Fundamentals

When you experience shifts in your vitality, perhaps a persistent fatigue that defies explanation, or a subtle yet undeniable change in your metabolic rhythm, it is natural to seek clarity. You might feel a sense of disconnection from your own body, a quiet frustration with symptoms that conventional explanations fail to address. This personal experience, this intuitive sense that something is out of balance, often leads individuals to explore the intricate world of hormonal health and advanced wellness protocols. Within this pursuit, peptides frequently surface as compounds of significant interest, holding the promise of recalibrating biological systems.

The journey toward reclaiming optimal function often involves considering substances that interact directly with your body’s internal messaging systems. Peptides, as short chains of amino acids, serve as these biological messengers, orchestrating a vast array of physiological processes. Their precise structure dictates their function, acting like keys fitting into specific cellular locks to initiate a cascade of biochemical events.

The integrity of these keys, their purity, and their accurate composition, becomes paramount. Without a clear understanding of how these compounds are produced and verified, the very foundation of your wellness strategy rests on uncertain ground.

Understanding the origin and quality of peptides is a cornerstone for any personalized wellness strategy.

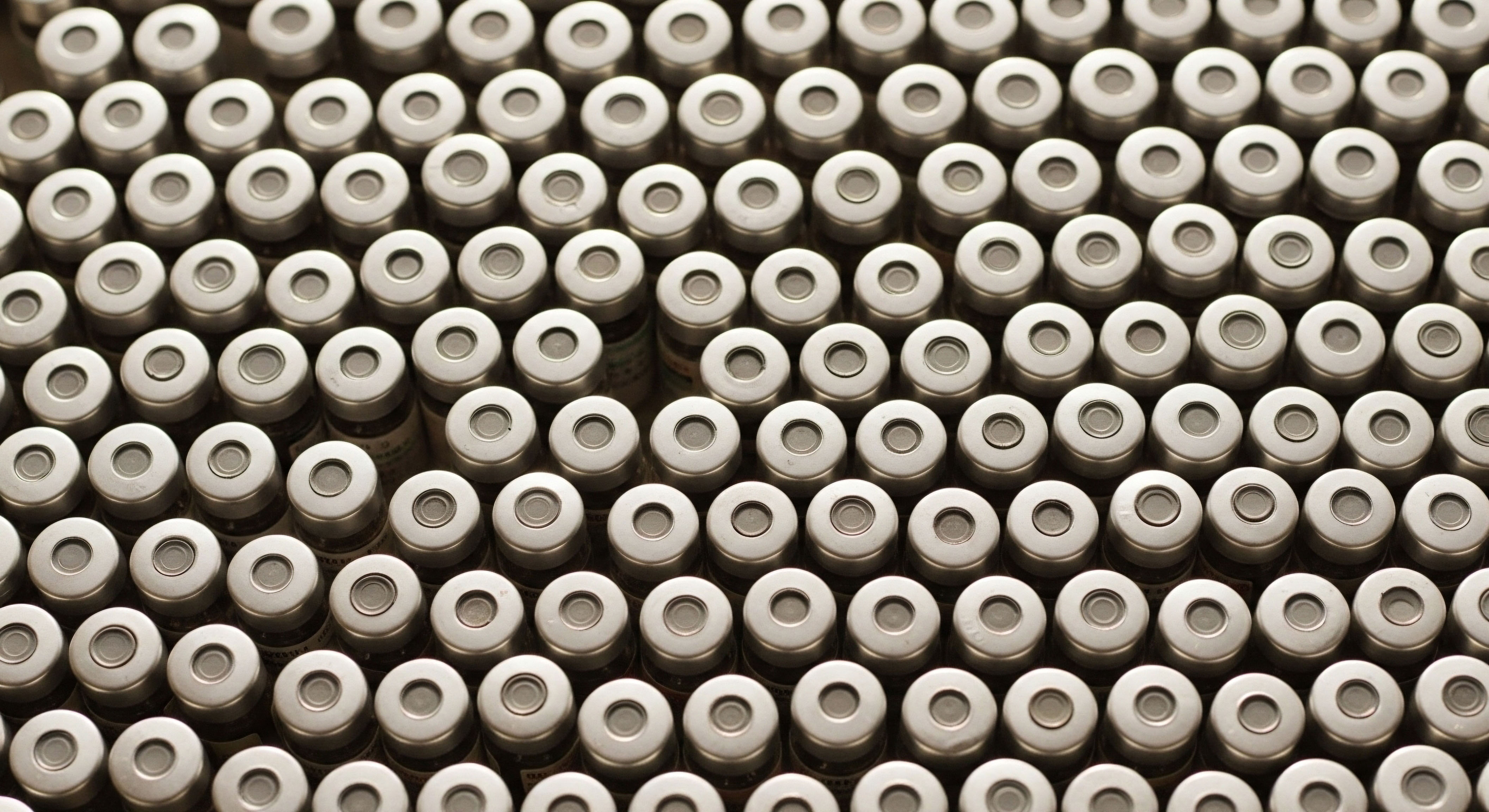

Consider the global landscape of pharmaceutical and research material production. China stands as a significant contributor to the world’s supply chain for various compounds, including peptides. This prominence necessitates a close examination of the regulatory frameworks that govern production within its borders. When we discuss “research peptide production” in China, we are not merely talking about laboratory curiosities.

These substances, even if initially designated for research, can influence the trajectory of scientific discovery and, by extension, the development of future therapeutic applications that might one day impact your health directly. The standards applied during their creation shape their reliability and safety profile.

What Is a Research Peptide?

A research peptide is a synthetic compound designed for scientific investigation rather than immediate therapeutic application in humans. These peptides are tools for scientists to study biological pathways, identify potential drug targets, or develop diagnostic methods. They might be used in cell cultures, animal models, or in vitro assays.

The distinction between a research peptide and a therapeutic peptide is primarily one of intended use and, consequently, the regulatory oversight applied to its manufacturing. A therapeutic peptide, destined for human administration, undergoes a far more rigorous and extensive regulatory approval process.

Despite their “research” designation, the quality of these compounds remains critically important. Flawed research materials can lead to erroneous scientific conclusions, wasting valuable time and resources. More concerning, if these research-grade materials are diverted or misused for human consumption, they pose substantial health risks due to a lack of stringent purity, sterility, and safety testing. This inherent risk underscores the necessity of robust regulatory guidance, even for compounds not yet classified as pharmaceutical agents.

The National Medical Products Administration’s Role

The central authority overseeing pharmaceutical products, medical devices, and cosmetics in China is the National Medical Products Administration (NMPA). This governmental body establishes and enforces the regulations that dictate how substances, including peptides, are manufactured, tested, and distributed within the country. The NMPA’s directives aim to safeguard public health by ensuring the safety, efficacy, and quality of regulated products. Its scope extends beyond finished pharmaceutical products to encompass active pharmaceutical ingredients (APIs) and, in certain contexts, even materials used in research that could eventually enter the human health pipeline.

The NMPA’s regulatory framework is dynamic, continually adapting to global standards and scientific advancements. Its role is akin to a vigilant guardian, ensuring that the biochemical components that influence our health are produced with precision and accountability. This oversight provides a foundational layer of assurance, even as the complexities of peptide chemistry and application continue to expand.

Intermediate

When considering personalized wellness protocols, particularly those involving peptide compounds, a deeper understanding of manufacturing standards becomes indispensable. The efficacy and safety of any biochemical recalibration protocol hinge directly on the quality of the substances employed. This is where the concept of Good Manufacturing Practices (GMP) enters the discussion, serving as a universal language of quality assurance in pharmaceutical production.

GMP is not merely a checklist of rules; it represents a comprehensive system designed to ensure products are consistently produced and controlled according to quality standards. This encompasses everything from the initial sourcing of raw materials to the final packaging and distribution. For peptides, this means meticulous attention to their synthesis, purification, and handling to prevent contamination, ensure consistent potency, and verify structural integrity. A peptide produced without adherence to these principles is like a message sent with missing words or incorrect punctuation; its intended biological communication may be distorted or entirely lost, potentially leading to unpredictable outcomes.

Good Manufacturing Practices provide the blueprint for biochemical precision, ensuring consistent quality and safety in peptide production.

China’s Alignment with Global Quality Standards

China’s regulatory landscape has undergone significant reforms, particularly since its accession to the International Council for Harmonisation (ICH) in 2017. This move signifies a commitment to aligning its drug regulatory system with international benchmarks. For peptide production, this means a growing emphasis on standards such as ICH Q7, which provides guidance for Good Manufacturing Practice for Active Pharmaceutical Ingredients. Manufacturers in China aiming for global markets, or even those supplying high-quality materials domestically, increasingly adopt these international guidelines.

Companies like GenScript, for instance, explicitly state their facilities meet ICH Q7 guidelines and FDA 21 CFR Part 210/211 regulations for peptide API manufacturing. This international alignment helps to bridge the gap between local production capabilities and global expectations for quality and safety.

The Chinese Pharmacopoeia also plays a central role, establishing mandatory national drug standards for products approved within China. Compliance with these pharmacopoeial monographs is critical during the review, testing, and inspection phases of new drug applications. This dual adherence to both national and international standards reflects a maturing regulatory environment.

Categorizing Peptides and Their Regulatory Pathways

The regulatory requirements for peptides in China vary significantly based on their intended use. It is not a monolithic system, but rather a tiered approach that reflects the potential risk associated with a product’s application.

- Therapeutic Peptides (Active Pharmaceutical Ingredients – APIs) ∞ These are peptides intended for direct human administration as drugs. They fall under the most stringent NMPA regulations, requiring comprehensive clinical trial data, detailed Chemistry, Manufacturing, and Controls (CMC) documentation, and adherence to cGMP (current Good Manufacturing Practices) standards throughout their production lifecycle. This includes rigorous testing for purity, identity, potency, and the absence of contaminants like heavy metals or endotoxins.

- Cosmetic Peptides ∞ Peptides used as ingredients in cosmetic products are regulated under China’s Cosmetics Supervision and Administration Regulations (CSAR). While less stringent than pharmaceutical API regulations, CSAR still mandates safety assessments and, for new peptide ingredients not on the existing inventory (IECIC 2021), requires a New Cosmetic Ingredient (NCI) application process. This ensures that even topical applications meet defined safety profiles.

- Research Peptides ∞ This category presents a unique regulatory consideration. Peptides explicitly labeled “for research use only” and not intended for direct human or animal therapeutic use, or as cosmetic ingredients, typically face less direct NMPA oversight as pharmaceutical products. However, reputable manufacturers still adhere to internal quality control standards, often drawing from GMP principles, to ensure the reliability of their products for scientific investigation. For example, companies may offer “non-GMP research peptides” alongside their cGMP-grade offerings, indicating a difference in the level of regulatory documentation and stringency, though still implying a commitment to a certain quality level. The phrase “not for direct human use” is a common disclaimer.

The distinction between these categories is vital for anyone considering peptide use. A peptide produced for research purposes, even if chemically identical to a therapeutic one, lacks the regulatory validation and quality assurance steps essential for human safety and efficacy.

Essential Elements of Quality Control in Peptide Production

Regardless of the specific regulatory classification, high-quality peptide production relies on a series of critical control points. These measures are designed to ensure the final product is pure, potent, and free from harmful contaminants.

- Raw Material Qualification ∞ The starting materials, primarily amino acids and resins, must meet strict purity standards. Contaminants introduced at this initial stage are difficult to remove later in the process.

- Synthetic Method Development and Validation ∞ The chosen synthesis method (e.g. solid-phase peptide synthesis, solution-phase synthesis) must be robust and reproducible. Validation ensures the process consistently yields the desired product with minimal impurities.

- In-Process Controls ∞ Monitoring the synthesis at various stages helps to identify and correct deviations early, preventing large batches of substandard product. This includes checks on reaction completion and intermediate purity.

- Product Purification ∞ After synthesis, crude peptides undergo rigorous purification, typically using techniques like High-Performance Liquid Chromatography (HPLC), to separate the desired peptide from truncated sequences, deletion products, and other impurities.

- Analytical Method Development and Validation ∞ Precise analytical methods are developed and validated to confirm the identity, purity, and potency of the final peptide. These methods must be reliable and sensitive.

- Release Specification Design and Testing ∞ Each peptide batch must meet predefined specifications before release. This includes tests for purity, molecular weight, amino acid composition, water content, and endotoxin levels.

- Stability Testing ∞ For therapeutic peptides, stability studies are conducted to determine shelf life and appropriate storage conditions, ensuring the peptide remains effective and safe over time.

- Documentation and Traceability ∞ Comprehensive records are maintained for every step of the production process, allowing for complete traceability from raw materials to the finished product. This documentation is a cornerstone of GMP compliance.

These elements collectively form a robust system, providing confidence in the integrity of the peptide. Without such controls, the potential for variability, contamination, and ultimately, compromised health outcomes, increases significantly.

How Do Regulatory Standards Guide Research Peptide Production in China?

While “research peptides” may not face the same direct NMPA drug registration requirements as therapeutic APIs, the regulatory environment in China still influences their production through several indirect and direct mechanisms.

Firstly, many manufacturers producing research peptides also produce cGMP-grade therapeutic peptides or cosmetic ingredients. This means their facilities, personnel, and quality management systems are often built to higher standards, even for their research-grade offerings. The infrastructure and expertise developed for stringent pharmaceutical production naturally elevate the quality of other products. Companies frequently leverage their cGMP capabilities to offer a higher standard of “research-grade” material, even if not strictly mandated by regulation for that specific product line.

Secondly, the increasing global demand for high-quality research materials, coupled with China’s desire to be a leading player in biotechnology, drives manufacturers to adopt international best practices. Researchers worldwide require reliable and reproducible materials for their studies, pushing Chinese suppliers to meet these expectations. This market-driven pressure complements formal regulatory mandates.

Thirdly, while a specific “research peptide” might not require NMPA drug approval, if it is later intended for preclinical or clinical development, its initial quality can significantly impact its regulatory pathway. Data generated from studies using poorly characterized or impure research peptides may be deemed invalid by regulatory bodies like the NMPA, FDA, or EMA, necessitating costly and time-consuming re-studies. This forward-looking perspective encourages manufacturers to maintain high standards from the outset.

The table below illustrates the varying levels of regulatory oversight for different peptide categories in China.

| Peptide Category | Primary Regulatory Body | Key Regulations/Standards | Level of Oversight | Typical End Use |

|---|---|---|---|---|

| Therapeutic API | NMPA | Drug Administration Law, cGMP (ICH Q7, 21 CFR Part 210/211), Chinese Pharmacopoeia | Most Stringent (Full registration, clinical trials, extensive CMC) | Human pharmaceutical drugs |

| Cosmetic Ingredient | NMPA | CSAR (Cosmetics Supervision and Administration Regulations), IECIC, NCI application | Moderate (Safety assessment, ingredient notification/registration) | Topical cosmetic products |

| Research Reagent | Indirect NMPA influence, Industry Standards | Internal Quality Control (often GMP-aligned), ISO standards, customer requirements | Less Direct (No specific drug approval, but quality is market-driven) | Laboratory research, preclinical studies, in vitro assays |

Academic

The exploration of regulatory standards guiding research peptide production in China extends beyond mere compliance checklists; it delves into the fundamental principles that underpin biological integrity and therapeutic efficacy. For individuals seeking to optimize their hormonal health and metabolic function, understanding these deeper layers is paramount. The quality of a peptide, meticulously controlled through stringent regulatory frameworks, directly influences its interaction with the body’s intricate systems, impacting everything from cellular signaling to systemic metabolic balance.

Consider the endocrine system, a sophisticated network of glands and hormones that serves as the body’s internal communication hub. Hormones, many of which are peptides, act as precise messengers, transmitting instructions to distant cells and tissues. When these messengers are impure, incorrectly folded, or contaminated, their signals can become garbled, leading to unintended biological responses or a complete lack of desired effect. This disruption can cascade through interconnected pathways, affecting the delicate equilibrium of the Hypothalamic-Pituitary-Gonadal (HPG) axis, the growth hormone axis, or even metabolic pathways governing glucose regulation and lipid metabolism.

The purity of a peptide, ensured by rigorous regulatory standards, is essential for its precise interaction with the body’s complex biological systems.

Pharmacokinetics and Pharmacodynamics in Focus

Regulatory standards, particularly those derived from GMP principles, ensure predictable pharmacokinetics and pharmacodynamics. Pharmacokinetics describes how the body handles a substance ∞ its absorption, distribution, metabolism, and excretion. Pharmacodynamics, conversely, describes how the substance affects the body ∞ its mechanism of action and physiological effects. For a peptide to elicit its intended biological response, its structure must be exact.

Impurities, such as truncated sequences or modified amino acids, can significantly alter these properties. A peptide with an altered pharmacokinetic profile might be cleared too quickly or accumulate in unintended tissues, reducing its therapeutic window. An altered pharmacodynamic profile could lead to off-target effects or a diminished primary action, rendering the compound ineffective or even harmful.

The NMPA’s stringent requirements for therapeutic peptides, and the industry’s voluntary adoption of similar controls for high-quality research peptides, aim to guarantee that a peptide behaves as expected within a biological system. This level of control is not just about safety; it is about ensuring the scientific validity of research and the clinical predictability of therapeutic outcomes.

Minimizing Immunogenicity and Ensuring Safety

One of the most critical aspects of peptide quality, directly addressed by regulatory oversight, is the minimization of immunogenicity. Immunogenicity refers to the capacity of a substance to provoke an immune response in the body. For peptides, especially larger ones or those with modifications, even minor impurities can act as neoantigens, triggering an unwanted immune reaction. This could range from mild allergic responses to severe anaphylaxis or, more subtly, the development of neutralizing antibodies that render the peptide therapy ineffective over time.

Regulatory guidelines, particularly those for therapeutic peptides, mandate rigorous testing for impurities and aggregates, which are known to increase immunogenic potential. For instance, the FDA’s guidance for synthetic peptide drug products emphasizes assessing immunogenicity for impurities present above a certain threshold. While “research peptides” may not undergo the same level of immunogenicity testing, manufacturers adhering to higher quality standards recognize this risk and employ purification methods designed to reduce such contaminants. This proactive approach safeguards the integrity of research findings and, ultimately, the safety of any future human applications.

Advanced Analytical Techniques for Verification

The ability to verify peptide purity and identity relies on sophisticated analytical methodologies. Regulatory bodies and quality-conscious manufacturers employ a suite of advanced techniques to ensure compliance and product integrity.

The table below outlines some of these critical analytical tests and their purpose in peptide quality control.

| Analytical Technique | Purpose in Peptide Quality Control | Regulatory Relevance |

|---|---|---|

| High-Performance Liquid Chromatography (HPLC) | Determines peptide purity and identifies related impurities (e.g. truncated sequences, deamidated forms). | Mandatory for purity assessment in cGMP production; essential for research peptide characterization. |

| Mass Spectrometry (MS) | Confirms the exact molecular weight and amino acid sequence, verifying identity. | Required for identity confirmation; detects unexpected modifications or contaminants. |

| Amino Acid Analysis (AAA) | Quantifies the amino acid composition, confirming the peptide’s primary structure. | Ensures the correct ratio of amino acids is present, supporting identity. |

| Endotoxin Testing (LAL Assay) | Detects and quantifies bacterial endotoxins, which can cause fever and inflammation. | Critical for injectable peptides; regulatory limits apply to minimize pyrogenic reactions. |

| Chiral Purity Analysis | Ensures all amino acids are in the correct stereoisomeric form (L-amino acids for natural peptides). | Prevents incorporation of D-amino acids, which can alter biological activity and stability. |

| Counter Ion Content Analysis | Measures the amount of counter ions (e.g. TFA) from synthesis, which can impact stability and formulation. | Important for formulation development and long-term stability. |

These analytical tools are the eyes and ears of quality control, providing objective data that substantiates a peptide’s quality. The NMPA, through its Center for Drug Evaluation (CDE) and National Institutes for Food and Drug Control (NIFDC), utilizes such data during its review and inspection processes. For research peptides, while not always subject to direct NMPA review, the use of these techniques by manufacturers signifies a commitment to scientific rigor.

The Interplay of Quality and Clinical Research Outcomes

The quality of research peptides has a direct and profound impact on the validity of preclinical and clinical research. If a research study utilizes an impure or inconsistent peptide, any observed biological effects cannot be reliably attributed to the peptide itself. This can lead to:

- Misleading Data ∞ Erroneous results can misdirect subsequent research efforts, wasting resources and delaying the discovery of effective therapies.

- Safety Concerns ∞ Undetected impurities in research-grade materials, if later used in animal studies or early human trials, could cause unexpected toxicity or adverse reactions, jeopardizing patient safety.

- Regulatory Hurdles ∞ When a promising research peptide transitions to therapeutic development, regulatory agencies will scrutinize the quality of materials used in foundational studies. Poor quality documentation or inconsistent batch records from the research phase can create significant obstacles during drug approval processes.

This academic perspective highlights that even “research peptide production” in China, while not always under direct pharmaceutical regulation, is intrinsically linked to the broader ecosystem of drug discovery and personalized wellness. The pursuit of vitality and optimal function through advanced protocols necessitates a deep appreciation for the unseen layers of quality control and regulatory guidance that ensure the integrity of the very compounds we consider for our health journey.

Challenges in Peptide Regulation and Production

Despite advancements, the regulatory landscape for peptides, particularly in a global context, presents ongoing challenges.

- Complexity of Peptides ∞ Peptides are more complex than small molecules, with variations in length, sequence, and post-translational modifications. This complexity makes their synthesis and characterization more challenging, requiring highly specialized analytical techniques.

- Impurities Management ∞ The synthesis process can generate numerous related impurities (e.g. deletion peptides, oxidized forms, aggregates). Identifying, quantifying, and controlling these impurities to acceptable levels is a continuous challenge for manufacturers and regulators.

- Analytical Method Harmonization ∞ While ICH aims for harmonization, differences in pharmacopoeial requirements and analytical test methods across regions (e.g. Chinese Pharmacopoeia vs. USP/EP) can still pose issues for global product registration.

- Evolving Science ∞ The rapid pace of peptide science, with new modifications, delivery systems, and therapeutic applications constantly emerging, means regulatory frameworks must continuously adapt to keep pace with innovation while ensuring safety.

- Distinction Between Grades ∞ Maintaining a clear distinction between research-grade, cosmetic-grade, and pharmaceutical-grade peptides, and preventing the misuse of lower-grade materials for human therapeutic purposes, remains a practical challenge for the industry and regulatory bodies worldwide.

These challenges underscore the ongoing need for vigilance and collaboration between regulatory agencies, manufacturers, and researchers to ensure that the promise of peptide-based therapies is realized safely and effectively.

How Do Chinese Regulatory Standards Influence Global Peptide Innovation?

China’s regulatory standards, particularly its alignment with ICH guidelines and its evolving NMPA framework, significantly influence global peptide innovation. As a major producer of both research and therapeutic peptides, China’s adherence to international quality benchmarks means that peptides originating from its facilities are increasingly recognized and accepted worldwide. This fosters a more harmonized global supply chain, reducing barriers for international research collaborations and drug development efforts. The emphasis on cGMP and robust quality control within China’s leading peptide manufacturers sets a higher bar for all participants in the global market, driving overall quality improvements.

References

- Chalamaiah, M. et al. “Bioactive peptides from food proteins ∞ A review on their production, purification, and health benefits.” Food Chemistry, vol. 296, 2019, pp. 100-111.

- Chao, Y. et al. “Recent advances in the preparation and biological activities of food-derived bioactive peptides.” Journal of Agricultural and Food Chemistry, vol. 61, no. 40, 2013, pp. 9425-9435.

- El Hajj, S. Sepulveda-Rincon, M. et al. “Bioactive peptides from milk proteins ∞ Production, purification, and health applications.” Comprehensive Reviews in Food Science and Food Safety, vol. 20, no. 5, 2021, pp. 4769-4796.

- Karami, Z. & Akbari-adergani, B. “Bioactive peptides ∞ A review on their production, purification, and health benefits.” Journal of Food Science and Technology, vol. 56, no. 1, 2019, pp. 1-11.

- Kumari, B. et al. “Bioactive peptides from microbial fermentation ∞ A review.” Journal of Food Science and Technology, vol. 57, no. 10, 2020, pp. 3547-3560.

- O’Brien, J. “Food safety and regulation in China ∞ An overview.” Food Control, vol. 50, 2015, pp. 884-890.

- United States Pharmacopeia. “USP International Forum on Therapeutic Peptides Quality and Standards 2018 successfully held in China.” USP, 2018.

- GenScript Biotech Corporation. “GenScript Expands Peptide Production Capabilities to Include Neoantigen Peptides and APIs.” FirstWord Pharma, 2023.

- ZMUni Compliance Centre. “Unlocking Opportunities in China’s Booming Peptide Market ∞ Key Insights and Compliance Pathways.” ZMUni Compliance Centre, 2024.

- National Medical Products Administration. “China’s NMPA releases new regulation on the Registration of Biologics in China.” 2020.

- Pharmaceutical Engineering. “Evolving China’s Regulatory System in Alignment with ICH.” 2019.

- CSBio China. “GMP manufactured peptides.” CSBio, 2023.

Reflection

As you consider your personal health journey, particularly in navigating the complex terrain of hormonal balance and metabolic well-being, the insights gained into peptide production standards serve as a vital compass. This understanding moves beyond simply identifying a potential solution; it empowers you to ask discerning questions about the origins and integrity of the compounds you might consider. Your body’s systems are remarkably adaptive, yet they respond with precision to the signals they receive. Ensuring those signals, in the form of peptides, are pure and consistent is a fundamental act of self-care.

This knowledge is not an endpoint, but rather a significant step in your ongoing exploration of vitality. It prompts a deeper introspection ∞ What does it truly mean to support your biological systems without compromise? The path to reclaiming optimal function is deeply personal, and armed with this clarity about regulatory frameworks and quality assurance, you are better equipped to make informed choices that align with your unique physiological needs and long-term wellness aspirations.