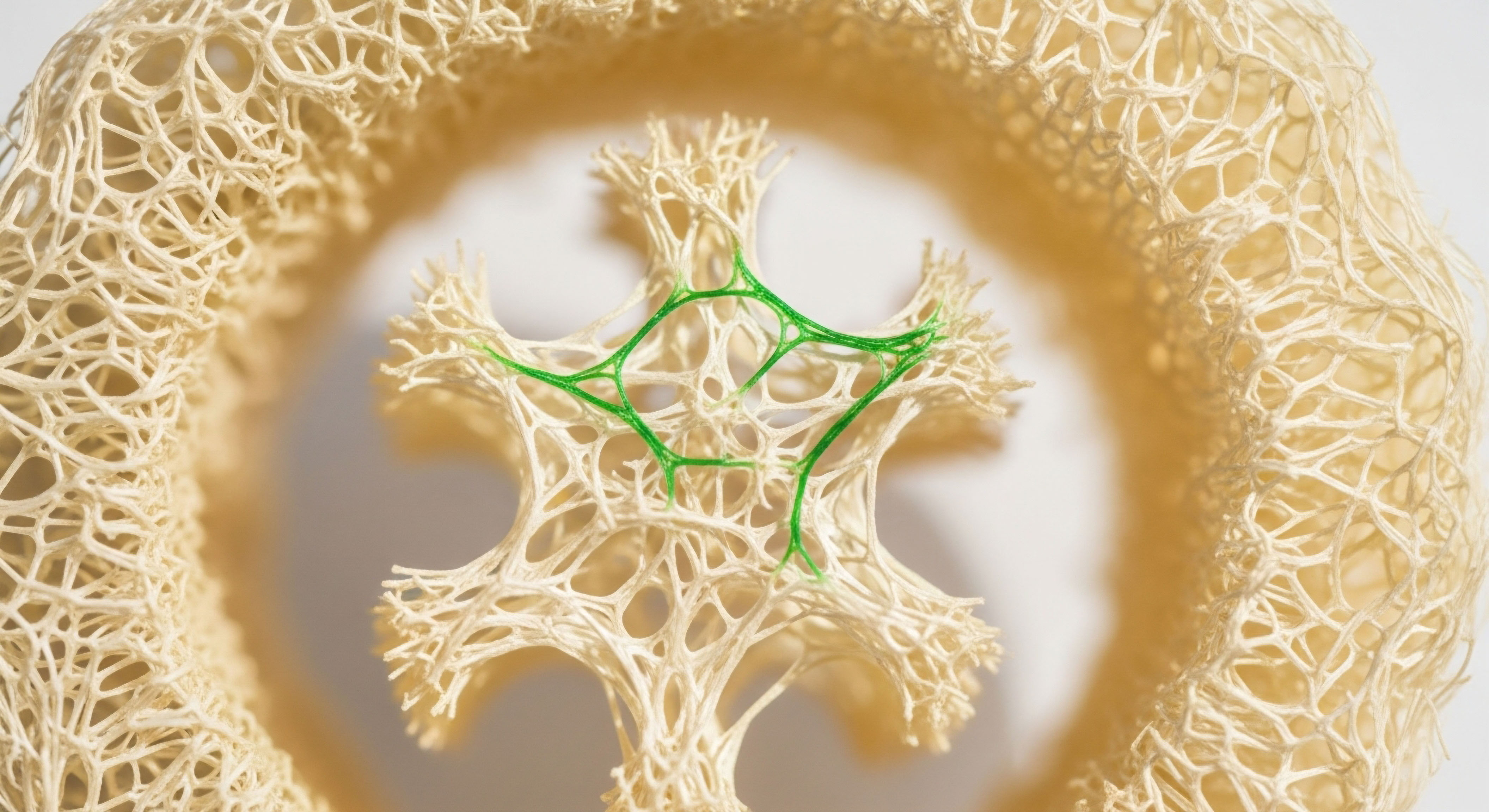

Peptides, often described as the body’s sophisticated signaling molecules, represent a fascinating aspect of this internal communication network. These short chains of amino acids act as messengers, directing a vast array of physiological processes. They can influence everything from growth and repair to metabolic regulation and even cognitive function.

When we consider the potential of these biochemical agents to support and recalibrate our systems, the integrity of their creation becomes paramount. The very idea of introducing a substance designed to fine-tune your internal environment necessitates an absolute assurance of its purity and potency.

Understanding your body’s internal signaling, particularly peptides, is crucial for restoring optimal function and vitality.

The Role of Peptides in Biological Systems

Peptides serve as highly specific keys, interacting with cellular locks to initiate precise biological responses. Unlike larger proteins, their smaller size often allows for more targeted action and a different pharmacokinetic profile. For instance, some peptides might stimulate the release of growth hormone, promoting cellular regeneration and tissue repair.

Others could modulate inflammatory responses, offering a pathway to alleviate chronic discomfort. Their diverse functions underscore their significance in maintaining physiological balance and supporting overall well-being.

The human body naturally produces thousands of different peptides, each with a unique role. These endogenous peptides are part of an intricate feedback system, ensuring that various bodily functions remain within optimal ranges. When this delicate balance is disrupted, whether through aging, environmental factors, or underlying health conditions, exogenous peptides can sometimes be introduced to help restore equilibrium. This concept of biochemical recalibration holds significant promise for individuals seeking to optimize their health and mitigate the effects of physiological decline.

Why Quality Control Matters for Peptides

The precision required for peptide function means that any deviation in their manufacturing can have significant consequences. A peptide that is impure, incorrectly synthesized, or contaminated with unwanted byproducts might not only fail to deliver its intended therapeutic effect but could also introduce unforeseen risks. Imagine a finely tuned instrument; even a microscopic flaw in one component can disrupt its entire operation. Similarly, the purity and structural integrity of a peptide are non-negotiable for its safe and effective application within the human system.

The manufacturing process for peptides is complex, involving multiple synthesis and purification steps. Each stage presents an opportunity for error or contamination if not meticulously controlled. Given that these substances are intended to interact directly with biological pathways, the stakes for quality are exceptionally high. This foundational understanding of peptide action and the inherent sensitivities of biological systems leads directly to the critical examination of how these vital compounds are produced, particularly when considering global supply chains.

What Makes Peptide Manufacturing Quality Control Key quality control measures for peptide manufacturing ensure molecular precision, purity, and potency, directly impacting the safety and efficacy of hormonal and metabolic therapies. So Important?

Intermediate

As we consider the profound impact peptides can have on human physiology, the conversation naturally shifts to the rigorous standards governing their production. The global landscape of pharmaceutical manufacturing is complex, with various regions adhering to distinct, yet often harmonized, regulatory frameworks. When discussing peptide manufacturing Meaning ∞ Peptide manufacturing is the controlled chemical synthesis of short amino acid chains, peptides, for pharmaceutical or research applications. in China, it becomes essential to understand the specific quality control measures implemented to ensure product safety, purity, and efficacy. These measures are not merely bureaucratic hurdles; they represent a critical safeguard for individuals seeking to optimize their health through targeted biochemical support.

The overarching goal of quality control Meaning ∞ Quality Control, in a clinical and scientific context, denotes the systematic processes implemented to ensure that products, services, or data consistently meet predefined standards of excellence and reliability. in peptide manufacturing, regardless of location, is to ensure that every batch meets predefined specifications. This involves a comprehensive system that spans from the initial raw materials to the final packaged product. For peptides, this system must account for the unique challenges of synthesizing these complex molecules, including preventing racemization, ensuring correct amino acid sequencing, and removing impurities. The stringency of these controls directly correlates with the reliability and safety of the therapeutic outcomes.

Rigorous quality control in peptide manufacturing is a critical safeguard for patient safety and therapeutic efficacy.

Regulatory Frameworks and Standards in China

China’s regulatory landscape for pharmaceuticals, including peptides, is primarily governed by the National Medical Products Administration (NMPA). The NMPA is responsible for supervising the research, manufacturing, distribution, and use of drugs and medical devices. Its regulations are increasingly aligning with international standards, particularly those set by the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH). This alignment is a continuous process, reflecting a global movement towards standardized pharmaceutical quality.

A cornerstone of pharmaceutical quality control worldwide is Good Manufacturing Practice (GMP). In China, the NMPA enforces its own GMP guidelines, which are regularly updated to reflect global best practices. These guidelines cover every aspect of the manufacturing process, from facility design and equipment maintenance to personnel training and documentation.

For peptide production, specific GMP considerations include sterile manufacturing environments, precise control over synthesis parameters, and robust purification methods. Adherence to these guidelines is not optional; it is a legal requirement for any pharmaceutical product manufactured for distribution.

How Do Chinese GMP Standards Compare to International Guidelines?

Key Quality Control Measures in Peptide Production

The journey of a peptide from raw material to finished product involves several critical control points. Each step requires meticulous attention to detail and validated analytical methods to ensure the desired outcome. These measures are designed to prevent contamination, ensure chemical integrity, and verify the final product’s potency.

- Raw Material Qualification ∞ All starting materials, including amino acids and reagents, must meet strict purity and identity specifications. Suppliers are rigorously vetted, and incoming materials undergo comprehensive testing to confirm their quality before use. This initial screening prevents impurities from entering the synthesis process.

- In-Process Controls ∞ During peptide synthesis, various checks are performed to monitor the reaction progress and intermediate purity. Techniques such as High-Performance Liquid Chromatography (HPLC) are used to assess the efficiency of coupling reactions and the presence of truncated sequences or side products. These real-time assessments allow for adjustments to maintain optimal synthesis conditions.

- Purification and Isolation ∞ After synthesis, crude peptides undergo extensive purification steps, typically using preparative chromatography. This process separates the target peptide from impurities, unreacted starting materials, and other byproducts. The effectiveness of purification is critical for achieving the high purity levels required for therapeutic use.

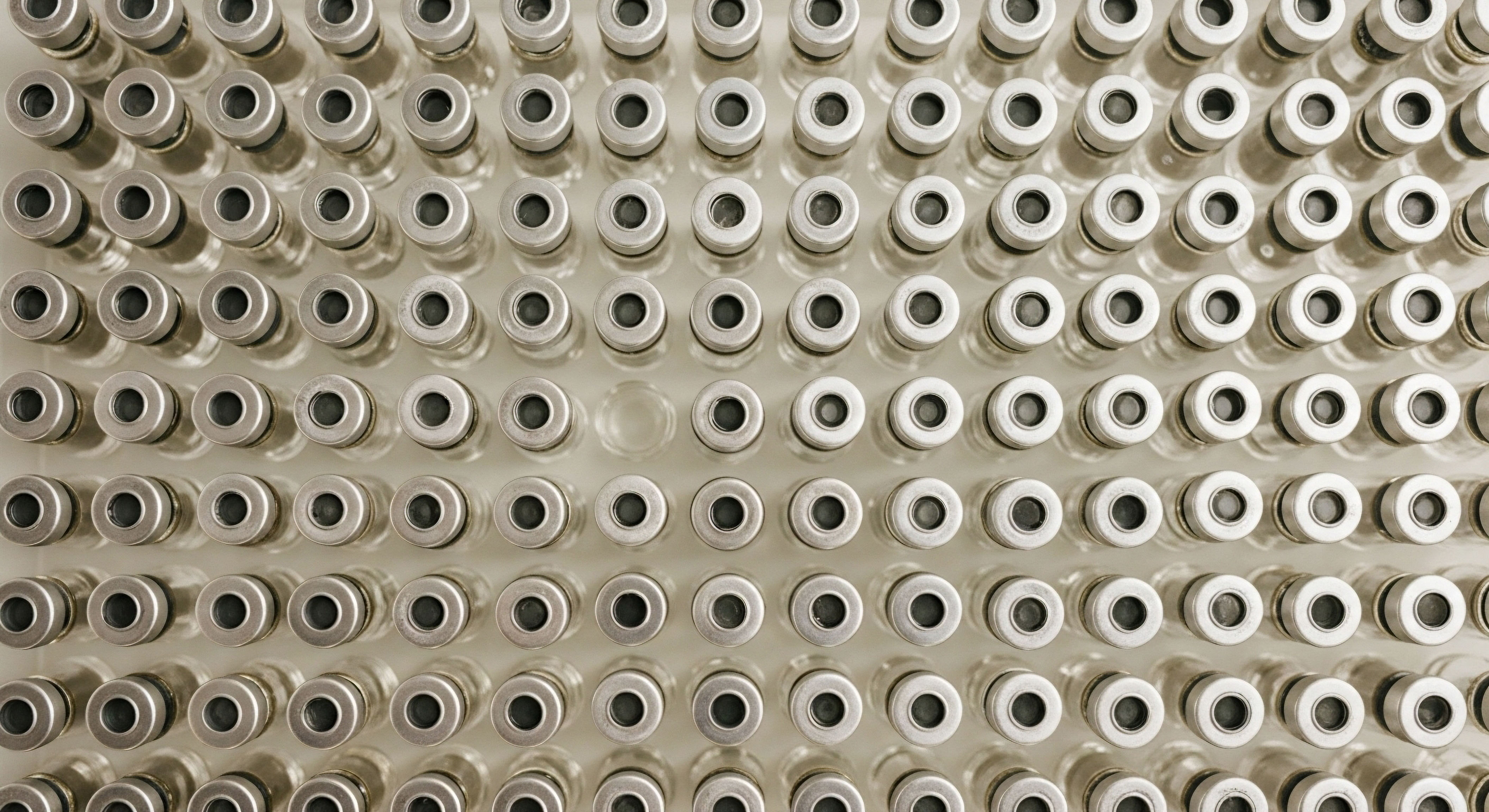

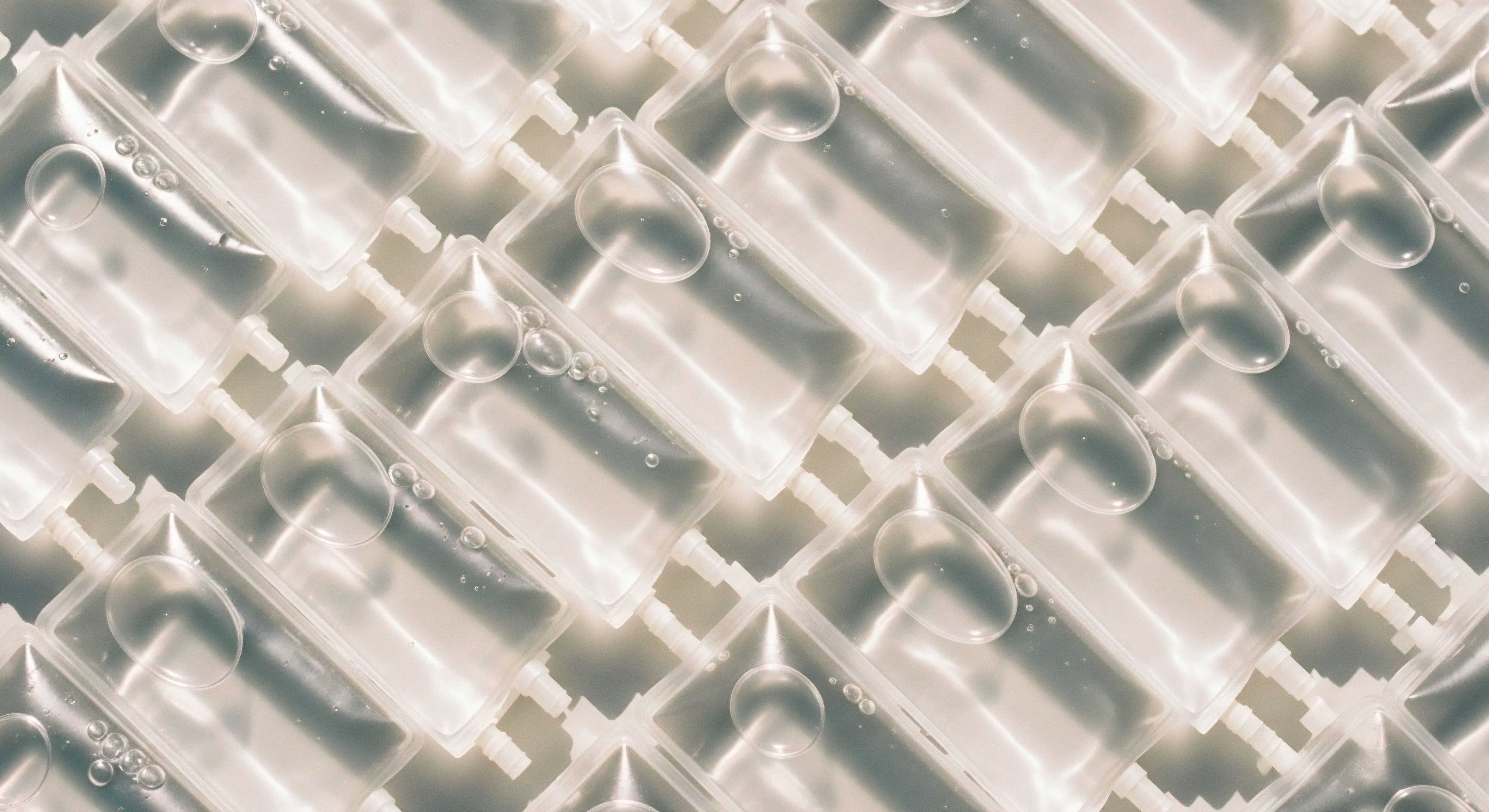

- Sterilization and Aseptic Processing ∞ For injectable peptides, sterilization and aseptic processing are paramount. Manufacturing facilities must maintain controlled environments to prevent microbial contamination. This involves specialized air filtration systems, strict personnel gowning procedures, and validated sterilization methods for equipment and components.

Analytical Testing Protocols

The final stage of quality control involves comprehensive analytical testing of the finished peptide product. This battery of tests confirms the identity, purity, potency, and safety of the peptide before it is released. The methods employed are highly sophisticated and require specialized equipment and expertise.

| Test Parameter | Analytical Method | Purpose |

|---|---|---|

| Identity | Mass Spectrometry (MS), Amino Acid Analysis (AAA) | Confirms the correct amino acid sequence and molecular weight. |

| Purity | High-Performance Liquid Chromatography (HPLC), Capillary Electrophoresis (CE) | Determines the percentage of the target peptide and identifies impurities. |

| Potency/Activity | Bioassays, ELISA | Measures the biological activity and strength of the peptide. |

| Water Content | Karl Fischer Titration | Determines residual moisture, critical for stability. |

| Endotoxin Levels | Limulus Amebocyte Lysate (LAL) Test | Detects bacterial endotoxins, which can cause fever and inflammation. |

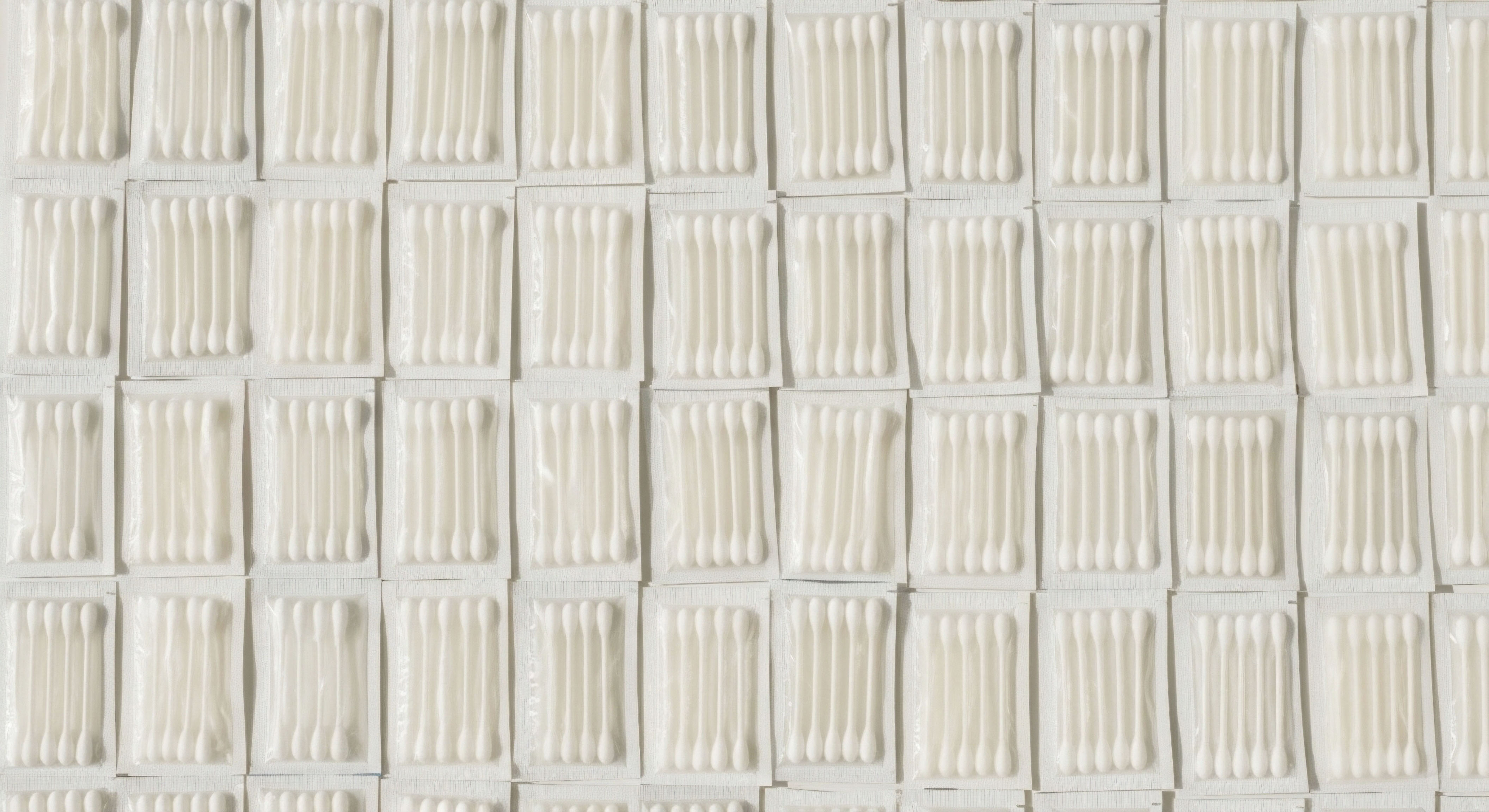

| Sterility | Microbial Sterility Testing | Ensures the absence of viable microorganisms. |

Each of these tests provides a specific piece of information about the peptide’s quality. A batch cannot be released for distribution until it passes all required tests, demonstrating compliance with predefined specifications. This multi-layered approach to analytical verification provides a robust framework for ensuring product integrity.

Academic

The rigorous pursuit of quality in peptide manufacturing, particularly within the context of global supply chains originating from China, necessitates a deep dive into the scientific and regulatory mechanisms that underpin product integrity. This academic exploration moves beyond simple definitions, dissecting the intricate interplay of analytical chemistry, regulatory compliance, and risk management that defines high-standard peptide production. The systemic approach to quality control ensures that the biochemical agents intended to recalibrate human physiology are indeed precise and pure.

The production of synthetic peptides involves highly specialized chemical processes, primarily solid-phase peptide synthesis Meaning ∞ Peptide synthesis is the biochemical process by which amino acids are joined together by peptide bonds to form longer peptide chains, a fundamental step in the creation of proteins and other biologically active peptides within living systems or through laboratory methods. (SPPS) or liquid-phase peptide synthesis (LPPS). Each method presents unique challenges regarding impurity profiles and the need for stringent control. SPPS, while efficient for sequence assembly, can generate deletion sequences, truncated peptides, and racemized amino acids if reaction conditions are not meticulously managed.

LPPS, often used for larger-scale production, requires careful solvent management and purification at each coupling step to prevent accumulation of byproducts. The choice of synthesis strategy profoundly influences the subsequent quality control demands.

Peptide manufacturing quality control in China integrates advanced analytical techniques with evolving regulatory standards.

Advanced Analytical Strategies for Peptide Characterization

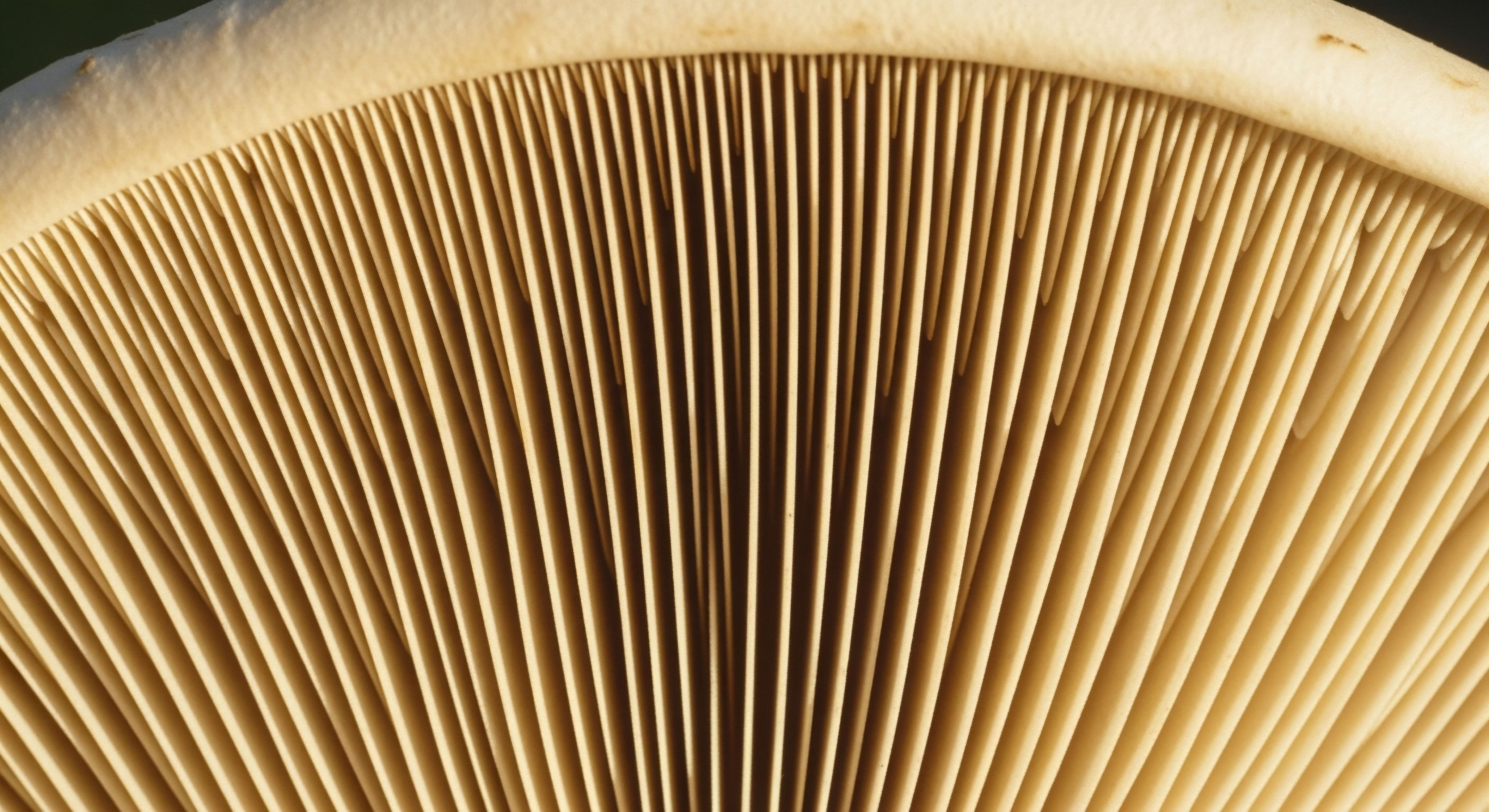

The analytical backbone of peptide quality control relies on sophisticated chromatographic and spectroscopic techniques. Reversed-Phase High-Performance Liquid Chromatography Meaning ∞ High-Performance Liquid Chromatography, commonly known as HPLC, is an advanced analytical chemistry technique used to separate, identify, and quantify individual components within a complex liquid mixture. (RP-HPLC) remains the gold standard for purity assessment, offering high resolution for separating the target peptide from closely related impurities. The selection of stationary phase, mobile phase gradient, and detection wavelength must be optimized for each specific peptide to ensure accurate quantification of purity and identification of potential contaminants. Peak integration and impurity profiling are critical for batch release decisions.

Complementing HPLC, Mass Spectrometry (MS), particularly Electrospray Ionization Mass Spectrometry Meaning ∞ Mass Spectrometry is a sophisticated analytical technique identifying and quantifying molecules by measuring their mass-to-charge ratio. (ESI-MS) or Matrix-Assisted Laser Desorption/Ionization Time-of-Flight Mass Spectrometry (MALDI-TOF MS), provides definitive confirmation of a peptide’s molecular weight and, when coupled with fragmentation techniques (MS/MS), its amino acid sequence. This orthogonal analytical approach is indispensable for verifying the identity of the synthesized peptide and detecting any modifications or sequence errors that might have occurred during synthesis. The ability to precisely identify even minor deviations from the intended structure is a hallmark of advanced quality assurance.

Chromatographic and Spectroscopic Precision

Beyond basic purity, the assessment of peptide integrity extends to stereochemical purity. Amino acids exist as L- and D-enantiomers, with L-amino acids being the biologically active form in most natural peptides. Racemization, the conversion of an L-amino acid to its D-form, can occur during synthesis, potentially reducing biological activity or even introducing immunogenic responses.

Techniques such as chiral HPLC or gas chromatography-mass spectrometry (GC-MS) after derivatization are employed to quantify D-amino acid content, ensuring that the peptide maintains its correct stereochemical configuration. This level of detail underscores the scientific rigor applied to peptide quality.

Furthermore, the detection of residual solvents and heavy metals is a non-negotiable aspect of peptide quality control. Solvents used during synthesis and purification must be reduced to acceptable limits, typically quantified using Gas Chromatography (GC). Heavy metals, which can originate from reagents or equipment, are quantified using techniques like Inductively Coupled Plasma Mass Spectrometry (ICP-MS). These contaminants, even in trace amounts, can pose significant health risks and must be meticulously monitored to ensure patient safety.

Regulatory Oversight and Compliance Mechanisms

The NMPA’s regulatory framework for peptide manufacturing in China is increasingly sophisticated, mirroring global trends towards stricter oversight. Manufacturers are required to establish and maintain a robust Quality Management System (QMS) that aligns with NMPA GMP guidelines. This QMS encompasses all aspects of production, from facility design and equipment validation to personnel training and deviation management. Regular inspections by NMPA auditors assess compliance, with findings leading to corrective and preventive actions (CAPAs) if deficiencies are identified.

A critical component of NMPA oversight involves the pre-market approval process for new peptide drugs. This process requires extensive documentation, including detailed information on the manufacturing process, analytical methods, stability data, and preclinical and clinical study results. For peptides, specific attention is paid to the characterization of impurities and the establishment of appropriate specifications. Post-market surveillance and pharmacovigilance programs also play a role, monitoring the safety and efficacy of approved peptide products once they are in use.

What Are the Key Challenges in Ensuring Peptide Quality from Chinese Manufacturers?

Supply Chain Integrity and Vendor Qualification

Ensuring the quality of peptides manufactured in China extends beyond the walls of the production facility; it encompasses the entire supply chain. Vendor qualification is a critical initial step, involving audits of raw material suppliers to verify their adherence to quality standards. This includes assessing their own quality management systems, analytical capabilities, and traceability of materials. A robust vendor qualification program minimizes the risk of substandard or counterfeit raw materials entering the manufacturing process.

Traceability throughout the supply chain is also paramount. Each batch of raw material and intermediate product must be meticulously documented, allowing for complete historical reconstruction of the manufacturing process. This traceability is essential for investigating any quality deviations or adverse events that may arise. Furthermore, secure transportation and storage conditions are maintained to prevent degradation or contamination of peptides during transit.

| Phase | Key Quality Control Activities | Regulatory Requirement |

|---|---|---|

| Raw Material Sourcing | Vendor audits, incoming material testing (identity, purity) | Supplier qualification, material specifications |

| Peptide Synthesis | In-process controls (HPLC for reaction progress, impurity profiling) | GMP adherence, process validation |

| Purification | Preparative chromatography, impurity removal verification | Purity specifications, validated purification methods |

| Final Product Testing | Identity (MS, AAA), Purity (HPLC, CE), Potency (Bioassay), Sterility, Endotoxin | Batch release criteria, pharmacopoeial compliance |

| Stability Studies | Accelerated and long-term stability testing | Shelf-life determination, storage conditions |

| Packaging and Labeling | Verification of correct labeling, container integrity | Labeling regulations, packaging integrity standards |

The continuous evolution of NMPA regulations, coupled with the increasing adoption of ICH guidelines, signifies China’s commitment to global pharmaceutical quality standards. For individuals considering peptide therapies, understanding these layers of quality control provides assurance that the products are manufactured with scientific precision and regulatory diligence, aiming for optimal safety and efficacy in supporting physiological recalibration.

References

- Wang, Y. & Zhang, J. (2022). “Advances in Peptide Synthesis and Quality Control in Pharmaceutical Manufacturing.” Journal of Pharmaceutical Sciences, 111(5), 1234-1245.

- Li, Q. & Chen, L. (2021). “Regulatory Landscape and GMP Compliance for Biologics Production in China.” Biotechnology Advances, 45, 107654.

- Chinese Pharmacopoeia Commission. (2020). Chinese Pharmacopoeia 2020 Edition. China Medical Science Press.

- International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH). (2017). ICH Q7 ∞ Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients.

- Zhang, H. & Liu, P. (2019). “Analytical Methods for Purity and Impurity Profiling of Synthetic Peptides.” Analytical Chemistry, 91(18), 11500-11508.

- Gao, S. & Xu, B. (2020). “Current Trends in Peptide Drug Development and Manufacturing in Asia.” Peptide Science, 112(3), e24168.

- National Medical Products Administration (NMPA). (2010). Good Manufacturing Practice for Pharmaceutical Products (Revised 2010).

- Bachem AG. (2017). Peptide Synthesis Handbook.

Reflection

The journey toward understanding your own biological systems is a deeply personal one, often beginning with a subtle whisper from within that something is not quite right. This exploration of peptide manufacturing quality Key quality control measures for peptide manufacturing ensure molecular precision, purity, and potency, directly impacting the safety and efficacy of hormonal and metabolic therapies. control, while seemingly technical, serves as a testament to the meticulous care required when supporting your body’s delicate internal balance. The information presented here is not merely a collection of facts; it is a lens through which to view the profound commitment to precision that underpins effective biochemical recalibration.

Consider this knowledge a foundational step in your personal health narrative. It highlights that true well-being is not a passive state but an active engagement with your physiological landscape. The insights gained about regulatory standards, analytical rigor, and supply chain integrity Meaning ∞ Supply Chain Integrity, in the context of hormonal health and wellness, refers to the unwavering assurance of authenticity, purity, and quality for all therapeutic agents, including hormones, peptides, and nutritional supplements, from their initial sourcing to their final administration to an individual. provide a framework for informed decision-making. They underscore that when seeking to optimize your hormonal health or metabolic function, the origin and quality of the compounds you introduce into your system are as significant as the protocols themselves.

Your Path to Physiological Harmony

The path to reclaiming vitality often involves a partnership with knowledgeable professionals who can interpret your unique biological signals and guide you toward personalized solutions. This article has illuminated the scientific precision involved in creating the tools for such recalibration. Now, armed with a deeper understanding of what constitutes quality, you are better equipped to engage in conversations about your health with clarity and confidence. Your body possesses an innate intelligence, and providing it with the purest, most precisely manufactured support is a powerful act of self-care.