Fundamentals

Your body operates as an intricate, interconnected system where hormonal signals dictate function, mood, and overall vitality. When seeking personalized hormone optimization, the origin of your therapeutic compounds is a critical component of your health journey.

Understanding the distinction between a 503A and a 503B facility is the first step in comprehending the regulatory landscape that governs the medications designed to recalibrate your internal biochemistry. This knowledge empowers you to appreciate the precision, safety, and scale at which these essential therapies are produced.

A 503A compounding pharmacy functions to serve the specific needs of an individual patient. It prepares medications based on a prescription written explicitly for you by your provider. This model allows for a high degree of personalization, tailoring dosages and formulations to your unique physiological requirements, such as creating a testosterone cream without a specific allergen or adjusting a progesterone dose to a non-standard level.

These pharmacies are primarily regulated by state boards of pharmacy and must adhere to standards set by the United States Pharmacopeia (USP), particularly chapters for non-sterile and sterile compounding. This framework ensures a focus on patient-specific care, connecting your prescription directly to the pharmacist’s preparation.

A 503A pharmacy compounds customized medications for individual patients based on a specific prescription.

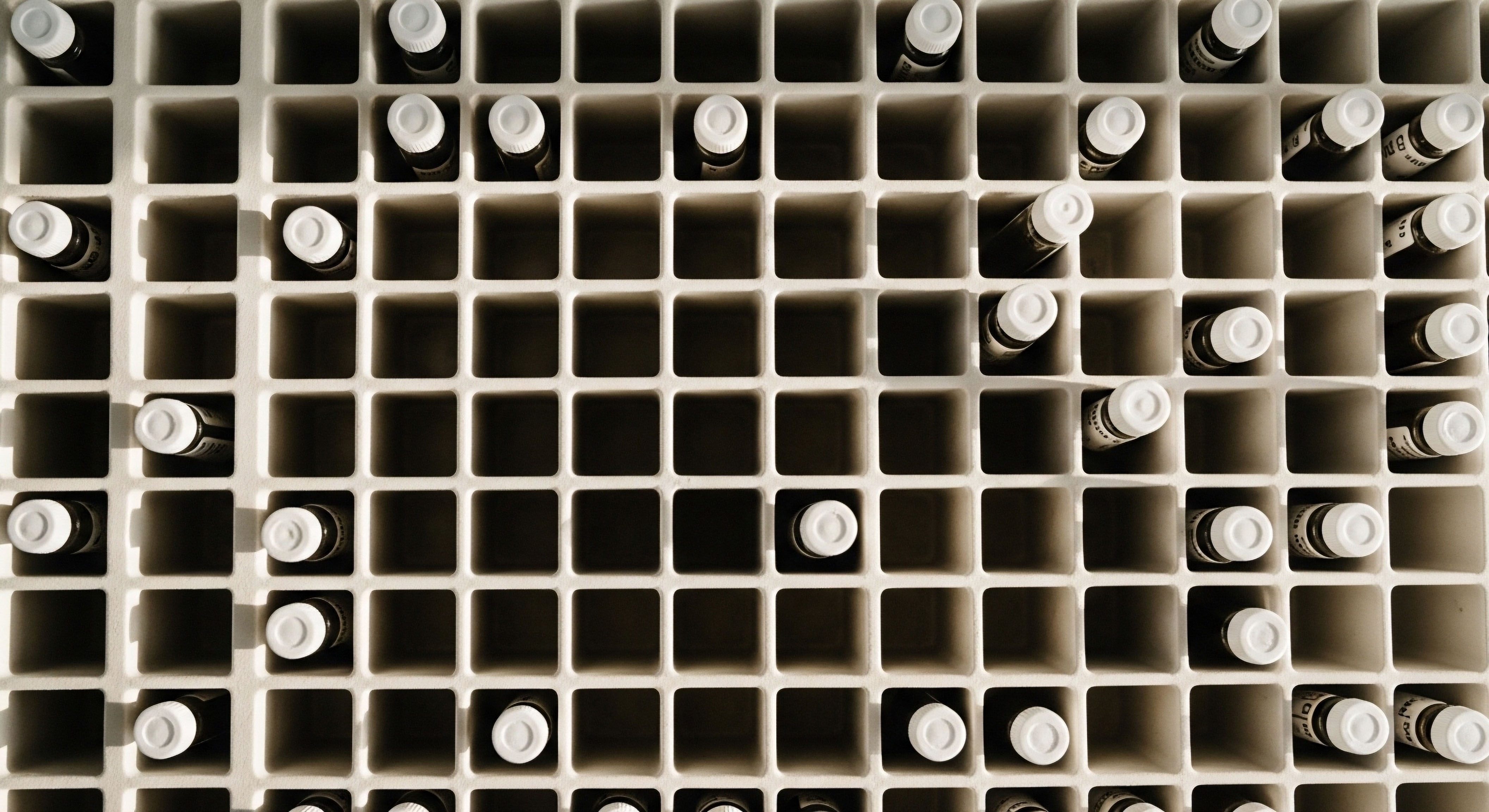

In contrast, a 503B outsourcing facility operates on a much larger scale, functioning more like a pharmaceutical manufacturer. These facilities produce large batches of compounded medications that are not tied to individual patient prescriptions. This allows hospitals, clinics, and medical practices to purchase sterile medications, like injectable Testosterone Cypionate or Sermorelin, in bulk for office use.

The regulatory standards for 503B facilities are significantly more stringent, as they must register with the FDA and comply with Current Good Manufacturing Practices (cGMP). This is the same set of rigorous standards that conventional drug manufacturers must follow, ensuring a high level of quality control, sterility, and batch-to-batch consistency.

The core difference lies in their operational purpose and regulatory oversight. A 503A pharmacy is centered on the individual, creating bespoke medications under state-level supervision. A 503B facility is designed for broader distribution, producing large quantities of standardized compounds under federal FDA oversight and cGMP standards to ensure safety and consistency for widespread clinical use.

Intermediate

As you progress on your path to hormonal and metabolic wellness, the source of your therapeutic agents becomes directly linked to the efficacy and safety of your protocol. The distinction between 503A and 503B facilities moves from a simple definition to a practical consideration that impacts everything from the consistency of your weekly Testosterone Replacement Therapy (TRT) injections to the purity of the peptides used for tissue repair and metabolic optimization. This understanding is central to building confidence in your personalized wellness plan.

How Do Regulations Impact Your Protocol?

The regulatory framework governing these facilities has direct implications for your treatment. For men on a TRT protocol involving weekly Testosterone Cypionate injections, sourcing from a 503B facility ensures a high degree of product uniformity. Because 503B facilities operate under cGMP, each batch of testosterone is subject to rigorous testing for potency, purity, and sterility before it is released.

This means the 0.5ml you inject this week is identical in quality and concentration to the 0.5ml you will inject next month, providing a stable foundation for your hormonal optimization. This level of consistency is vital for maintaining steady serum testosterone levels and minimizing unwanted fluctuations that can impact mood, energy, and physical performance.

For women requiring nuanced hormonal support, such as low-dose Testosterone Cypionate for libido and energy or bioidentical progesterone, a 503A pharmacy often provides the necessary flexibility. These pharmacies can compound a specific concentration of testosterone in a base that suits the patient, or create a progesterone capsule at a precise dose that is not commercially available.

While 503A pharmacies are not held to the same cGMP standards as 503B facilities, they follow strict USP guidelines to ensure quality for patient-specific preparations. The trade-off for this customization is a reliance on the individual pharmacy’s quality control processes rather than the federally mandated batch testing of a 503B facility.

For office-use sterile medications like TRT, 503B facilities provide manufacturing-level quality control.

Comparing Operational Scopes and Clinical Applications

The table below outlines the key operational and regulatory differences that influence the clinical application of products from 503A and 503B facilities, helping to clarify why your provider might choose one source over another for different components of your wellness protocol.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Focus | Patient-specific prescriptions for individual needs. | Large-scale production for healthcare facilities (office use). |

| Regulatory Oversight | State Boards of Pharmacy and USP standards. | FDA registration and Current Good Manufacturing Practices (cGMP). |

| Prescription Requirement | Required for each compounded medication. | Can produce without patient-specific prescriptions. |

| Batch Production | Limited quantities based on prescription history. | Large batches intended for broad distribution. |

| Typical Medications | Customized creams, capsules, or unique dosage forms. | Sterile injectables (e.g. TRT, peptides), standardized formulations. |

Consider a comprehensive protocol that includes both injectable peptides and a specialized topical cream. The injectable peptide, such as Ipamorelin/CJC-1295, would likely be sourced from a 503B facility. This ensures the sterility and stability of the product, which is critical for injectable medications.

The large-batch production model of a 503B is well-suited to manufacturing these types of therapies. Conversely, if a patient requires a custom-formulated topical hormone cream, a 503A pharmacy would be the appropriate choice, as it can tailor the formulation to the individual’s specific needs.

Academic

A sophisticated approach to personalized medicine requires a deep appreciation of the pharmaceutical supply chain and its regulatory architecture. The bifurcation of compounding into 503A and 503B models under the Drug Quality and Security Act (DQSA) reflects a fundamental tension between individualized therapy and the need for scalable, consistent, and sterile preparations.

Examining this distinction from a systems-biology perspective reveals how these two models directly influence the predictability and reliability of hormonal optimization protocols, impacting the delicate balance of endocrine feedback loops like the Hypothalamic-Pituitary-Gonadal (HPG) axis.

CGMP as a Foundation for Endocrine Stability

The mandate for 503B outsourcing facilities to adhere to Current Good Manufacturing Practices (cGMP) is a critical factor in achieving predictable clinical outcomes in hormone replacement therapy. The HPG axis, which governs testosterone production in men, is a sensitive system that relies on consistent hormonal signals.

The introduction of exogenous testosterone, as in a TRT protocol, suppresses the release of Luteinizing Hormone (LH) and Follicle-Stimulating Hormone (FSH) from the pituitary gland. The precision of this suppression and the subsequent management with agents like Gonadorelin depend on a stable and predictable dose of testosterone.

Deviations in the potency or bioavailability of a testosterone preparation can introduce chaotic inputs into this system. A sub-potent batch could lead to inadequate symptom control and a failure to achieve therapeutic serum levels, while a supra-potent batch could result in excessive aromatization, elevated estradiol levels, and a greater need for ancillary medications like Anastrozole.

The cGMP requirement for 503B facilities, which includes rigorous process validation and finished product testing, minimizes this variability. This ensures that each dose administered delivers the intended pharmacological effect, allowing for a more controlled and stable modulation of the endocrine system.

The stringent cGMP standards of 503B facilities are essential for maintaining the stability of sensitive endocrine systems during hormonal therapy.

What Are the Implications for Advanced Peptide Therapies?

The sourcing of therapeutic peptides, such as Sermorelin or Tesamorelin for growth hormone optimization, further highlights the importance of this distinction. These complex biomolecules are susceptible to degradation if not manufactured, stored, and distributed under exacting conditions. A 503B facility’s adherence to cGMP provides a framework for ensuring the integrity of these delicate compounds from raw material sourcing to final product sterility testing.

This level of quality assurance is paramount for therapies that act on sensitive signaling pathways. For instance, the efficacy of a growth hormone secretagogue like Ipamorelin is dependent on its ability to bind to the ghrelin receptor with high affinity. Any impurities or degradation products could alter its pharmacological activity, leading to suboptimal clinical results or unexpected side effects.

The robust quality systems of a 503B facility provide a higher degree of confidence in the product’s identity, purity, and potency, which is essential for both patient safety and the successful implementation of advanced anti-aging and wellness protocols.

The following table details the quality assurance measures that differentiate the two facility types, providing insight into the scientific rigor underpinning the medications used in clinical practice.

| Quality Assurance Metric | 503A Compounding Pharmacy (USP Standards) | 503B Outsourcing Facility (cGMP Standards) |

|---|---|---|

| Ingredient Verification | Must meet USP/NF monograph standards or be part of an FDA-approved drug. | Rigorous vetting of all raw material suppliers, including on-site inspections. |

| Process Validation | Follows prescribed compounding procedures. | Every manufacturing process must be formally validated for consistency and reproducibility. |

| Finished Product Testing | Testing may be performed, but is not universally required for all preparations. | Every batch must be tested for potency, purity, and sterility before release. |

| Stability Testing | Beyond-Use Dating (BUD) can be based on scientific literature. | Requires real-time stability testing to establish expiration dates. |

| Facility Environment | Environmental monitoring performed periodically (e.g. every six months). | Continuous and rigorous environmental monitoring to maintain aseptic conditions. |

Ultimately, the choice between a 503A and 503B source is a clinical decision based on the specific therapeutic agent and the patient’s needs. For sterile, injectable therapies that form the backbone of many hormonal and metabolic protocols, the cGMP-compliant manufacturing environment of a 503B facility offers a level of quality assurance that is indispensable for predictable and safe outcomes. For highly personalized, non-sterile formulations, the flexibility of a 503A pharmacy remains an essential tool in the clinician’s arsenal.

- 503A Pharmacies are tailored for individual patient prescriptions, operating under state board regulations and USP guidelines, which allows for customized medication formulations.

- 503B Facilities function as large-scale outsourcing operations, adhering to stringent FDA and cGMP standards to produce sterile medications for broader clinical use without patient-specific prescriptions.

- Clinical Application dictates the choice, with 503B facilities being the preferred source for standardized sterile injectables like TRT and peptides, while 503A pharmacies are ideal for unique, personalized dosage forms.

References

- “503A vs. 503B ∞ A Quick-Guide to Compounding Pharmacy Designations & Regulations.” AUSTAR, 16 Nov. 2021.

- “503A Vs. 503B Compounding Pharmacies ∞ Similarities & Differences.” Empower Pharmacy, 2023.

- “What is a Compounding Pharmacy? FDA-Regulated 503A Vs 503B Pharmacy.” Acacia Pharmacy, 29 Mar. 2024.

- “Understanding the differences between 503A, 503B compounding pharmacies.” TechTarget, 10 June 2024.

- “503A VS. 503B – What is the Difference?” Carie Boyd Pharmaceuticals, 14 May 2024.

Reflection

Charting Your Own Path Forward

You have now seen how the regulatory framework of pharmaceutical compounding directly impacts the tools available for your health. This knowledge is more than academic; it is the foundation upon which you can build a confident and informed partnership with your clinical team.

The journey to optimal function is a process of continual learning and precise calibration. As you move forward, consider how this understanding of quality, consistency, and personalization shapes your perspective on your own protocol. Your path is unique, and appreciating the science behind your therapies is a powerful step toward reclaiming your vitality.

Glossary

503b facility

503a compounding pharmacy

sterile compounding

503b outsourcing facility

current good manufacturing practices

503b facilities

cgmp standards

503a pharmacy

testosterone replacement therapy

cgmp

hormonal optimization

503a pharmacies

personalized medicine

good manufacturing practices

503b outsourcing

quality assurance