Fundamentals

You may be looking at a vial of a therapeutic peptide, a tool designed to help recalibrate a specific biological process, and wonder about the journey it took to get to you. The feeling of holding a potential key to renewed vitality is often accompanied by a deep, implicit trust in its safety and reliability.

That trust is not accidental; it is built upon a rigorous framework of scientific validation, a process where a regulatory body like China’s National Medical Products Administration (NMPA) plays a guardian role. The NMPA’s guidelines for peptide drug stability testing are a direct reflection of a profound understanding of the unique nature of these molecules.

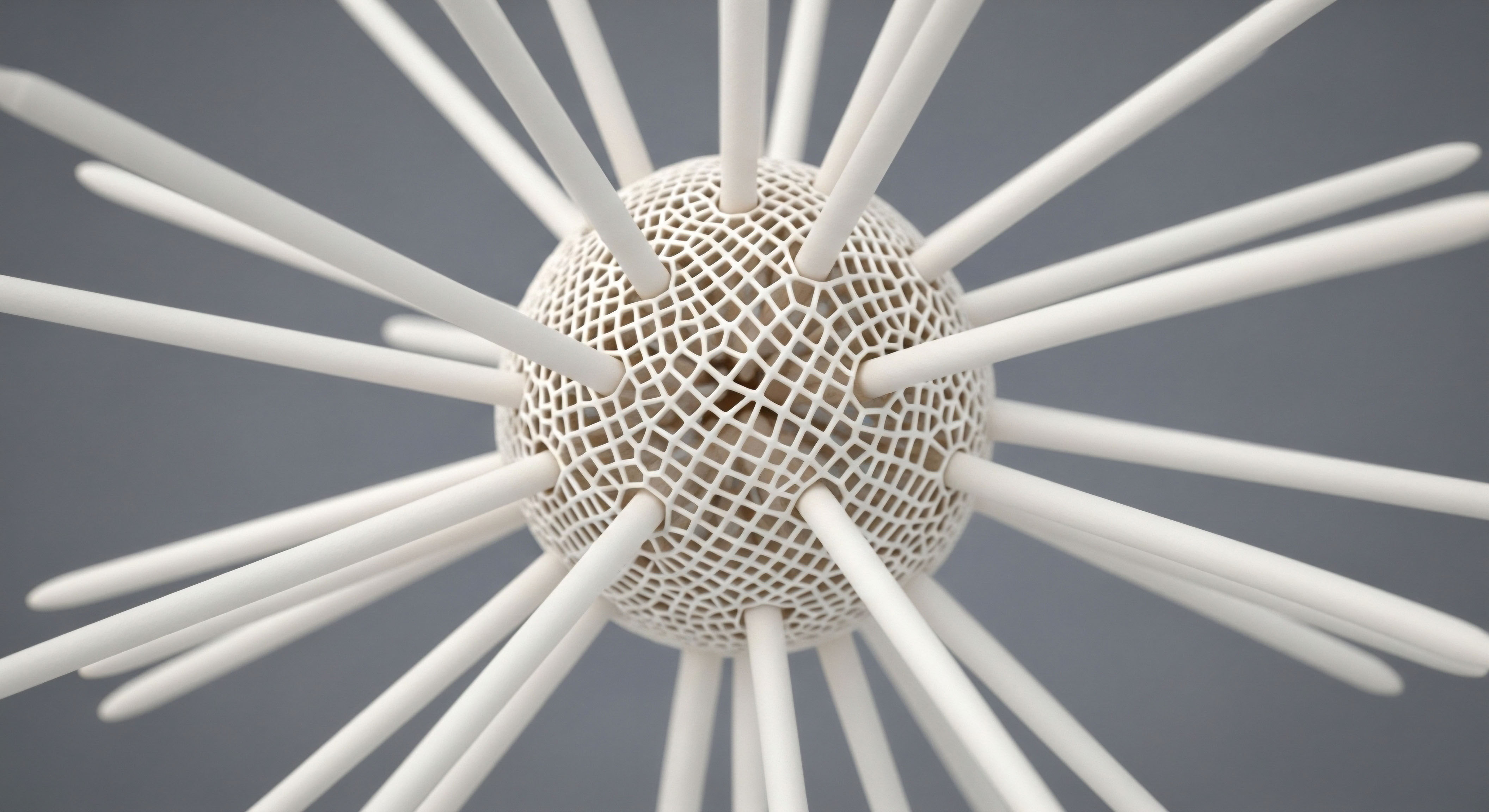

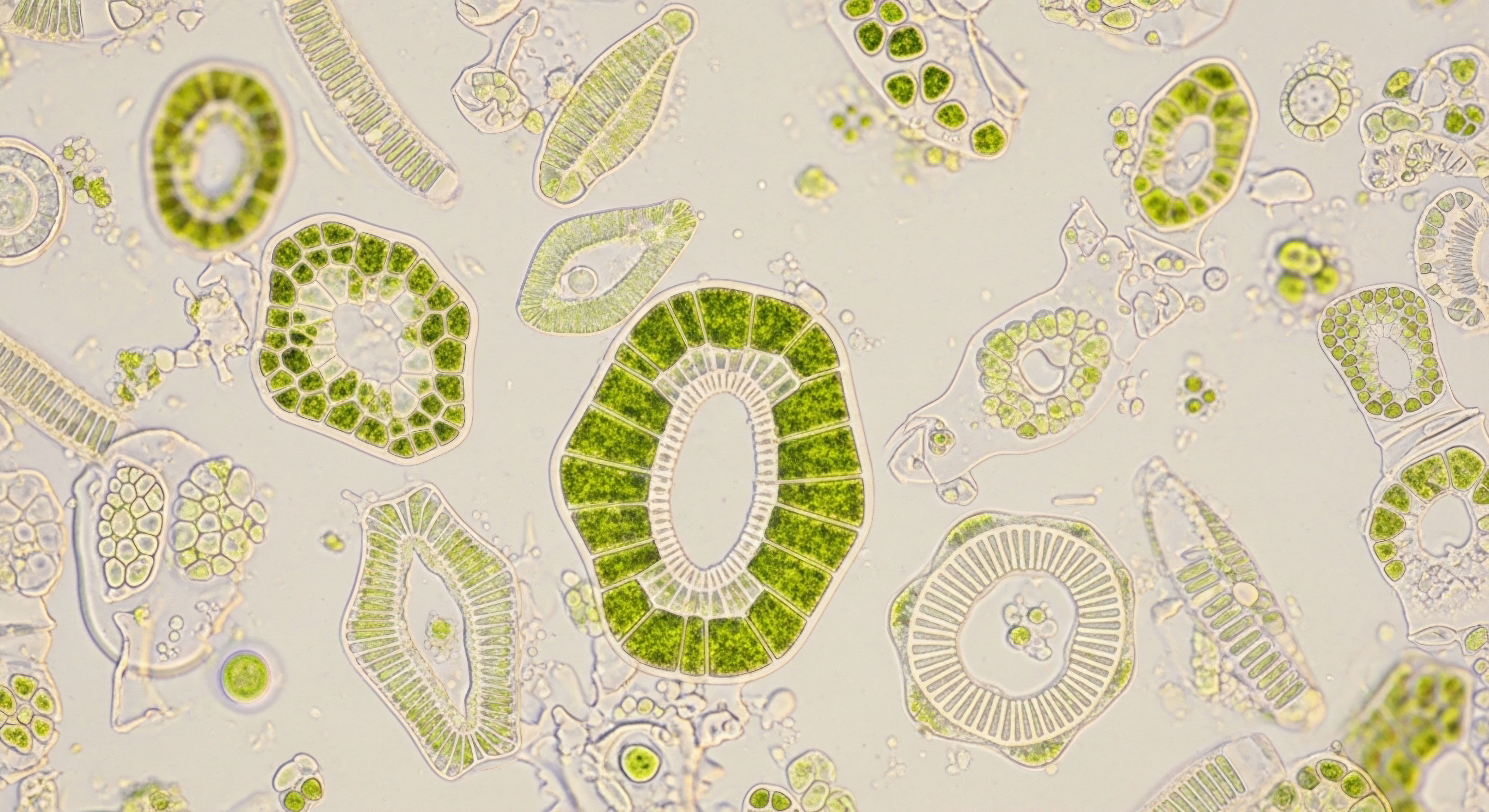

Peptides are intricate chains of amino acids, far more complex and delicate than conventional small-molecule drugs. Their structure is their function, and that structure is susceptible to degradation from heat, light, and even time itself.

The guidelines, therefore, are designed to answer a critical question ∞ how does this specific peptide behave under various conditions to ensure that what is administered on the last day of its shelf life is just as safe and potent as it was on the day it was manufactured?

Understanding these stability requirements is the first step in appreciating the immense quality control that underpins modern therapeutic protocols. The NMPA mandates that the data submitted must be true, accurate, and traceable, with original records that match the application dossiers precisely. This is a foundational principle of patient safety.

It ensures that the journey from large-scale manufacturing to your personal use is documented and verified at every step. The stability studies themselves are designed to simulate the life of the product, from storage in a warehouse to its time in your refrigerator.

These tests examine how the peptide’s identity, purity, and strength are maintained over time, providing the evidence needed to establish a reliable expiration date. This meticulous process ensures the therapeutic agent you rely on performs its biological task with predictable precision, safeguarding your health and the integrity of your wellness protocol.

Intermediate

To ensure the unwavering integrity of peptide therapeutics, the NMPA’s regulatory framework aligns with global standards, such as those established by the International Council for Harmonisation (ICH). These guidelines provide a detailed blueprint for stability testing, which can be understood as a series of controlled experiments designed to predict the peptide’s long-term behavior.

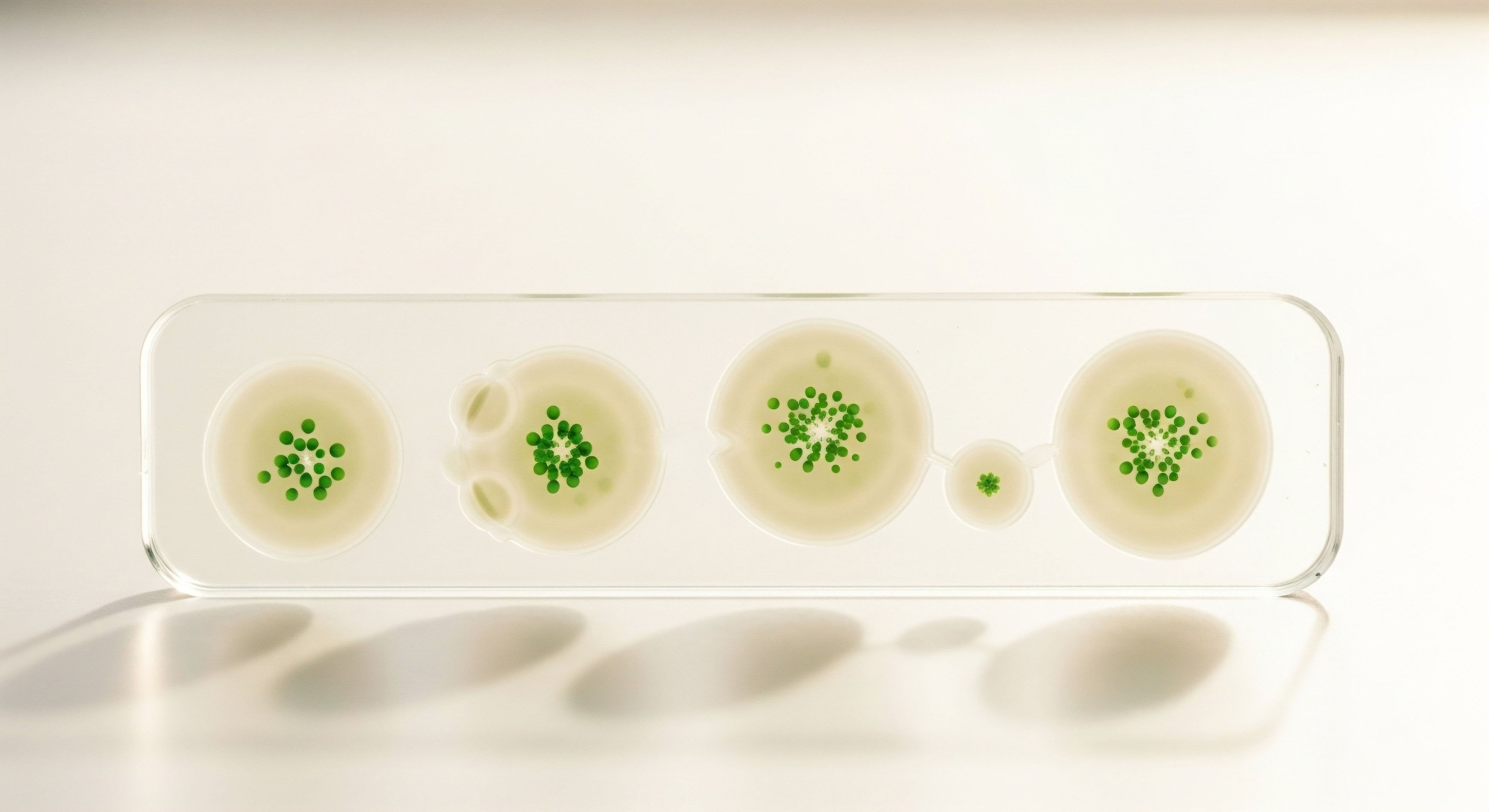

The process involves subjecting multiple production batches of the drug to a range of environmental conditions over specific time periods. The core of this process is built on three distinct types of stability studies ∞ long-term, accelerated, and stress testing. Each serves a unique purpose in building a comprehensive stability profile for the peptide.

The Core Stability Testing Protocols

The foundation of shelf-life determination rests on long-term and accelerated stability studies. The NMPA requires these tests to be performed on at least three primary batches manufactured at a commercial scale. This ensures the results are representative of the actual product that reaches the patient.

Long-term testing involves storing the peptide at its recommended storage condition and monitoring it at regular intervals until the end of its proposed shelf life. Accelerated testing exposes the peptide to elevated temperature and humidity to speed up potential chemical degradation and physical changes. Data from these accelerated studies are used to help establish the expiration date and to assess the impact of short-term excursions outside the labeled storage conditions, such as during shipping.

The stability profile of a peptide is meticulously mapped using data from long-term, accelerated, and stress testing on commercial-scale batches.

The conditions for these studies are globally harmonized, providing a consistent benchmark for quality. While specific NMPA documents detail the procedural submission, the technical conditions often mirror the ICH Q1A(R2) guidelines, which are the gold standard in the pharmaceutical industry.

| Study Type | Storage Condition | Minimum Duration |

|---|---|---|

| Long-term | 5°C ± 3°C or -20°C ± 5°C | 12 months |

| Accelerated | 25°C ± 2°C / 60% RH ± 5% RH | 6 months |

| Intermediate | 30°C ± 2°C / 65% RH ± 5% RH | 6 months |

What Are the NMPA Requirements for Packaging and Samples?

A crucial aspect of the NMPA’s oversight is the requirement that stability studies use the same packaging and container closure system intended for the final marketed product. This is because the interaction between the peptide and its container can be a source of instability.

For instance, leachables from the vial or stopper could potentially degrade the peptide or introduce impurities. The NMPA requires that these packaging materials, along with the active pharmaceutical ingredients and excipients, have their suppliers audited and their quality verified.

Furthermore, samples submitted for inspection must be from commercial production scale batches, have a shelf life of at least six months remaining, and be provided in a quantity sufficient for full testing, typically three times the amount required for a single analysis. This meticulous attention to detail ensures that the stability data is a true representation of the product’s real-world performance.

Academic

The NMPA’s regulatory requirements for peptide stability are rooted in the complex physicochemical realities of these molecules. Unlike chemically synthesized small molecules, peptides are prone to a unique spectrum of degradation pathways that can compromise their therapeutic efficacy and, in some cases, induce an immunogenic response.

The guidelines are therefore designed to characterize the intrinsic stability of the molecule and identify the specific degradation products that form under various conditions. This involves the use of sophisticated, stability-indicating analytical methods, a core tenet of the ICH Q6B guidelines which are foundational for protein and peptide drugs.

A stability-indicating method is a validated analytical procedure that can accurately separate, detect, and quantify the intact peptide from its potential degradation products, ensuring a true measure of the drug’s potency and purity over time.

Characterizing Peptide Degradation Pathways

The NMPA’s framework necessitates a deep investigation into the specific chemical and physical instabilities of a given peptide. This goes far beyond simple potency testing. The primary degradation routes for peptides include:

- Oxidation ∞ Certain amino acid residues, particularly methionine and cysteine, are highly susceptible to oxidation, which can alter the peptide’s conformation and biological activity.

- Deamidation ∞ Asparagine and glutamine residues can undergo deamidation, introducing a negative charge that can affect the peptide’s structure and function.

- Aggregation ∞ Peptides can self-associate to form soluble or insoluble aggregates. This is a significant concern as aggregates can be less effective and have the potential to elicit an immune response in the patient.

- Proteolysis ∞ The peptide bonds themselves can be cleaved, particularly at aspartic acid residues, leading to fragmentation of the molecule.

Stress testing is the primary tool used to elucidate these pathways. By subjecting the peptide to extreme conditions (e.g. high temperature, strong light, and a wide pH range), manufacturers can intentionally induce degradation. The resulting products are then identified and characterized. This information is vital for developing a formulation that protects the peptide from its specific vulnerabilities and for establishing appropriate specifications for the final product.

Regulatory stability mandates for peptides focus on identifying and controlling specific degradation products like aggregates and oxidized variants to ensure clinical safety and efficacy.

How Does Stability Data Influence Drug Formulation?

The data generated from these NMPA-mandated stability studies directly informs the formulation of the final drug product. For example, if a peptide is found to be susceptible to oxidation, an antioxidant may be included in the formulation. If aggregation is the primary concern, formulation scientists may adjust the pH or include stabilizing excipients.

The NMPA requires a full declaration of the formulation’s prescription and production process, linking the stability data directly to the manufacturing controls. This creates a powerful feedback loop where the scientific understanding of the peptide’s weaknesses informs the strategies used to protect it. This integrated approach, from molecular characterization to final product formulation and packaging, is the cornerstone of ensuring that peptide therapeutics are both safe and consistently effective throughout their entire lifecycle.

| Instability Pathway | Key Amino Acids Involved | Potential Formulation Solution |

|---|---|---|

| Oxidation | Methionine, Cysteine, Tryptophan | Inclusion of antioxidants; packaging under inert gas (e.g. nitrogen). |

| Deamidation | Asparagine, Glutamine | Formulation at optimal pH; lyophilization (freeze-drying). |

| Aggregation | Hydrophobic residues | Addition of surfactants or stabilizers; optimization of protein concentration. |

| Photodegradation | Tryptophan, Tyrosine, Phenylalanine | Use of light-protective packaging (e.g. amber vials). |

References

- National Medical Products Administration. “Announcement on the Requirements for Dossiers and Samples for Verification and Inspection of Specifications for Overseas New Drugs Urgently Needed in Clinical Settings.” NMPA, 18 July 2019.

- Shaim, A. S. et al. “Regulatory Guidelines for the Analysis of Therapeutic Peptides and Proteins.” Proteomics, vol. 31, 2024, e70001.

- Center for Drug Evaluation, NMPA. “Guidelines for the Acceptance Review of Chemical Drug Registration (Trial).” NMPA, 10 March 2025.

- FDA. “Regulatory Considerations for Peptide Drug Products.” Regulations.gov, Presentation, 5 June 2013.

- Center for Food and Drug Inspection, NMPA. “Key Points and Determination Principles of Pharmaceutical R&D and Manufacturing Site Inspection.” National Medical Products Administration, 2021.

- International Council for Harmonisation. “ICH Harmonised Tripartite Guideline ∞ Stability Testing of New Drug Substances and Products Q1A(R2).” ICH, August 2003.

- International Council for Harmonisation. “ICH Harmonised Tripartite Guideline ∞ Specifications ∞ Test Procedures and Acceptance Criteria for Biotechnological/Biological Products Q6B.” ICH, 10 March 1999.

Reflection

The journey to understanding the body’s intricate systems often leads to advanced therapeutic tools. Appreciating the immense regulatory science that validates these tools is a critical part of that process. The rigorous stability testing frameworks are not merely bureaucratic hurdles; they are a profound commitment to your safety and to the predictability of your outcome.

As you move forward on your path to wellness, consider how this foundation of evidence and quality control empowers your decisions, allowing you to focus on the biological response and the reclamation of your own vitality with confidence and trust in the science.