Fundamentals

You feel it when your system is out of sync. It might manifest as a persistent fatigue that sleep doesn’t resolve, a subtle shift in your metabolism, or a change in your mood that you can’t quite pinpoint. These experiences are valid, and they often point to deeper biological narratives unfolding within your body.

When we consider therapeutic interventions, particularly those involving peptides, the conversation naturally turns to their composition. The question of what regulatory requirements govern peptide purity in pharmaceutical manufacturing is deeply personal. It is a question about the safety and integrity of what you are putting into your body to restore balance.

The answer begins with understanding that the agencies overseeing these protocols, like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), operate from a foundational principle of patient safety. They establish a framework known as Good Manufacturing Practices (GMP) to ensure every therapeutic peptide is produced with consistent quality and is free from harmful contaminants.

This journey into understanding peptide regulation is an act of self-advocacy. It involves appreciating the meticulous science required to create a therapeutic agent that your body can recognize and use effectively. Peptides are short chains of amino acids, the very building blocks of proteins, which act as precise signaling molecules within our endocrine and metabolic systems.

Their power lies in their specificity. An impurity, which could be an incorrect amino acid sequence or a residual chemical from the manufacturing process, can alter this specificity. This could render the peptide ineffective or, more seriously, cause an unintended and adverse reaction.

Therefore, the regulatory standards are designed to protect the intricate communication network of your body. They are a clinical extension of the foundational principle of medicine to first do no harm, ensuring that any intervention aimed at restoring your vitality is both safe and effective.

Regulatory agencies establish Good Manufacturing Practices as the foundational framework for ensuring the safety, efficacy, and quality of all therapeutic peptides.

The core of these regulations is the mandate for a robust Quality Management System (QMS). This system is the operational blueprint for every stage of peptide production, from the initial synthesis to the final packaging. It requires manufacturers to proactively identify and mitigate risks, ensuring that each batch of a peptide meets stringent specifications for identity, purity, and potency.

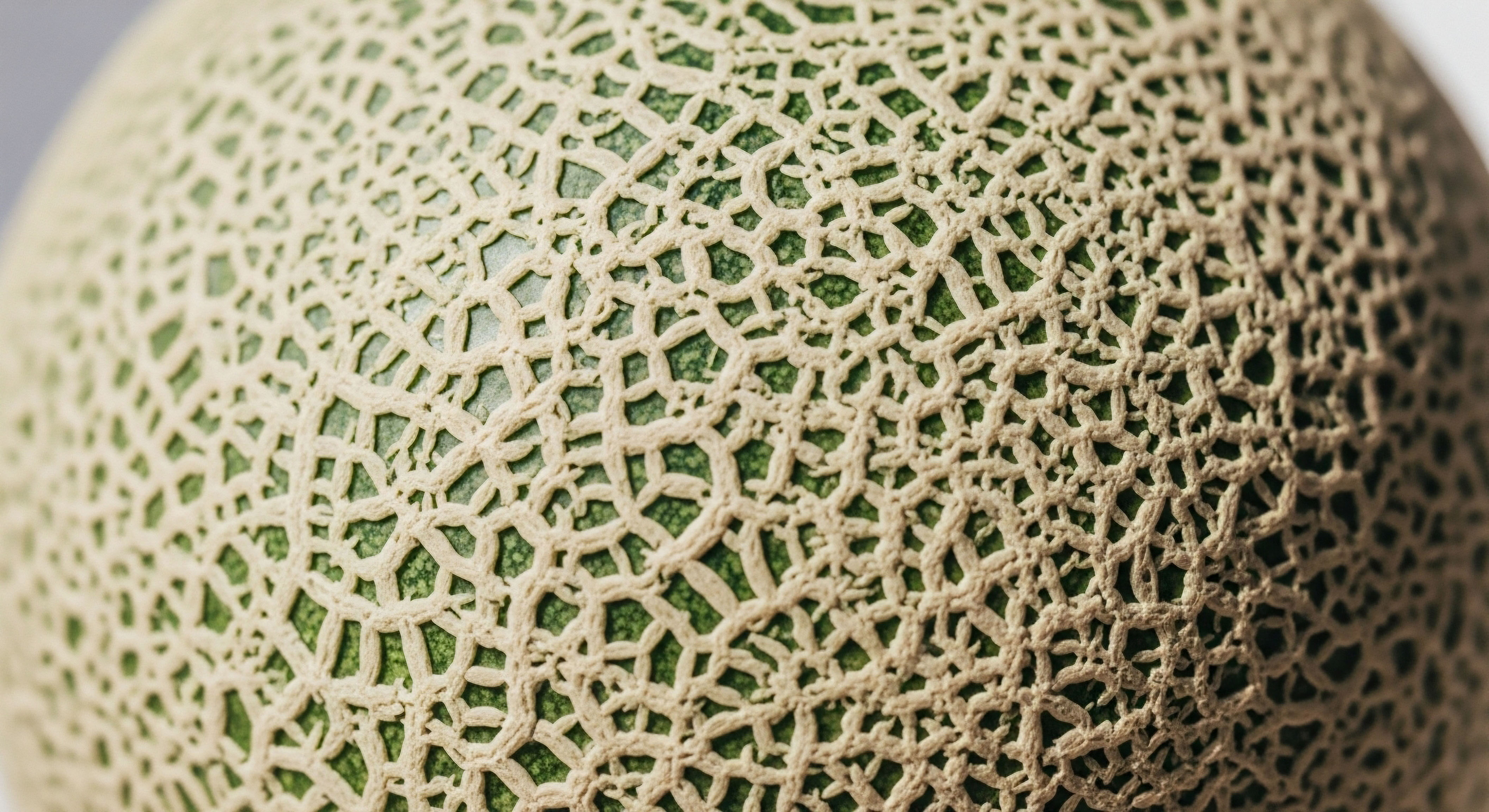

Think of it as a series of checkpoints. At each critical step, the peptide is tested and verified. This meticulous process ensures that the final product is precisely what it claims to be, with a purity level that is often required to be above 97%.

This level of precision is necessary because your body’s hormonal systems operate with exquisite sensitivity. The introduction of a therapeutic peptide must be a clean signal, unburdened by the noise of impurities. Understanding this helps to connect the dots between a regulatory document and your personal health journey. The numbers on a lab report and the guidelines in a federal code are all part of a larger system designed to support your body’s return to optimal function.

Intermediate

For those already familiar with the basics of hormonal health, the regulatory landscape for peptide purity can be understood as a sophisticated dialogue between the manufacturer and regulatory bodies. This dialogue is documented in the Chemistry, Manufacturing, and Controls (CMC) section of a drug application.

The CMC is where the scientific evidence for a peptide’s quality is presented, and it is scrutinized with exacting detail. The primary tool for assessing purity is High-Performance Liquid Chromatography (HPLC), a powerful analytical technique that separates the target peptide from any impurities.

The resulting chromatogram provides a visual representation of the peptide’s purity, with the main peak representing the active pharmaceutical ingredient (API) and smaller peaks indicating impurities. Regulators require that the HPLC method be validated, meaning it must be proven to be accurate, precise, and reliable for its intended purpose.

The regulatory requirements extend beyond simply identifying the purity level. They demand a comprehensive characterization of the impurities themselves. This is where the science becomes particularly granular. Impurities are categorized based on their origin. Process-related impurities might include residual solvents or reagents used during synthesis.

Product-related impurities could be molecules with incorrect sequences, such as deletion sequences where an amino acid is missing. Each of these has the potential to affect the peptide’s biological activity or safety profile. For instance, an impurity with a similar structure to the active peptide could compete for the same receptor, diminishing the therapeutic effect. Consequently, regulatory guidelines, such as those from the International Council for Harmonisation (ICH), provide a framework for setting acceptable limits for these impurities.

How Are Impurity Thresholds Determined?

The process of setting impurity thresholds is a risk-based assessment. It considers the potency of the peptide, the daily dose, and the potential toxicity of the impurity. For many peptide products, a common specification is that no single impurity should exceed 1% of the total peptide content.

This is a general benchmark, and the specific limits for a given peptide are established based on extensive stability and toxicology studies. These studies are designed to understand how the peptide degrades over time and to ensure that any potential impurities are safe at the levels they are present. This rigorous approach provides a high degree of confidence in the quality and safety of the final product.

High-Performance Liquid Chromatography is the cornerstone analytical technique for separating and quantifying peptide purity, providing a detailed profile for regulatory review.

To further illustrate the specificity required, consider the following table outlining common analytical tests mandated for peptide characterization and their purposes:

| Analytical Test | Purpose in Demonstrating Purity and Identity |

|---|---|

| High-Performance Liquid Chromatography (HPLC) | Separates the main peptide from impurities to determine purity and quantify the amount of the active ingredient. |

| Mass Spectrometry (MS) | Confirms the molecular weight of the peptide, verifying its identity and helping to characterize any detected impurities. |

| Amino Acid Analysis (AAA) | Determines the amino acid composition of the peptide, ensuring the correct building blocks are present in the correct ratios. |

| Peptide Mapping | Provides a “fingerprint” of the peptide by breaking it into smaller fragments and analyzing the pattern, which confirms the correct sequence. |

These tests, when used in combination, provide a comprehensive picture of the peptide’s quality. They allow manufacturers to demonstrate to regulators that they have robust control over their manufacturing process and can consistently produce a high-purity product. This level of analytical rigor is what underpins the trust that both clinicians and patients place in these advanced therapies.

It is the scientific foundation upon which personalized wellness protocols are built, ensuring that the therapeutic signals being introduced into your body are clear, precise, and aligned with your health goals.

Academic

From an academic and clinical perspective, the regulatory framework governing peptide purity is a direct reflection of our evolving understanding of molecular biology and its therapeutic applications. Peptides occupy a unique space between small-molecule drugs and larger biologics, and this has historically presented regulatory challenges.

The primary guidance document in the United States has been the “Guidance for Industry for the Submission of Chemistry, Manufacturing, and Controls Information for Synthetic Peptide Substances,” issued in 1994. While this document provides a foundational framework, the increasing complexity of synthetic peptides and their diverse mechanisms of action necessitate a more nuanced, systems-biology approach to quality assessment. The regulatory expectation is for a deep molecular understanding of the product, extending far beyond a simple percentage purity value.

The core of this advanced assessment lies in the concept of the “quality target product profile” (QTPP). The QTPP defines the desired characteristics of the final drug product, including its purity, potency, and stability. This profile is then used to guide the development of the manufacturing process and the analytical methods used for its control.

The focus is on understanding the potential critical quality attributes (CQAs) of the peptide, which are the physical, chemical, biological, or microbiological attributes that should be within an appropriate limit, range, or distribution to ensure the desired product quality. For peptides, CQAs often include aspects like secondary structure, aggregation potential, and the presence of specific post-translational modifications, all of which can be influenced by impurities.

What Is the Role of Orthogonal Analytical Methods?

To provide a comprehensive characterization of a peptide and its impurity profile, regulators expect the use of orthogonal analytical methods. These are distinct analytical techniques that measure the same attribute using different scientific principles. For example, while reverse-phase HPLC is the standard for purity analysis, it may not be able to separate certain isomeric impurities.

In such cases, an orthogonal method like ion-exchange chromatography or capillary electrophoresis might be employed. The use of multiple, complementary methods provides a much higher degree of confidence in the quality assessment. The following list outlines key considerations in an advanced analytical control strategy:

- Forced Degradation Studies These studies intentionally expose the peptide to harsh conditions (e.g. heat, light, oxidation) to identify potential degradation products. This information is then used to develop stability-indicating analytical methods.

- Chiral Purity Analysis Because amino acids can exist in different stereoisomers (L- and D-forms), it is essential to ensure the chiral purity of the peptide, as the incorrect isomer can be inactive or even immunogenic.

- Host-Cell Protein Analysis For peptides produced via recombinant DNA technology, it is necessary to quantify and control for residual proteins from the host cells used in production.

The integration of orthogonal analytical methods and a deep understanding of critical quality attributes forms the basis of a modern, risk-based approach to ensuring peptide purity.

The ultimate goal of this rigorous, multi-faceted approach is to ensure the therapeutic consistency and safety of every batch of a peptide drug. The table below contrasts the traditional approach to quality control with the modern, CQA-focused paradigm that is increasingly expected by regulatory authorities.

| Aspect of Quality Control | Traditional Approach | Modern CQA-Focused Approach |

|---|---|---|

| Process Development | Empirical, based on trial and error. | Systematic, based on a deep understanding of the product and process. |

| Analytical Strategy | Relies on a limited set of standard tests. | Employs a suite of orthogonal, validated methods targeted at specific CQAs. |

| Impurity Control | Focuses on meeting a general purity specification. | Involves identifying, characterizing, and controlling specific impurities based on their potential risk. |

| Regulatory Submission | Presents a fixed set of data from the final product. | Provides a comprehensive narrative demonstrating control over the entire manufacturing process. |

This evolution in regulatory science reflects a deeper appreciation for the complexity of biological systems. It acknowledges that restoring hormonal or metabolic function requires therapeutic agents of the highest possible quality and purity. For the clinician and the patient, this academic rigor is profoundly practical.

It is the silent, meticulous work that happens in the background to ensure that when a peptide therapy is prescribed, it is with the full confidence that the molecule is precisely what is needed to interact with the body’s own systems and guide it back toward a state of health and vitality.

References

- U.S. Food and Drug Administration. “Guidance for Industry ∞ CGMP for Phase 1 Investigational Drugs.” 2008.

- Polypeptide Group. “Quality control in peptide manufacturing ∞ specifications for GMP peptides.” 2010.

- International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use. “ICH Harmonised Tripartite Guideline ∞ Specifications ∞ Test Procedures and Acceptance Criteria for New Drug Substances and New Drug Products ∞ Chemical Substances Q6A.” 1999.

- U.S. Food and Drug Administration. “Guidance for Industry for the Submission of Chemistry, Manufacturing, and Controls Information for Synthetic Peptide Substances.” 1994.

- Mire-Sluis, A. et al. “Regulatory Considerations for Peptide Therapeutics.” Royal Society of Chemistry, 2019.

Reflection

Having explored the intricate systems that regulate peptide purity, the path forward becomes clearer. This knowledge is more than academic; it is a tool for informed decision-making on your personal health journey. The stringent standards and meticulous testing are in place to honor the complexity of your own biology.

They exist to ensure that any step you take to reclaim your vitality is built on a foundation of safety and precision. The next chapter in your story involves translating this understanding into a personalized dialogue with a qualified clinician.

It is about asking the right questions, interpreting your own body’s signals, and co-creating a protocol that is uniquely yours. The potential for optimized health is immense, and it begins with this commitment to understanding the science that supports your journey.

Glossary

peptide purity

food and drug administration

good manufacturing practices

quality management system

your personal health journey

cmc

high-performance liquid chromatography

api

international council for harmonisation

analytical methods

critical quality attributes