Fundamentals

You have arrived at this point in your health journey because you recognize a disconnect. There is a gap between how you feel and how you know you are capable of feeling. The fatigue, the subtle shifts in mood, the changes in your body’s composition, or the decline in vitality are not abstract concepts; they are your daily, lived experience.

When you consider a path involving personalized wellness protocols, such as those using therapeutic peptides like Sermorelin or Ipamorelin, or bioidentical hormones, you are seeking a precise, biological recalibration. You are looking to restore a system that has drifted from its optimal state.

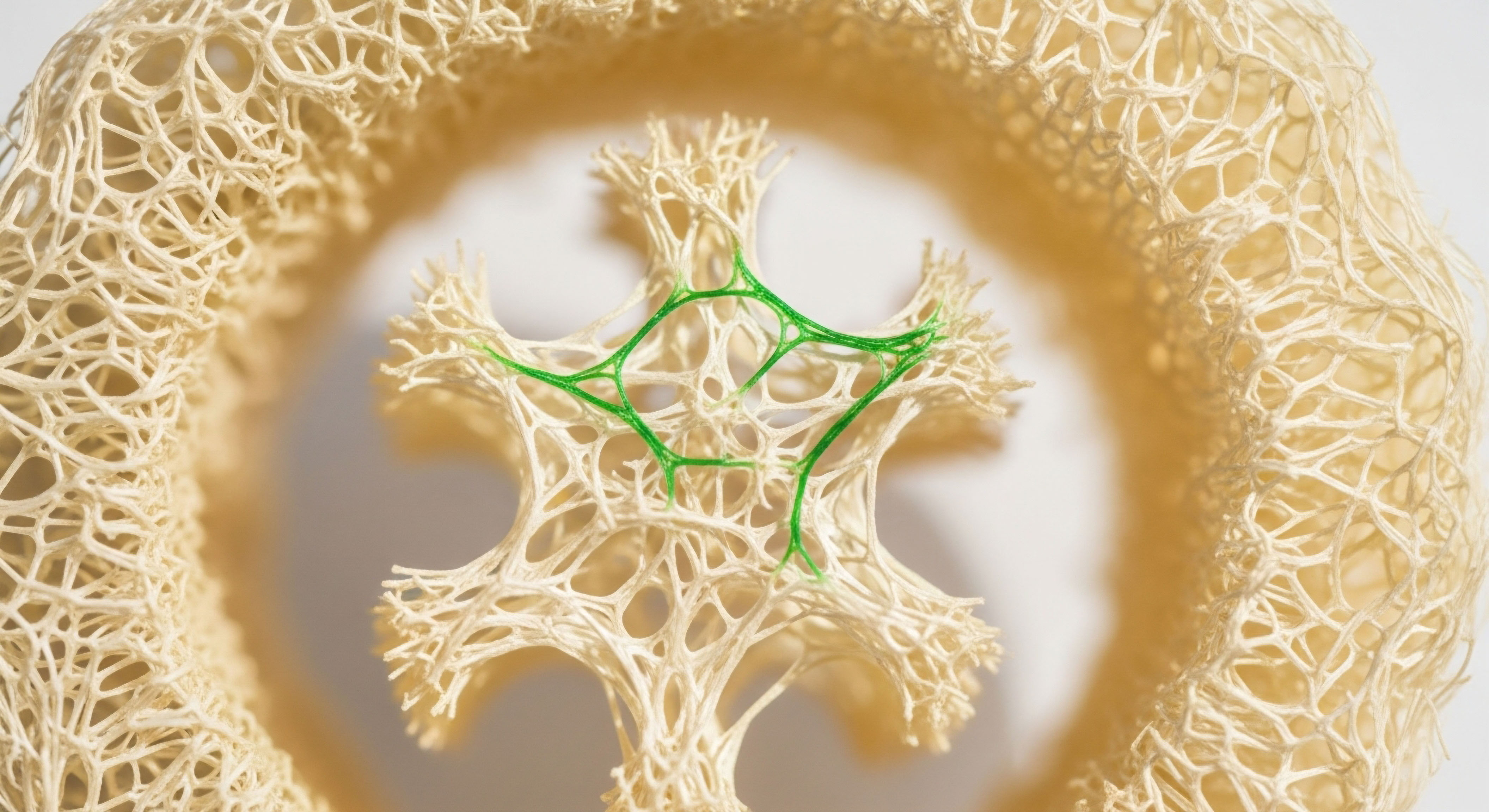

The conversation about this restoration rightfully centers on the active molecules themselves ∞ the hormones and peptides that act as powerful messengers within your body. Yet, there is a silent, indispensable framework that ensures these messengers are pure, correct, and safe. This framework is known as Good Manufacturing Practice, or GMP. Understanding its role is fundamental to trusting the process of reclaiming your well-being.

GMP is the rigorous, scientifically grounded system of controls and procedures that governs the entire lifecycle of a therapeutic compound. It is the architecture of quality that ensures every single vial of a substance meets exacting standards for identity, purity, strength, and composition. For the person seeking to optimize their endocrine system, this translates into confidence.

It is the assurance that the molecule intended to signal your pituitary gland to release growth hormone is exactly that molecule, unburdened by contaminants or structural errors that could alter its function or, worse, cause harm. The requirements are a direct reflection of the respect we must have for the body’s intricate signaling pathways.

Introducing a therapeutic agent is a significant biological event, and GMP is the methodology that guarantees the agent is precisely what it purports to be, allowing your body to respond as intended.

The Core Pillars of Manufacturing Quality

At its heart, GMP is built upon several core principles that function in concert to create a safe and effective product. These are not arbitrary rules; each one addresses a potential point of failure in the complex process of creating a peptide or hormone from raw materials to a finished, sterile therapeutic. Comprehending these pillars allows you to appreciate the immense detail that underpins the therapies you may be considering.

Personnel and Training

The process begins with the people involved. GMP mandates that all personnel, from laboratory scientists to quality control analysts, possess the education, training, and experience to perform their assigned functions correctly. They must undergo continuous training on GMP principles and specific procedures relevant to their roles.

This human element is foundational because even the most advanced equipment is only as effective as the expert operating it. This ensures that every step, from weighing raw materials to operating a complex purification apparatus, is performed with precision and a deep understanding of its impact on the final product.

Facility and Environment Design

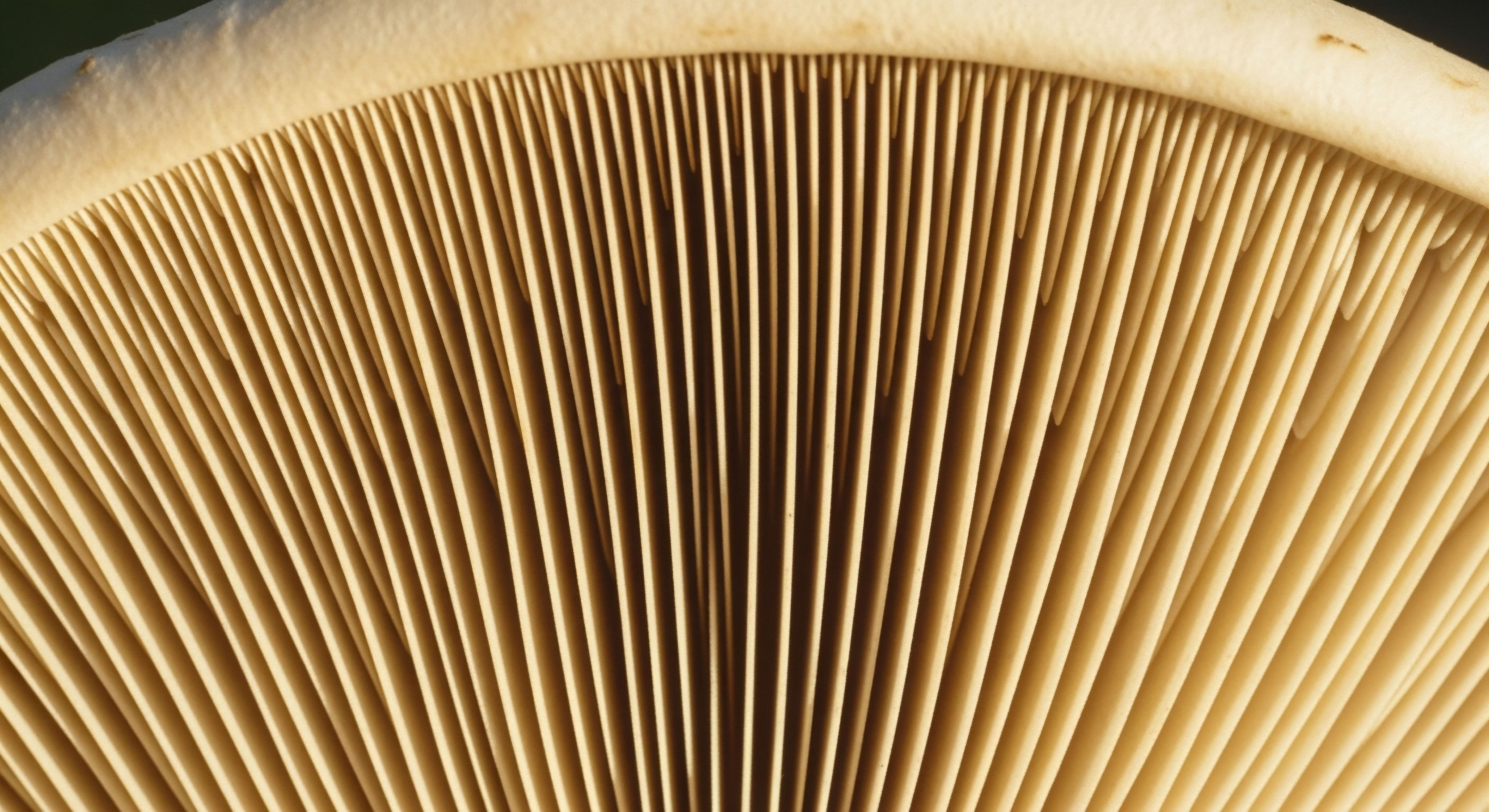

The environment where peptides are synthesized and handled is a critical control point. GMP requires manufacturing facilities to be designed, constructed, and maintained to prevent contamination. This involves the use of controlled environments and cleanrooms with specialized air handling systems (HVAC) that regulate particulates, temperature, and humidity.

The surfaces must be smooth, non-porous, and easy to clean to prevent the accumulation of microbes or residual materials. For injectable therapies, which bypass the body’s primary defense mechanisms, the sterility of the environment is paramount. This meticulous control of the physical space is a direct measure to protect the integrity of the peptide and the safety of the person who will ultimately use it.

The entire manufacturing environment is engineered to protect the product from contamination and ensure its stability.

Raw Material Control

A finished peptide can only be as good as its starting components. GMP places immense emphasis on the quality of raw materials, particularly the amino acids that are the building blocks of peptides. Each batch of raw material must be sourced from a qualified vendor and undergo rigorous testing for identity, purity, and quality before it is approved for use.

For amino acids, this includes verifying their chemical structure and ensuring they have the correct stereochemistry (the specific three-dimensional arrangement of atoms), as an incorrect isomer could result in a biologically inactive or even harmful peptide. This stringent initial control prevents impurities from entering the manufacturing process at the very beginning, simplifying purification later and leading to a safer final product.

What Is the Role of Documentation in GMP?

If an action is not documented, it is considered not to have happened. This is a central tenet of GMP. Every single aspect of the manufacturing process must be recorded in clear, traceable documents. This creates a complete history of each batch, from start to finish. These records are known as Batch Production Records (BPRs).

These documents include:

- Master Production Records ∞ A detailed recipe and set of instructions for manufacturing a specific peptide. It outlines every step, the required materials, the equipment to be used, and the in-process controls.

- Batch Production Records ∞ The real-time log of a specific batch being made, demonstrating that the steps in the Master Production Record were followed exactly. Any deviation, no matter how small, must be documented, investigated, and justified.

- Standard Operating Procedures (SOPs) ∞ Detailed, written instructions for performing routine tasks, such as equipment cleaning, calibration, and analytical testing. Following SOPs ensures consistency and reproducibility.

- Certificates of Analysis (CoA) ∞ A document that reports the test results for a specific batch of product, confirming that it meets all of its quality specifications before it can be released.

This comprehensive documentation provides full traceability and accountability. It allows for thorough investigation if an issue ever arises and is a core component of the quality assurance system that regulatory agencies like the Food and Drug Administration (FDA) review during inspections. For the individual on a wellness journey, it represents a chain of custody for quality, ensuring the product you receive is the result of a controlled, reproducible, and well-documented process.

Understanding these fundamentals reveals that GMP is the essential, non-negotiable foundation for creating therapeutic peptides. It is the disciplined application of scientific principles to manufacturing, ensuring that the powerful molecules designed to recalibrate your body’s systems are pure, safe, and effective. This allows you to focus on your primary goal ∞ restoring your health with confidence and trust in the tools you are using.

Intermediate

Moving beyond the foundational principles of Good Manufacturing Practice, we arrive at the specific, intricate processes that transform simple amino acids into a precisely defined therapeutic peptide. This is where the theoretical framework of GMP is put into practice, creating the tangible substance ∞ be it Tesamorelin for metabolic health or PT-141 for sexual function ∞ that interacts with your body’s biology.

The journey from raw material to finished product is a multi-stage process, with each step governed by stringent controls to ensure the final molecule is exactly what it is intended to be. The focus here is on the “how” ∞ the validated methods and analytical technologies that build and verify the peptide’s identity and purity.

The Synthetic Pathway Solid Phase Peptide Synthesis

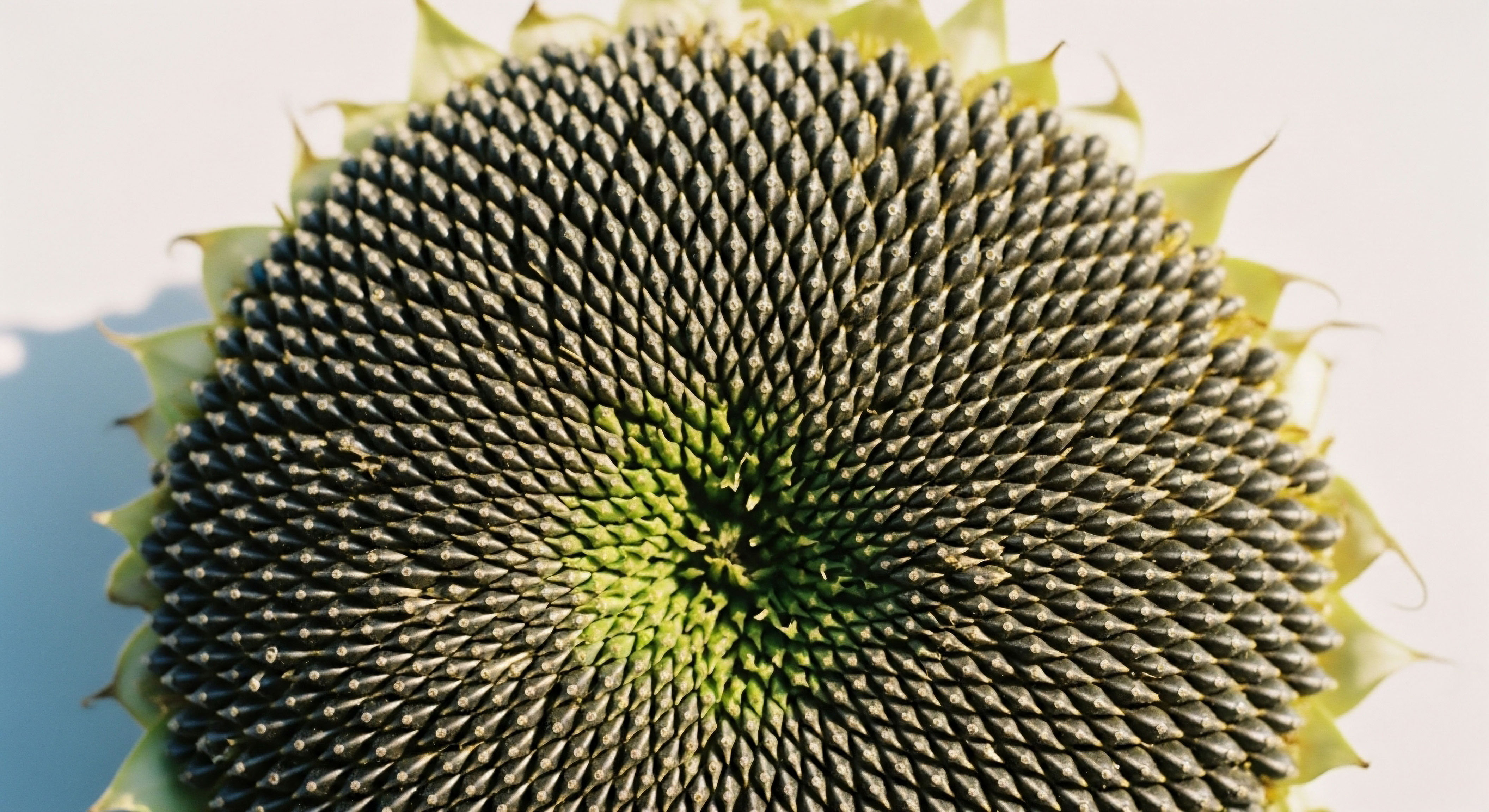

The most common method for manufacturing therapeutic peptides is Solid-Phase Peptide Synthesis (SPPS). This ingenious technique, which allows for the automation of the process, involves building the peptide chain one amino acid at a time while it is chemically anchored to a solid resin support. This anchoring simplifies the entire procedure by allowing excess reagents and byproducts to be washed away after each step, a critical feature for maintaining purity.

The SPPS cycle involves a sequence of chemical reactions:

- Deprotection ∞ The first amino acid is attached to the resin. Its N-terminus (the amino end) is protected by a chemical group. This protecting group is selectively removed, exposing the N-terminus for the next reaction.

- Coupling ∞ The next protected amino acid in the sequence is introduced along with activating reagents. This new amino acid forms a peptide bond with the N-terminus of the resin-bound amino acid.

- Washing ∞ The resin is thoroughly washed with solvents to remove all excess reagents and byproducts from the coupling reaction. This step is vital to prevent side reactions in subsequent steps.

This cycle is repeated for every amino acid in the peptide’s sequence. For a peptide like CJC-1295, which has 29 amino acids, this cycle is performed 28 times. The success of each coupling and deprotection step is monitored using in-process controls to ensure the chain is elongating correctly. Any failure in this repetitive process can lead to the formation of process-related impurities, such as deletion sequences where an amino acid is missing.

Cleavage and Final Deprotection

Once the full-length peptide chain is assembled on the resin, it must be cleaved from its solid support. This is typically accomplished using a strong acid, such as trifluoroacetic acid (TFA). This “cleavage cocktail” also serves to remove any remaining protecting groups from the side chains of the individual amino acids.

The result is the “crude” peptide ∞ a mixture containing the full-length target peptide along with a variety of impurities generated during the synthesis. This crude product is not suitable for therapeutic use and must undergo extensive purification.

Purification the Central Role of HPLC

The purification of the crude peptide is arguably one of the most critical stages in GMP manufacturing. The goal is to isolate the target peptide from all the closely related impurities. The primary tool for this task is preparative High-Performance Liquid Chromatography (HPLC). This technique separates molecules based on their physicochemical properties as they are passed through a column packed with a stationary phase. For peptides, Reversed-Phase HPLC (RP-HPLC) is the most common method.

In RP-HPLC, the stationary phase is hydrophobic (water-repelling), and the mobile phase is a mixture of water and an organic solvent (like acetonitrile). The crude peptide mixture is dissolved and pumped through the column. Molecules with greater hydrophobicity will “stick” more strongly to the stationary phase, while more hydrophilic molecules will pass through more quickly.

By gradually increasing the concentration of the organic solvent in the mobile phase (a process called gradient elution), the bound peptides are sequentially released from the column based on their hydrophobicity. The target peptide, having a unique retention time, can be collected as a highly purified fraction, physically separated from the impurities that elute at different times. This process may be repeated multiple times with different conditions to achieve the desired level of purity, often greater than 98%.

Purification via HPLC is the critical step that isolates the desired therapeutic peptide from synthesis-related impurities.

How Is the Final Product Analyzed and Verified?

After purification, the peptide undergoes a battery of analytical tests to confirm it meets all pre-defined specifications. This is the final quality control check before a batch can be released. A Certificate of Analysis (CoA) is generated, summarizing these results. The key tests are outlined in the table below.

| Analytical Test | Purpose and Significance in a Clinical Context |

|---|---|

| Purity by HPLC |

This test quantifies the percentage of the target peptide in the final product. A high purity level (e.g. >98%) ensures that the vast majority of the administered substance is the active therapeutic, minimizing the patient’s exposure to potentially harmful or inactive impurities that could cause side effects or reduce efficacy. |

| Identity by Mass Spectrometry (MS) |

MS measures the precise molecular weight of the peptide. This confirms that the correct sequence of amino acids was assembled. For a person using a therapy like BPC-157, this test verifies that the molecule has the exact mass corresponding to its 15-amino-acid sequence, ensuring it is the correct compound for the intended biological action. |

| Peptide Content |

This analysis determines the actual amount of peptide in the lyophilized (freeze-dried) powder, accounting for the presence of water and counter-ions (from the purification process). This is crucial for accurate dosing. Knowing the precise peptide content allows a clinician to calculate the exact volume needed to administer a specific dose, ensuring the hormonal or regenerative protocol is executed with precision. |

| Bioburden and Endotoxin Testing |

These tests are vital for any injectable product. Bioburden testing checks for the presence of viable microorganisms (bacteria, fungi), while endotoxin testing detects lipopolysaccharides, toxic substances from the cell walls of certain bacteria that can cause a severe inflammatory response or fever. Passing these tests is a non-negotiable safety requirement for parenteral therapies. |

These intermediate steps of synthesis, purification, and rigorous analysis form the practical core of GMP for peptides. They represent the translation of quality principles into a series of controlled, validated actions. Each step is designed to build the correct molecule and then systematically remove anything that is not that molecule.

This meticulous process ensures that when a therapeutic peptide is prescribed as part of a personalized health protocol, the substance being administered is precisely defined, pure, and safe, allowing for a predictable and effective biological response.

Academic

An academic examination of Good Manufacturing Practice for therapeutic peptides moves into the domain of analytical chemistry and regulatory science, focusing on the rigorous characterization and control of impurities. The central challenge in peptide manufacturing is not merely the synthesis of the target sequence but the comprehensive identification, quantification, and mitigation of a complex profile of related substances.

These impurities, arising from the intricacies of solid-phase synthesis and subsequent handling, represent potential risks to both the safety and efficacy of the final drug product. Regulatory bodies like the FDA and EMA mandate a deep understanding of this impurity profile, as even structurally similar variants can exhibit altered biological activity or, more critically, elicit an immunogenic response in the patient.

The entire control strategy is therefore built around a foundational principle ∞ you must be able to detect and control what you can anticipate, and you must have methods sensitive enough to reveal the unexpected.

A Deep Dive into Impurity Profiling

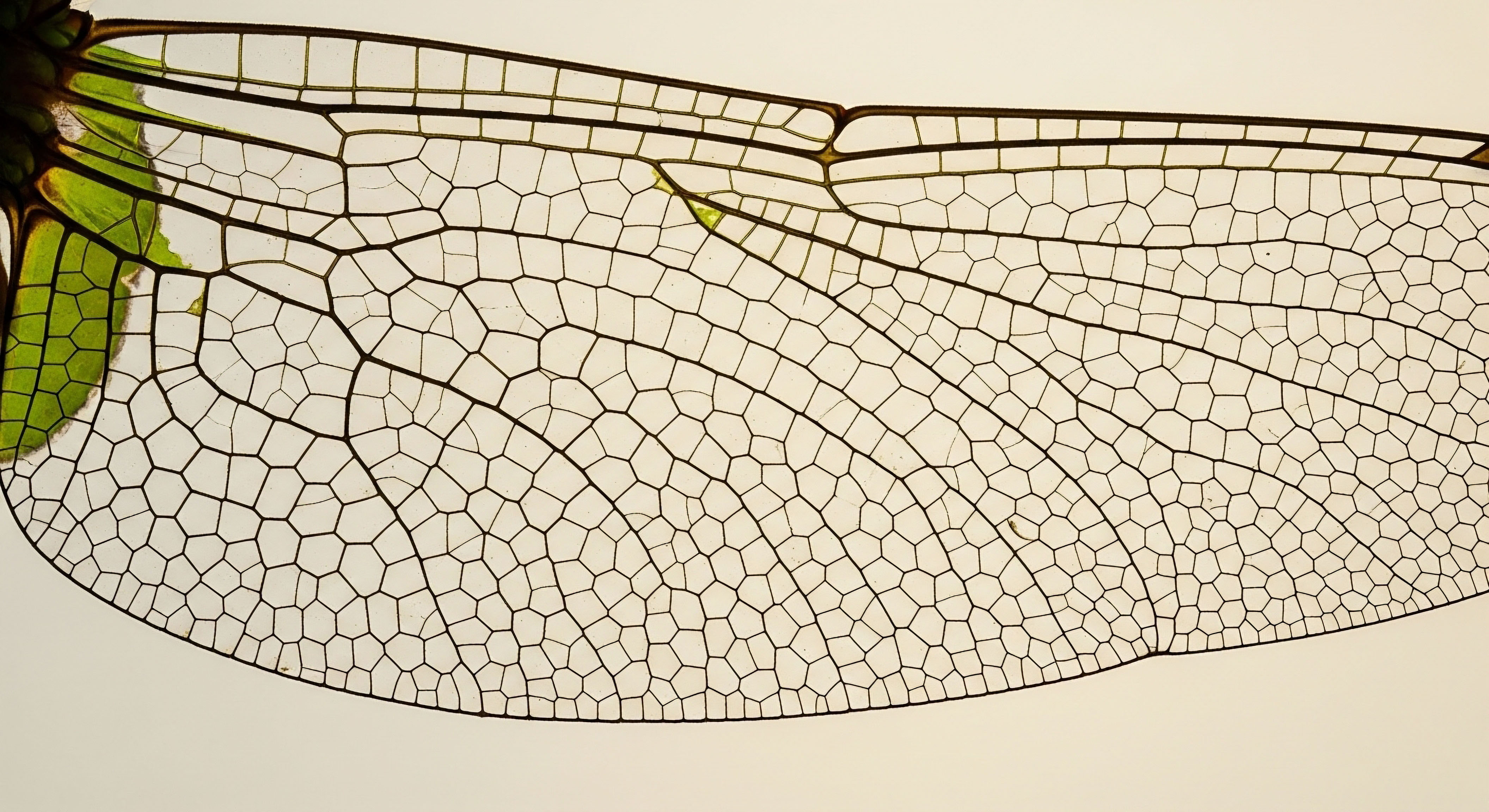

The impurity profile of a synthetic peptide is a unique fingerprint of its manufacturing process. Impurities are broadly categorized as process-related or product-related. Process-related impurities are variants of the target peptide formed during synthesis, while product-related impurities arise from degradation of the peptide itself during purification, handling, or storage. A robust control strategy, as expected by regulators, requires orthogonal analytical methods ∞ using multiple techniques that measure different chemical properties ∞ to build a complete picture.

Process-Related Impurities from SPPS

The stepwise nature of Solid-Phase Peptide Synthesis (SPPS) is efficient but also susceptible to a predictable set of side reactions that generate impurities. The ability to control these is a hallmark of a well-designed manufacturing process.

- Deletion Sequences ∞ These occur due to an incomplete coupling reaction, where an amino acid fails to attach to the growing chain before the next one is added. The resulting peptide is missing one or more residues. Analytically, these are often detected by LC-MS, as they have a lower molecular weight than the target peptide. Their presence can dramatically alter the peptide’s three-dimensional structure and its ability to bind to its biological target.

- Insertion Sequences ∞ This happens when a single amino acid is coupled more than once at a specific position, resulting in a peptide that is one or more residues too long. This is often caused by incomplete removal of the temporary protecting group on the incoming amino acid. Like deletions, these are identified by their higher molecular weight via mass spectrometry.

- Truncated Sequences ∞ These are sequences that stop elongating prematurely. This can be caused by a “capping” step, sometimes done intentionally to terminate failed sequences, or by other side reactions. The result is a mixture of shorter peptides that must be removed during purification.

- Diastereomers ∞ This is one of the most challenging classes of impurities to control. It involves epimerization, a chemical process where an amino acid with a specific L-chiral configuration flips to its D-chiral mirror image. This can be catalyzed by the basic conditions used during deprotection, especially for amino acids like histidine or cysteine. Because diastereomers have the exact same mass as the target peptide, they are invisible to standard MS. Their separation requires specialized chiral chromatography methods. Their control is critical, as a change in stereochemistry can render a peptide biologically inactive or even immunogenic.

The Power of Orthogonal Analytical Methods

No single analytical method can fully characterize a peptide drug substance. GMP requires a suite of validated techniques that provide complementary information. The combination of liquid chromatography and mass spectrometry (LC-MS) is the workhorse of impurity analysis, but it is not sufficient on its own.

| Methodology | Specific Application in Impurity Profiling | Limitations |

|---|---|---|

| LC-MS/MS |

Liquid Chromatography-Tandem Mass Spectrometry is the primary tool for identifying unknown impurities. After separation by HPLC, an impurity peak can be fragmented in the mass spectrometer. The resulting fragmentation pattern provides sequence information, allowing for precise identification of deletion, insertion, or modified sequences. |

Cannot distinguish between isomers (e.g. leucine and isoleucine, which have the same mass) or diastereomers. Quantification can be complex and may not be linear for all impurities. |

| High-Resolution Mass Spectrometry (HRMS) |

HRMS instruments (like Orbitrap or TOF) measure mass with extremely high accuracy. This allows for the determination of the elemental composition of the peptide and its impurities, providing a higher degree of confidence in their identification. |

Still cannot resolve diastereomers. The instrumentation is more complex and expensive than standard MS. |

| Amino Acid Analysis (AAA) |

The peptide is hydrolyzed into its constituent amino acids, which are then quantified. This confirms the overall amino acid composition and can help identify major discrepancies, although it cannot provide sequence information or detect minor impurities. |

Destructive to the sample. Does not provide information on the sequence or the location of any modification or deletion. |

| Chiral Chromatography |

Specialized HPLC columns with a chiral stationary phase are used to separate diastereomers. This is a specific test developed to control for epimerization, a critical quality attribute for many peptides. |

The method is specific to chiral separation and does not provide information on other types of impurities. Method development can be challenging. |

Regulatory Expectations and Thresholds

Regulatory guidances, such as the FDA’s “ANDAs for Certain Highly Purified Synthetic Peptide Drug Products That Refer to Listed Drugs of rDNA Origin,” establish thresholds for reporting, identifying, and qualifying impurities. For many peptides, any impurity found at a level above 0.10% must be identified.

If a new impurity is found that was not present in the reference product, it may need to be assessed for its potential immunogenicity, a complex and resource-intensive process. This stringent threshold drives manufacturers to optimize their synthesis and purification processes to an extraordinary degree.

The goal is to produce a peptide with an impurity profile that is as clean as possible, minimizing potential risks to the patient. This deep analytical understanding is the pinnacle of GMP, ensuring that the final product is not only pure in a general sense but is well-understood down to a fraction of a percent.

A comprehensive understanding and control of the impurity profile is a primary focus of regulatory agencies and is essential for ensuring patient safety.

This academic perspective reveals that GMP for peptides is a science of profound detail. It is a systematic approach to controlling chemical complexity. For the clinician prescribing a hormonal or peptide therapy, and for the individual receiving it, this rigorous, analytical foundation is what makes a personalized, systems-based approach to health both possible and safe. It is the assurance that the powerful biological messages being sent are clear, precise, and free of confounding noise.

References

- U.S. Food and Drug Administration. (2021). Guidance for Industry ∞ ANDAs for Certain Highly Purified Synthetic Peptide Drug Products That Refer to Listed Drugs of rDNA Origin. Center for Drug Evaluation and Research.

- Dong, M. W. & Lin, M. (2021). Characterization of Synthetic Peptide Therapeutics Using Liquid Chromatography-Mass Spectrometry ∞ Challenges, Solutions, Pitfalls, and Future Perspectives. Journal of Pharmaceutical and Biomedical Analysis, 198, 113998.

- White, B. & Gisch, D. (2014). Control Strategies for Synthetic Therapeutic Peptide APIs Part III ∞ Manufacturing Process Considerations. Pharmaceutical Technology.

- De Spiegeleer, B. et al. (2008). Impurity profiling quality control testing of synthetic peptides using liquid chromatography-photodiode array-fluorescence and liquid chromatography-electrospray ionization-mass spectrometry ∞ The obestatin case. Journal of Chromatography A, 1208(1-2), 164-171.

- Van Der Hage, E. R. E. & De Spiegeleer, B. (2010). Quality Considerations for Peptide Manufacturing Processes. BioPharm International, 23(3).

- European Medicines Agency. (2023). Draft Guideline on the Development and Manufacture of Synthetic Peptides. Committee for Medicinal Products for Human Use (CHMP).

- Grosse, S. Samonig, M. De Pra, M. & Steiner, F. (2020). Impurity profiling of the synthetic peptide LL-37 by using high-performance liquid chromatography with combined UV and single quadrupole mass spectrometry. Thermo Fisher Scientific.

- Teva Pharmaceutical Industries Ltd. (2022). Challenges in the Changing Peptide Regulatory Landscape. TAPI.

Reflection

The knowledge you have gained about the rigorous architecture of peptide manufacturing is a powerful tool. It transforms the concept of a therapeutic protocol from a simple prescription into a partnership with a process of immense scientific discipline.

This understanding of GMP demystifies the contents of the vial, replacing uncertainty with a comprehension of the meticulous controls that ensure its purity and identity. The journey to reclaim your vitality and function is deeply personal, rooted in your unique biology and experience. The science of manufacturing provides the stable, reliable foundation upon which that personal journey can be built.

What Does This Mean for Your Path Forward?

Consider the biological systems you are seeking to influence. Your endocrine network is a system of delicate balances and powerful feedback loops. The decision to introduce a therapeutic peptide or hormone is a decision to communicate with that system in a very specific language. The GMP framework is what guarantees the integrity of that language.

It ensures the message is clear, free from the static of impurities or structural errors. As you move forward, this understanding allows you to ask more informed questions and to appreciate the quality that must underpin any effective protocol. Your path is one of proactive restoration, and your knowledge is the most valuable asset you possess in navigating it.

Glossary

therapeutic peptides

good manufacturing practice

amino acids

food and drug administration

quality assurance

therapeutic peptide

solid-phase peptide synthesis

deletion sequences

high-performance liquid chromatography

endotoxin testing

peptide manufacturing

impurity profile

synthetic peptide

peptide synthesis

mass spectrometry

diastereomers

liquid chromatography