Fundamentals

Your journey toward understanding your own biological systems begins with a foundational question. When you consider introducing a therapeutic agent into your body, a profound sense of diligence is activated. You begin to ask not just what it does, but what it is.

This line of inquiry is particularly salient when we approach the world of peptides. These small chains of amino acids Meaning ∞ Amino acids are fundamental organic compounds, essential building blocks for all proteins, critical macromolecules for cellular function. function as precise biological messengers, keys designed to fit specific molecular locks within your body’s intricate communication network. The effectiveness and safety of these keys depend entirely on their structural integrity.

When we discuss peptide purity, we are truly discussing the fidelity of that key. A purely synthesized peptide is the exact key, shaped correctly to turn a specific lock and initiate a desired physiological response, such as signaling for tissue repair or modulating hormone production.

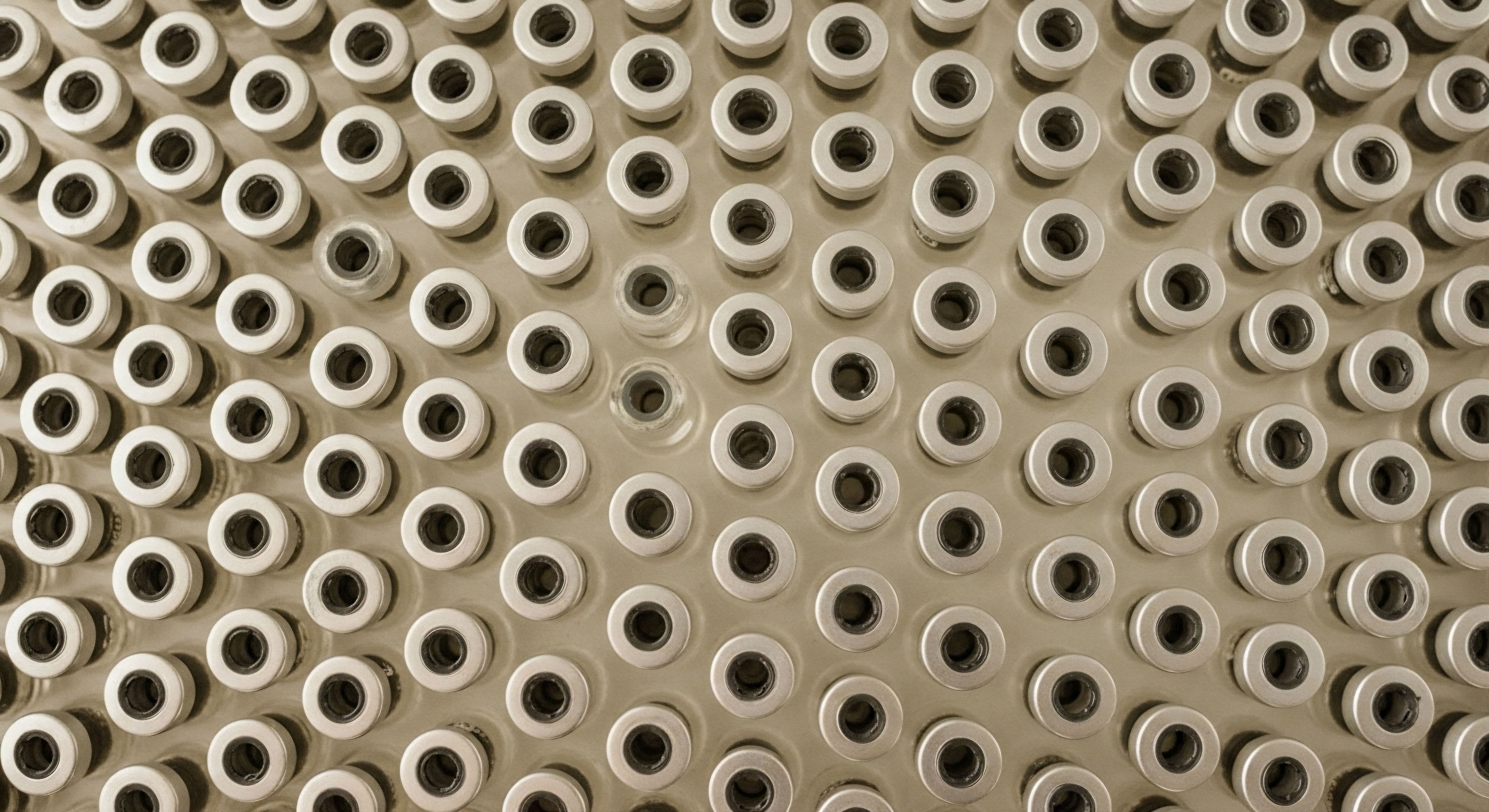

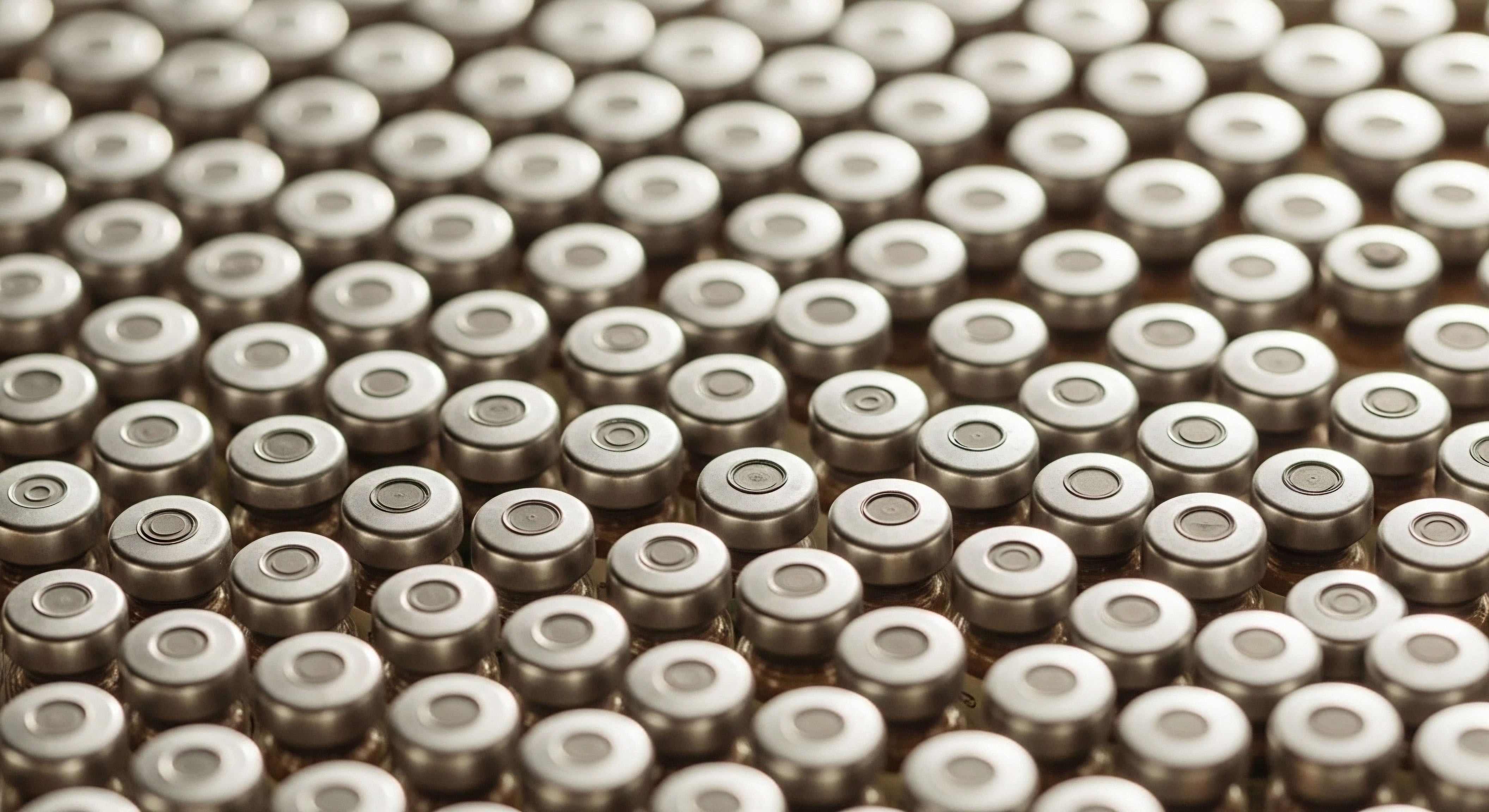

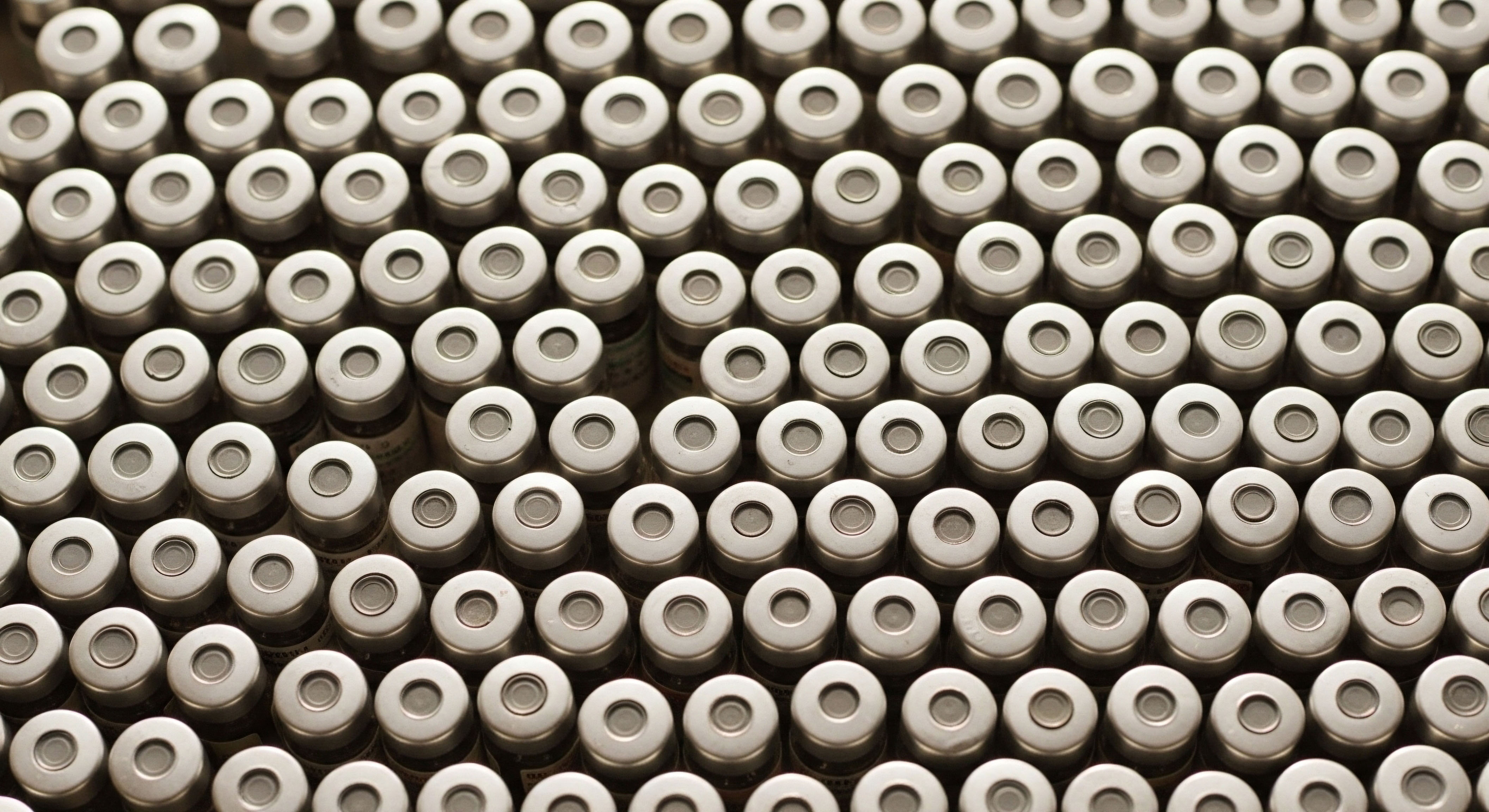

The concept of reconstitution introduces another layer of personal responsibility and biochemical precision. Most therapeutic peptides are produced in a lyophilized, or freeze-dried, state. This powdered form represents a state of suspended animation, preserving the peptide’s delicate structure until the moment of use.

Reconstitution is the process of reawakening it, typically by mixing it with a sterile liquid like bacteriostatic water. The method and care with which this is done directly impact the final product’s viability. It is a clinical procedure performed outside of a clinical setting, a moment where you become an active participant in ensuring the therapy’s potential.

Understanding the standards that govern both the purity of the initial product and the sterile techniques for its preparation is the first step in transforming a vial of powder into a safe and effective biological tool.

The Language of Purity

In the world of therapeutic compounds, purity is an exacting language measured in percentages. A peptide preparation labeled as 99% pure contains 99 parts of the intended amino acid sequence for every one part of something else. That “something else” is a collection of impurities, the inevitable byproducts of even the most sophisticated chemical synthesis.

These are not benign bystanders. They can include truncated or incomplete peptide chains, sequences with missing amino acids, or molecules that failed to fold into their correct three-dimensional shape. Each of these molecular errors represents a key that is misshapen. It may fail to fit the lock, do nothing at all, or, more concerningly, fit partially and jam the mechanism. In some instances, these impurities can even trigger an unintended and adverse response from the immune system.

Regulatory bodies like the U.S. Food and Drug Administration Meaning ∞ The Food and Drug Administration (FDA) is a U.S. (FDA) have established stringent purity thresholds for any peptide intended for human therapeutic use. For a compound to be considered for clinical trials and eventual approval as a prescription medication, its purity must typically meet or exceed 95%, with many pharmaceutical-grade products achieving greater than 98% purity.

This standard is not arbitrary; it is a scientifically determined benchmark designed to ensure that the vast majority of molecules in a preparation are the active, intended therapeutic agent. This minimizes the risk of off-target effects and ensures a predictable, reliable dose with every administration. The journey of a peptide from a laboratory synthesis to a pharmacy shelf is a testament to this rigorous commitment to purity, a process designed entirely around patient safety and therapeutic consistency.

A peptide’s purity is the direct measure of its potential for a precise biological effect, distinguishing the intended therapeutic signal from molecular noise.

Reconstitution a Protocol of Activation

Reconstitution is the bridge between a peptide’s stable, powdered form and its active, injectable state. The process requires meticulous attention to sterility and measurement. The choice of diluent, the liquid used for mixing, is the first critical decision.

Bacteriostatic water, which is sterile water Meaning ∞ Sterile water is a highly purified form of water, meticulously processed to eliminate all viable microorganisms, bacterial endotoxins, and particulate matter. containing a small amount of a preservative agent, is often used for multi-use vials as it inhibits bacterial growth. Sterile water, lacking this agent, is typically intended for single-use applications. The goal is to create a solution that is both effective and safe for administration, free from microbial contamination that could cause infection.

The physical act of reconstitution also demands a gentle hand. Peptides are complex, folded molecules, and their structure can be damaged by aggressive handling. The process involves slowly introducing the diluent into the vial, allowing it to run down the side of the glass rather than spraying it directly onto the lyophilized powder.

The vial is then gently swirled or rolled between the hands until the powder is fully dissolved. Shaking the vial can shear the peptide chains, breaking them apart and rendering them ineffective. This careful protocol ensures that the reawakened peptide retains its precise three-dimensional shape, the very shape that allows it to bind to its target receptor and perform its function.

Each step is a deliberate action aimed at preserving the molecule’s integrity, ensuring that what is drawn into the syringe is the same potent, correctly formed messenger that was so carefully purified at its creation.

Intermediate

Navigating the landscape of peptide acquisition reveals a stark bifurcation in regulatory philosophy. On one path lies the world of FDA-approved pharmaceutical peptides, governed by a transparent, deeply rigorous framework. On the other path lies the vast, opaque market of products sold under the label “for research use only” (RUO).

Understanding the profound differences between these two worlds is essential for anyone considering these therapies. The oversight that exists for an FDA-approved peptide like Tesamorelin, prescribed for specific metabolic conditions, is fundamentally different from the oversight for a vial of CJC-1295/Ipamorelin purchased from an online supplier.

The divergence is not a matter of degree; it is a matter of entirely separate regulatory universes, one built on accountability and patient safety, and the other on a legal disclaimer that shifts all responsibility to the end-user.

The FDA’s authority is anchored in the Food, Drug, and Cosmetic Act. For a peptide to be legally marketed as a drug, its manufacturer must provide exhaustive proof of its identity, purity, potency, and safety through a process called an Investigational New Drug (IND) application, followed by multi-phase clinical trials.

This process scrutinizes every aspect of the product, from the raw materials used in its synthesis to the stability of the final, reconstituted solution. The standards for purity are absolute and non-negotiable, verified by specific analytical methods like High-Performance Liquid Chromatography Meaning ∞ High-Performance Liquid Chromatography, commonly known as HPLC, is an advanced analytical chemistry technique used to separate, identify, and quantify individual components within a complex liquid mixture. (HPLC), which separates the target peptide from any synthesis-related impurities.

Conversely, the RUO market operates in a regulatory vacuum. These products are not intended for human use, and therefore, they are not subject to FDA oversight regarding their manufacturing standards, purity, or sterility. The purity percentage advertised by an RUO supplier is a self-reported claim, often unverified by any independent or regulatory body.

This creates a significant knowledge gap for the individual, who must place their trust in the supplier’s internal quality control, a process that lacks the transparency and external validation inherent in the pharmaceutical supply chain.

The Pharmaceutical Standard a Mandate for Purity

When a physician prescribes a peptide, they are prescribing a product that has successfully navigated one of the most demanding regulatory pathways in the world. The FDA, in concert with international bodies like the International Council for Harmonisation (ICH), mandates a suite of quality controls known as Chemistry, Manufacturing, and Controls (CMC).

These guidelines require manufacturers to characterize their product with extreme detail. This involves not just confirming the peptide’s primary amino acid sequence but also its three-dimensional structure, which is often essential for its biological activity. Furthermore, they must develop and validate analytical methods to create a detailed impurity profile. This profile identifies and quantifies every significant byproduct of the synthesis, from small organic molecules to incorrectly formed peptide chains. Each impurity is assessed for its potential toxicity or immunogenicity.

The table below illustrates the stark contrast in requirements between a pharmaceutical-grade peptide and a typical RUO product.

| Quality Attribute | FDA-Approved Pharmaceutical Peptide | “Research Use Only” (RUO) Peptide |

|---|---|---|

| Purity Verification | Mandatory HPLC analysis with a certificate of analysis (COA) from a third-party, GMP-certified lab. Purity typically ≥95%. | Self-reported purity, often without independent verification. The provided COA may be from an in-house, uncertified lab. |

| Impurity Profiling | Required identification and toxicological assessment of all significant impurities. | Generally absent. The nature and quantity of impurities are unknown. |

| Endotoxin Testing | Mandatory testing for bacterial endotoxins (lipopolysaccharides), which can cause severe inflammatory reactions. Strict limits are enforced. | Optional and often skipped to reduce costs. The risk of endotoxin contamination is significant. |

| Sterility Assurance | Manufactured under sterile conditions (aseptic processing) and subject to mandatory sterility testing. | No guarantee of sterility. Vials may be filled in non-sterile environments, posing an infection risk. |

| Reconstitution Guidance | Provided with precise, validated instructions for reconstitution, including the specific diluent and handling procedures. | No official instructions. Users rely on anecdotal information from online forums or other unregulated sources. |

What Does Research Use Only Truly Mean?

The “research use only” disclaimer is a legal construct that allows manufacturers to sell substances that have not been approved for human consumption. By purchasing an RUO product, the buyer is implicitly agreeing that they will not be using it on themselves or any other human.

This label effectively removes the product from the FDA’s jurisdiction over drugs and places it in a category akin to any other laboratory chemical. Consequently, there are no federal standards for the purity, sterility, or accurate labeling of these products. While some RUO suppliers may be diligent about their quality control, others may not. The financial incentive to cut corners is substantial, as the rigorous processes of purification and testing are the most expensive parts of peptide manufacturing.

This lack of oversight extends directly to the reconstitution process. An FDA-approved medication comes with a package insert that provides explicit, validated instructions on how to prepare it for injection. This includes the exact type and volume of diluent to use, storage conditions for the reconstituted solution, and its beyond-use date.

For RUO peptides, no such validated information exists. The user is left to crowdsource protocols from the internet, a practice fraught with risk. Incorrect reconstitution can lead to a loss of potency, degradation of the peptide, or, in the case of non-sterile technique, a serious systemic infection. The burden of ensuring safety and efficacy is transferred entirely from the manufacturer to the individual.

The regulatory divide between pharmaceutical and research-grade peptides creates two distinct realities of safety and accountability.

How Are Reconstitution Standards Determined?

For pharmaceutical peptides, reconstitution standards are determined through rigorous stability studies conducted as part of the FDA approval process. Scientists test the peptide with various diluents (e.g. sterile water, bacteriostatic water, saline) to see which one best preserves its chemical structure and biological activity Meaning ∞ Biological activity defines the specific, measurable effects a substance or process exerts on a living organism, cell, or biological system. over time.

They perform stress tests, exposing the reconstituted solution to different temperatures and light conditions to determine its degradation curve. From this data, they establish a precise protocol that guarantees the peptide will remain stable and potent for a specific period after being mixed. This is why a prescription medication will have a clear expiration date and specific storage instructions, such as “refrigerate after reconstitution and discard after 14 days.”

In the RUO market, these studies are not performed. Any guidance on reconstitution is based on the chemical properties of peptides in general, not the specific product in the vial. For example, it is known that peptides are susceptible to oxidation and hydrolysis, so refrigeration is recommended.

It is known that bacteriostatic water Meaning ∞ Bacteriostatic water is a sterile aqueous solution containing a bacteriostatic agent, typically 0.9% benzyl alcohol, designed to inhibit the growth of most common bacteria. can help prevent contamination in multi-use vials. This general knowledge is a far cry from the product-specific, validated data that underpins pharmaceutical standards. The user must assume that the general principles apply to their specific, unverified product, introducing another layer of uncertainty into their therapeutic protocol.

Academic

The regulatory dichotomy between pharmaceutical and research-grade peptides is predicated on intended use, yet the biochemical reality of their interaction with human physiology is identical. A molecule of Ipamorelin Meaning ∞ Ipamorelin is a synthetic peptide, a growth hormone-releasing peptide (GHRP), functioning as a selective agonist of the ghrelin/growth hormone secretagogue receptor (GHS-R). does not behave differently at a cellular level based on the label on its vial.

The critical distinction lies in the verifiable purity and structural integrity of the molecule being administered. The oversight framework for approved therapeutics is designed to mitigate the inherent risks of peptide synthesis and handling, risks that are magnified in the unregulated space.

From a clinical and biochemical perspective, the primary concerns are not just the absence of the intended therapeutic effect, but the potential for deleterious off-target activity from unidentified contaminants. These contaminants are not inert; they are structurally related molecules that can possess their own, often unpredictable, biological activity.

The gold standard for peptide purification and analysis is Reverse-Phase High-Performance Liquid Chromatography (RP-HPLC) coupled with Mass Spectrometry (MS). This combination of technologies allows for both the separation and identification of the target peptide from a complex mixture of synthesis byproducts. RP-HPLC separates molecules based on their hydrophobicity.

As a solvent gradient is passed through a column packed with a nonpolar stationary phase, the target peptide and its impurities elute at characteristic times, generating a chromatogram. The area under the peak corresponding to the target peptide, relative to the total area of all peaks, defines the purity percentage.

Mass Spectrometry then confirms the molecular weight of the substance in each peak, verifying that the main peak is indeed the correct peptide and helping to identify the nature of the impurities. This analytical rigor is a mandatory component of any CMC package submitted to the FDA. It provides a molecular fingerprint of the drug substance, ensuring batch-to-batch consistency and safety.

The Molecular Consequences of Impurity

Peptide synthesis is an imperfect process. The most common method, solid-phase peptide synthesis (SPPS), involves the sequential addition of amino acids to a growing chain. At each step, a small fraction of the reactions may fail to complete, leading to a variety of potential impurities. Understanding the nature of these impurities is central to appreciating the necessity of stringent regulatory oversight.

- Truncated Sequences These are peptides where the synthesis process terminated prematurely. A truncated version of a growth hormone secretagogue, for example, may be completely inactive or could potentially act as a competitive antagonist, binding to the ghrelin receptor without activating it and thereby blocking the action of the full-length, active peptide.

- Deletion Sequences In this case, one or more amino acids are missing from the middle of the chain. This can dramatically alter the three-dimensional folding of the peptide, potentially creating a novel structure that the immune system recognizes as foreign. This process, known as immunogenicity, can lead to the formation of anti-drug antibodies, which can neutralize the therapeutic effect of the peptide and even trigger systemic inflammatory responses.

- Diastereomeric Impurities Amino acids (with the exception of glycine) are chiral molecules, existing in left-handed (L) and right-handed (D) forms. Biological systems almost exclusively use L-amino acids. During synthesis, some amino acids can racemize, converting from the L-form to the D-form. The presence of even a single D-amino acid in a peptide sequence can prevent it from adopting its correct conformation, rendering it inactive or, in a more problematic scenario, giving it a completely different and unstudied biological activity.

- Residual Solvents and Reagents The synthesis process uses a variety of harsh organic solvents and chemical reagents. While the final purification steps are designed to remove these, incomplete purification can leave residual amounts in the final lyophilized powder. These substances can be directly toxic or can degrade the peptide over time, reducing its stability and potency.

The purity of a peptide is not a simple percentage but a complex assessment of its molecular fidelity, with direct implications for its interaction with biological systems.

Reconstitution Science Stability and Degradation Pathways

The act of reconstitution initiates a series of chemical processes that can affect the peptide’s viability. The introduction of water, the universal solvent, exposes the peptide to hydrolysis, where water molecules can break the amide bonds that link the amino acids together. This process is accelerated at non-neutral pH values and higher temperatures.

Another significant degradation pathway is oxidation, particularly for peptides containing susceptible amino acids like methionine, cysteine, or tryptophan. Dissolved oxygen in the reconstitution diluent can react with these residues, altering the peptide’s structure and function.

The table below details key considerations in reconstitution science, highlighting the variables that are controlled in a pharmaceutical setting and left to chance in the RUO domain.

| Parameter | Pharmaceutical Control | Unregulated Variable |

|---|---|---|

| pH of Diluent | The formulation includes buffering agents to maintain the pH at a level where the specific peptide has maximal stability. This is determined during development. | The pH of unbuffered bacteriostatic or sterile water can vary, potentially accelerating degradation for pH-sensitive peptides. |

| Presence of Excipients | Formulations may include cryoprotectants (like mannitol or sucrose) to protect the peptide during freeze-drying and stabilizing agents to prevent aggregation in solution. | RUO products contain only the peptide powder. There are no excipients to enhance stability upon reconstitution. |

| Oxidation Risk | Manufacturing and reconstitution protocols may specify the use of de-gassed, oxygen-poor water. Some formulations may include antioxidants. | Standard diluents contain dissolved oxygen, posing a risk to oxidation-prone peptides. The extent of degradation is unknown. |

| Aggregation Propensity | Peptide concentration and formulation are optimized to prevent self-aggregation, where peptide molecules clump together, reducing bioavailability and potentially causing an immune response. | The user determines the concentration by choosing the diluent volume. High concentrations can increase the risk of aggregation, an effect that is invisible to the naked eye. |

What Are the Gaps in Current Peptide Regulation?

The primary gap in the current regulatory framework is the existence of the “research use only” market itself. This binary system, which distinguishes between products based on their label rather than their content, creates a significant public health challenge.

The FDA has recently begun to address this, moving to place certain peptides that are commonly compounded into a category of substances with “Significant Safety Risks,” effectively limiting their use by compounding pharmacies. This action, however, does not directly impact the vast online market for RUO peptides sold directly to consumers.

The challenge for regulatory agencies is one of jurisdiction and intent. As long as a product is not explicitly marketed for human consumption, it falls outside the purview of drug safety regulations. This legal distinction fails to account for the reality of how these products are being used, placing the burden of risk assessment entirely on individuals who lack the analytical tools to verify the quality of what they are purchasing.

The future of peptide regulation may involve a more nuanced approach. This could include the creation of a third category for certain wellness and longevity agents, with standards for purity and manufacturing that are more rigorous than the current RUO market but perhaps different from the standards for life-saving drugs.

Until such a framework exists, the responsibility falls upon the clinical community to educate patients about the profound differences in quality, safety, and oversight between a prescribed, FDA-approved peptide and a product sourced from the unregulated market. The conversation must shift from a simple discussion of a peptide’s purported benefits to a more sophisticated analysis of its source, purity, and the verifiable data that supports its use.

References

- Thundimadathil, J. “Peptides in Clinical Development.” Peptide Information, 2012.

- U.S. Food and Drug Administration. “Guidance for Industry ∞ Bioanalytical Method Validation.” FDA, 2018.

- Lax, R. et al. “Regulatory Guidelines for the Analysis of Therapeutic Peptides and Proteins.” Journal of Pharmaceutical and Biomedical Analysis, vol. 31, 2022, e70001.

- DLRC Group. “Synthetic Peptides ∞ Understanding The New CMC Guidelines.” DLRC Group, 2023.

- Rupa Health. “Peptides ∞ What They Are, And Why The FDA Is Paying Attention.” Rupa Health, 2024.

Reflection

Your Personal Standard of Care

You have absorbed the technical distinctions, the regulatory frameworks, and the biochemical principles that define peptide quality. This knowledge does more than simply answer a question; it equips you with a new lens through which to view your own health protocols.

The journey from a lyophilized powder in a vial to a bioactive messenger in your bloodstream is a process you are now able to critically evaluate. The path you choose is a reflection of your personal standard of care, a standard informed by an understanding of the profound difference between a validated therapeutic agent and an unverified chemical compound.

Your body’s intricate hormonal and metabolic systems operate on a principle of precision. The information you now possess allows you to honor that principle, making choices that align with a commitment to safety, predictability, and genuine biological efficacy. This is the foundation of empowered wellness, where knowledge transforms you from a passive recipient into an active, informed architect of your own health.