Fundamentals

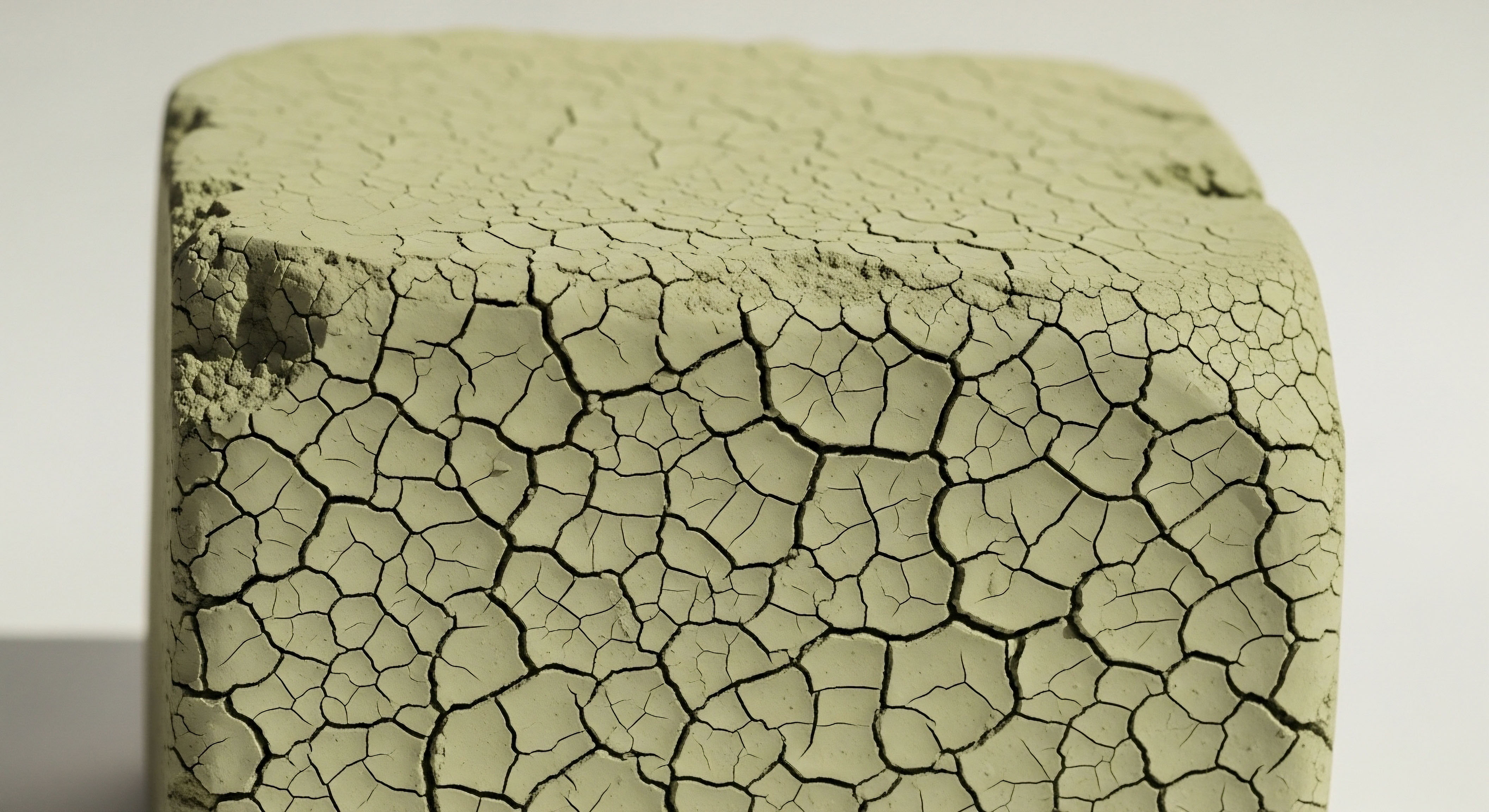

Perhaps you have experienced a subtle shift in your vitality, a quiet diminishment of the energy and resilience that once felt innate. This sensation, often dismissed as an unavoidable consequence of time, can leave individuals feeling disconnected from their own physical systems. When the body’s intricate internal messaging falters, symptoms such as persistent fatigue, changes in body composition, or a general sense of unease can arise.

These experiences are not merely isolated occurrences; they often signal a deeper imbalance within the endocrine system, the very network that orchestrates our hormonal health. Understanding these biological systems is the first step toward reclaiming optimal function and well-being.

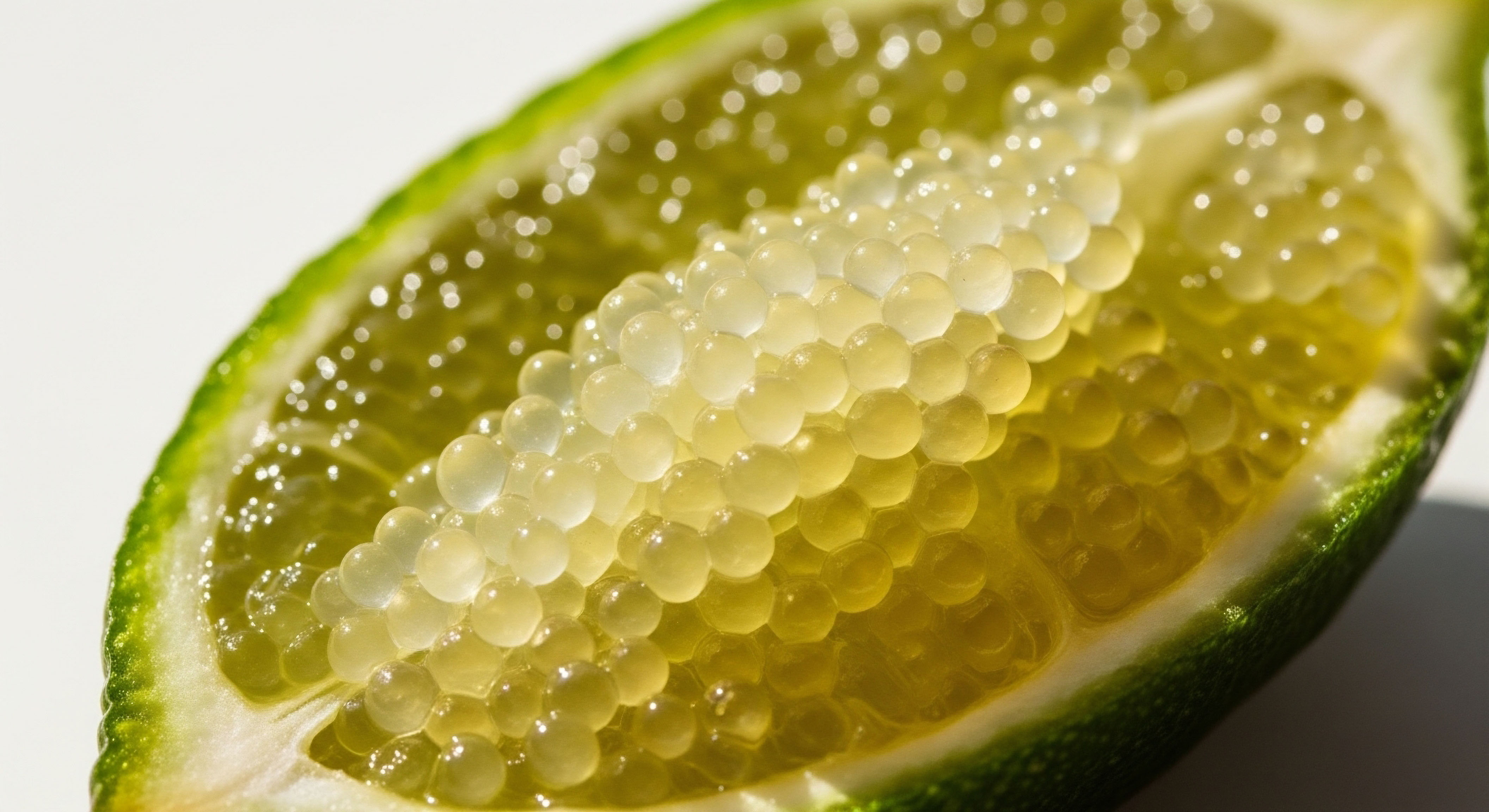

For those exploring avenues to restore hormonal equilibrium, the quality and integrity of therapeutic agents, such as peptides, become paramount. Peptides, as short chains of amino acids, act as specific signaling molecules within the body, influencing a wide array of physiological processes. Their precision in targeting cellular receptors makes them compelling tools in personalized wellness protocols, from supporting metabolic function to enhancing tissue repair. However, the efficacy and safety of these compounds hinge entirely on their manufacturing purity and the rigorous oversight they receive.

The body’s internal messaging system, when imbalanced, can manifest as subtle yet persistent changes in overall vitality.

Consider the journey of a peptide from its initial synthesis to its eventual application in a therapeutic setting. This path is not arbitrary; it is meticulously governed by regulatory bodies to protect public health. In China, the National Medical Products Administration, known as the NMPA, serves as the vigilant guardian of pharmaceutical quality and safety.

Their comprehensive framework ensures that every therapeutic agent, including peptides, meets stringent standards before it can be made available. This regulatory vigilance directly impacts the availability of safe, effective options for individuals seeking to optimize their hormonal health.

The NMPA’s foundational requirements for peptide manufacturing are rooted in principles of Good Manufacturing Practice, or GMP. These guidelines are not simply bureaucratic hurdles; they represent a commitment to consistency and purity in production. GMP ensures that peptides are produced in controlled environments, minimizing risks of contamination, cross-contamination, and errors.

This systematic approach to quality control is essential for any compound intended to interact with the delicate balance of human physiology. Without such rigorous oversight, the potential for variability in product quality could undermine any therapeutic benefit and introduce unforeseen risks.

Why Does Regulatory Oversight Matter for Your Health?

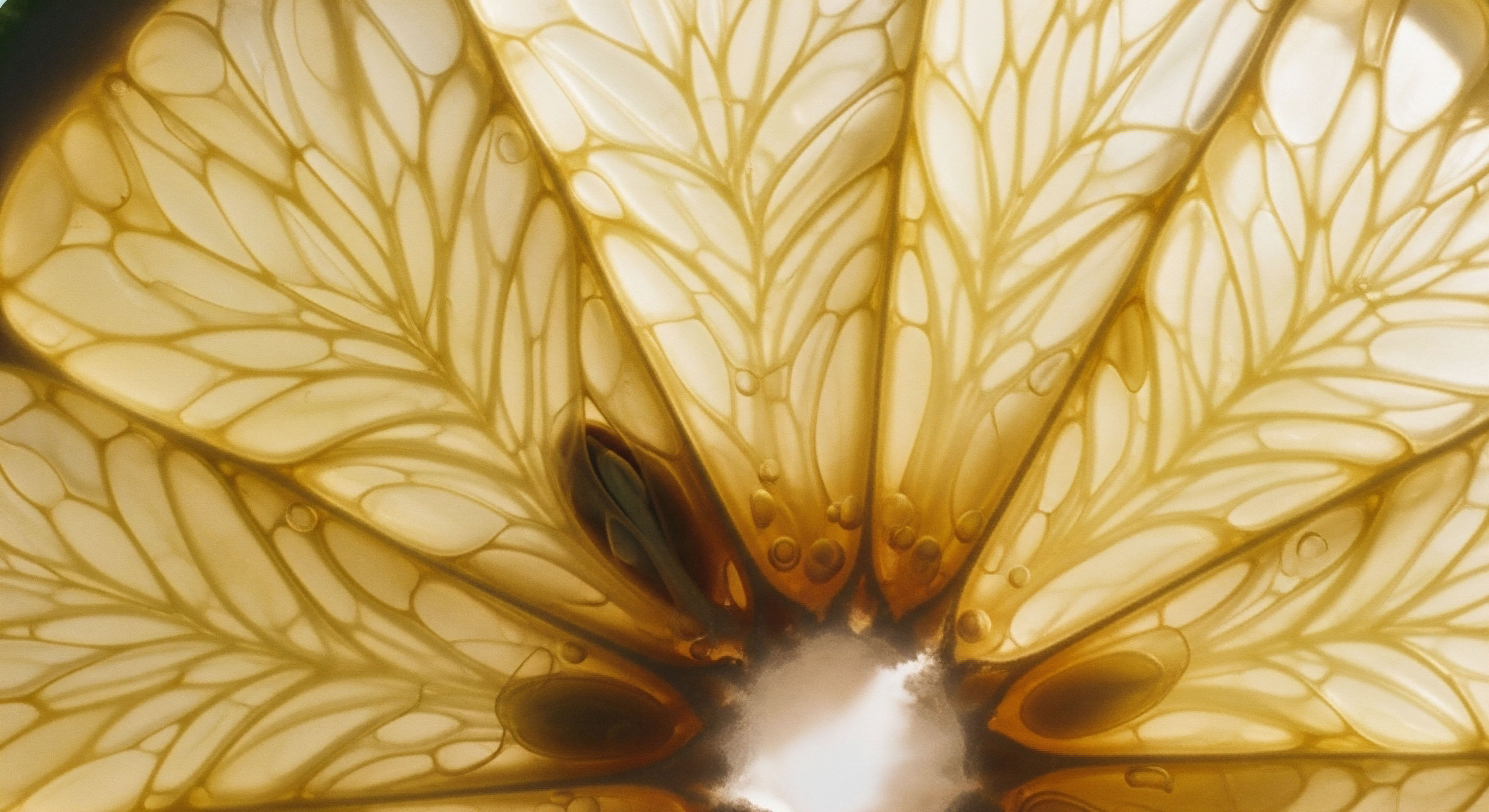

The integrity of a therapeutic peptide directly correlates with its ability to interact predictably and safely with your biological systems. Imagine a finely tuned orchestra where each instrument must play its part precisely. Hormones and peptides are similar; they are the conductors and soloists of your internal symphony. If the quality of these biochemical messengers is compromised during manufacturing, their ability to perform their intended roles is diminished, potentially leading to unpredictable outcomes or a lack of desired therapeutic effect.

The NMPA’s regulations provide a critical layer of assurance. They mandate that manufacturers adhere to specific protocols for everything from raw material sourcing to the final packaging of the product. This includes detailed documentation of every step in the production process, allowing for complete traceability and accountability. For individuals considering peptide therapies, understanding these regulatory underpinnings offers peace of mind, knowing that the compounds they introduce into their bodies have met a defined benchmark of quality.

Intermediate

Navigating the landscape of therapeutic peptides requires an understanding of the specific regulatory pathways that govern their production and market entry. The NMPA classifies peptides intended for therapeutic use as biological products, a categorization that subjects them to a distinct set of stringent requirements. This classification acknowledges their complex nature and their profound impact on human biological systems. The regulatory journey for these compounds begins long before they reach a patient, encompassing meticulous stages of development, manufacturing, and approval.

Manufacturing Standards and Quality Assurance

At the heart of NMPA’s oversight for peptide manufacturing lies the comprehensive adherence to Good Manufacturing Practice (GMP) guidelines. These guidelines are not static; they are continuously refined to reflect advancements in pharmaceutical science and production technologies. For peptides, GMP compliance dictates every facet of the manufacturing process, ensuring product identity, strength, quality, and purity.

- Facility Design ∞ Production environments must be designed to prevent contamination and cross-contamination, often involving segregated areas for different manufacturing stages.

- Personnel Training ∞ All individuals involved in peptide production must possess appropriate qualifications and receive ongoing training in GMP principles and specific operational procedures.

- Raw Material Control ∞ Strict controls are applied to the sourcing, testing, and storage of all raw materials, including amino acids and reagents, to verify their quality and suitability.

- Equipment Qualification ∞ All manufacturing and testing equipment must be properly installed, calibrated, and maintained to ensure accurate and consistent performance.

- Process Validation ∞ Each step of the peptide synthesis, purification, and formulation process must be validated to demonstrate its ability to consistently produce a product meeting predefined quality attributes.

The NMPA’s GMP for drugs, revised in 2010, outlines these fundamental requirements, emphasizing the establishment of a robust quality management system that covers the entire product lifecycle. This system ensures that drugs are consistently manufactured in accordance with registration requirements and are suitable for their intended use, minimizing risks of errors or mix-ups.

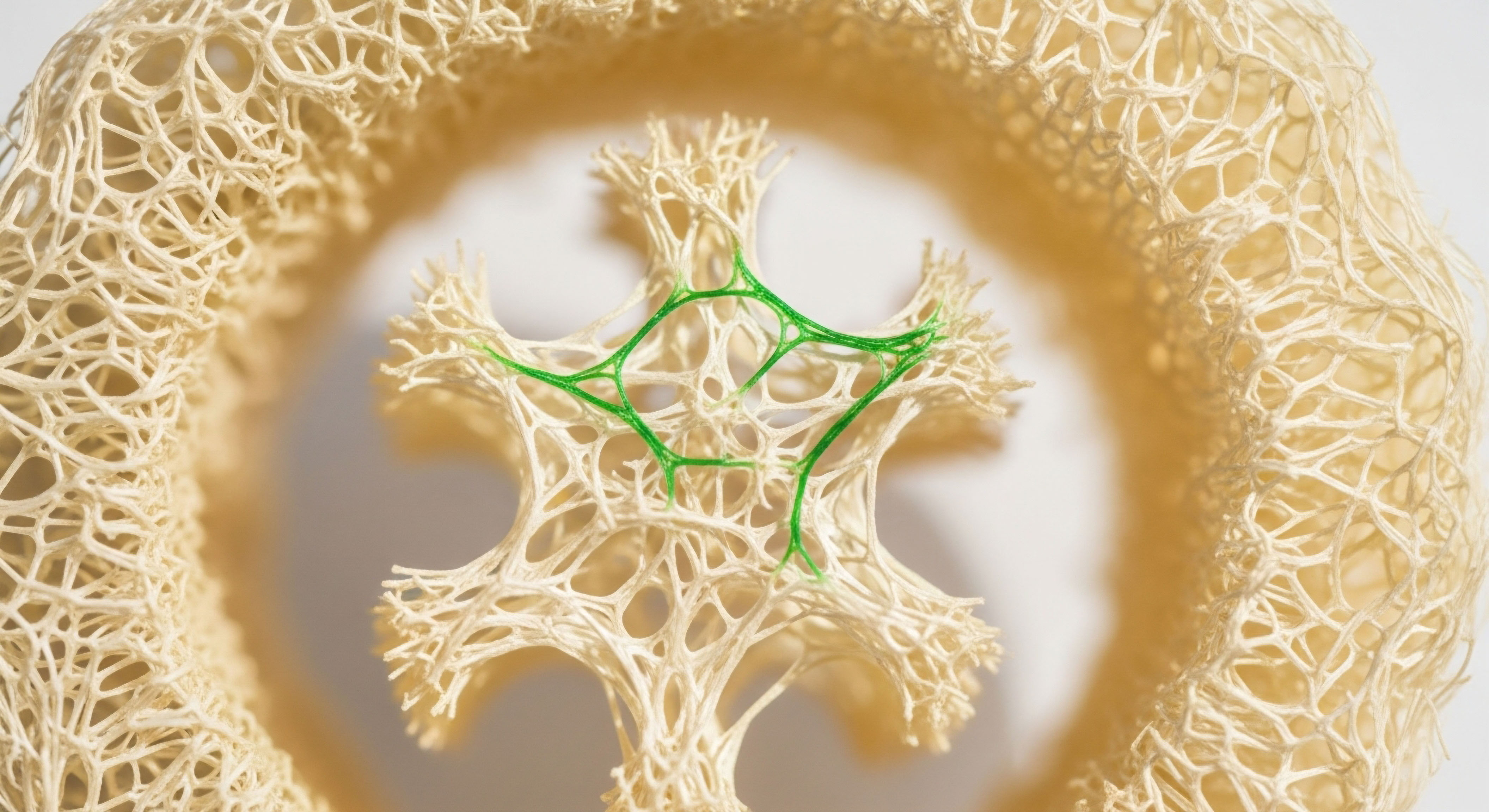

Rigorous adherence to Good Manufacturing Practice ensures the purity and consistency of therapeutic peptides, safeguarding patient well-being.

The Drug Registration Process for Peptides

Before a therapeutic peptide can be marketed in China, it must undergo a comprehensive drug registration process overseen by the NMPA’s Center for Drug Evaluation (CDE). This process is designed to assess the safety, efficacy, and quality of the product through a multi-stage evaluation.

The initial phase involves extensive preclinical studies conducted under Good Laboratory Practice (GLP) guidelines. These studies evaluate the peptide’s pharmacological properties, toxicology, and pharmacokinetics in laboratory settings, providing foundational data on its biological activity and potential risks. The results of these studies form a critical part of the Investigational New Drug (IND) application submitted to the NMPA.

Upon IND approval, the peptide progresses to clinical trials in human subjects, conducted in accordance with Good Clinical Practice (GCP) standards. These trials are typically structured in three phases ∞

- Phase I ∞ Involves a small group of healthy volunteers to assess the peptide’s safety, dosage range, and how it is metabolized within the human body.

- Phase II ∞ Expands to a larger group of patients with the target condition to evaluate the peptide’s efficacy and further monitor for side effects.

- Phase III ∞ Encompasses a large patient population to confirm efficacy, monitor adverse reactions, and compare the peptide with existing treatments, gathering comprehensive safety and effectiveness data.

The NMPA requires clinical data to be representative of the Chinese population, which may necessitate specific adaptations to trial protocols or the conduct of trials within China. Once clinical trials are successfully completed, a comprehensive New Drug Application (NDA) dossier is compiled and submitted to the NMPA for review. This dossier includes all preclinical and clinical data, detailed manufacturing information, and proposed labeling. The NMPA’s review process involves technical assessment, on-site inspections of manufacturing facilities for GMP compliance, and expert evaluation of the drug’s safety, efficacy, and quality.

How Do NMPA Requirements Shape Peptide Availability?

The rigorous nature of NMPA’s manufacturing and registration requirements directly influences which peptides become available for therapeutic use in China. This stringent oversight ensures that only products meeting high standards of quality and safety reach patients. While this process can be time-consuming, it ultimately serves to protect individuals seeking these specialized therapies. The NMPA has also introduced reforms to streamline approval timelines for innovative drugs, including the acceptance of foreign clinical trial data under certain conditions, aiming to accelerate market entry for beneficial compounds.

The NMPA’s classification system for biological products, including peptides, further dictates the specific application materials required. Therapeutic biological products are categorized based on their innovation level ∞

| Category | Description | Registration Implications |

|---|---|---|

| Innovative Biological Products | Not previously marketed anywhere globally. | Requires extensive preclinical and clinical data, full dossier submission. |

| Improved Biological Products | Listed in China or globally, with significant improvements in safety, effectiveness, or quality control. | Requires data demonstrating the improvements and advantages over existing products. |

| Domestic or Overseas Listed Products | Already marketed and approved elsewhere, or generic versions of existing products. | May have a more streamlined review if foreign data is accepted and local requirements are met. |

Academic

Beyond the initial manufacturing and registration, the NMPA maintains a vigilant eye on therapeutic peptides through comprehensive post-market surveillance (PMS). This ongoing monitoring is a critical component of ensuring patient safety and product efficacy throughout the entire lifecycle of a pharmaceutical agent. The rationale behind such continuous oversight is clear ∞ real-world usage can unveil issues not apparent during controlled clinical trials, necessitating a dynamic approach to risk management.

Mechanisms of Post-Market Surveillance

The NMPA’s PMS framework for drugs, including peptides, is multifaceted, integrating various mechanisms to collect, analyze, and act upon safety and performance data. This system is designed to identify, monitor, and mitigate potential risks that may arise once a product is widely available to the public.

- Adverse Drug Reaction (ADR) Monitoring ∞ Manufacturers, healthcare professionals, and patients are obligated to report suspected adverse reactions to the NMPA. This includes both serious and non-serious events. The NMPA’s National Center for Adverse Drug Reaction Monitoring (NCADRM) collects and analyzes these reports to detect safety signals.

- Periodic Risk Evaluation Reports ∞ Marketing Authorization Holders (MAHs) are required to submit annual post-market periodic risk evaluation reports to the NMPA. These reports provide an ongoing assessment of the benefit-risk profile of the peptide, synthesizing all available safety data from various sources.

- Re-evaluation and Risk Control ∞ If significant safety concerns or new risks are identified through ADR monitoring or other surveillance activities, the NMPA can initiate a re-evaluation of the peptide. This may lead to updated labeling, restrictions on use, or, in severe cases, product recalls or withdrawal from the market.

- On-site Inspections ∞ The NMPA conducts routine and unannounced inspections of manufacturing facilities and MAHs to verify ongoing compliance with GMP and quality management systems. These inspections can be triggered by adverse event reports or as part of a risk-based assessment. For overseas manufacturers, the NMPA also conducts international inspections.

The emphasis on PMS reflects a mature regulatory philosophy that recognizes the dynamic nature of drug safety. Even with rigorous pre-market evaluation, the sheer scale and diversity of real-world patient populations can reveal rare or long-term adverse effects. For instance, data from 2022 showed that while deaths related to medical devices were rare (0.02% of reports), serious injuries accounted for 6.48% of reported adverse events, underscoring the need for continuous monitoring.

Post-market surveillance acts as a vital feedback loop, ensuring the ongoing safety and efficacy of therapeutic peptides in real-world applications.

Regulatory Science and Patient Outcomes

The NMPA’s stringent requirements for peptide manufacturing and post-market surveillance are not merely administrative burdens; they are deeply rooted in regulatory science aimed at optimizing patient outcomes. The focus on quality control, from raw materials to finished product, directly influences the purity and consistency of peptides, which in turn affects their biological activity and safety profile. A peptide with impurities or inconsistent potency could lead to unpredictable physiological responses, undermining the precise nature of hormonal optimization protocols.

Consider the implications for personalized wellness protocols, such as those involving Growth Hormone Peptide Therapy. Peptides like Sermorelin, Ipamorelin/CJC-1295, or Tesamorelin are designed to stimulate the body’s natural growth hormone release, influencing muscle gain, fat loss, and sleep quality. The effectiveness of these therapies relies on the exact molecular structure and purity of the administered peptide. NMPA’s GMP requirements ensure that these complex molecules are synthesized with high fidelity, minimizing the presence of truncated peptides or contaminants that could elicit unintended immune responses or reduce therapeutic benefit.

The Interplay of Regulatory Frameworks and Therapeutic Innovation

The NMPA’s regulatory environment also plays a role in shaping therapeutic innovation within China. The classification of peptides as biological products, coupled with the rigorous approval process, encourages manufacturers to invest in robust research and development, as well as high-quality manufacturing infrastructure. This fosters a landscape where novel peptide therapies, such as GLP-1 analogs, which are increasingly relevant for metabolic health and weight management, can be developed and introduced with a strong foundation of safety and efficacy.

A recent pilot program in China allowing for segmented production of biological products, including certain peptides, illustrates the NMPA’s adaptive approach. This program aims to reduce costs and improve efficiency by permitting different stages of manufacturing to occur at separate facilities. While offering commercial advantages, this also introduces new regulatory challenges related to quality control during transportation between sites and the clear delineation of responsibilities among multiple entities. The NMPA, through its Centre for Food and Drug Inspection, has issued guidelines for on-site inspection of segmented production, demonstrating its commitment to maintaining quality oversight even with evolving manufacturing models.

| Regulatory Aspect | Impact on Peptide Quality & Safety | Relevance to Hormonal Health Protocols |

|---|---|---|

| GMP Compliance | Ensures purity, consistency, and absence of contaminants in manufactured peptides. | Directly affects the predictability and safety of compounds like Testosterone Cypionate or Gonadorelin used in hormonal optimization. |

| Clinical Trial Requirements (GCP) | Verifies safety and efficacy in human populations, identifying potential adverse effects. | Provides evidence for the appropriate dosing and application of peptides such as PT-141 for sexual health or Pentadeca Arginate for tissue repair. |

| Post-Market Surveillance (PMS) | Monitors long-term safety and identifies rare adverse events once products are widely used. | Offers ongoing assurance for therapies like MK-677, allowing for continuous risk-benefit assessment and adjustments to clinical guidance. |

| Dossier Submission (CTD) | Requires comprehensive data on manufacturing, quality control, and clinical performance. | Ensures a transparent and verifiable record of the peptide’s development, supporting informed clinical decisions. |

The NMPA’s framework, therefore, serves as a vital safeguard, ensuring that the peptides utilized in advanced wellness protocols are not only available but also meet the highest standards of quality and safety. This meticulous regulatory environment underpins the trust individuals place in these therapeutic interventions as they pursue their personal health journeys.

References

- National Medical Products Administration. (2019). Good Manufacturing Practice for Drugs (2010 Revision).

- Artixio. (n.d.). Biologics/Biosimilars Regulations and Registration in China (NMPA).

- Pacific Bridge Medical. (2025). Understanding China’s Drug Registration Process.

- National Medical Products Administration. (2022). Provisions for Drug Registration.

- CMS Law. (2024). China Launched Pilot Program on Segmented Production of Biological Products.

- ZMUni Compliance Centre. (2024). Unlocking Opportunities in China’s Booming Peptide Market ∞ Key Insights and Compliance Pathways.

- ClinRegs. (n.d.). Clinical Research Regulation For China.

- HMK. (n.d.). NMPA Requirements for Post-Market Surveillance (PMS) of Medical Devices.

Reflection

As you consider the intricate regulatory landscape governing therapeutic peptides in China, reflect on your own biological systems. Do you recognize the subtle signals your body might be sending, indicating a need for recalibration? The knowledge presented here, detailing the meticulous processes of manufacturing oversight and post-market surveillance, is not merely information; it is a lens through which to view the commitment to safety and efficacy in modern medicine.

Your personal health journey is a unique exploration, and understanding the foundations of quality in therapeutic interventions empowers you to make informed choices. This deeper comprehension of regulatory science can serve as a guiding light, helping you discern the path toward restoring your innate vitality and function.