Fundamentals

Embarking on a path toward optimized health often involves considering advanced therapeutic agents, such as peptides. The thought of introducing a precisely designed molecule into your body to support its intricate systems calls for an absolute foundation of trust. This trust begins long before a product reaches you; it is forged in the highly controlled environments where these molecules are created.

Understanding the framework that governs the manufacturing of peptide Active Pharmaceutical Ingredients (APIs) in China is an exploration into the very science of safety and purity. It is a journey into the systems designed to protect your own biological system.

An Active Pharmaceutical Ingredient Meaning ∞ The Active Pharmaceutical Ingredient, often abbreviated as API, refers to the biologically active component within a drug product responsible for its intended therapeutic effect. is the core component of any medication, the specific molecule responsible for creating the desired physiological effect. For the therapies we discuss, the API is the peptide itself—be it Sermorelin, Ipamorelin, or another targeted agent. Peptides are unique. They are relatively large, complex molecules, often consisting of a specific sequence of amino acids.

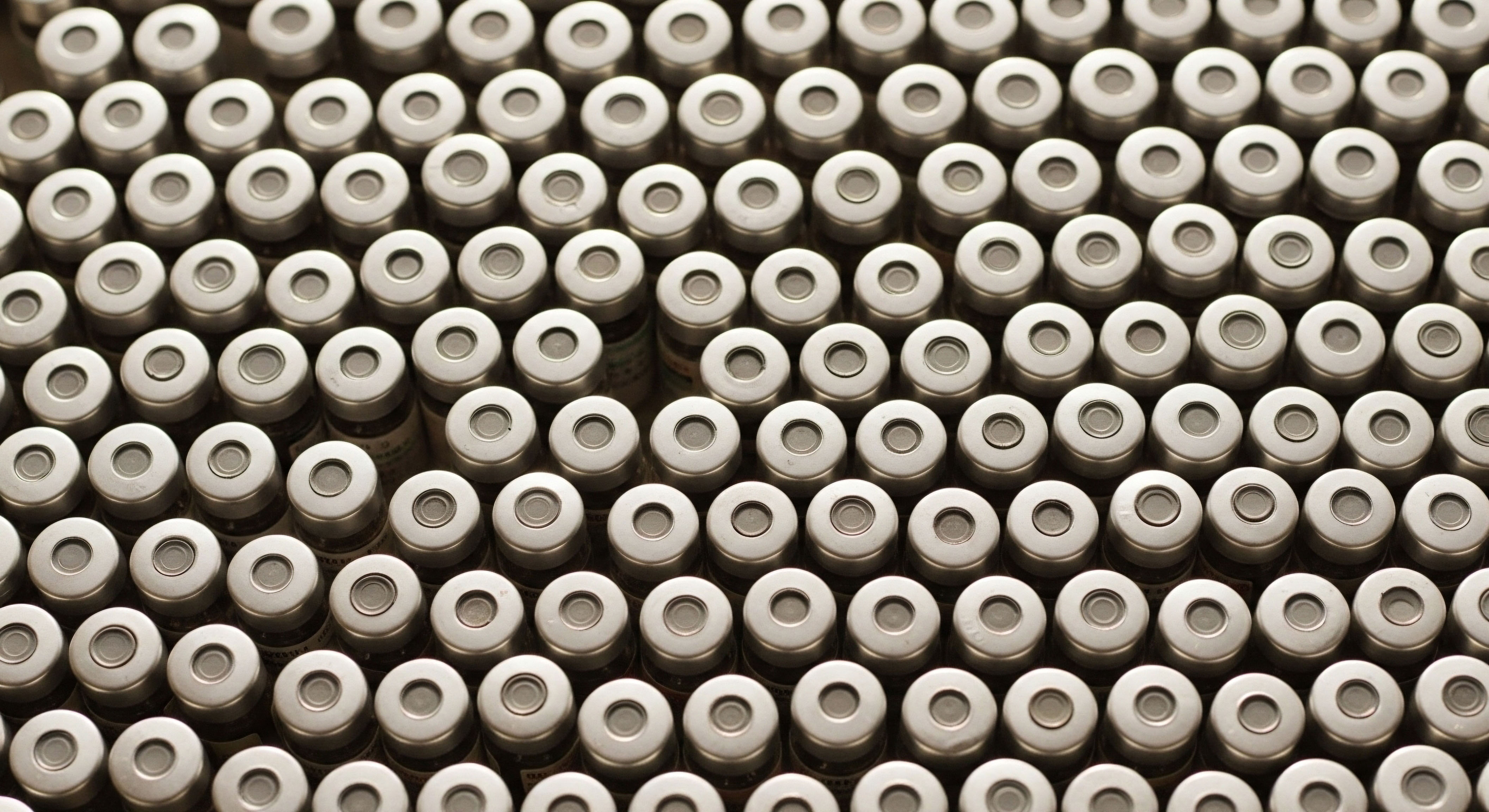

Their structure is their function. Any deviation, any impurity, any error in that sequence can alter its biological action. This inherent complexity demands a manufacturing process of exceptional precision and control. The National Medical Products Administration National growth hormone therapy reimbursement policies vary by strict clinical criteria, quality of life metrics, and health system funding models. (NMPA), the regulatory authority in China, establishes the rules for this process through its Good Manufacturing Practice (GMP) guidelines. These regulations provide a robust framework ensuring that every single vial of a peptide API meets exacting standards for identity, strength, quality, and purity.

Good Manufacturing Practice is the essential regulatory framework that ensures the safety, consistency, and purity of therapeutic molecules from their creation to their final form.

The Human Meaning of Manufacturing Quality

The term “Good Manufacturing Practice” may sound like industrial jargon, yet its implications are deeply personal. For an individual seeking to restore vitality, the quality of a therapeutic peptide is paramount. GMP regulations are the tangible expression of a commitment to your well-being. They address the critical questions that arise when you place your trust in a therapeutic protocol.

How can you be certain that the peptide you use contains the correct molecular sequence? How is it protected from contamination by bacteria, heavy metals, or other harmful substances? What ensures that the dose you administer today has the same potency as the dose you administer next month? The answers to these questions are found within the detailed articles of China’s GMP regulations.

These guidelines compel manufacturers to build quality into the product at every conceivable stage. This begins with the very first molecules used in the synthesis process and extends through every purification step, every filtration, and the final placement into sterile containers. The NMPA’s approach is aligned with global standards, including the internationally harmonized ICH Q7 guideline, which is the gold standard for API manufacturing worldwide.

This global alignment means that the principles of quality are universal, creating a common language of safety and efficacy that protects patients everywhere. The GMP framework is a scientific and ethical pledge that the molecule intended to support your body’s health is itself a product of the highest standards of care and precision.

Why Peptides Demand Specialized Oversight

Peptides occupy a unique space in the world of pharmaceuticals, and their manufacturing presents distinct challenges that GMP regulations are designed to address. Unlike simpler chemical drugs, peptides are large and fragile. Their complex, folded structures can be easily damaged by changes in temperature, pH, or mechanical stress. Furthermore, the process of synthesizing a peptide involves sequentially adding amino acids, a procedure where errors can occur, leading to the formation of closely related but incorrect sequences.

These potential issues are why GMP for peptides is so rigorous. It mandates exacting control over every variable:

- Raw Material Purity The quality of the final peptide is directly dependent on the quality of its building blocks—the individual amino acids. GMP requires stringent testing and qualification of all suppliers to ensure these raw materials are free from impurities.

- Process Control Every step of the synthesis and purification process, from chemical reactions to chromatography, must be precisely defined and monitored. This ensures that the correct peptide sequence is produced and that process-related impurities are effectively removed.

- Analytical Characterization Sophisticated analytical techniques are required to confirm the identity and purity of the final peptide API. GMP mandates the use of multiple, highly sensitive tests to prove that the product is exactly what it claims to be and that it is free from contaminants.

- Stability and Storage Because peptides can degrade over time, GMP regulations enforce rigorous stability testing programs. These studies determine the appropriate storage conditions (e.g. temperature, light protection) and shelf life for the API, ensuring it remains potent and safe until its use.

Ultimately, the GMP requirements for peptide APIs in China are a reflection of the profound respect that must be shown to the human body’s own intricate biochemistry. They provide the assurance that the therapeutic tools used to optimize health are themselves crafted with an uncompromising dedication to quality and safety.

Intermediate

For those familiar with the foundational importance of manufacturing quality, the next step is to understand the specific architecture of China’s Good Manufacturing Practice Meaning ∞ Good Manufacturing Practice (GMP) defines a system of regulations for manufacturing processes and facilities. regulations as they apply to peptide APIs. The NMPA’s GMP framework, detailed in its 2010 Revision and associated provisions, is not a mere checklist. It is an integrated philosophy of quality assurance that mandates a state of continuous control over the entire manufacturing lifecycle. This system is designed to minimize the risks inherent in pharmaceutical production, such as contamination, mix-ups, and deviations, which are particularly acute in the context of complex molecules like peptides.

At the heart of these regulations is the establishment and maintenance of a robust Quality Management System Meaning ∞ A Quality Management System, within biological regulation and clinical practice, represents structured processes ensuring consistent physiological states and therapeutic outcomes. (QMS). Think of the QMS as the operating system or the central nervous system of the entire manufacturing facility. It is the formalized system that documents and directs every process, procedure, and responsibility with the goal of ensuring that the final peptide API consistently meets its predetermined specifications and quality attributes. The NMPA mandates that this system be comprehensive, covering all aspects of production and control, from the receipt of raw materials to the release and distribution of the finished API.

Core Pillars of the NMPA GMP Framework

The Chinese GMP regulations are structured around several key pillars, each addressing a critical domain of manufacturing. For a peptide API facility, adherence to these pillars is not optional; it is a prerequisite for legal operation and a condition for obtaining the necessary Drug Manufacturing Certificate. These pillars work in concert to create a resilient and reliable production environment.

The Quality Management System

The QMS is the overarching system that integrates various quality principles. Its primary components include:

- Standard Operating Procedures (SOPs) These are detailed, written instructions for every significant operation. For peptide synthesis, there would be specific SOPs for operating the synthesis reactor, for performing purification via High-Performance Liquid Chromatography (HPLC), and for conducting each analytical test.

- Change Control Science evolves, and processes can be improved. However, any change—to a raw material supplier, a piece of equipment, or a step in the manufacturing process—must be managed through a formal change control system. This system evaluates the potential impact of the change on the peptide’s quality and ensures that any necessary validation studies are performed.

- Deviation and CAPA Management No process is perfect. When a deviation from a procedure occurs, it must be documented, investigated, and its impact assessed. The Corrective and Preventive Action (CAPA) system is then used to identify the root cause of the deviation and implement changes to prevent it from happening again.

- Internal Audits Manufacturers are required to conduct regular self-inspections to verify that all aspects of the QMS are functioning as intended and that the facility remains in a state of GMP compliance. This proactive self-assessment is crucial for continuous improvement.

Personnel the Human Element of Quality

GMP regulations place immense emphasis on the people involved in manufacturing. The guidelines stipulate that personnel must have the appropriate education, training, and experience to perform their assigned functions. Three key roles are specifically defined:

- Head of Production This individual is responsible for ensuring that peptides are produced and stored according to approved procedures to meet the required quality standards. They oversee all production operations and ensure that batch records are meticulously completed.

- Head of Quality Control Operating independently from production, this person leads the department responsible for all testing activities. They approve specifications, sampling plans, and test methods, and they ensure that all necessary analyses are performed on raw materials, intermediates, and the final peptide API.

- The Qualified Person (QP) The QP holds a unique and powerful position. This individual is personally responsible for ensuring that each batch of API has been manufactured and tested in accordance with all relevant regulations and registration requirements before it is released for use. The QP’s signature on a batch release document is a legal attestation of that batch’s quality.

The Qualified Person serves as the final gatekeeper of quality, holding personal accountability for the compliance and safety of every manufactured batch.

Premises and Equipment the Controlled Environment

The physical environment where peptides are made is a critical factor in their quality. GMP regulations for premises and equipment are designed to prevent contamination and ensure consistent operation.

For peptide APIs, especially those intended for injectable use, these requirements are particularly stringent. Facilities must be designed with logical workflows to prevent mix-ups. Air handling systems (HVAC) are critical, providing classified cleanrooms with filtered air to control particle and microbial levels. The surfaces of walls, floors, and ceilings must be smooth and easy to clean.

Equipment must be designed, installed, and maintained to be suitable for its intended purpose. This involves a formal process of qualification.

| Qualification Stage | Purpose | Key Activities for a Peptide Purifier (HPLC) |

|---|---|---|

| Design Qualification (DQ) | Verifies that the design of the equipment is suitable for the intended purpose. | Ensuring the HPLC system’s specifications (e.g. pressure limits, detector sensitivity, material compatibility) meet the requirements for purifying the specific peptide. |

| Installation Qualification (IQ) | Verifies that the equipment is installed correctly and as per the manufacturer’s recommendations. | Checking that the HPLC unit is installed, all modules are connected correctly, and necessary utilities (power, data lines) are in place. |

| Operational Qualification (OQ) | Verifies that the equipment operates according to its specifications in the user’s environment. | Testing the pump’s flow rate accuracy, the detector’s linearity and wavelength accuracy, and the injector’s precision. |

| Performance Qualification (PQ) | Verifies that the equipment consistently performs as intended in its routine use. | Repeatedly running the actual peptide purification method to demonstrate that it consistently separates the target peptide from impurities with high reproducibility. |

How Does China Regulate the Purity of Peptide Ingredients?

The NMPA’s regulations mandate a multi-faceted approach to ensuring peptide purity. It begins with rigorous control over starting materials and reagents and extends to the validation of the entire manufacturing process. Process validation Meaning ∞ Process Validation, within clinical practice, signifies the rigorous, documented confirmation that a specific clinical procedure, diagnostic methodology, or therapeutic protocol consistently yields its anticipated physiological effect or analytical result. is the documented evidence that the manufacturing process, when operated within established parameters, consistently produces a peptide API that meets its quality specifications. For a peptide, this means demonstrating that the process can effectively remove specific types of impurities, such as truncated or deletion sequences that may have formed during synthesis.

This validation provides a high degree of assurance that every batch will be of the same quality. Finally, each batch of the finished API must be tested against a comprehensive set of specifications using validated analytical methods before it can be released by the Qualified Person.

Academic

A sophisticated analysis of China’s Good Manufacturing Practice requirements for peptide Active Pharmaceutical Ingredients necessitates a deep dive into the intersection of regulatory frameworks, advanced analytical chemistry, and the specific molecular challenges posed by synthetic peptides. The NMPA’s regulations, while having their own national character, are fundamentally built upon the globally harmonized principles of the International Council for Harmonisation Meaning ∞ The International Council for Harmonisation (ICH) is a global initiative uniting regulatory authorities and pharmaceutical industry associations. of Technical Requirements for Pharmaceuticals for Human Use, specifically the ICH Q7 guideline, “Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients.” Understanding the NMPA’s expectations requires viewing them through the lens of ICH Q7, as this document provides the detailed scientific and technical rationale that underpins modern API manufacturing oversight worldwide.

For peptide APIs, this regulatory scrutiny intensifies, focusing on the unique failure modes of their synthesis and purification processes. The core objective of GMP in this context is to control for the potential heterogeneity of the final product. Unlike a small molecule drug that may have a few predictable impurities, a peptide synthesized via a stepwise process like Solid-Phase Peptide Synthesis Meaning ∞ Solid-Phase Peptide Synthesis (SPPS) is a robust chemical method for creating peptides by sequentially adding amino acid building blocks to a growing chain that is anchored to an insoluble polymeric support, typically a resin bead. (SPPS) can generate a complex family of closely related impurities.

These can include deletion sequences (missing one or more amino acids), truncated sequences (incomplete chains), and diastereomers (incorrect stereochemistry of an amino acid). The GMP framework is designed to ensure the manufacturing process is robust enough to minimize the formation of these impurities and effective enough to remove them to clinically insignificant levels.

The Central Role of Process Validation and Impurity Control

Process validation for a peptide API is a complex undertaking that goes far beyond simple batch testing. It is a holistic exercise designed to demonstrate that the entire manufacturing process Safely stopping TRT involves a guided protocol to reactivate the body’s natural testosterone production and restore hormonal balance. is understood and under a state of control. The NMPA, in line with ICH Q7, expects a science and risk-based approach.

This involves identifying Critical Process Parameters (CPPs)—such as coupling times and temperatures in an SPPS reactor or the gradient slope in a purification chromatography step—and demonstrating that variations within a defined range do not negatively impact the Critical Quality Attributes (CQAs) of the peptide. CQAs for a peptide API typically include its identity, purity, potency, and impurity profile.

The impurity profile is of paramount concern. A key aspect of validation is demonstrating the clearance of process-related impurities. This often involves “spiking” studies, where known amounts of specific impurities are intentionally added to the process stream and the purification steps are then challenged to show they can effectively remove them. The analytical methods used to track these impurities must themselves be validated for specificity, linearity, range, accuracy, and precision, ensuring they are capable of reliably detecting and quantifying the impurities at the required low levels.

| Impurity Type | Description | Primary Control Strategy | Analytical Detection Method |

|---|---|---|---|

| Deletion Sequences | Peptide chains missing one or more amino acids from the target sequence. | Optimization of coupling efficiency during synthesis; high-resolution purification. | Mass Spectrometry (MS), HPLC with UV detection. |

| Truncated Sequences | Incomplete peptide chains that were not fully synthesized. | Ensuring high “capping” efficiency to terminate unreacted chains during synthesis. | HPLC, MS. |

| Diastereomers | Peptides containing one or more amino acids with the incorrect stereoisomer (e.g. a D-amino acid instead of an L-amino acid). | Use of high-purity amino acid raw materials with minimal racemization; process control to avoid harsh conditions that induce racemization. | Chiral Chromatography, specialized HPLC methods. |

| Residual Solvents | Organic solvents used during synthesis or purification that remain in the final API. | Effective drying and lyophilization processes, validated to reduce solvents to levels defined in ICH Q3C guidelines. | Gas Chromatography (GC) with headspace analysis. |

| Endotoxins | Pyrogenic substances from the cell walls of gram-negative bacteria, a critical contaminant for injectable products. | Use of endotoxin-free water and materials; stringent aseptic technique; validated depyrogenation steps for equipment. | Limulus Amebocyte Lysate (LAL) test or Recombinant Factor C (rFC) assay. |

The Drug Master File a Conduit for Regulatory Review

For foreign manufacturers wishing to supply peptide APIs to the Chinese market, the Drug Master File Meaning ∞ A Drug Master File (DMF) is a confidential document submitted to a regulatory authority. (DMF) system is a critical regulatory pathway. The DMF is a confidential submission made directly to the NMPA’s Center for Drug Evaluation (CDE). It contains the complete Chemistry, Manufacturing, and Controls (CMC) information for the API.

This mechanism allows the API manufacturer to protect its proprietary process information while permitting the CDE to conduct a thorough review of the API’s quality. The finished drug product manufacturer who will use the API can then reference this DMF in their own drug application, and the CDE links the two filings together.

A DMF for a peptide API is an extensive document. Its successful review hinges on the depth and quality of the data provided. Key sections include:

- Characterization and Structure Elucidation This section provides the comprehensive evidence proving the peptide’s primary, secondary, and, where applicable, tertiary structure. It involves data from amino acid analysis, peptide mapping, mass spectrometry, and other advanced spectroscopic techniques.

- Manufacturing Process Description This is a detailed, step-by-step narrative of the entire manufacturing process, from the first chemical reaction to the final packaging of the API. It identifies all raw materials, solvents, reagents, and operating parameters.

- In-Process Controls This details all the tests and checks that are performed during the manufacturing process to monitor its progress and ensure it remains in a state of control.

- Control of the API This section contains the release specifications for the final peptide API, a description of the analytical methods used to test against those specifications, and the validation reports for those methods.

- Stability Data A comprehensive stability package is required, including data from long-term and accelerated stability studies on multiple batches to justify the proposed retest date and storage conditions for the API.

The Drug Master File provides regulators with a transparent, in-depth view of the entire manufacturing and control strategy, serving as the ultimate evidence of quality.

What Are the Specific NMPA Expectations for Aseptic Peptides?

When a peptide API is intended for use in an injectable drug product and is not terminally sterilized, it must be manufactured as a sterile API. This introduces an entirely new layer of GMP complexity governed by principles of aseptic processing. The NMPA’s requirements in this area are extremely stringent. The final purification steps, filtration, and packaging of the API must be performed in a Grade A (ISO 5) cleanroom environment, typically within a laminar air flow hood or isolator, which is itself located within a Grade B (ISO 6) background environment.

All personnel entering these areas must be highly trained in aseptic technique, and all equipment and containers must be sterilized before use. The process must be validated through media fill simulations, where a sterile microbiological growth medium is passed through the entire process in place of the peptide. The absence of microbial growth in the medium after incubation provides evidence that the aseptic process is capable of maintaining sterility.

References

- China. National Medical Products Administration. Good Manufacturing Practice for Drugs (2010 Revision). MOH Decree No. 79, 17 Jan. 2011.

- China. Provisions for the Supervision and Administration of Drug Manufacturing. State Administration for Market Regulation Order No. 28, 31 Dec. 2019.

- International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use. ICH Harmonised Tripartite Guideline Q7 ∞ Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients. 10 Nov. 2000.

- China. Drug Administration Law of the People’s Republic of China. Amended by the Standing Committee of the National People’s Congress, 26 Aug. 2019.

- International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use. ICH Harmonised Tripartite Guideline Q3C(R8) ∞ Impurities ∞ Guideline for Residual Solvents. 22 Apr. 2021.

- Rathore, Anurag S. and G. Kumaraswamy. “An overview of regulations and guidelines for contamination control in biopharmaceutical manufacturing.” Biopharm International, vol. 32, no. 11, 2019, pp. 26-33.

- White, W. C. and P. M. Lovalenti. “Solid-Phase Peptide Synthesis (SPPS) Process Development and Scale-Up ∞ A Review of the Literature.” Organic Process Research & Development, vol. 26, no. 8, 2022, pp. 2219-2231.

Reflection

The journey through the intricate world of Good Manufacturing Practice reveals a profound architecture of control, science, and accountability. These regulations, with their detailed clauses on validation, personnel, and documentation, are the bedrock upon which therapeutic trust is built. For the individual on a personal health journey, this knowledge transforms the abstract concept of “quality” into a tangible reality. It offers a new lens through which to view the therapies designed to support your body’s own complex systems.

Understanding this framework is an act of empowerment. It equips you with a deeper appreciation for the immense effort and precision required to produce a pure, potent, and safe therapeutic peptide. The knowledge that a system of such rigor exists, designed to protect the integrity of the very molecules intended to optimize your physiology, can provide a powerful sense of reassurance. As you move forward, this understanding becomes a foundational element of your wellness strategy, allowing you to engage with your health protocols not just as a recipient, but as an informed and confident partner in your own biological journey.