Fundamentals

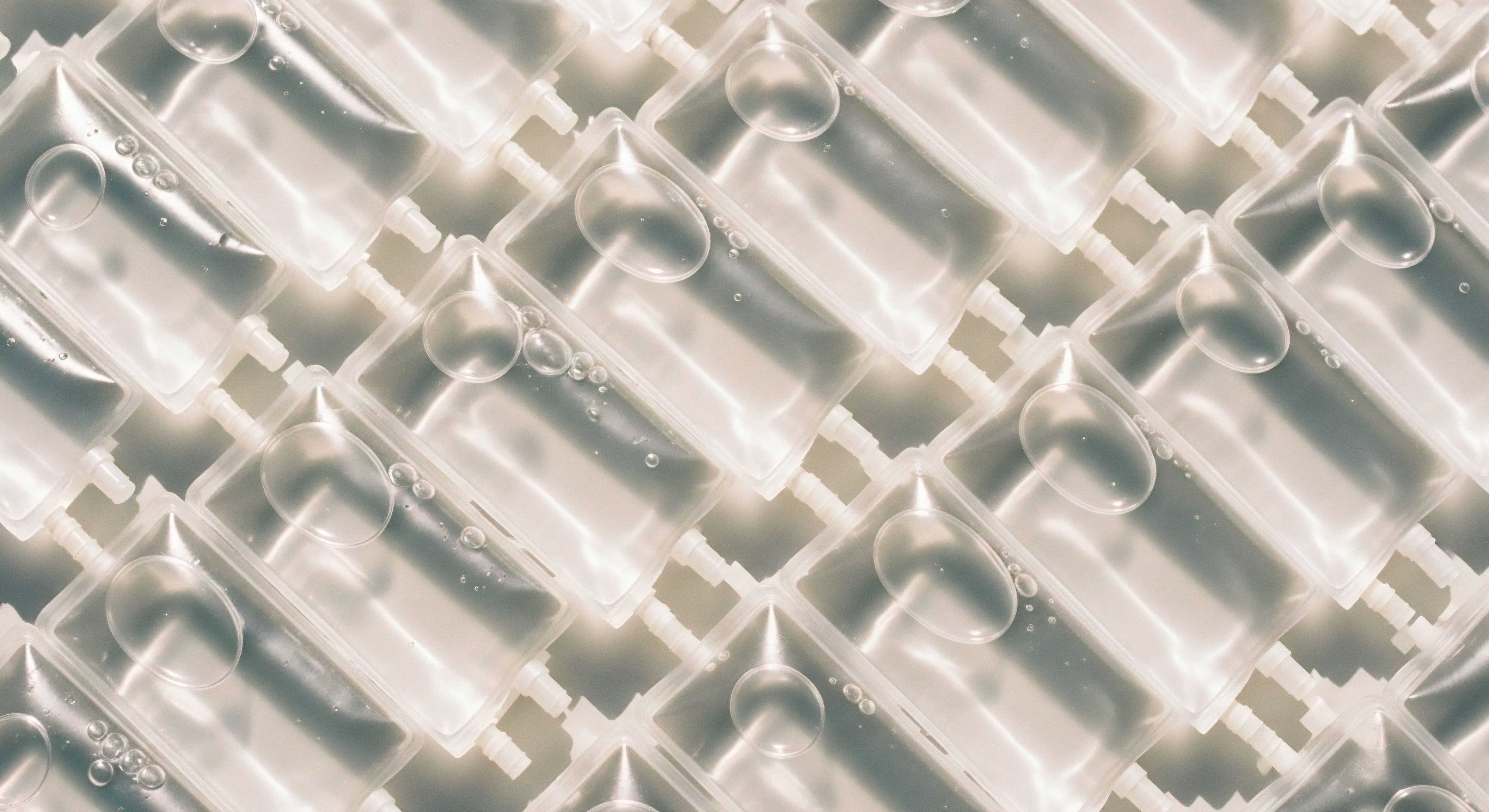

The decision to begin a personalized wellness protocol involving injectable therapies is a significant step in your health journey. It represents a commitment to understanding and recalibrating your body’s intricate systems. When you hold a vial of a compounded preparation, such as Testosterone Cypionate or a specific peptide blend like Ipamorelin, you are holding a key designed to unlock a higher level of function.

Central to this entire process is a silent, foundational promise made to you by the medical and pharmaceutical professionals you work with. This promise is one of absolute sterility.

Injectable medications are unique because they are introduced directly into your muscle tissue or bloodstream, completely bypassing the body’s powerful frontline defenses. The skin, the acidic environment of the stomach, and the complex ecosystem of the gut are all designed to neutralize foreign invaders. An injection site is a direct portal to your internal environment.

Consequently, the introduction of any microbial life ∞ bacteria, fungi, or spores ∞ can have serious consequences, leading to localized infections, systemic illness, or a dangerous immune response. The absolute absence of these microorganisms is what defines sterility. It is a state of being free from all viable microbes.

The sterility of an injectable preparation is the non-negotiable foundation upon which the safety and efficacy of your therapeutic protocol are built.

This is why the procedures ensuring the sterility of compounded injectables are so rigorous. A compounding pharmacy creates personalized medications tailored to your specific needs, as prescribed by your clinician. This could be a unique dosage of Testosterone, a combination of peptides for tissue repair, or a formulation of Gonadorelin to support your endocrine system.

Unlike mass-produced pharmaceuticals, these are often made individually or in small batches. This bespoke nature necessitates an unwavering adherence to a specialized set of procedural controls to prevent contamination at every single step.

The Human Element in a Sterile World

The process begins with a deep understanding of the invisible world of microbiology. The air we breathe, the surfaces we touch, and even our own skin are teeming with microorganisms. The professionals handling your medication must operate within a system designed to eliminate these variables.

They undergo extensive training to adopt a mindset where every action is considered for its potential to introduce contamination. Every movement, from washing their hands to handling a vial, is deliberate and follows a strict, scientifically validated protocol. This human factor, the disciplined and knowledgeable technician or pharmacist, is the most critical component in the entire chain of sterility.

The Environment as a Sanctuary

To support the human element, a highly controlled environment is constructed. This space, known as a cleanroom, is engineered to be a sanctuary from microbial contamination. The air is continuously filtered through High-Efficiency Particulate Air (HEPA) filters, which remove more than 99.97% of airborne particles of a specific size.

This creates a space where the primary sources of potential contamination have been systematically removed, allowing for the safe handling of sterile ingredients and preparations. The very architecture of these facilities is a testament to the seriousness with which sterility is approached, forming the physical bedrock of your safety.

Intermediate

To translate the principle of sterility into a consistent reality, compounding pharmacies adhere to a comprehensive set of standards. The primary guiding document in the United States is the United States Pharmacopeia (USP) General Chapter <797>. This chapter details the minimum procedural requirements for preparing compounded sterile preparations (CSPs), including the hormone and peptide therapies central to personalized wellness protocols. Adherence to USP <797> is the procedural backbone that ensures your injectable medication is safe.

The framework of USP <797> can be understood by examining its core pillars. Each pillar represents a critical control point in the compounding process, and failure in one area compromises the entire structure. These pillars work in concert to create a state of control over the compounding environment and process.

Facility Design and Engineering Controls

The physical space where compounding occurs is meticulously designed to control air quality. This involves a suite of rooms with increasing levels of cleanliness.

- The Ante-Room ∞ This is the initial entry point where personnel perform hand hygiene and don personal protective equipment (PPE). The air quality is controlled, typically at an ISO 8 standard, making it cleaner than a normal room.

- The Buffer Area ∞ This is the main cleanroom where the primary engineering control is located. It must maintain a higher level of air cleanliness, an ISO 7 environment. Access is restricted, and the materials brought into this area are carefully controlled.

- The Primary Engineering Control (PEC) ∞ This is the device that creates the most critical sterile workspace, an ISO 5 environment. This is where the aseptic manipulations ∞ the actual transfer of drugs from one container to another ∞ occur. Examples include Laminar Airflow Workbenches (LAFWs) or Compounding Aseptic Isolators (CAIs). These devices bathe the work area in HEPA-filtered air, preventing particles from the room or the operator from entering the sterile field.

Personnel Garbing and Hygiene

The single greatest source of contamination in a cleanroom is the personnel working within it. USP <797> outlines a detailed, sequential procedure for garbing to minimize the shedding of particles and microbes.

The process involves donning specific, low-lint garments in a specific order in the ante-room before entering the buffer area. This includes:

- Shoe Covers ∞ Donned first to prevent tracking in dirt from outside areas.

- Hair and Beard Covers ∞ To contain hair and facial hair.

- Face Mask ∞ To minimize the expulsion of oral and nasal droplets.

- Hand Hygiene ∞ A thorough hand washing with soap and water is performed.

- Gown ∞ A low-particulate gown that closes at the neck and has long sleeves with tight-fitting cuffs is donned.

- Sterile Gloves ∞ After entering the buffer area, sterile gloves are put on. They are regularly sanitized with sterile 70% isopropyl alcohol (IPA) throughout the compounding process.

Aseptic technique is a set of specific practices performed by compounding personnel to maintain the sterility of the preparations.

Aseptic Manipulation and Technique

Inside the ISO 5 environment of the PEC, all actions are performed using aseptic technique. This is a method of handling sterile products in a way that prevents contamination. It involves a deep understanding of airflow within the hood. For example, nothing should pass behind a sterile object in the hood, as this could introduce unfiltered air and contaminants.

All vial stoppers and injection ports are meticulously disinfected with sterile IPA before being punctured. Every needle is used for a limited number of entries to prevent coring and the introduction of rubber particles into the solution. This disciplined way of working is the active defense of your medication’s sterility.

The table below outlines the key procedural areas governed by USP <797> and the objectives of each.

| Procedural Area | Primary Objective | Key Activities |

|---|---|---|

| Environmental Control | To maintain air quality and surface cleanliness. | HEPA filtration, pressure differentials between rooms, regular cleaning and disinfection of all surfaces. |

| Personnel Conduct | To minimize contamination from operators. | Strict garbing procedures, validated hand hygiene, adherence to aseptic technique, restricted movement. |

| Procedural Validation | To verify that both personnel and processes can produce a sterile outcome. | Gloved fingertip sampling, media-fill testing, ongoing training and competency assessments. |

| Material Handling | To prevent the introduction of contamination from supplies. | Wiping down all components with a sporicidal agent or sterile IPA before entry into the buffer area. |

Academic

A deeper examination of sterile compounding procedures reveals a sophisticated interplay of microbiology, physics, and quality management systems. The standards outlined in USP <797> are not arbitrary rules; they are evidence-based controls designed to mitigate specific, quantifiable risks.

For the individual on a personalized hormone or peptide protocol, understanding this level of detail provides the ultimate reassurance of the integrity of their treatment. The science behind the standards is what transforms the process from a series of steps into a robust system of quality assurance.

What Is the Scientific Basis for CSP Categories?

The 2019 revision of USP <797> moved from a three-tiered risk level system (low, medium, high) to a two-tiered system of classifying Compounded Sterile Preparations (CSPs) ∞ Category 1 and Category 2. This change reflects a more functional approach to risk assessment, focusing on the environment in which a CSP is prepared and the time until it is used, known as the Beyond-Use Date (BUD).

- Category 1 CSPs ∞ These have a shorter BUD. They can be prepared in a segregated compounding area (SCA), which does not need to meet the full air quality and design requirements of a cleanroom suite. This category is intended for preparations that will be administered soon after compounding. The BUD for a Category 1 CSP is typically 12 hours or less at controlled room temperature.

- Category 2 CSPs ∞ These are permitted to have longer BUDs. Their preparation must occur within the stricter environment of a cleanroom suite (an ISO 7 buffer room with an ISO 8 ante-room). The extended dating is justified by the superior environmental controls, more rigorous personnel testing, and the potential for sterility testing on the final preparation.

This categorical distinction is critical for therapies like Testosterone Cypionate, which may be dispensed for a week’s use, or for peptide vials intended for multiple subcutaneous injections over a period of days. These treatments require the stringent environmental controls associated with Category 2 compounding to ensure they remain sterile and stable throughout their intended use period.

The Microbiology of Contamination and Sterility Testing

The entire framework of sterile compounding is built to combat invisible threats. The primary microbial contaminants of concern are bacteria (like Staphylococcus epidermidis from skin flora) and fungi (like Aspergillus species from the environment). These microbes can cause severe infections if introduced into the bloodstream. A secondary, yet equally dangerous, threat comes from endotoxins.

These are fragments of the cell wall of Gram-negative bacteria that can remain even after the bacteria are killed. Endotoxins can cause a potent inflammatory response, leading to fever, shock, and other severe symptoms.

To verify the effectiveness of the controls, a multi-faceted quality assurance program is essential. This program provides objective data on the state of control within the compounding facility.

| Test Type | Purpose | Methodology and Interpretation |

|---|---|---|

| Gloved Fingertip Sampling | To verify proper hand hygiene and garbing technique. | The gloved fingertips of the compounder are pressed onto a growth medium plate after garbing. The plates are incubated, and the number of colony-forming units (CFUs) is counted. Zero CFUs is the goal. |

| Media-Fill Test | To validate the aseptic technique of personnel. | A compounder performs a simulation of the most complex compounding procedure they undertake, but using a sterile microbial growth medium (like soybean-casein digest medium) instead of actual drugs. The final container is incubated. Any visible turbidity indicates microbial growth and a failure of technique. |

| Environmental Monitoring | To assess the cleanliness of the air and surfaces. | Air sampling is conducted to count viable airborne microbes. Surface sampling is performed on work surfaces, equipment, and floors to detect microbial contamination. Results are compared against established action levels for each ISO-classified area. |

| Endotoxin Testing | To detect the presence of bacterial endotoxins. | Required for certain high-risk and batch-compounded CSPs. The most common method is the Limulus Amebocyte Lysate (LAL) test, which uses a protein from the blood of the horseshoe crab that clots in the presence of endotoxins. |

The validation of sterility is an ongoing, data-driven process that provides objective evidence of a facility’s ability to produce safe medications.

How Are Compounding Facilities Held Accountable?

Accountability is maintained through rigorous documentation and regulatory oversight. Every step of the compounding process, from the receipt of raw ingredients to the final release checks of a preparation, must be documented. This includes cleaning logs, personnel training records, environmental monitoring results, and master formulation records for each specific CSP.

These records create a complete and traceable history of your medication. State Boards of Pharmacy are the primary regulatory bodies responsible for inspecting compounding facilities and enforcing compliance with USP <797>. This external oversight provides a final layer of assurance that the standards designed for your safety are being consistently met.

References

- United States Pharmacopeial Convention. “General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations.” United States Pharmacopeia and National Formulary (USP-NF), 2023.

- Kastango, Eric S. and James T. Wagner. “Quality assurance for sterile product compounding.” International Journal of Pharmaceutical Compounding, vol. 24, no. 2, 2020, pp. 118-124.

- Allen, Loyd V. “Basics of Compounding for Sterile Preparations.” Secundum Artem, vol. 15, no. 2, 2010.

- “The 2019 Revisions to USP Chapter <797> ∞ A Deep Dive.” Pharmacy Purchasing & Products, vol. 16, no. 8, 2019.

- Cundell, Anthony M. “Microbial Testing of Compendial Articles.” Pharmaceutical Technology, vol. 38, no. 1, 2014, pp. 40-47.

- “Guidance for Industry ∞ Insanitary Conditions at Compounding Facilities.” U.S. Food and Drug Administration, 2020.

- Briggerman, K. and D. Kienle. “Environmental Monitoring in Pharmacy Compounding Cleanrooms.” International Journal of Pharmaceutical Compounding, vol. 22, no. 4, 2018, pp. 284-289.

- Douglas, Kevin. “Aseptic Technique ∞ A Cornerstone for Preventing Healthcare-Associated Infections.” Journal of Hospital Infection, vol. 98, no. 4, 2018, pp. 345-351.

Reflection

You have now journeyed through the meticulous world that exists to protect you, a world of controlled air, validated procedures, and disciplined professionals. The knowledge of these procedural steps does more than simply answer a question; it transforms your relationship with your therapy.

Your weekly injection of Testosterone Cypionate or your daily dose of a restorative peptide is no longer just a medication. It is the final, tangible result of a complex system dedicated entirely to your safety and well-being.

This understanding equips you to be an active, informed partner in your health journey. The path to hormonal optimization and enhanced vitality is deeply personal, and the trust you place in your clinical and pharmaceutical team is paramount. You now possess the vocabulary and the conceptual framework to engage in meaningful conversations about the quality standards behind your compounded therapies.

Consider this knowledge not as a final destination, but as a new starting point ∞ a foundation from which you can build a more resilient, informed, and empowered approach to your own biological restoration.