Fundamentals

You feel it in your bones, a pervasive sense of fatigue that sleep does not seem to touch. There is a fog that clouds your thoughts, making focus a distant memory. The vitality that once defined your days has been replaced by a persistent drag, a feeling that your own internal systems are no longer working in your favor.

This experience, this intimate and often frustrating dialogue with your own body, is the very starting point for understanding the profound importance of therapeutic peptides. When you consider a protocol involving molecules like Sermorelin to restore growth hormone pulses or Testosterone to recalibrate your endocrine axis, the most important question you can ask is one of absolute certainty ∞ is the substance I am using precisely what it claims to be, and nothing else?

This question is the foundation upon which all therapeutic efficacy and safety are built. It is the same question that drives the complex world of regulatory science.

The journey to reclaiming your biological function begins with appreciating what these therapeutic agents are. A peptide is a sequence of amino acids, a specific molecular messenger designed by nature or science to interact with a particular receptor in your body. Think of it as a key, engineered with incredible precision to fit a single lock.

When the correct key (the peptide) enters the correct lock (the receptor), it initiates a cascade of downstream physiological events. For instance, the peptide Ipamorelin is designed to selectively pulse the pituitary gland, prompting the release of growth hormone. This action can influence metabolism, sleep quality, and tissue repair.

If the key is misshapen, even slightly, it will not fit the lock. If the key is accompanied by a handful of other, differently shaped keys (impurities), you risk jamming the lock or opening other, unintended doors. The entire purpose of regulatory oversight is to guarantee the integrity of that key.

Regulatory agencies exist to scientifically validate that a therapeutic peptide is the correct molecular key, free from impurities that could compromise its specific biological function.

The Guardians of Molecular Integrity

In the United States, the Food and Drug Administration (FDA), and specifically its Center for Drug Evaluation and Research (CDER), is tasked with this monumental responsibility. Within CDER, the Office of Pharmaceutical Quality (OPQ) holds the purview over the Chemistry, Manufacturing, and Controls (CMC) data for new drugs.

This is the scientific dossier, the complete biography of the peptide molecule, that demonstrates its quality. The FDA’s role is one of rigorous scientific validation. They are the arbiters who ensure that every vial of a therapeutic peptide meets exacting standards before it can be considered for human use. This process is built upon three core pillars of quality that directly address the fundamental concerns of any individual seeking treatment.

The Pillar of Identity

The first and most essential question is one of identity. Is the molecule in the vial actually the molecule it purports to be? For a peptide like Tesamorelin, which has a specific 44-amino-acid sequence, confirming identity means verifying that exact sequence, its structure, and its molecular weight.

Scientists use sophisticated analytical techniques, such as mass spectrometry, to create a unique molecular fingerprint of the peptide. This fingerprint is then compared against a verified reference standard. A mismatch indicates an error in synthesis, resulting in a completely different key that will not perform its intended function and could have unpredictable effects on the body.

The Pillar of Purity

Purity addresses the question ∞ “What else is in here with the active molecule?”. No manufacturing process is perfect, and impurities are an inevitable byproduct. The critical task for regulators is to ensure these impurities are identified, quantified, and proven to be non-harmful at the levels present.

Impurities can arise from several sources. Process-related impurities might include residual chemicals from the synthesis process or, in the case of peptides made using recombinant DNA technology, proteins from the host cells (like E. coli). Product-related impurities could be molecules where the amino acid sequence is incorrect or where the peptide has degraded into smaller fragments.

Each of these represents a “wrong key” that could potentially interfere with the intended biological signal or, in a worst-case scenario, trigger an adverse immune response. The FDA requires manufacturers to develop a detailed impurity profile, essentially a census of all non-target molecules in the final product.

The Pillar of Potency

Potency, or strength, measures the biological activity of the peptide. It answers the question ∞ “Does this key actually turn the lock?”. A vial could contain a peptide with perfect identity and purity, but if the molecule is folded incorrectly or has been damaged by heat, it may be biologically inert.

Potency is often assessed using cell-based bioassays, which measure the actual physiological response the peptide elicits at a cellular level. For a Growth Hormone Releasing Hormone (GHRH) analogue like CJC-1295, a bioassay would confirm its ability to bind to pituitary cell receptors and stimulate growth hormone secretion. Without confirmed potency, the therapy is functionally useless. These three pillars ∞ identity, purity, and potency ∞ form the bedrock of peptide quality, ensuring the safety and potential efficacy of these powerful therapeutic tools.

Intermediate

Understanding the foundational pillars of peptide quality opens the door to a more granular exploration of the regulatory mechanics. For any individual on a personalized wellness protocol, from a man utilizing Testosterone Replacement Therapy (TRT) with Gonadorelin to maintain testicular function, to an athlete using BPC-157 for tissue repair, the assurance of quality comes from a specific and exhaustive set of documents known as the Chemistry, Manufacturing, and Controls (CMC) section of a drug application.

This is the master blueprint submitted to the FDA, detailing every conceivable aspect of the peptide’s life, from its constituent raw materials to its final packaging. It is within the hundreds of pages of the CMC that the scientific narrative of the peptide’s quality is told.

The CMC is a holistic examination of the product and the process, built on the principle that a well-understood and tightly controlled manufacturing process is the ultimate guarantor of quality. Regulators scrutinize this data to connect the dots between the steps taken during production and the final characteristics of the peptide that will enter a patient’s body.

This intense evaluation is what separates a pharmaceutical-grade therapeutic from a research-grade chemical, a distinction that has profound implications for safety and biological effect. The standards are not arbitrary; they are a direct reflection of the need to manage the inherent complexities of these molecules.

Deconstructing the CMC Dossier

The CMC submission is methodically organized to provide a complete picture of the therapeutic agent. Each section addresses a critical stage of the manufacturing journey, leaving no variable unexamined. This systematic approach is essential for ensuring that each batch of a peptide, whether it’s the first or the ten-thousandth, is consistent in its quality and clinical performance.

Drug Substance the Molecule Itself

This part of the CMC focuses entirely on the active pharmaceutical ingredient (API), which is the peptide itself. It begins with a thorough characterization. For a synthetic peptide like PT-141, used for sexual health, this includes detailing its amino acid sequence, physicochemical properties, and structural data obtained from techniques like Nuclear Magnetic Resonance (NMR).

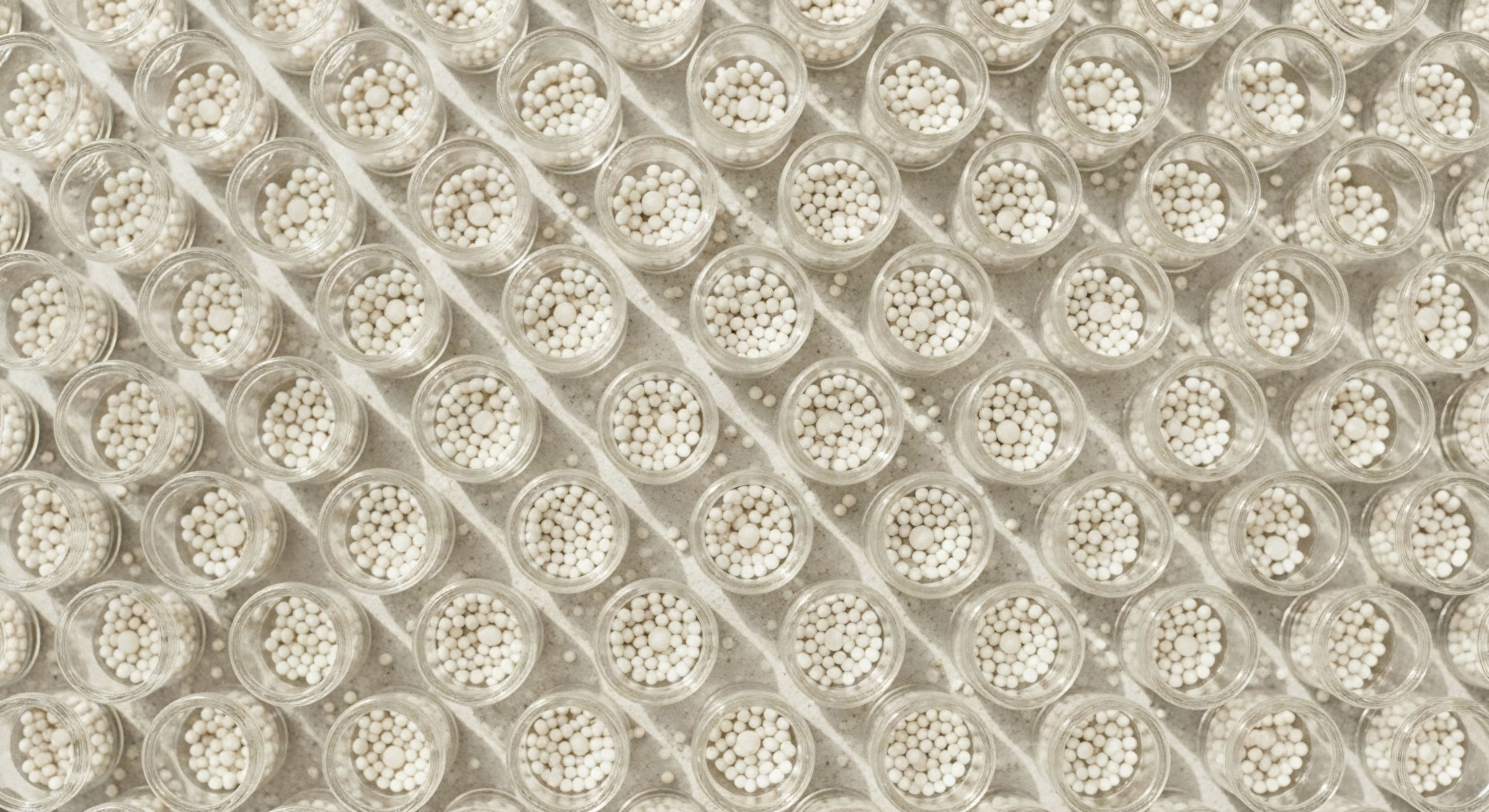

It also requires a detailed discussion of the manufacturing process. For synthetic peptides, this often involves Solid-Phase Peptide Synthesis (SPPS), where amino acids are sequentially added to a growing chain anchored to a resin bead. The manufacturer must detail every reagent, every solvent, and every temperature used in this process.

For recombinant peptides, produced in cellular systems, the process description includes the master cell bank, fermentation conditions, and harvesting methods. This level of detail allows regulators to anticipate potential impurities based on the specific manufacturing pathway used.

The Chemistry, Manufacturing, and Controls dossier serves as the definitive scientific biography of a peptide, detailing every step from raw material to final product to ensure batch-to-batch consistency and safety.

Impurity Profiling the Unwanted Companions

A significant portion of the regulatory review is dedicated to the identification and control of impurities. The FDA expects a comprehensive impurity profile, which is a detailed catalog of every substance in the final product that is not the intended peptide. These are generally categorized to assess their risk.

- Starting Material Impurities ∞ This includes contaminants present in the initial amino acids or chemical reagents. For instance, using a D-amino acid where an L-amino acid was required can create a completely different peptide isomer with unknown biological effects.

- Process-Related Impurities ∞ These are byproducts of the manufacturing process itself. For synthetic peptides, this can include deletion sequences (where an amino acid is missing) or truncated sequences. For recombinant peptides, this includes host cell proteins, DNA, and components from the cell culture media.

- Degradation Products ∞ These are impurities that form over time as the peptide breaks down due to factors like temperature or oxidation. Stability testing is designed to identify these and establish an appropriate shelf life.

The manufacturer must not only identify these impurities but also establish acceptance criteria, which are the maximum allowable levels for each. These levels are determined based on toxicological data and the potential impact on the peptide’s efficacy and immunogenicity.

The following table illustrates the distinct impurity concerns for the two primary peptide manufacturing methods:

| Impurity Source | Synthetic Peptides (e.g. Ipamorelin) | Recombinant Peptides (e.g. Teriparatide) |

|---|---|---|

| Synthesis/Expression Errors |

Deletion sequences, insertion sequences, truncated peptides, incorrect amino acid incorporation. |

Sequence variants from DNA mutation, errors in post-translational modification. |

| Process Contaminants |

Residual solvents, reagents (e.g. TFA), and coupling agents from the chemical synthesis process. |

Host cell proteins (HCPs), host cell DNA, endotoxins, components of the growth media. |

| Degradation |

Oxidation (especially of methionine), deamidation (of asparagine/glutamine), aggregation. |

Similar degradation pathways, plus potential for protease contamination from host cells. |

What Are the Standards for Compounded Peptides?

While the FDA oversees the approval of manufactured drugs, many peptides are dispensed through compounding pharmacies. These pharmacies operate under a different regulatory framework, primarily governed by state boards of pharmacy and federal laws like the Drug Quality and Security Act. Compounded preparations are not FDA-approved drugs.

They are created for an individual patient based on a prescription. While compounding pharmacies are expected to source their active pharmaceutical ingredients (APIs) from FDA-registered facilities and adhere to United States Pharmacopeia (USP) standards for quality and sterile preparations, the resulting product does not undergo the same rigorous, molecule-specific review as a commercially manufactured drug.

This creates a different risk profile. The responsibility for verifying the quality of the peptide API often falls more heavily on the compounding pharmacy itself, making their choice of supplier and their internal quality control processes absolutely paramount for patient safety.

Academic

The conventional regulatory paradigm, while robust, is fundamentally a reactive system. It focuses on exhaustively testing a final product against a predefined set of specifications. A more sophisticated and scientifically elegant approach, now strongly advocated by regulatory bodies like the FDA, is Quality by Design (QbD).

This represents a fundamental shift in the philosophy of pharmaceutical manufacturing. QbD is a systematic, proactive, and risk-based methodology that builds quality into the product from the earliest stages of development. It is predicated on the principle that quality can be assured by a deep, mechanistic understanding of the product and its manufacturing process, rather than by end-product testing alone.

For complex biomolecules like therapeutic peptides, QbD is particularly powerful. The subtle interplay of hundreds of process variables can influence critical attributes of the final molecule, such as its folding, aggregation state, and impurity profile, which in turn dictate its clinical safety and efficacy.

The QbD framework provides the tools to map these intricate relationships, moving the manufacturing process from a rigid, fixed recipe to an adaptable, science-driven operation. This approach is not merely a regulatory preference; it is the embodiment of advanced process science, aimed at creating a state of control that ensures consistent quality with every single batch.

The Core Tenets of Quality by Design

The implementation of QbD follows a logical and structured progression, beginning with the clinical outcome in mind and working backward to define the process parameters necessary to achieve it. This systematic approach ensures that all efforts are focused on aspects that are truly critical to the patient.

Defining the Quality Target Product Profile

The entire QbD process begins with the patient. The Quality Target Product Profile (QTPP) is a prospective summary of the quality characteristics of a drug product that ideally will be achieved to ensure the desired quality, taking into account safety and efficacy.

For a peptide like Sermorelin, the QTPP would include not just its identity and concentration, but also its route of administration (subcutaneous injection), its sterility, its pH, and its stability profile. It defines what the product must be to be effective and safe for the patient. Every subsequent step in the QbD process is designed to ensure this profile is met.

Identifying Critical Quality Attributes

Once the QTPP is defined, the next step is to identify the Critical Quality Attributes (CQAs) of the drug substance and drug product. A CQA is a physical, chemical, biological, or microbiological attribute or characteristic that should be within an appropriate limit, range, or distribution to ensure the desired product quality. For a therapeutic peptide, CQAs are numerous and include:

- Primary Structure ∞ The correct amino acid sequence.

- Higher-Order Structure ∞ The correct three-dimensional folding, which is essential for biological activity.

- Impurity Profile ∞ The levels of specific product-related and process-related impurities. An impurity that could provoke an immune response would be a CQA.

- Aggregation ∞ The tendency of peptide molecules to clump together, which can reduce efficacy and increase immunogenicity risk.

- Potency ∞ The quantitative measure of biological activity.

Identifying CQAs requires a deep understanding of the molecule’s mechanism of action and its potential failure modes. This is where a systems-biology perspective becomes invaluable, connecting a molecular attribute to a physiological outcome.

How Does QbD Handle Manufacturing Variability?

The central innovation of QbD is the development of a “Design Space.” The Design Space is the multidimensional combination and interaction of input variables (e.g. material attributes) and process parameters that have been demonstrated to provide assurance of quality. Working within the Design Space is not considered a change.

Moving out of it is. To establish this space, manufacturers perform multivariate experiments to model the relationship between Critical Process Parameters (CPPs) ∞ such as temperature, pH, or reaction time ∞ and the CQAs. For example, they might systematically vary the temperature and pH during a purification step to understand how that combination affects the level of a specific aggregate (a CQA).

Quality by Design transforms pharmaceutical manufacturing from a rigid, historically-based process to a flexible, scientifically-grounded system that ensures quality by deeply understanding and controlling process variables.

This data is used to create a mathematical model of the process. The resulting Design Space is an operational zone where, as long as the CPPs are maintained within its boundaries, the CQAs of the peptide will reliably meet their targets. This allows for unprecedented manufacturing flexibility and a focus on continuous improvement.

It also fundamentally changes the dialogue with regulators. A manufacturer can present a Design Space as evidence of their process understanding, providing a scientific basis for real-time adjustments and process optimizations without needing to file a new regulatory submission for every minor change.

The following table contrasts the traditional quality approach with the Quality by Design framework:

| Aspect | Traditional Approach | Quality by Design (QbD) Approach |

|---|---|---|

| Focus |

Empirical; based on batch history and end-product testing. |

Systematic and scientific; based on product and process understanding. |

| Process |

Fixed and validated at a specific operating point. |

Adjustable within the Design Space. Process is understood. |

| Quality Control |

Testing the final product to confirm it meets specifications (quality by testing). |

Built into the product and process from the start (quality by design). Real-time release is possible. |

| Regulatory Interaction |

Submissions are based on batch data. Changes require extensive regulatory post-approval submissions. |

Submissions are based on knowledge and risk management. Flexibility within the Design Space is possible. |

Ultimately, the QbD framework represents the pinnacle of pharmaceutical quality assurance. It aligns manufacturing science directly with clinical outcomes, ensuring that the complex process of creating a therapeutic peptide is guided at every step by the ultimate goal ∞ delivering a safe, pure, and potent molecule that can precisely and reliably interact with the patient’s own biological systems to restore health and function.

References

- Duncan, Katharine. “FDA’s Katharine Duncan on CMC Expectations for Therapeutic Peptides.” International Pharmaceutical Quality Consortium, 21 May 2024.

- Malav, Yogesh K. et al. “Regulatory Considerations for Peptide Therapeutics.” Peptide and Protein-Based Therapeutics, edited by Shaji J. George and V. J. V. Kumar, Royal Society of Chemistry, 2019, pp. 1-28.

- U.S. Food and Drug Administration. “Guidance for Industry ∞ Process Validation ∞ General Principles and Practices.” FDA, Jan. 2011.

- Teixido, M. et al. “Regulatory Guidelines for the Analysis of Therapeutic Peptides and Proteins.” Pharmaceuticals, vol. 18, no. 2, 2025, p. 87.

- Wu, L.C. et al. “Bioanalytical approaches for the quantitation of therapeutic peptides in biological matrices.” International Journal of Pharmaceutics, vol. 518, no. 1-2, 2017, pp. 320-334.

Reflection

You began this exploration with the lived reality of your own body ∞ the fatigue, the mental fog, the sense that your internal harmony is off-key. The journey through the intricate world of regulatory standards, from the foundational pillars of identity and purity to the sophisticated science of Quality by Design, leads back to this very personal starting point.

The complex regulations are not an abstract bureaucracy. They are the structured, scientific expression of a single, vital goal ∞ to ensure that the molecule you introduce into your system is a pure, potent, and precise signal, capable of restoring a specific biological conversation.

Your Path Forward

This knowledge provides a new lens through which to view your health journey. It transforms you from a passive recipient of a therapy into an informed participant. Understanding the immense scientific effort required to guarantee the quality of a pharmaceutical-grade peptide illuminates the importance of sourcing and discernment.

It equips you to ask more precise questions of your clinical partners and to appreciate the profound difference between a molecule that is simply available and one that is verifiably pure and active. The path to recalibrating your body’s systems is a partnership between your commitment and the precision of the tools you use.

The science of quality assurance is the silent, essential partner in that process, working to ensure that your efforts to reclaim vitality are built on a foundation of molecular certainty.