Fundamentals

Understanding the systems that provide specialized medications is a deeply personal part of a health journey. When a specific formulation is required, one that is tailored to your unique biological needs, the source of that preparation becomes paramount.

The conversation about personalized medicine often centers on the therapies themselves, yet the integrity of their creation is the silent, foundational pillar upon which successful outcomes are built. This is where the function of a 503B outsourcing facility becomes directly relevant to your pursuit of wellness. These are not standard pharmacies.

They are facilities registered with the Food and Drug Administration (FDA) that prepare medications in larger batches, operating under a specific and stringent set of federal guidelines designed to ensure each dose is consistent, stable, and sterile.

The establishment of these facilities arose from a critical need for a higher standard of quality control in compounding. For individuals relying on therapies like hormone optimization protocols or specialized peptide treatments, the consistency of a medication from one month to the next is a biological necessity.

A 503B facility operates in the space between a conventional pharmaceutical manufacturer and a local compounding pharmacy that prepares a single prescription for a specific person. They are authorized to compound sterile drugs, which are preparations intended for injection, infusion, or application to sensitive tissues, making their role in producing injectable therapies like Testosterone Cypionate or Growth Hormone peptides biologically significant.

The decision to register as a 503B facility is a voluntary election to operate under federal oversight, including regular FDA inspections and adherence to Current Good Manufacturing Practices (CGMP).

A 503B outsourcing facility provides sterile compounded medications under strict FDA oversight, ensuring quality and safety for batch-produced therapies.

The Core Mandate of a 503b Facility

The primary directive for a 503B outsourcing facility is to produce compounded medications that are uniform and free from contamination. This mandate is what separates them from other types of pharmacies. To achieve this, every process, from the sourcing of raw ingredients to the final packaging, is governed by a set of rigorous standards.

All compounding activities must be conducted under the direct supervision of a licensed pharmacist. This ensures that professional expertise is integrated into every step of the production cycle. The facility itself is designed to minimize the risk of contamination, with controlled environments and meticulous procedures for maintaining sterility.

This operational framework is what allows a physician to confidently prescribe a therapy, knowing that the medication adheres to a predictable and reliable standard of quality, which is the bedrock of any effective personalized wellness protocol.

What Does This Mean for Your Treatment?

When your protocol involves a compounded medication from a 503B facility, it signifies a commitment to quality assurance. It means the testosterone, progesterone, or peptide preparation you administer has been produced in an environment that is held to the same high standards as a large-scale drug manufacturer.

These facilities must report detailed information about the products they compound to the FDA, including a list of all drugs produced every six months and reports on any adverse events. This transparency creates a system of accountability. For anyone on a journey to recalibrate their endocrine system, this level of oversight provides a sense of security.

The biological systems of the human body are incredibly sensitive to inputs; therefore, the purity and consistency of therapeutic inputs are not merely details, they are central to the success of the treatment itself.

Intermediate

To appreciate the operational integrity of a 503B outsourcing facility, it is necessary to examine the architecture of its regulatory obligations. The framework these facilities operate within is defined by the Federal Food, Drug, and Cosmetic Act (FD&C Act), specifically section 503B.

This section establishes the legal foundation, but the practical, day-to-day standards are dictated by Current Good Manufacturing Practices (CGMP). These are the same quality systems that govern pharmaceutical manufacturers, adapted for the unique context of compounding. Adherence to CGMP is not a suggestion; it is a legal requirement for registration and continued operation as a 503B facility.

This system is designed to ensure that every batch of a compounded drug product has the identity, strength, quality, and purity it purports to possess.

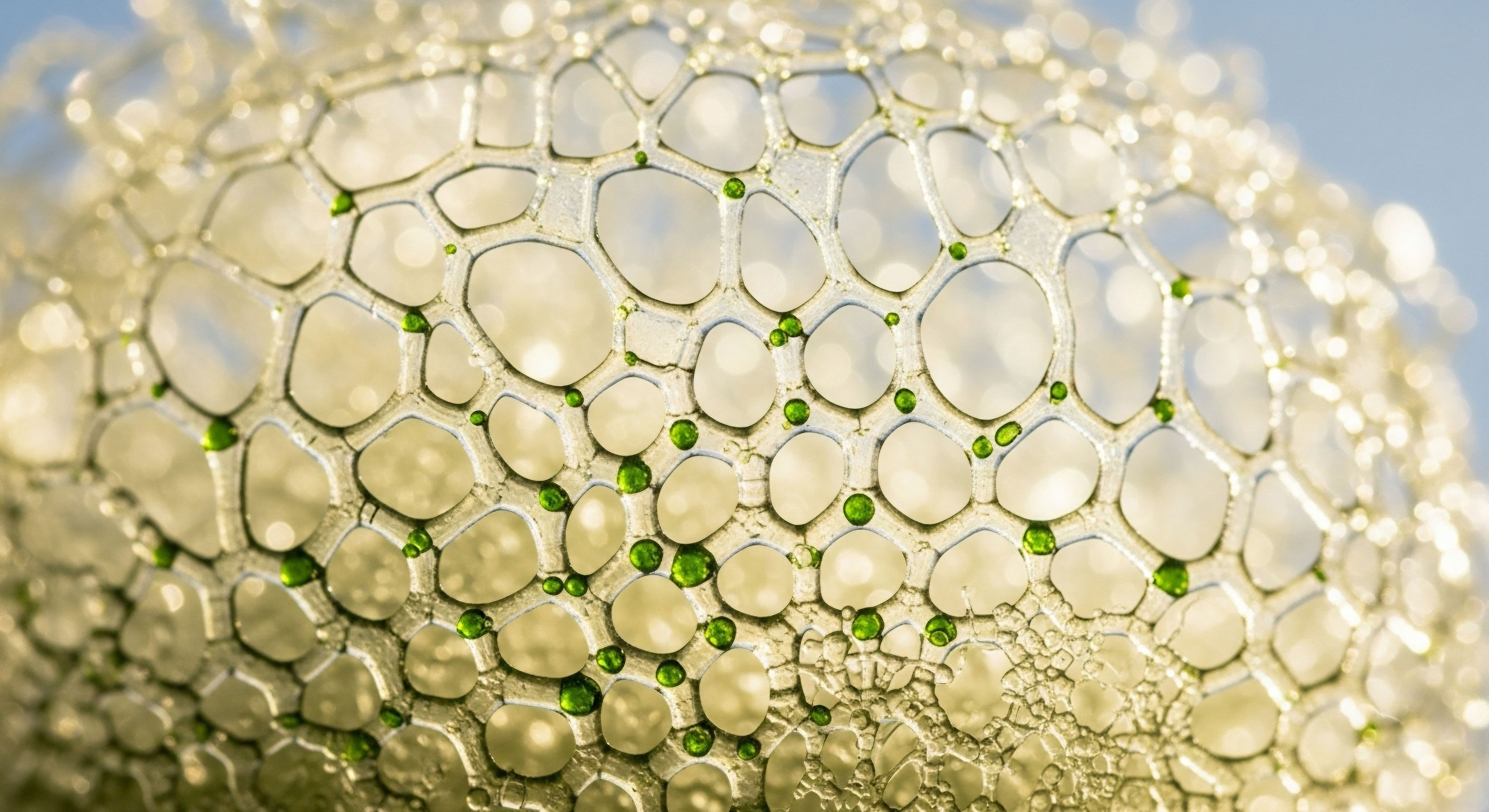

The CGMP framework can be understood as a series of interlocking systems, each designed to control a different aspect of the production process. Think of it as the body’s own endocrine system, where different glands and hormones create a complex web of feedback loops to maintain homeostasis.

In a 503B facility, the quality control unit acts as the pituitary gland of the operation, providing oversight and direction to ensure all other systems function in harmony. This unit holds the authority to approve or reject all components, drug product containers, closures, in-process materials, packaging material, labeling, and the final drug products themselves. This centralized command structure is fundamental to preventing errors and ensuring consistency from one batch to the next.

Key Pillars of Current Good Manufacturing Practices

The CGMP requirements are extensive, covering every facet of production. These regulations are detailed in the Code of Federal Regulations and are enforced through regular FDA inspections. A facility’s compliance with these standards is a direct measure of its ability to produce safe and effective medications.

- Facility Design and Environmental Controls The physical layout of a 503B facility is engineered to prevent contamination. This includes the use of cleanrooms with specific air quality standards, logical flows for personnel and materials to prevent mix-ups, and surfaces that are smooth, hard, and easy to clean. Environmental monitoring is a continuous process, with regular testing for microbial and particulate contamination to ensure the sterile compounding environment is maintained.

- Process Validation and Control Every process, from the sterilization of equipment to the compounding of the final product, must be validated. This means there is documented evidence providing a high degree of assurance that a specific process will consistently produce a product meeting its predetermined specifications and quality attributes. For sterile drugs, this includes aseptic process simulations (media fills) to demonstrate that the facility’s procedures can reliably produce a sterile product.

- Quality Control Unit and Testing A dedicated quality control unit, independent from production, must be established. This unit is responsible for a wide array of functions, including the review of all production records, the investigation of any deviations or failures, and the testing of raw materials and finished products. Finished sterile drug products must be tested for identity, strength, and sterility before they can be released and distributed. For injectable products, testing for bacterial endotoxins is also a critical requirement.

- Documentation and Record-Keeping A core tenet of CGMP is to document every action. If it was not documented, it did not happen. This includes detailed batch production records that trace the entire lifecycle of a product, from the raw materials used to the final release testing. These records provide a complete history of each batch and are essential for investigating any issues that may arise.

How Do These Requirements Ensure Drug Quality?

The stringent requirements of CGMP create a robust system of checks and balances. The focus on validated processes and extensive testing provides a high degree of confidence that each vial of medication meets the required specifications. The table below outlines some of the key differences in requirements between a 503B outsourcing facility and a traditional 503A compounding pharmacy, illustrating the elevated standards under which 503B facilities operate.

| Regulatory Aspect | 503B Outsourcing Facility | 503A Compounding Pharmacy |

|---|---|---|

| Governing Standard | Current Good Manufacturing Practices (CGMP) | State Pharmacy Board Standards (USP Chapters) |

| FDA Registration | Required to register with the FDA | Not required to register with the FDA |

| Production Volume | Can produce large batches without prescriptions | Limited to patient-specific prescriptions |

| FDA Inspections | Subject to routine, risk-based FDA inspections | Primarily inspected by state boards of pharmacy |

| Adverse Event Reporting | Mandatory reporting to the FDA | Reporting requirements vary by state |

This regulatory structure is what enables a 503B facility to function as a reliable source of sterile medications for hospitals, clinics, and individual patients. The investment in infrastructure, personnel, and quality systems required to meet CGMP standards is substantial, but it is this investment that provides the necessary assurance of quality for therapies that are central to a person’s health and well-being.

Academic

A granular analysis of the operational demands placed on 503B outsourcing facilities reveals a sophisticated matrix of scientific and regulatory controls, particularly concerning the assurance of sterility. The entire framework of Current Good Manufacturing Practices (CGMP) as applied to these facilities is predicated on a deep understanding of microbiology, chemistry, and environmental engineering.

The production of sterile drug products, especially those intended for injection, represents the apex of pharmaceutical compounding risk. Consequently, the FDA’s regulatory expectations are focused on the design, validation, and maintenance of processes that eliminate microbial contamination. This is achieved through a multi-layered strategy that integrates facility design, personnel behavior, process control, and rigorous testing.

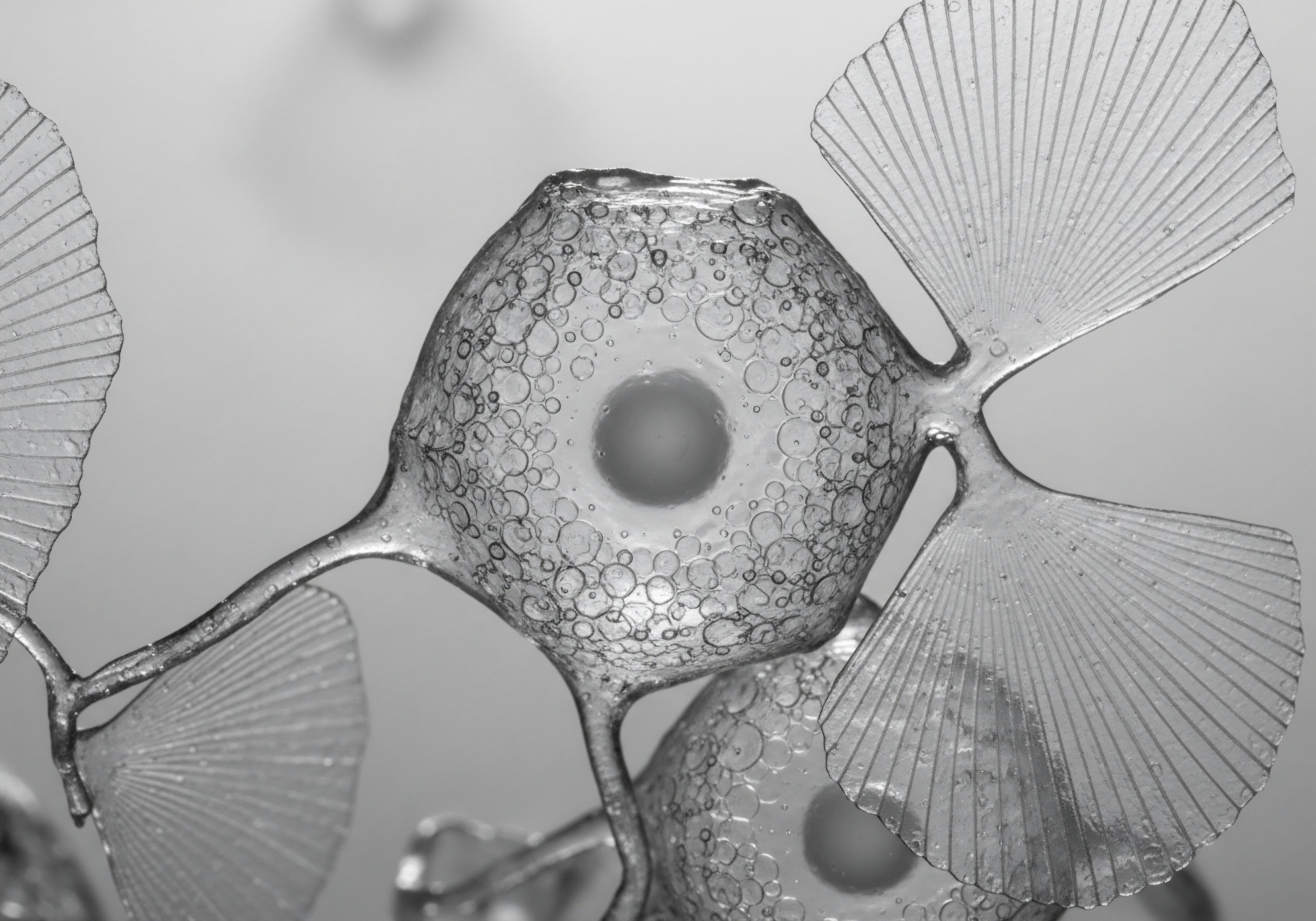

The foundational scientific principle is that sterility cannot be adequately assured by simply testing the finished product. While finished product sterility testing is a requirement, its statistical limitations are well-documented. A batch of product could contain a low level of microbial contamination that is missed by random sampling.

Therefore, the assurance of sterility must be built into the process itself. This is the core concept behind aseptic processing. The objective is to create an environment and a set of procedures that are so meticulously controlled that the probability of a non-sterile unit being produced is exceptionally low. The FDA guidance for industry on sterile drug products produced by aseptic processing provides the scientific basis for many of the CGMP requirements for 503B facilities.

Sterility in 503B facilities is achieved by designing and validating an entire system of controls, as end-product testing alone is insufficient to guarantee quality.

The Science of Aseptic Process Validation

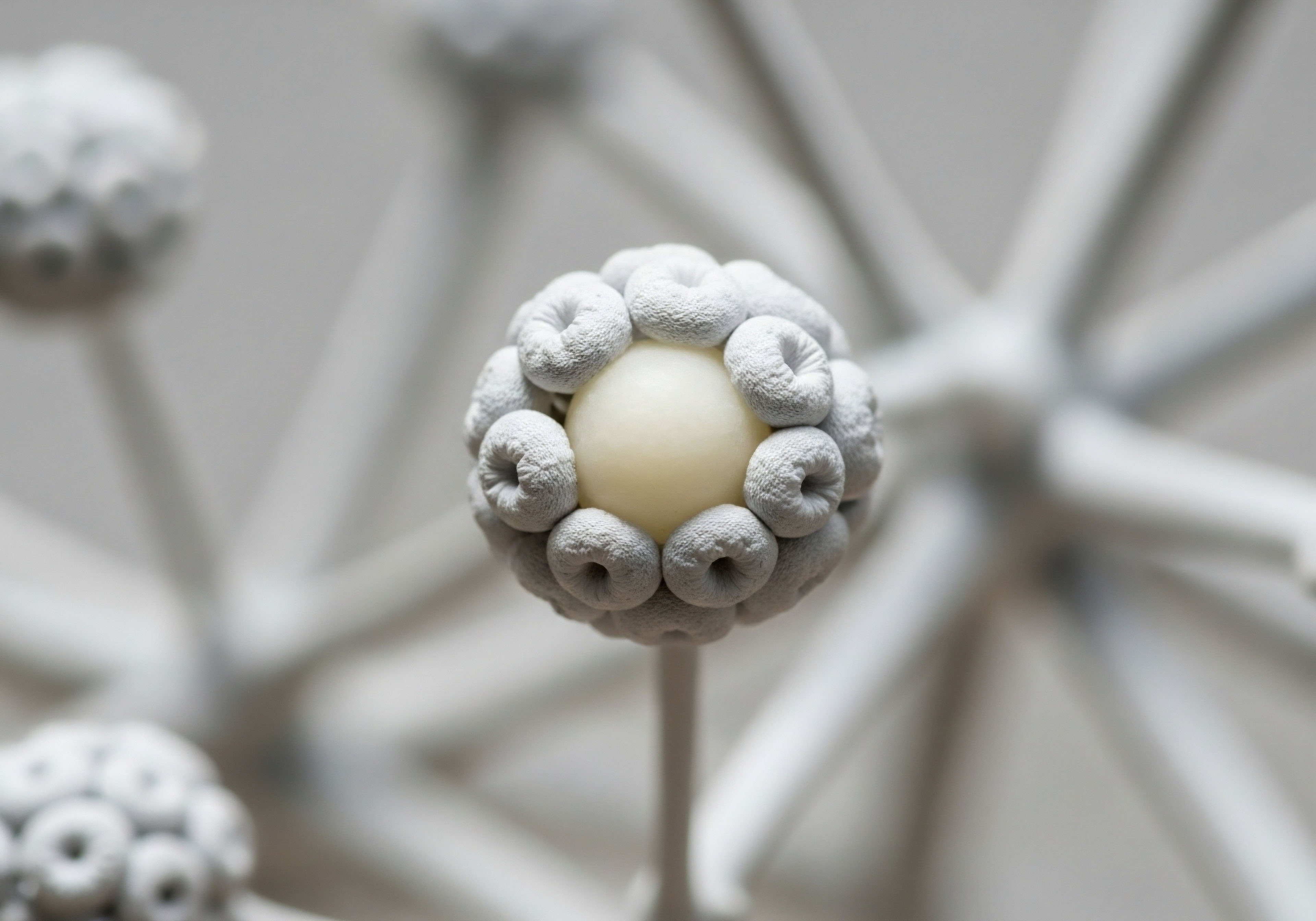

The qualification of an aseptic processing operation is one of the most critical and complex undertakings for a 503B facility. This is accomplished through a procedure known as a media fill or aseptic process simulation.

In a media fill, a sterile microbial growth medium (like soybean-casein digest medium) is used in place of the actual drug product and is processed in the exact same manner as a normal production batch. This includes simulating all the manipulations, interventions, and durations that would occur during routine production.

The filled units are then incubated under specific conditions to promote the growth of any microorganisms that may have entered the container during the filling process. The goal is to have zero positive (contaminated) units. A successful media fill provides documented evidence that the facility’s aseptic processing line, including the equipment, environment, and personnel, is capable of consistently producing sterile drug products.

These simulations must be performed upon initial qualification of a process and then typically on a semi-annual basis for each processing line and for each operator to maintain their qualification.

Environmental Monitoring and Control

To support aseptic processing, the facility must maintain a meticulously controlled environment. The CGMP requirements specify a system for classifying cleanrooms based on the number and size of airborne particles. The most critical area, where sterile products and containers are exposed, must meet ISO 5 classification standards. This is achieved through the use of high-efficiency particulate air (HEPA) filters and carefully designed airflow patterns.

An extensive environmental monitoring program is required to verify that the controlled environment is being maintained. This program involves both non-viable and viable monitoring.

| Monitoring Type | Description | Methodology |

|---|---|---|

| Non-Viable Monitoring | Measures the concentration of airborne particles of various sizes. | Utilizes laser-based particle counters to provide real-time data on air cleanliness. |

| Viable Monitoring | Detects the presence of microorganisms (bacteria, yeast, mold) in the air and on surfaces. | Includes active air sampling, passive air sampling (settle plates), surface sampling (contact plates and swabs), and personnel monitoring (glove and gown sampling). |

The data from this program is trended over time to detect any shifts in the microbial state of the facility. Any result that exceeds the established action levels must trigger a thorough investigation to identify the source of the contamination and implement corrective actions. This continuous feedback loop is essential for maintaining a state of control and ensuring the ongoing quality of the sterile products being compounded.

The scientific and regulatory demands on 503B outsourcing facilities are substantial. They require a deep expertise in pharmaceutical science and a significant investment in quality systems. These requirements are what provide the high degree of assurance necessary for medications that are administered directly into the body’s most sensitive systems, forming a critical link in the chain of personalized medicine.

References

- U.S. Food and Drug Administration. (2013). Drug Quality and Security Act (DQSA).

- U.S. Food and Drug Administration. (2020). Current Good Manufacturing Practice ∞ Guidance for Human Drug Compounding Outsourcing Facilities Under Section 503B of the FD&C Act.

- Code of Federal Regulations, Title 21, Part 210, “Current Good Manufacturing Practice in Manufacturing, Processing, Packing, or Holding of Drugs; General.”

- Code of Federal Regulations, Title 21, Part 211, “Current Good Manufacturing Practice for Finished Pharmaceuticals.”

- Sutton, S. (2012). “The Sterility Testing of Pharmaceutical Products.” Journal of GXP Compliance, 16(3), 61-73.

- Agalloco, J. & Akers, J. E. (2016). “Aseptic Processing ∞ A Review of Current Industry Practice.” Pharmaceutical Technology, 40(5), 36-43.

- Cundell, A. M. (2018). “Risk-Based Environmental Monitoring.” In Microbial Control and Identification (pp. 1-32). CRC Press.

Reflection

The knowledge of how specialized medications are created provides a new lens through which to view your own health protocol. Understanding the systems of quality and control that underpin a 503B facility transforms the abstract concept of ‘medication safety’ into a tangible set of processes and commitments.

This information is a tool, empowering you to ask more precise questions and to appreciate the profound difference that regulatory adherence makes. Your path to optimized function is a collaborative one, built on a foundation of scientific integrity and informed trust. The journey forward involves continuing this dialogue, connecting the science of these preparations to the unique biological system that is you, and ensuring every element of your protocol is aligned with your ultimate goal of sustained vitality.