Fundamentals

You feel it in your bones when your body is functioning in true alignment. There is a clarity to your thoughts, a resilience in your energy, and a sense of vitality that permeates your days. This state of well-being is the direct result of a silent, elegant conversation happening within you, a biological dialogue orchestrated by molecular messengers.

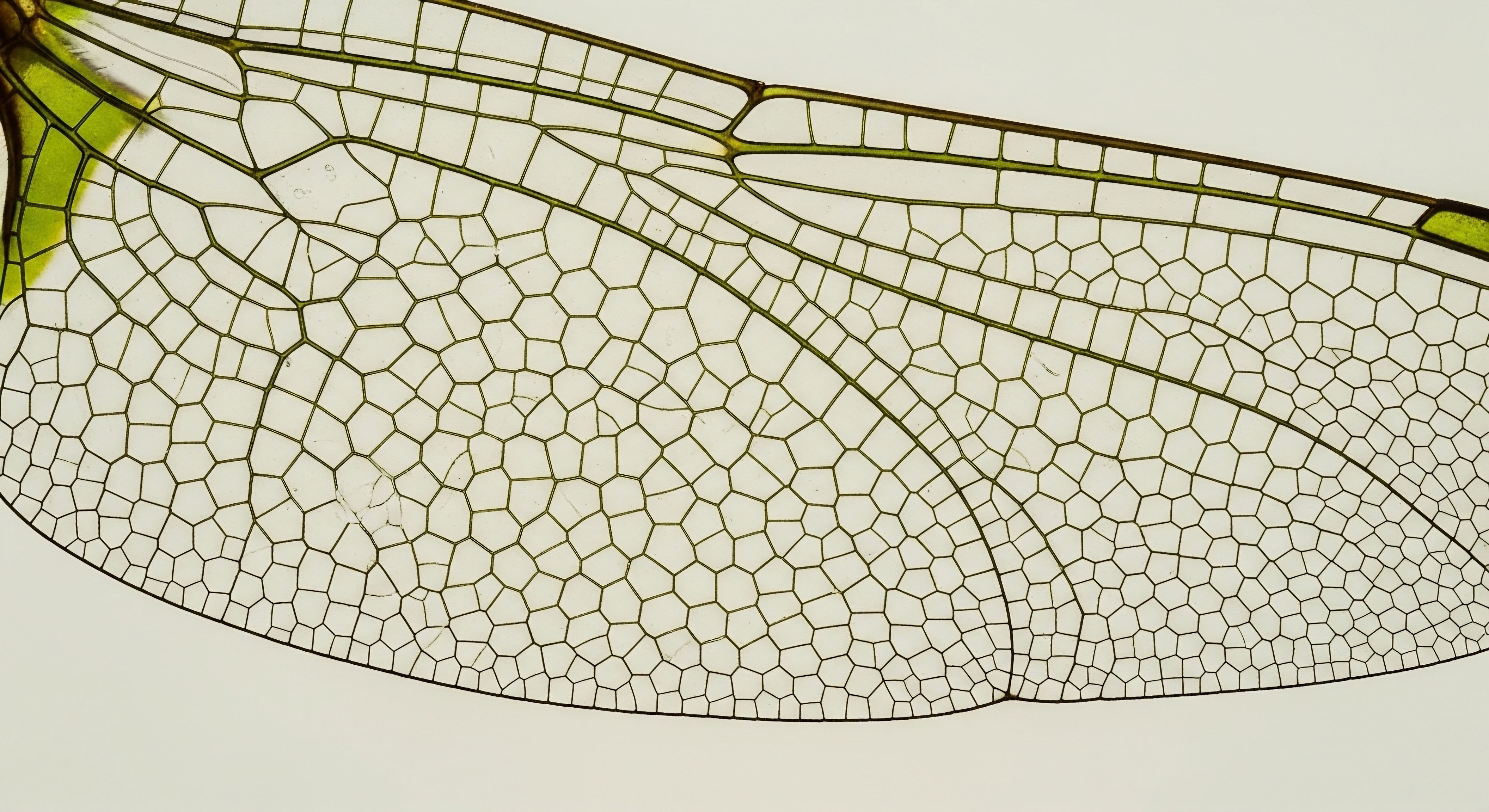

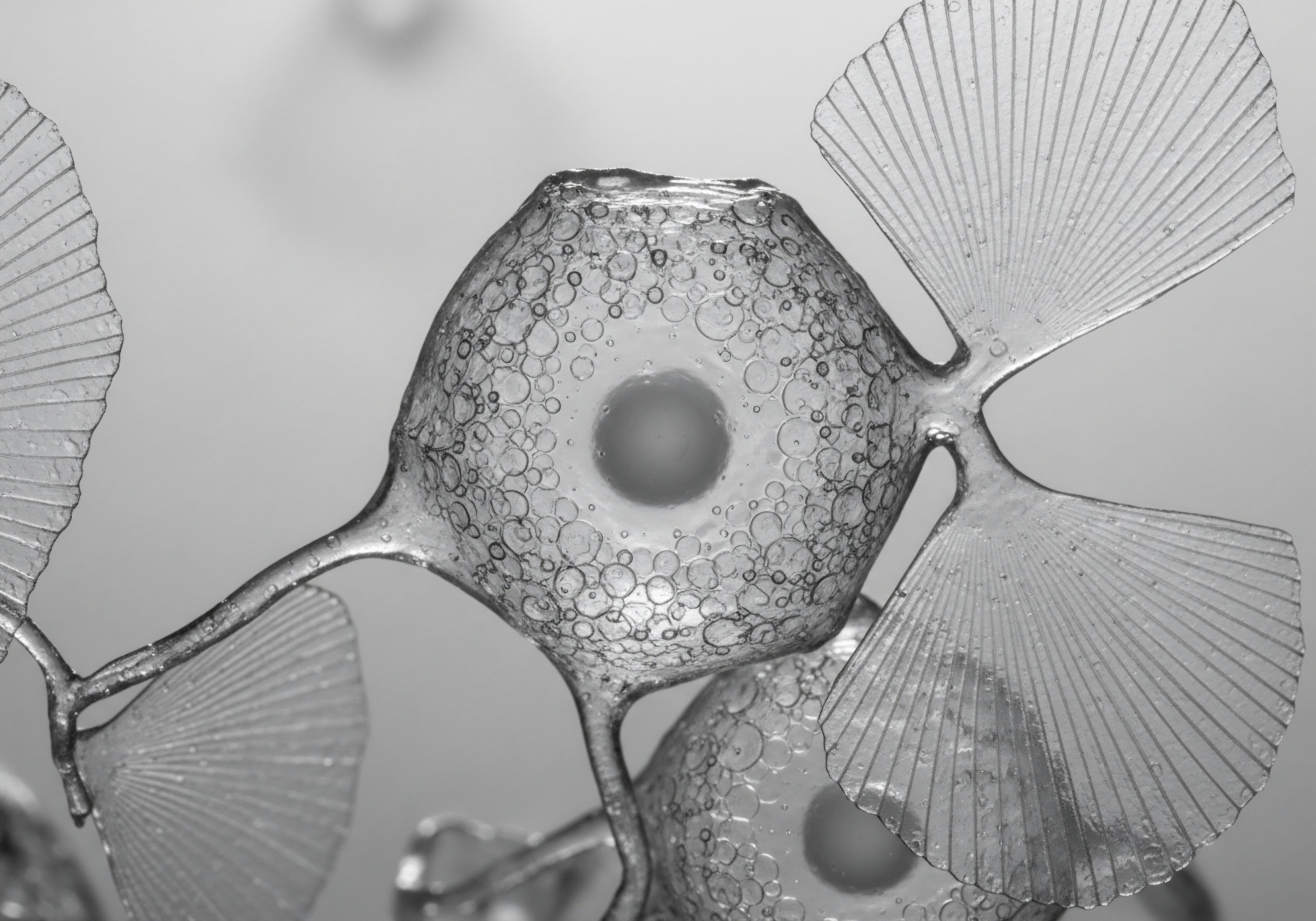

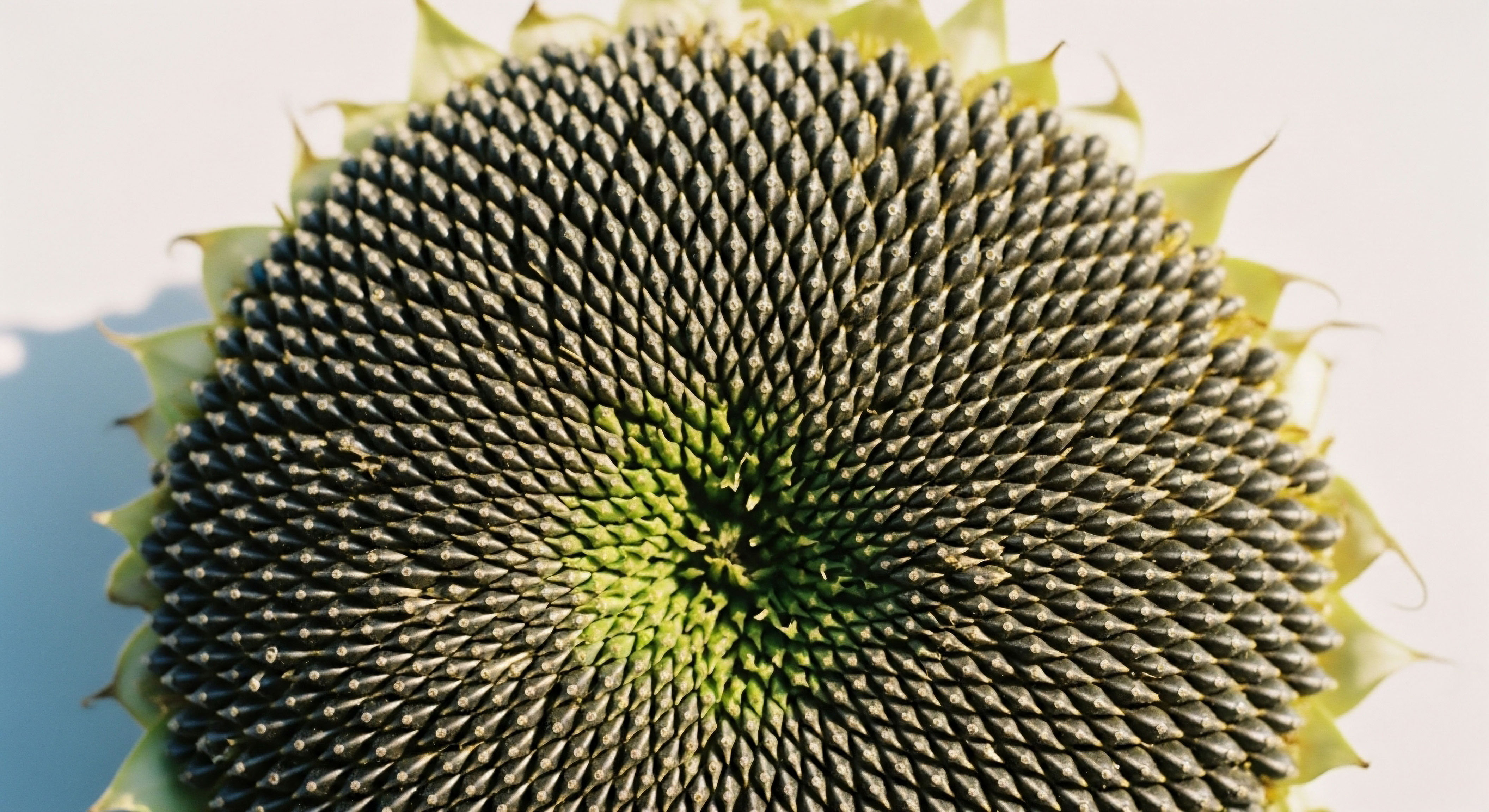

Peptides are a critical part of this conversation. They are precise, single-purpose instructions, short chains of amino acids Meaning ∞ Amino acids are fundamental organic compounds, essential building blocks for all proteins, critical macromolecules for cellular function. that tell your cells exactly what to do, from initiating tissue repair to modulating your metabolism. Your body’s ability to hear and act on these instructions defines your health.

The role of manufacturing standards Meaning ∞ Manufacturing standards denote the systematic protocols and specifications governing the production of pharmaceutical agents, dietary supplements, and diagnostic reagents to ensure their consistent quality, safety, and efficacy. in peptide availability is to ensure the absolute integrity of these molecular instructions. When we introduce a therapeutic peptide into our system, we are adding a new voice to that internal conversation.

For that voice to be understood correctly, for it to be biologically “available” to your cells, it must be an identical copy of the instruction your body is designed to recognize. Manufacturing standards, specifically Good Manufacturing Practices Meaning ∞ Good Manufacturing Practices (GMP) represent a regulatory framework and a set of operational guidelines ensuring pharmaceutical products, medical devices, food, and dietary supplements are consistently produced and controlled according to established quality standards. (GMP), are the protocols that guarantee this fidelity. They ensure the peptide possesses the exact structure, purity, and potency required to fit its designated cellular receptor, much like a perfectly crafted key is made to fit a specific lock.

A peptide’s effectiveness is a direct consequence of its structural and chemical purity, a quality guaranteed only by stringent manufacturing oversight.

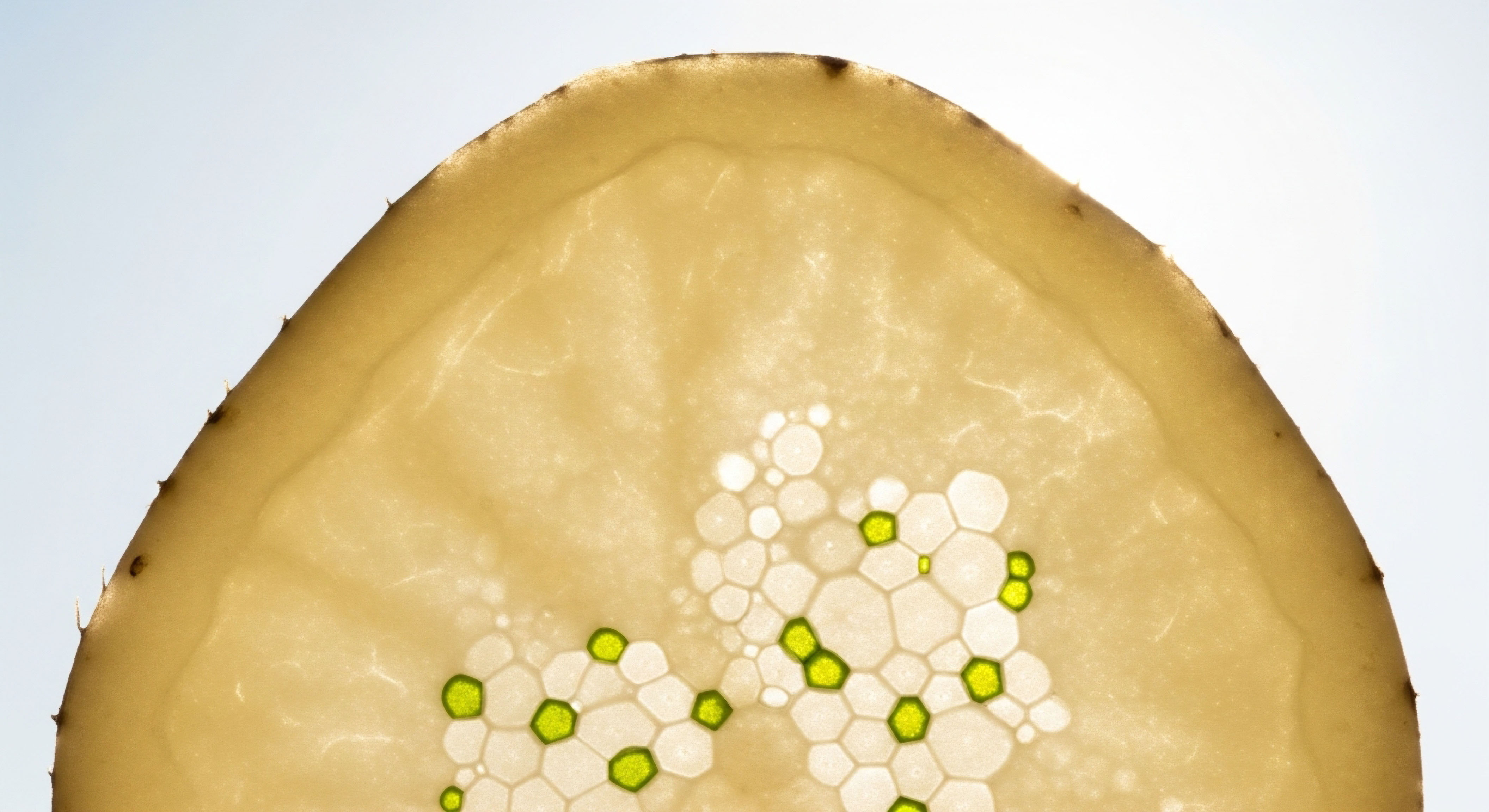

The Language of Cellular Communication

Think of your body as a vast, interconnected network. Hormones and peptides are the data packets, the messengers that carry vital information from one system to another. A peptide like Sermorelin, for instance, is designed to deliver a very specific message to the pituitary gland ∞ “release growth hormone.” The pituitary will only act on this message if it recognizes the messenger’s structure perfectly.

Any deviation, any impurity or malformation in the peptide chain, corrupts the message. The instruction becomes garbled, and the intended biological action fails to occur.

This is where the concept of manufacturing standards moves from a technical detail to a personal health imperative. A peptide synthesized outside of a controlled, GMP-compliant environment is a gamble. It may contain fragments of incorrect sequences, residual solvents from the chemical synthesis process, or molecules with the wrong three-dimensional shape.

These are not benign additions. They are biological noise. This noise can prevent the correct peptide from reaching its target, or worse, it can trigger unintended and unwanted cellular responses. The availability of a peptide, therefore, is about its ability to be recognized and used by your body as intended.

What Guarantees a Clear Biological Signal?

Good Manufacturing Practices (GMP) provide the framework for creating a clear, unadulterated biological signal. These are not arbitrary regulations; they are a systematic approach to quality control Meaning ∞ Quality Control, in a clinical and scientific context, denotes the systematic processes implemented to ensure that products, services, or data consistently meet predefined standards of excellence and reliability. that governs every single step of the peptide’s creation, from the initial raw amino acids to the final sterile vial.

Adherence to GMP ensures that each batch of a peptide is identical to the last, providing a consistent and predictable therapeutic effect. It is the only way to be certain that the molecule being introduced into your body is a precise biological key, ready to unlock a specific, beneficial cellular function.

Choosing a peptide product is a decision about the quality of the information you are providing to your own biological systems. The integrity of that information begins and ends with the standards by which it was made.

Intermediate

Understanding the necessity of manufacturing standards is the first step. The next is to appreciate the intricate processes that these standards govern. For a therapeutic peptide Meaning ∞ A therapeutic peptide is a short chain of amino acids, typically 2 to 50 residues, designed to exert a specific biological effect for disease treatment or health improvement. to be effective and safe, its journey from raw chemical components to a finished, injectable product is one of meticulous control and validation.

Good Manufacturing Practices (GMP) provide the exacting blueprint for this journey, ensuring that the final molecule is not only pure but also biologically active and stable. This is a process of systematic risk mitigation, designed to eliminate the variables that could compromise the peptide’s function within the human body.

The Architecture of Peptide Synthesis

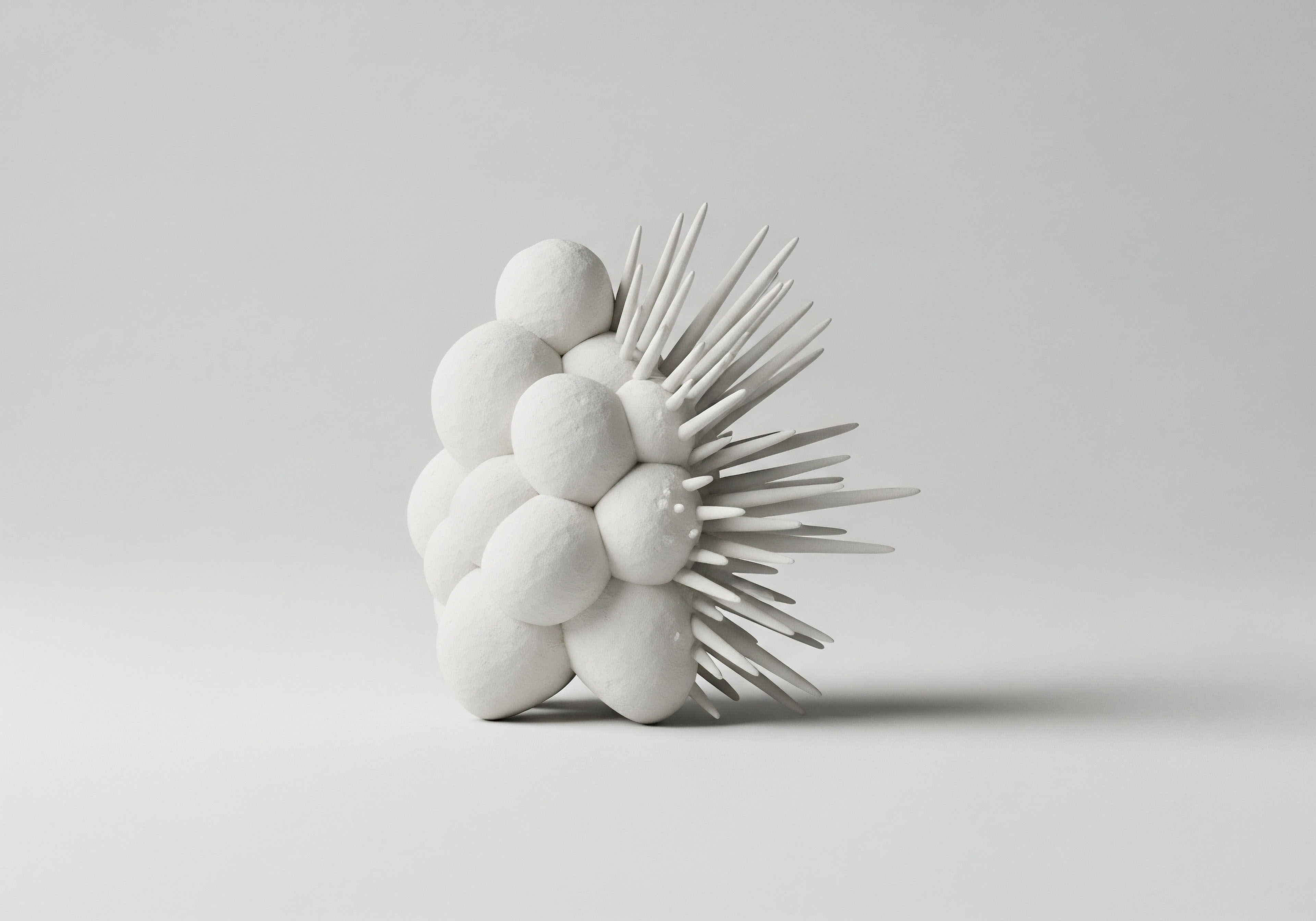

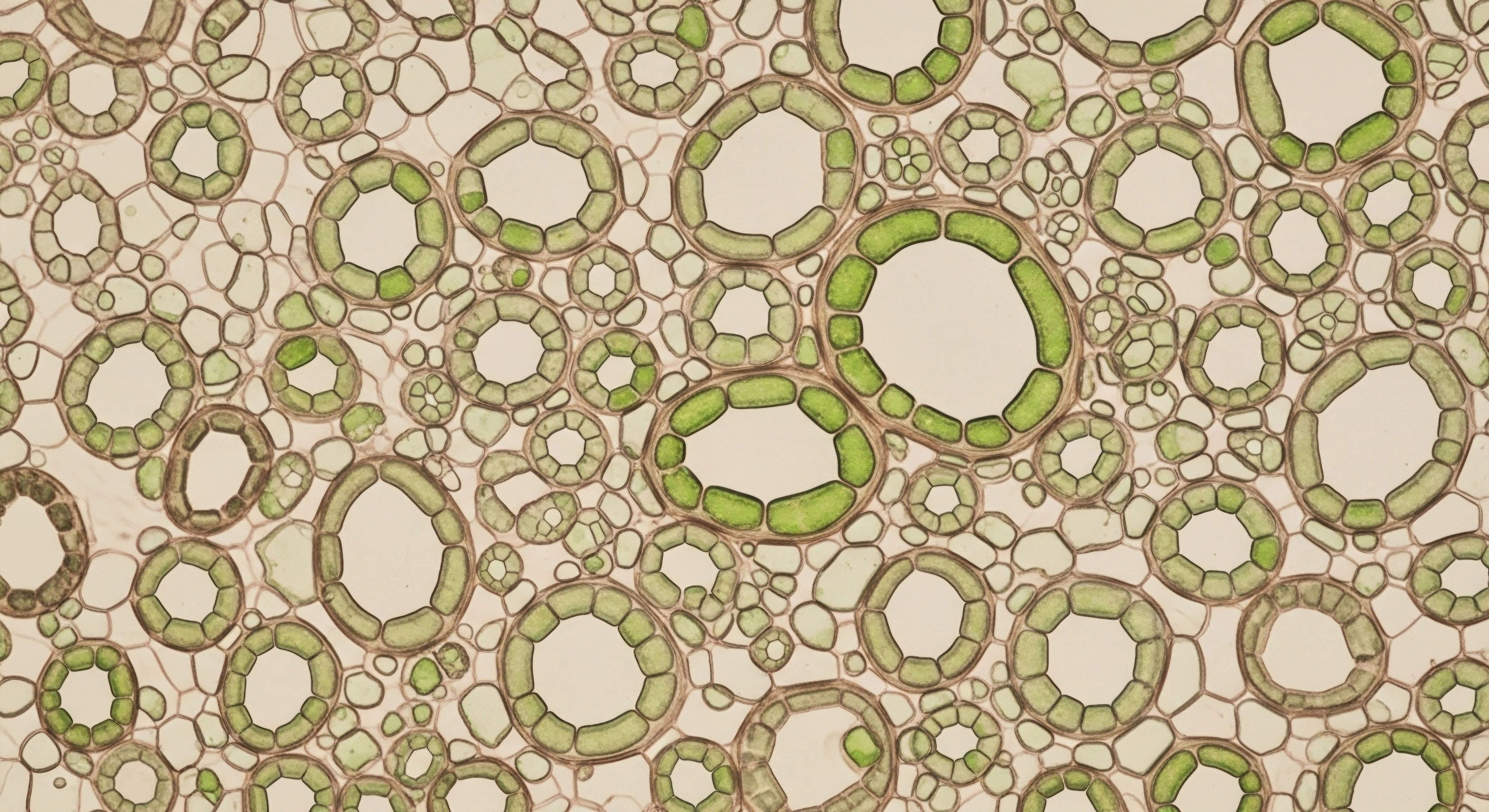

The vast majority of therapeutic peptides Meaning ∞ Therapeutic peptides are short amino acid chains, typically 2 to 50 residues, designed or derived to exert precise biological actions. are built using a method called Solid-Phase Peptide Synthesis Meaning ∞ Solid-Phase Peptide Synthesis (SPPS) is a robust chemical method for creating peptides by sequentially adding amino acid building blocks to a growing chain that is anchored to an insoluble polymeric support, typically a resin bead. (SPPS). This technique involves anchoring the first amino acid in the peptide chain to a solid resin bead and then sequentially adding the subsequent amino acids one by one.

Each addition is a multi-step chemical reaction that must be driven to completion before the next can begin. GMP controls are critical at this stage to ensure the correct sequence is assembled. Without such oversight, errors can occur, leading to impurities that are difficult to remove later.

- Deleted Sequences ∞ An amino acid is missed in the chain, resulting in a shorter, non-functional peptide.

- Truncated Sequences ∞ The synthesis process stops prematurely, creating incomplete fragments.

- Side-Reaction Products ∞ The chemicals used to add amino acids can sometimes modify other parts of the growing peptide chain, creating altered molecules with unknown biological effects.

After the full-length peptide chain is assembled, it is cleaved from the resin and must undergo an extensive purification process. The most common and powerful method for this is High-Performance Liquid Chromatography (HPLC). HPLC separates the desired full-length peptide from the “noise” of synthesis ∞ the failed sequences and chemical byproducts.

Under GMP, the HPLC process itself is validated to prove it can effectively remove specific, known impurities, ensuring the final product achieves a very high level of purity, often exceeding 98% or 99%.

Comparing Purity and Purpose

The distinction between peptides made under GMP for therapeutic use and those made for laboratory research is stark. The standards reflect the intended application, with human safety being the paramount concern for GMP-grade products.

| Feature | GMP Therapeutic Peptides | Research-Use-Only (RUO) Peptides |

|---|---|---|

| Intended Use | Human therapeutic applications (e.g. TRT protocols, Growth Hormone Peptide Therapy). | Laboratory experiments, in-vitro studies, non-human research. |

| Purity Standard | Typically >98% purity, with stringent limits on specific impurities. | Purity can vary widely (e.g. 70-95%) and is often not fully characterized. |

| Documentation | Extensive batch records, validation reports, and a Certificate of Analysis detailing identity, purity, and strength. | Minimal documentation, often just a stated sequence and an approximate purity level. |

| Regulatory Oversight | Manufactured in facilities inspected and compliant with FDA or equivalent regulatory bodies. | No regulatory oversight of the manufacturing process. |

The transition from a chemical sequence on paper to a reliable therapeutic agent is entirely dependent on a validated, multi-stage purification and verification process.

How Does Quality Assurance Validate the Final Product?

Once a peptide is synthesized and purified, GMP requires a final, rigorous phase of quality control testing to confirm its identity and character. This is the ultimate verification that the product is what it claims to be and is safe for human use. This testing protocol is multi-faceted, with each analysis providing a different piece of the quality puzzle.

These analytical tests provide a comprehensive profile of the peptide, guaranteeing that each vial contains a consistent, pure, and potent product. This level of scrutiny is what separates a therapeutic agent from a research chemical. It is the embodiment of the principle that in medicine, and especially in the nuanced world of hormonal health, precision and reliability are the foundation of any effective protocol.

Academic

The discourse surrounding peptide therapies often centers on their mechanism of action at the receptor level. An equally profound, though less discussed, aspect is the molecular integrity of the peptide itself, a direct function of its manufacturing process. The adherence to Good Manufacturing Practices (GMP) is the primary determinant of this integrity.

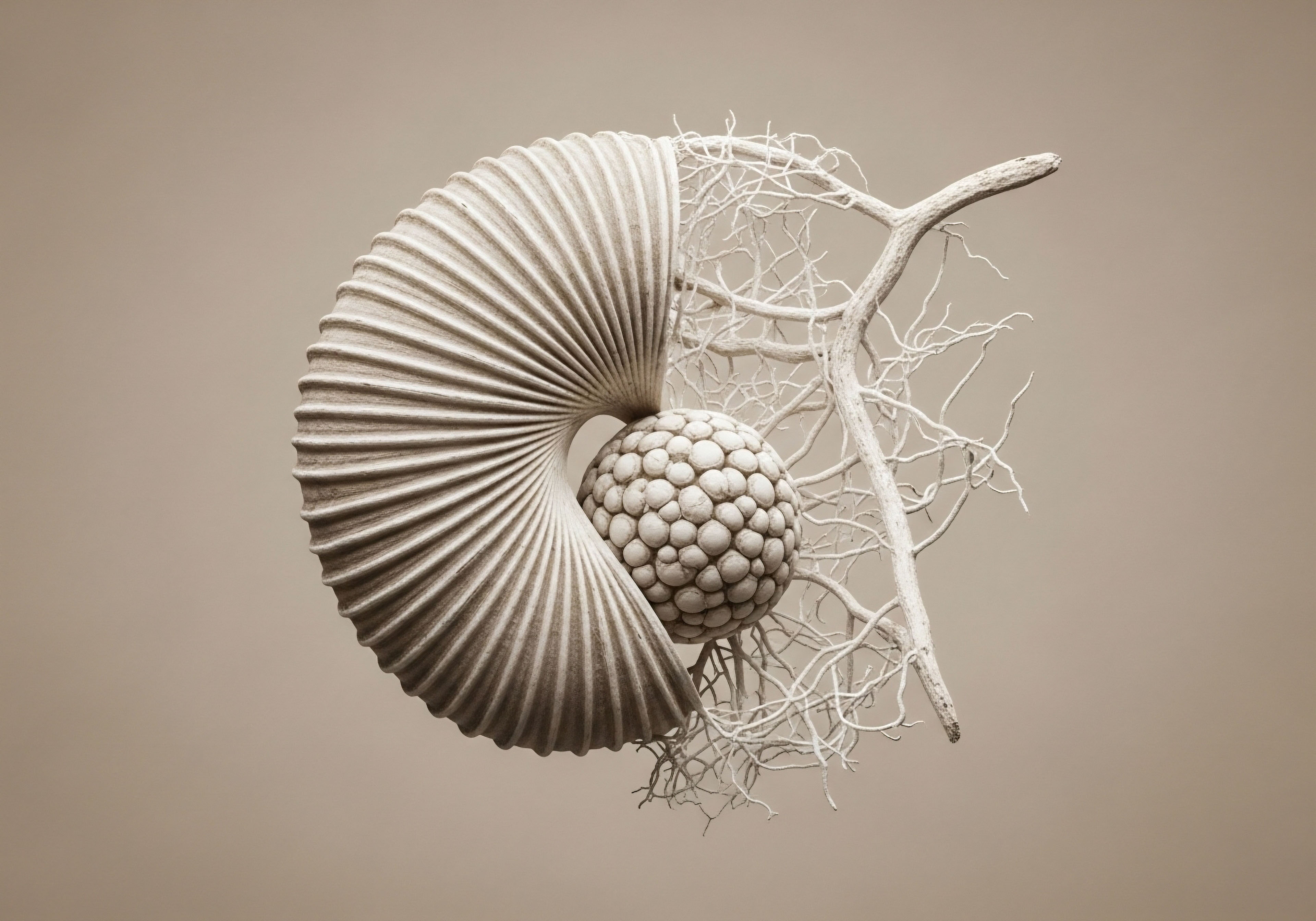

Deviations from GMP do not simply reduce a peptide’s efficacy; they introduce a spectrum of molecular liabilities that can alter its pharmacokinetics, immunogenicity, and receptor-binding kinetics, ultimately transforming a therapeutic agent into a source of biological chaos. From a systems-biology perspective, the role of manufacturing standards is to ensure the peptide acts as a high-fidelity signal within the complex signaling cascade of the human body, preventing the introduction of molecular static that can disrupt homeostasis.

The Biophysical Consequences of Impurities

The primary output of peptide synthesis, the crude product, is a heterogeneous mixture of the desired peptide and a constellation of closely related impurities. While purification methods like HPLC are designed to isolate the target molecule, the stringency of the GMP-validated process determines the final purity profile. The presence of residual impurities, even at low percentages, has significant biophysical implications.

For example, a deletion sequence ∞ a peptide missing a single amino acid ∞ may still possess a partial affinity for the target receptor. This can lead to competitive antagonism, where the impurity occupies the receptor site without initiating the downstream signal transduction cascade, effectively blocking the action of the correct, full-length peptide.

Another common impurity, a diastereomer (a peptide with one amino acid in the wrong stereochemical configuration), can cause the peptide to misfold. This alters its three-dimensional structure, which is as critical as its sequence for receptor binding. A misfolded peptide may have a drastically reduced binding affinity or, more concerningly, may exhibit off-target binding to other receptors, initiating unintended physiological effects.

Immunogenicity a Critical and Overlooked Risk

The human immune system is exquisitely tuned to identify and neutralize foreign or aberrant proteins. Peptides that are improperly synthesized or purified can present as immunological threats. This can occur through several mechanisms:

- Formation of Aggregates ∞ Impurities can act as nucleation points, causing peptides to clump together into larger aggregates. These aggregates are frequently recognized by antigen-presenting cells, triggering an adaptive immune response that can lead to the generation of anti-drug antibodies (ADAs).

- Modified Side Chains ∞ Uncontrolled side reactions during synthesis can create novel chemical structures on the peptide that the immune system identifies as non-self.

- Adjuvant Effect of Impurities ∞ Some chemical remnants from the synthesis process can act as adjuvants, non-specifically stimulating an immune response against the peptide itself.

The development of ADAs is a significant clinical concern. These antibodies can bind to the therapeutic peptide, neutralizing its activity and rendering the therapy ineffective over time. In some cases, they can even cross-react with the endogenous version of the peptide, leading to an autoimmune condition.

GMP standards, particularly those governing purification and the control of raw materials, are designed to minimize the presence of these immunogenic triggers, safeguarding both the short-term efficacy and long-term safety of the therapy.

Manufacturing deviations introduce structural variants that can trigger immune surveillance, converting a therapeutic signal into an antigenic threat.

Advanced Validation the Cornerstone of Biological Certainty

Ensuring the biological fidelity of a therapeutic peptide requires a suite of sophisticated analytical techniques that go far beyond a simple purity measurement. GMP protocols mandate the use of these methods to build a complete picture of the final product’s quality.

| Analytical Method | Purpose in GMP Peptide Validation |

|---|---|

| Mass Spectrometry (MS) | Confirms the molecular weight of the peptide with extreme precision, verifying that the correct amino acid sequence has been synthesized. |

| Tandem MS (MS/MS) | Fragments the peptide and analyzes the pieces to confirm the exact amino acid sequence, providing definitive proof of identity. |

| Amino Acid Analysis (AAA) | Quantifies the relative abundance of each amino acid after breaking the peptide down, ensuring the correct composition and providing an accurate measure of peptide content. |

| Chiral Chromatography | Separates and quantifies enantiomeric impurities (D-isomers), ensuring the correct stereochemistry required for biological activity. |

| Bacterial Endotoxin Test (LAL) | Detects the presence of endotoxins, which are fever-inducing substances from bacteria that can be present in non-sterile manufacturing environments. |

This rigorous, multi-modal analysis provides the highest possible assurance that a peptide is structurally correct, pure, and safe. It is this analytical certainty that underpins the availability of a truly effective peptide therapeutic. The standards are not about regulation for its own sake; they are the practical application of biochemical and immunological principles required to make a molecule that reliably and safely communicates with the human body.

References

- The United States Food and Drug Administration. “Current Good Manufacturing Practice (CGMP) Regulations.” Code of Federal Regulations, Title 21, Part 211, 2023.

- Isidro-Llobet, A. et al. “Amino Acid-Protecting Groups.” Chemical Reviews, vol. 109, no. 6, 2009, pp. 2455 ∞ 2504.

- European Medicines Agency. “Guideline on the quality of water for pharmaceutical use.” EMA/CHMP/CVMP/QWP/496873/2018, 2020.

- White, P. and J.M. Key. “Synthetic Peptides ∞ A Review of Current Trends and Future Applications.” Journal of Peptide Science, vol. 10, no. 1, 2004, pp. 1-15.

- Blumenthal, W. “Good Manufacturing Practices (GMPs) for Pharmaceutical Products.” Pharmaceutical Manufacturing Handbook ∞ Production and Processes, edited by Shayne Cox Gad, Wiley, 2008, pp. 1-38.

- Rasmussen, P.H. et al. “Impurities in synthetic peptides.” Journal of Peptide Science, vol. 16, no. S1, 2010, p. 10.

- Merrifield, R. B. “Solid Phase Peptide Synthesis. I. The Synthesis of a Tetrapeptide.” Journal of the American Chemical Society, vol. 85, no. 14, 1963, pp. 2149 ∞ 2154.

- The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use. “ICH Harmonised Tripartite Guideline ∞ Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients Q7.” 2000.

Reflection

Calibrating Your Biological Signals

The information presented here reframes the conversation about peptide therapies. It moves beyond a simple discussion of benefits and protocols to the very essence of the molecules themselves. Your body operates on a principle of absolute precision. The instructions that govern your health are specific, structured, and pure. Any therapeutic intervention that seeks to join this internal dialogue must honor that principle.

Consider the choices you make for your health not merely as actions, but as messages. When you choose a therapeutic agent, you are selecting a signal that you will send to your cells. Is that signal clear, precise, and unambiguous? Or is it clouded with the static of impurities and structural errors?

The journey to reclaiming your vitality and optimizing your function is one of restoring the integrity of your body’s communication network. The quality of the signals you introduce is the foundation of that process. Your biology is listening. The responsibility is to ensure you are speaking its language with perfect clarity.