Fundamentals

Your journey toward hormonal balance often begins with a set of symptoms. It could be persistent fatigue that sleep does not resolve, a subtle but continuous decline in physical performance, shifts in mood, or changes in your body’s metabolic patterns. These experiences are valid and significant.

They are biological signals from your endocrine system, an intricate communication network that governs much of your vitality. When you and your clinician decide to intervene with a personalized hormonal protocol, such as precisely dosed Testosterone Cypionate or a specific peptide like Ipamorelin, the conversation naturally turns to where this customized medication will come from. This is where understanding the source of your therapy becomes a critical component of your health strategy.

The distinction between two types of pharmaceutical providers, 503A compounding pharmacies and 503B outsourcing facilities, is directly relevant to your personal experience. A 503A pharmacy is a specialized facility where a pharmacist prepares a medication based on a prescription written specifically for you.

Think of it as a tailored suit, crafted to your exact measurements and needs. If your protocol requires a unique dosage of testosterone, or a formula free of a specific allergen, a 503A pharmacy is designed to meet that individual requirement. These pharmacies are primarily regulated by State Boards of Pharmacy and operate under standards set by the United States Pharmacopeia (USP). Their work is fundamentally tied to a direct relationship between you, your prescriber, and the pharmacist.

The Role of Patient Specific Prescriptions

The defining characteristic of a 503A compounding pharmacy is its focus on the individual. Every medication prepared is in response to a unique prescription. This model is foundational to personalized medicine, allowing for adjustments in strength, delivery method, and formulation that are not available in mass-produced pharmaceuticals.

For instance, a woman requiring a low dose of testosterone for hormonal balance might receive a subcutaneous injection prepared at a specific concentration that is not commercially available. Similarly, a man on a Testosterone Replacement Therapy (TRT) protocol might need Anastrozole at a dose that is only achievable through compounding. The 503A framework makes this level of personalization possible.

Understanding the 503b Outsourcing Facility

A 503B outsourcing facility operates on a different scale and under a different regulatory structure. These facilities register voluntarily with the U.S. Food and Drug Administration (FDA) and are held to a much more stringent set of standards known as Current Good Manufacturing Practices (cGMP).

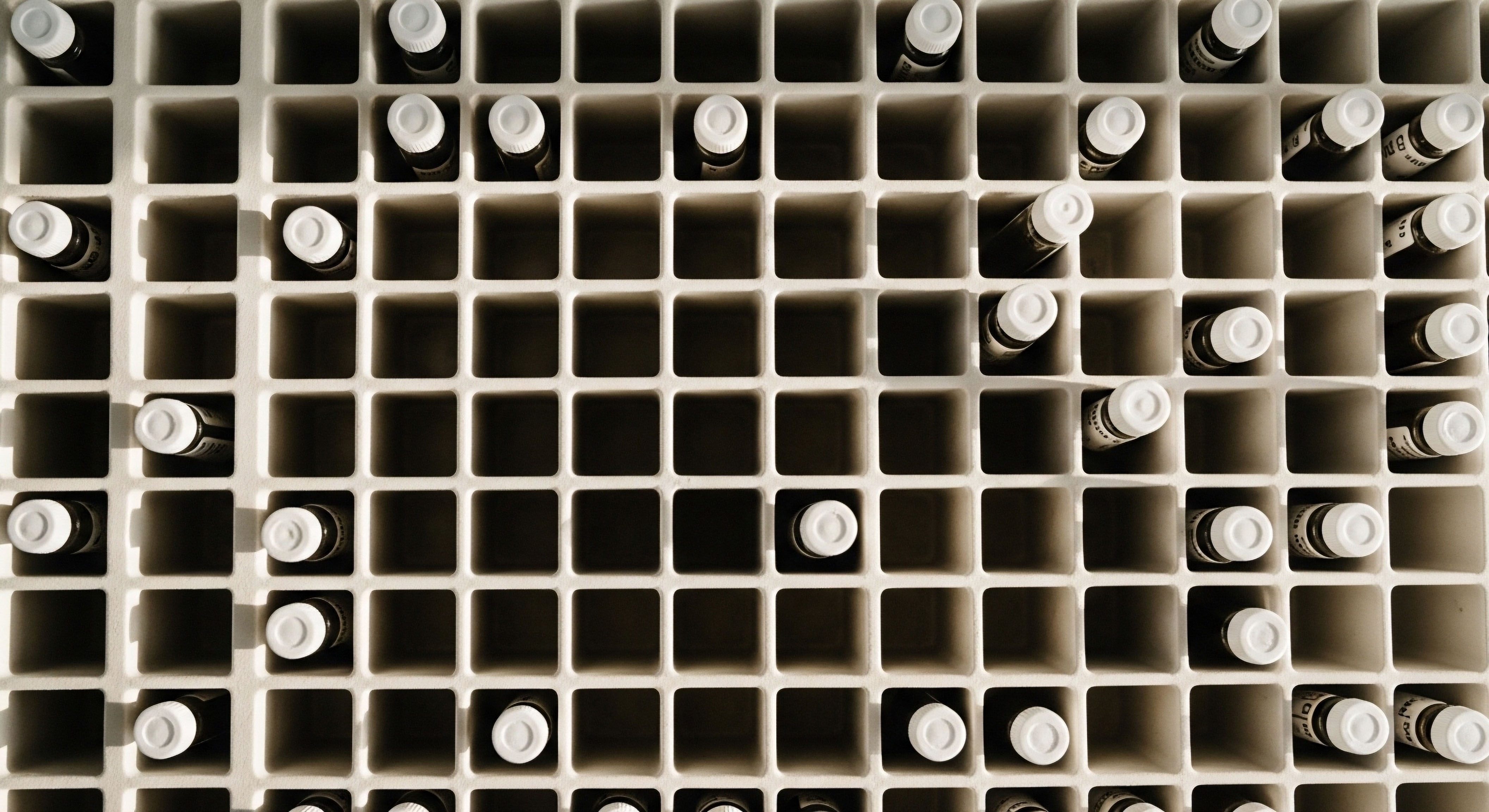

This is the same quality system that large pharmaceutical manufacturers follow. 503B facilities can produce large batches of sterile medications that are not necessarily tied to an individual patient prescription. This allows them to supply hospitals, clinics, and physician offices with consistent and readily available preparations for in-office use.

For example, a wellness clinic might source its Testosterone Cypionate, Gonadorelin, and certain peptide therapies directly from a 503B facility to ensure a stable supply for its patients. The emphasis here is on large-scale production, uniformity, and a federally mandated level of quality control.

A 503A pharmacy compounds for a specific patient, while a 503B facility manufactures batches of drugs for broader clinical use under stricter federal oversight.

Your experience with symptoms like brain fog, weight gain, or diminished libido is the start of a process. This process involves identifying the biochemical imbalance and then creating a therapeutic plan to restore function. The source of your medication is a key part of that plan.

A 503A pharmacy offers bespoke formulation tailored to your unique physiology, while a 503B facility provides medications produced under rigorous, federally regulated manufacturing standards, often used in clinical settings for established protocols. Both exist to serve patient needs, but they do so within different operational and regulatory frameworks that have direct implications for your personalized wellness journey.

Intermediate

As you become more engaged in managing your hormonal health, your understanding of the therapeutic options deepens. You begin to connect your subjective feelings of well-being to objective data from lab reports and the specific actions of your prescribed protocols.

This is the point where the distinction between 503A and 503B facilities moves from a simple definition to a practical consideration that impacts the quality, consistency, and reliability of your therapy. The choice between these two sources is a clinical decision, influenced by the regulatory landscape established by the Drug Quality and Security Act (DQSA). This legislation clarified the roles and responsibilities of each type of facility, creating a system designed to balance personalized medicine with public safety.

Regulatory Oversight a Tale of Two Systems

The primary divergence between 503A and 503B facilities lies in their regulatory supervision. This difference in oversight directly influences everything from product testing to labeling and distribution. A helpful analogy is to think of the body’s own regulatory systems.

State Boards of Pharmacy overseeing 503A facilities are like local paracrine signaling, where a cell communicates with its immediate neighbors. The system is localized, responsive, and tailored to individual circumstances. The FDA’s oversight of 503B facilities, conversely, is like the endocrine system itself, where a central gland releases hormones that have broad, systemic effects, governed by a strict feedback loop. This federal system is designed for widespread consistency and control.

The table below outlines the key operational and regulatory distinctions that are most relevant to a patient undergoing hormonal optimization.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Regulator | State Boards of Pharmacy | U.S. Food and Drug Administration (FDA) |

| Prescription Requirement | Required for each compounded medication (patient-specific). | Not required; can manufacture for office stock and institutional use. |

| Governing Quality Standard | United States Pharmacopeia (USP) Chapters, particularly <795> for non-sterile and <797> for sterile compounding. | Current Good Manufacturing Practices (cGMP) under 21 CFR Parts 210 and 211, a more rigorous standard. |

| Batch Production | Typically limited to small batches based on a history of prescriptions. | Permitted to produce large batches in anticipation of need. |

| Product Testing | Testing requirements vary by state but are generally less stringent than cGMP. Beyond-Use Dating (BUD) is often based on scientific literature. | Mandatory validation of every process. Each batch must be tested for sterility, potency, and endotoxins, with stability studies to determine expiration dates. |

| Adverse Event Reporting | Reporting requirements vary by state. | Mandatory reporting of serious adverse events to the FDA. |

| Interstate Distribution | Generally limited to distributing no more than 5% of total prescriptions out of state, unless the state has a Memorandum of Understanding (MOU) with the FDA. | Permitted to ship large quantities across state lines without restriction. |

What Do cGMP Standards Mean for Your Therapy?

The term Current Good Manufacturing Practices (cGMP) is the most significant differentiator for 503B facilities. This is a comprehensive quality assurance system that covers every aspect of production, from the sourcing of raw ingredients to the final packaging and labeling. For a patient on a long-term protocol, such as weekly injections of Testosterone Cypionate with Gonadorelin, cGMP compliance provides a high degree of assurance.

- Consistency ∞ cGMP requires that every batch of medication meets the exact same specifications for purity and concentration. This means the 0.5 mL dose you inject this week is identical to the one you will inject next month, minimizing variability in your physiological response.

- Sterility ∞ For injectable therapies like TRT or peptide protocols (e.g. Sermorelin, Ipamorelin/CJC-1295), sterility is paramount. cGMP mandates rigorous environmental monitoring and end-product testing to prevent contamination, a critical safety measure that was tragically highlighted by the 2012 New England Compounding Center outbreak which led to the DQSA.

- Stability ∞ 503B facilities must conduct extensive stability testing to establish reliable expiration dates for their products. This ensures that the complex molecules in your therapy, especially peptides which can be fragile, do not degrade over time and lose their therapeutic effect.

The stringent cGMP standards of 503B facilities ensure a level of product consistency, sterility, and stability analogous to that of major pharmaceutical manufacturers.

How Does This Impact Specific Hormonal Protocols?

Consider the standard male TRT protocol involving Testosterone Cypionate, Gonadorelin, and an aromatase inhibitor like Anastrozole. A physician might choose to source these medications from a 503B facility to ensure every component has been produced under cGMP standards, providing a reliable foundation for the therapy. This is particularly important for medications administered in-office or for clinics managing a large number of patients on similar protocols.

Conversely, if a patient has a demonstrated allergy to a specific preservative or requires a highly customized dose of Progesterone or Testosterone that is not available from a 503B facility, a 503A pharmacy is the essential choice. The 503A pharmacist’s expertise in formulation science allows them to create a product that meets the unique biochemical needs of that individual.

The trade-off for this personalization is a reliance on the quality standards of the specific pharmacy and its state-level regulation, rather than the federal cGMP system. Understanding this balance between personalization and industrial-scale quality assurance is key to being an informed participant in your own wellness protocol.

Academic

An academic exploration of the distinction between 503A and 503B entities transcends a simple comparison of regulatory statutes. It requires a systems-level analysis of the intersection between pharmaceutical law, public health, and the biochemical realities of endocrinology.

The critical pivot in this landscape was the 2013 Drug Quality and Security Act (DQSA), a legislative response to a public health crisis that fundamentally reshaped the governance of compounded medications. To fully appreciate the implications for hormonal therapies, one must examine the concept of pharmaceutical quality not as a monolithic attribute, but as a multidimensional variable influenced by process validation, chemical stability, and regulatory philosophy.

The Genesis of Bifurcation the NECC and the DQSA

The 2012 fungal meningitis outbreak traced to the New England Compounding Center (NECC) was a watershed moment. NECC operated in a gray area, functioning more like a large-scale manufacturer than a traditional pharmacy, yet it was regulated under the state-level framework intended for 503A-type pharmacies.

The catastrophic failure in sterile processing, which resulted in contaminated methylprednisolone acetate injections, exposed a critical vulnerability in the regulatory system. The subsequent investigation revealed a lack of adherence to even basic sterile compounding standards outlined in USP <797>, let alone the more rigorous cGMP required of manufacturers.

The DQSA was Congress’s attempt to resolve this ambiguity by creating a clear, voluntary pathway for large-scale compounders to register as 503B outsourcing facilities, thereby submitting to direct FDA oversight and cGMP standards. This created a bifurcated system.

The 503A pathway was preserved for its traditional role in providing individualized patient care, while the 503B pathway was established to ensure that facilities producing compounded drugs in bulk for office use would be held to the same quality standards as conventional drug manufacturers. This legal framework has profound implications for the clinical application of sensitive biologics like hormones and peptides.

cGMP and the Bioavailability of Hormonal Therapies

Current Good Manufacturing Practices are a set of systems and procedures designed to guarantee that a product is produced consistently and controlled to the quality standards appropriate for its intended use. For hormonal therapies, this has specific, tangible consequences beyond sterility.

Consider the molecular structure of peptide therapies like Sermorelin or CJC-1295. These are complex chains of amino acids that are inherently less stable than small-molecule drugs. Their therapeutic efficacy is contingent upon maintaining their precise three-dimensional structure. cGMP addresses this through several mechanisms:

- Raw Material Qualification ∞ 503B facilities must rigorously vet and test their suppliers of Active Pharmaceutical Ingredients (APIs). This ensures that the foundational testosterone powder or peptide sequence is pure and correctly identified from the outset.

- Process Validation ∞ The entire manufacturing process, from weighing ingredients to lyophilization (freeze-drying) of peptides, must be validated. This means producing multiple batches to prove the process consistently yields a product with the correct identity, strength, quality, and purity.

- Forced Degradation and Stability Studies ∞ To establish a scientifically sound expiration date, 503B facilities conduct stability studies under various conditions (e.g. temperature, light) to determine the rate at which the product degrades. This is critical for peptides, which can be rendered inactive by seemingly minor deviations in storage or handling. A BUD assigned by a 503A pharmacy based on general literature may not account for the specific formulation being used.

The federal cGMP framework provides a robust system for ensuring the molecular integrity and consistent bioavailability of complex hormonal and peptide therapies.

What Is the Clinical Impact of Sourcing on the HPG Axis?

The Hypothalamic-Pituitary-Gonadal (HPG) axis is a delicate hormonal feedback loop. Its proper regulation with therapies like TRT requires precise and consistent dosing. A sub-potent dose of Testosterone Cypionate due to degradation could fail to suppress LH and FSH adequately, leading to confusing lab results and suboptimal clinical outcomes.

An inconsistent dose of Gonadorelin, used to mimic GnRH and maintain testicular function, could lead to erratic stimulation of the pituitary. Sourcing these medications from a 503B facility operating under cGMP minimizes this iatrogenic variability, allowing the clinician to more accurately assess the patient’s true physiological response to a known quantity of the drug.

The following table provides a granular comparison of the quality assurance paradigms, viewed through the lens of ensuring therapeutic precision for hormonal protocols.

| Quality Assurance Domain | 503A Pharmacy (USP <797> Focus) | 503B Facility (cGMP Focus) |

|---|---|---|

| Environmental Control | Requires cleanrooms and regular environmental monitoring (e.g. every six months). | Requires a more comprehensive system of air quality control, pressure differentials, and continuous monitoring to minimize contamination risk. |

| Process Control | Focuses on the procedural competence of the pharmacist and technicians during the compounding act itself. | Requires formal validation of every step in the manufacturing process to ensure it is reproducible and consistently yields a quality product. |

| Finished Product Testing | Testing may be performed on batches, but is not universally required for all preparations in all states. Potency testing is not always mandatory. | Mandatory testing of every batch for identity, strength, quality, purity, and sterility before release. |

| Supplier Verification | Pharmacists are expected to use reputable suppliers, but the onus of verification is less formalized. | Requires a formal program for qualifying and auditing all suppliers of raw materials and components. |

The existence of these two distinct pathways reflects a sophisticated legislative and regulatory solution. It acknowledges the irreplaceable role of the 503A pharmacist in crafting bespoke medications for individual needs. Simultaneously, it provides a mechanism, through the 503B designation, to ensure that when compounded drugs are produced on a larger scale, they are subject to the same rigorous quality systems that govern the broader pharmaceutical industry.

For the clinician managing complex endocrine protocols and the patient seeking to restore biological function, understanding this distinction is fundamental to achieving safe, effective, and predictable therapeutic outcomes.

References

- Gudeman, J. Jozwiakowski, M. Chollet, J. & Randell, M. (2013). Potential Risks of Pharmacy Compounding. Drugs in R&D, 13(1), 1 ∞ 8.

- United States Food and Drug Administration. (2018). Guidance for Industry ∞ Current Good Manufacturing Practice ∞ Guidance for Human Drug Compounding Outsourcing Facilities Under Section 503B of the FD&C Act.

- The Pew Charitable Trusts. (2016). National Assessment of State Oversight of Sterile Drug Compounding.

- Drug Quality and Security Act, H.R. 3204, 113th Cong. (2013).

- United States Pharmacopeial Convention. (2019). General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations.

- Glass, G. (2014). The Drug Quality and Security Act of 2013 ∞ A New Law to Address Compounding Pharmacy. Journal of Oncology Practice, 10(4), e230-e233.

- Kawa, M. P. & Hayman, J. S. (2015). The Drug Quality and Security Act ∞ A Primer for Health-System Pharmacists. Hospital Pharmacy, 50(2), 149 ∞ 154.

- National Academies of Sciences, Engineering, and Medicine. (2020). The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of the Evidence. The National Academies Press.

- Low, J. C. (2015). The Drug Quality and Security Act ∞ A new era for compounding. American Journal of Health-System Pharmacy, 72(13), 1080-1088.

- United States Food and Drug Administration. (2021). FD&C Act Provisions that Apply to Human Drug Compounding.

Reflection

Calibrating Your Personal Health Equation

You began this inquiry seeking to understand the source of your medications. You now possess a detailed map of the regulatory and quality systems that govern their creation. This knowledge is a powerful tool. It transforms you from a passive recipient of care into an active, informed partner in your own health restoration. The journey to reclaim your vitality is deeply personal, yet it unfolds within this larger, complex system of science, law, and clinical practice.

Consider the data points of your own life ∞ the subtle shifts in energy, the changes in sleep architecture, the fluctuations in cognitive clarity. These are the variables in your unique biological equation. The therapies you undertake are the constants you introduce to solve for wellness.

Understanding whether that constant is derived from a 503A or 503B facility allows you to better interpret the results. It provides context for your progress and empowers you to ask more precise questions of your clinical team.

The path forward is one of continued calibration. It involves listening to your body’s signals, reviewing objective lab data, and working with a provider who appreciates the profound connection between the source of a therapy and its effect on your system. Your biology is dynamic.

Your approach to managing it should be equally informed and adaptable. The ultimate goal is to achieve a state of function and vitality that feels authentic to you, built upon a foundation of knowledge and trust in every component of your protocol.