Fundamentals

Your journey toward hormonal balance often begins with a deeply personal realization. You feel a shift in your body’s internal landscape ∞ a change in energy, mood, or vitality that laboratory tests may confirm. This leads many to the promise of compounded hormones, preparations designed specifically for your unique physiology.

This personalization is a powerful concept. It aligns with the body’s own intricate signaling system. Understanding the quality control measures that underpin these bespoke therapies is fundamental to ensuring the safety and predictability of your protocol.

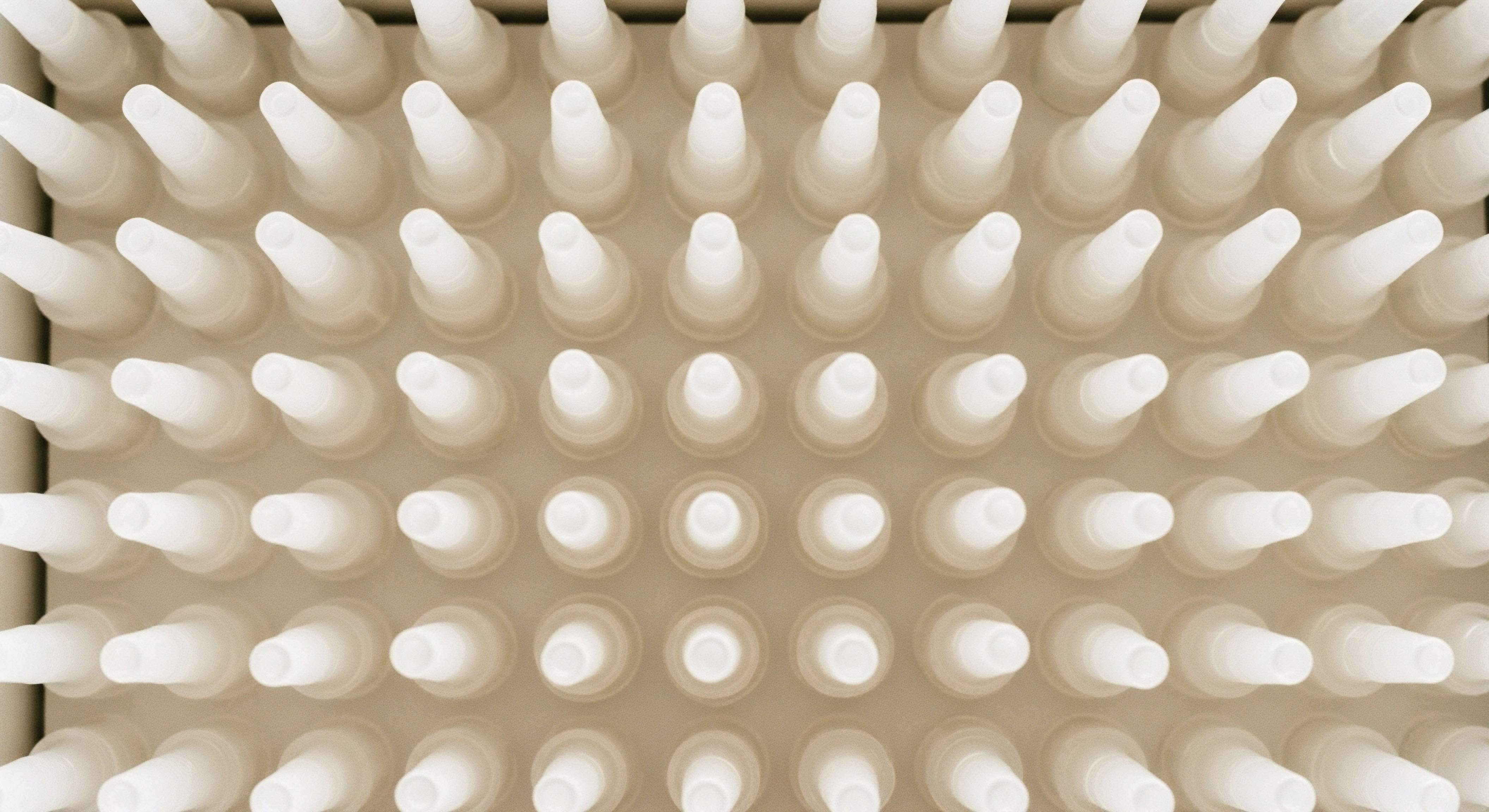

Think of a compounded hormone preparation as a highly specific key crafted for a single, complex lock ∞ your endocrine system. For that key to work perfectly, it must be fabricated with absolute precision. The three foundational pillars of quality control in this context are potency, purity, and sterility.

Potency ensures the key is the right size and shape, delivering the exact dose your body requires. Purity guarantees the key is made of the correct material, free from any impurities that could jam the lock or cause unintended effects. Sterility, particularly for injectable preparations, confirms the key is clean, introducing only the intended therapeutic agent into your system.

The Locus of Control in Compounding

Unlike commercially manufactured medications, which are produced in large, standardized batches, each compounded hormone preparation is made individually or in small batches. This shifts the locus of quality control directly to the compounding pharmacy and the prescribing clinician. The process relies on rigorous adherence to established protocols and a deep commitment to patient safety.

The dialogue between your physician and the compounding pharmacist is central to this process. It establishes the exact formulation and strength required to meet your specific biological needs, based on a careful assessment of your symptoms and lab work.

The integrity of a personalized hormone protocol rests upon the verifiable quality and precision of the compounded preparation itself.

This level of customization requires a system of checks and balances that begins with the raw ingredients. The active pharmaceutical ingredients (APIs) ∞ the base hormones like Testosterone Cypionate or Estradiol ∞ must be sourced from reputable suppliers who can provide a Certificate of Analysis (CofA).

This document is the first checkpoint, verifying the identity and purity of the raw material. From there, every step of the compounding process, from weighing and mixing to packaging and labeling, is governed by a detailed set of procedures designed to produce a final preparation that is both safe and effective for your use.

Intermediate

As you become more familiar with the landscape of hormonal optimization, it becomes clear that the term “compounding pharmacy” encompasses a range of facilities with different regulatory frameworks. These distinctions have direct implications for the quality control measures applied to your therapy. The two primary designations in the United States are 503A and 503B facilities. Understanding their operational differences is key to making an informed decision about where your personalized hormones are prepared.

A 503A facility is a traditional compounding pharmacy that prepares medications for specific patients pursuant to a prescription. They are primarily regulated by state boards of pharmacy. A 503B outsourcing facility, established under the Drug Quality and Security Act, can compound larger batches of sterile medications with or without a prescription.

These facilities must register with the FDA and adhere to full Current Good Manufacturing Practices (CGMP), the same standards required for pharmaceutical manufacturers. This distinction is central to the conversation about quality assurance.

Core Analytical Testing Protocols

Regardless of the facility type, several specific analytical tests form the backbone of quality control for compounded hormones. These tests provide objective data on the safety and accuracy of the final preparation.

- Potency Testing ∞ This is arguably the most critical quality control measure. It verifies that the finished preparation contains the exact amount of the active hormone specified in the prescription. The gold standard for this analysis is High-Performance Liquid Chromatography (HPLC), a sensitive technique that separates, identifies, and quantifies each component in a mixture. Consistent potency is essential for achieving predictable clinical outcomes and avoiding the risks of underdosing or overdosing.

- Sterility Testing ∞ For any preparation administered via injection or pellet insertion, sterility is non-negotiable. This testing involves culturing a sample of the preparation in specialized media to ensure there is no microbial growth, such as bacteria or fungi. A contaminated injectable can lead to serious localized or systemic infections.

- Endotoxin Testing ∞ Endotoxins are substances released from the cell walls of certain bacteria. Even in a sterile preparation where the bacteria have been killed, these endotoxins can remain and cause a pyrogenic response, such as fever and inflammation, if injected. The Limulus Amebocyte Lysate (LAL) test is used to detect their presence.

- Beyond-Use Dating (BUD) ∞ The BUD is the date after which a compounded preparation should not be used. A scientifically valid BUD is determined by stability studies, which assess how long the preparation maintains its potency and sterility under specific storage conditions. Many 503A pharmacies assign BUDs based on general guidelines rather than product-specific stability testing, which can be a significant variable.

How Do 503a and 503b Facilities Compare?

The regulatory requirements for 503A and 503B facilities create different quality control environments. While many 503A pharmacies voluntarily adhere to high standards and seek external accreditation, the baseline requirements are less stringent than those for 503B facilities. This table outlines some of the key operational differences.

| Quality Control Parameter | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Governing Regulation | State Boards of Pharmacy; USP Chapters | FDA Registration; Current Good Manufacturing Practices (CGMP) |

| Potency Testing | Often performed on a sample basis; not required for every batch. | Required for every batch of sterile product produced. |

| Sterility Testing | Required for sterile compounds; may be performed on a smaller sample size. | Required for every sterile batch before release. |

| Stability & BUD | Often based on USP guidelines; product-specific stability testing is not mandatory. | Must be supported by product-specific stability testing data. |

| Prescription Requirement | Requires a prescription for an individual patient. | Can produce for office use without individual prescriptions. |

Academic

A sophisticated appreciation of quality control in compounded hormones moves beyond the mere execution of tests and into the validation of the analytical methods themselves. Within the framework of clinical chemistry and pharmaceutical science, a result is only as reliable as the method that produced it.

For compounded preparations, where patient-to-patient variability is the norm, the robustness of the quality system is a direct determinant of therapeutic precision and patient safety. The entire quality assurance structure is built upon the Master Formulation Record (MFR), the comprehensive document that dictates every variable of the compounding process.

The Principle of Analytical Method Validation

For a test like HPLC to be considered scientifically valid for potency determination, the method itself must undergo a rigorous validation process. This process establishes the performance characteristics of the method, ensuring it is suitable for its intended purpose. Key validation parameters include:

- Accuracy ∞ The closeness of the test results to the true value. This is often determined by spiking a placebo cream or oil with a known quantity of the hormone API and measuring the recovery.

- Precision ∞ The degree of agreement among individual test results when the procedure is applied repeatedly to multiple samplings from a homogeneous batch. This is expressed as the relative standard deviation.

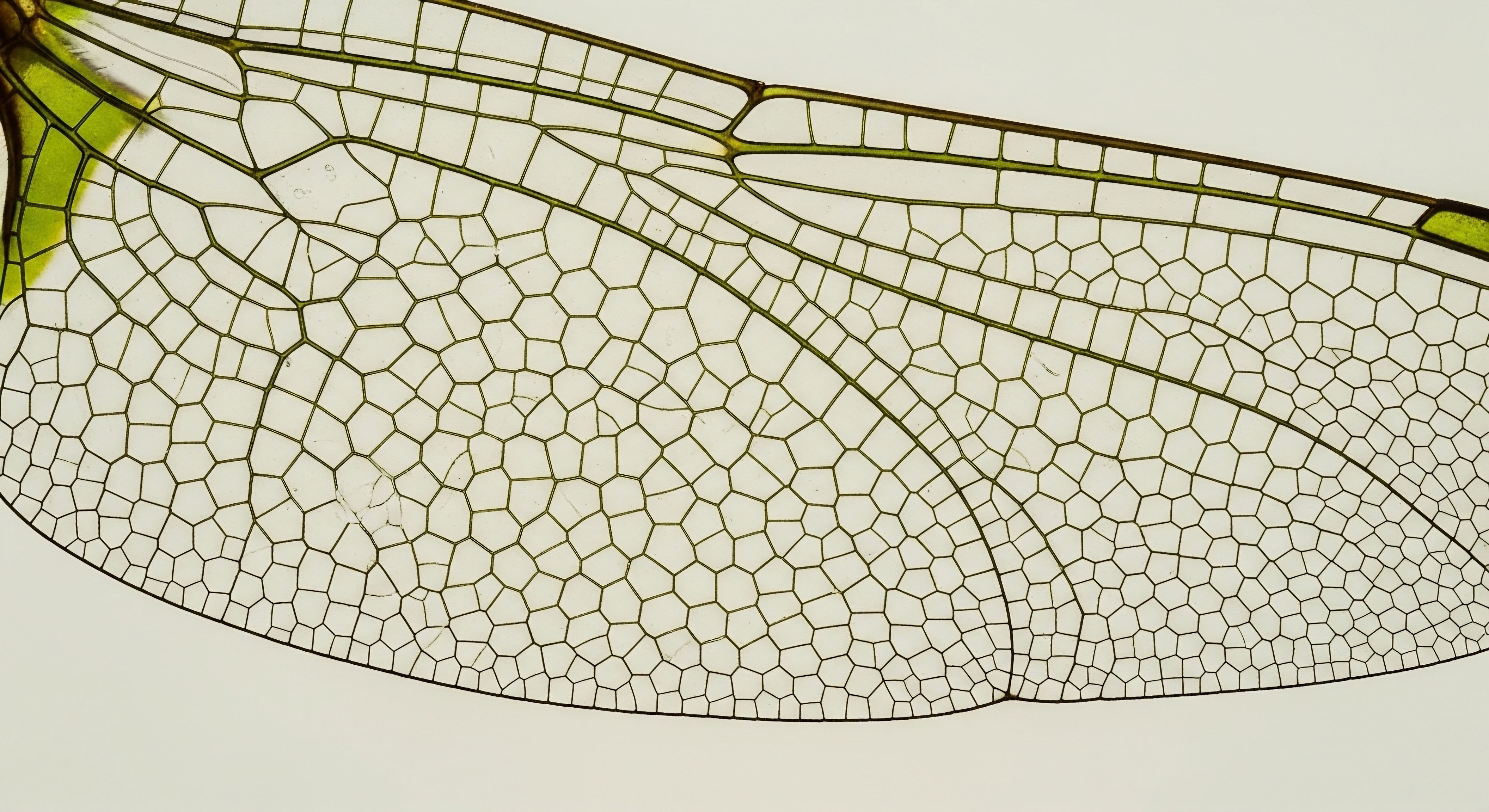

- Specificity ∞ The ability to assess the active hormone unequivocally in the presence of other components that may be expected to be present, such as degradation products, other hormones in a combination cream, or excipients from the base.

- Linearity ∞ The ability to elicit test results that are directly proportional to the concentration of the analyte within a given range. This confirms the method is reliable across the different strengths a clinician might prescribe.

Without this formal validation, potency results lack scientific certainty. A leading 503B outsourcing facility will have fully validated analytical methods for every hormone preparation it produces, with all data documented and available for review.

The reliability of a compounded hormone preparation is a direct function of the validated analytical science supporting its production.

Forced Degradation and Pharmacokinetic Considerations

Establishing a meaningful Beyond-Use Date requires an understanding of how a preparation degrades. Forced degradation studies intentionally expose the compounded hormone to harsh conditions ∞ such as elevated temperature, humidity, light, and acidic or basic environments ∞ to identify potential degradation products and degradation pathways.

This information is crucial for developing a stability-indicating analytical method, one that can accurately measure the amount of the intact active hormone without interference from its breakdown products. This level of analysis provides the scientific foundation for determining how long a preparation truly maintains its integrity.

True quality assurance in compounding involves not just verifying the starting product, but understanding its chemical behavior over time.

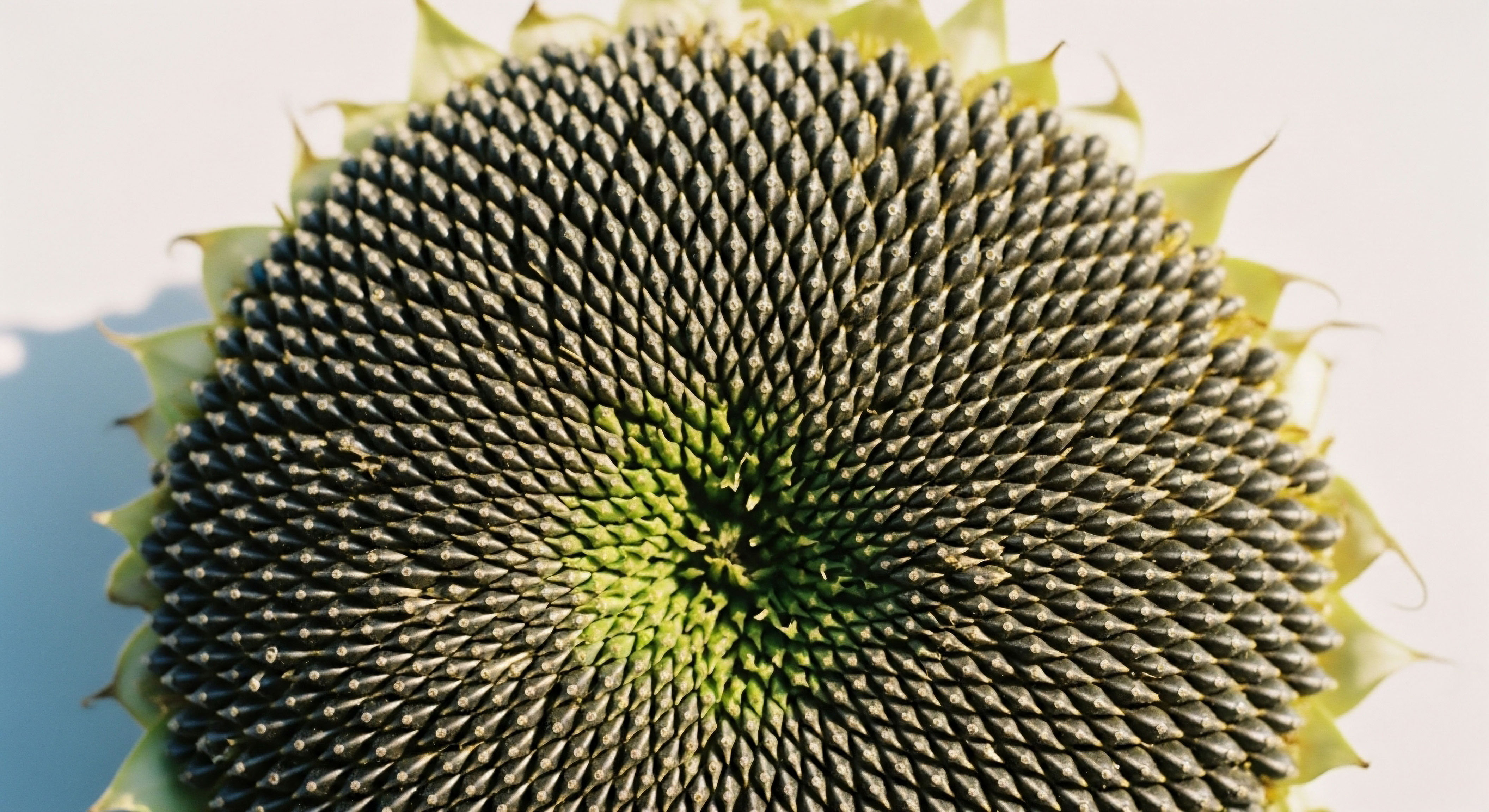

This academic rigor extends to the pharmacokinetic performance of the dosage form. For sustained-release preparations like testosterone pellets or transdermal creams, the quality control process should ideally include an assessment of the drug release profile. In-vitro dissolution testing can simulate the release of the hormone from its delivery vehicle over time.

A lack of such testing means the rate of absorption in the body is presumed rather than verified. This can lead to the supra-physiological spikes and sub-therapeutic troughs in hormone levels that many patients experience, which can manifest as mood volatility, fluctuating energy, or other side effects. True mastery in compounding involves engineering a preparation that delivers the hormone in a predictable, controlled manner, and having the analytical data to prove it.

Advanced Analytical Techniques in Hormone QC

The table below details specific analytical methods and their application in a high-quality compounding environment, demonstrating the depth of scientific oversight required to ensure patient safety.

| Analytical Method | Primary Application in Hormone QC | Biological Relevance |

|---|---|---|

| LC-MS/MS (Liquid Chromatography-Tandem Mass Spectrometry) | Purity analysis and identification of unknown trace contaminants or degradation products. | Ensures the preparation is free from potentially harmful impurities that could disrupt endocrine function or cause other adverse effects. |

| Gas Chromatography-Mass Spectrometry (GC-MS) | Screening for residual solvents left over from the synthesis of the raw hormone API. | Prevents patient exposure to organic volatile impurities that may be toxic. |

| Karl Fischer Titration | Quantifying the exact water content in raw materials and finished preparations. | Excess moisture can promote microbial growth and hydrolysis of the hormone, degrading its potency and compromising safety. |

| In-Vitro Dissolution Testing (e.g. USP Apparatus 2) | Measuring the rate and extent of hormone release from semi-solid (creams) or solid (pellets) dosage forms. | Provides data to predict the in-vivo pharmacokinetic profile, aiming for steady hormone levels and minimizing peaks and troughs. |

References

- Springer, G. & “The standardization of nonsterile compounding ∞ a study in quality control and assessment for hormone compounding.” International journal of pharmaceutical compounding, 17(5), 421 ∞ 426.

- National Academies of Sciences, Engineering, and Medicine. (2020). Compounded Bioidentical Hormone Preparations. In The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of the Evidence. National Academies Press (US).

- Santoro, N. Braunstein, G. D. Butts, C. L. Martin, K. A. McDermott, M. & Pinkerton, J. V. (2016). “Compounded Bioidentical Hormones in Endocrinology Practice ∞ An Endocrine Society Scientific Statement.” Journal of Clinical Endocrinology & Metabolism, 101(4), 1318 ∞ 1343.

- VUMC. “A Guide to Writing a Compounded Prescription for Hormone Replacement Therapy (HRT)”. Vanderbilt University Medical Center. 2024.

- Khan, Z. (2016). Quality control for hormonal product. SlideShare.

Reflection

You began this inquiry seeking to understand the systems that ensure the quality of your personalized therapy. The journey through the technical landscape of potency assays, sterility protocols, and regulatory frameworks ultimately leads back to a very personal place. The knowledge of these measures is a tool.

It equips you to engage in a more substantive dialogue with your clinician. It allows you to ask pointed questions about the pharmacy that prepares your hormones and the data that supports their stability and accuracy.

What Is the True Meaning of Precision in Your Health?

Your body operates on a system of exquisite sensitivity. The goal of hormonal optimization is to restore its delicate equilibrium. This requires a therapeutic agent that is as precise and reliable as the system it seeks to support. As you move forward, consider what level of scientific certainty you require to feel confident in your protocol.

The path to reclaiming your vitality is a partnership, one built on a foundation of shared knowledge, clinical expertise, and a mutual commitment to the highest standards of quality and safety.

Glossary

compounded hormones

quality control

compounded hormone preparation

compounding pharmacy

503b facilities

503b outsourcing facility

current good manufacturing practices

high-performance liquid chromatography

potency testing

sterility testing

product-specific stability testing

beyond-use dating