Fundamentals

When you hold a vial of medication intended to recalibrate your body’s intricate hormonal symphony, you are holding an instrument of profound biological potential. Whether it is Testosterone Cypionate to restore vitality, or a specific peptide like Sermorelin to optimize cellular function, the molecule itself is only half of the equation.

Its effectiveness, and more pointedly your safety, is entirely dependent on its absolute purity and precise concentration. You begin a wellness protocol with the goal of reclaiming function and vitality. The last thing you should have to consider is whether the very treatment meant to help you could introduce risk.

This is the precise space where the U.S. Food and Drug Administration (FDA) establishes a framework of trust, ensuring the integrity of specialized medications prepared outside of large manufacturing plants.

Your journey into personalized medicine, particularly therapies involving injectable sterile compounds, leads you to a specialized entity known as a 503B outsourcing facility. These are establishments registered with the FDA that prepare medications in batches for distribution to healthcare providers.

They occupy a critical space, supplying clinics with the exact formulations needed for protocols like Testosterone Replacement Therapy (TRT) or Growth Hormone Peptide Therapy. The Drug Quality and Security Act created this designation, establishing a clear set of rules to govern these facilities. The primary directive is adherence to a comprehensive set of standards known as Current Good Manufacturing Practices, or CGMP. This framework is the foundation upon which the safety of your treatment is built.

Understanding this regulatory layer is the first step in becoming a truly informed participant in your own health journey.

The Source of Your Hormonal Protocol

Many personalized hormonal therapies are not mass-produced. They are compounded, meaning they are prepared by combining, mixing, or altering ingredients to create a medication tailored to the needs of a patient or a group of patients. An outsourcing facility operates under Section 503B of the Federal Food, Drug, and Cosmetic Act.

This registration allows them to compound sterile drugs and supply them to healthcare practices without first receiving a prescription for an individual patient. This capacity is what enables your physician to maintain a supply of essential treatments, ready for you when you need them.

The facility’s decision to register as a 503B is an election to operate under direct FDA oversight, including regular inspections and strict reporting requirements. This oversight is a commitment to a higher standard of quality control, providing a verifiable assurance of the product’s integrity from the moment of its creation.

What Does CGMP Mean for Your Health?

Current Good Manufacturing Practices are the detailed regulations that ensure the identity, strength, quality, and purity of drug products. For the sterile compounds used in hormonal and metabolic therapies, these practices are of the utmost importance. An injectable therapy bypasses many of the body’s natural defense systems, introducing substances directly into your muscle tissue or bloodstream.

CGMP addresses every potential vector of contamination. It governs the physical environment where drugs are made, the training and hygiene of the personnel who make them, the quality of the raw ingredients, and the rigorous testing performed on the final product.

Adherence to CGMP means that the vial of Testosterone or Ipamorelin you use has been prepared in an environment designed to prevent microbial contamination and has been verified to contain the exact ingredients at the correct potency listed on its label. This system of controls is the invisible shield protecting your biological system as you work to optimize it.

Intermediate

The commitment of a 503B outsourcing facility to FDA regulations translates into a series of highly controlled, verifiable processes. These processes, collectively known as Current Good Manufacturing Practices (CGMP), are detailed in the Code of Federal Regulations and form the operational blueprint for ensuring every batch of compounded medication is safe and effective.

For any individual on a personalized wellness protocol, understanding these specific requirements provides a deeper appreciation for the quality assurances that underpin their therapy. The regulations are a complex architecture of procedures and environmental controls designed to minimize risk at every stage of production, from the moment raw ingredients enter the facility to the point where a finished, labeled vial is packaged for shipment.

The FDA provides specific guidance for 503B outsourcing facilities, recognizing their unique role in the healthcare system. This guidance tailors the broader CGMP regulations to the specific activities of compounding, with a strong emphasis on the production of sterile drugs. These are the injectable therapies that form the core of many hormonal optimization and regenerative medicine protocols.

The requirements create a state of constant vigilance within the facility, where quality is built into the process, documented at every step, and verified by a dedicated quality control unit. This systematic approach ensures that the final product meets exacting standards for sterility and potency, which are non-negotiable for injectable medications.

How Do Facilities Ensure a Sterile Environment?

The physical design of a 503B facility is the first line of defense against contamination. CGMP mandates a design that facilitates a logical flow of materials and personnel to prevent mix-ups and the introduction of contaminants. The core of this design for sterile compounding is the cleanroom suite. This is a series of rooms with progressively higher levels of environmental control.

- Air Quality ∞ Cleanrooms use high-efficiency particulate air (HEPA) filters to remove airborne particles, including microbes. The rooms are maintained at positive pressure differentials, meaning air flows from the cleanest spaces to less clean adjacent areas, preventing contaminated air from flowing into critical zones.

- Surface Materials ∞ All surfaces within the cleanroom, including walls, floors, and ceilings, must be smooth, non-porous, and resistant to cracking and sanitizing agents. This allows for effective and repeatable cleaning and disinfection.

- Environmental Monitoring ∞ The facility must have a robust program for continuously monitoring the environment. This includes sampling the air and surfaces for microbial contamination and measuring airborne particle counts to ensure the cleanroom is performing as designed. This data provides an ongoing record of the state of control within the facility.

The Human Element and Aseptic Technique

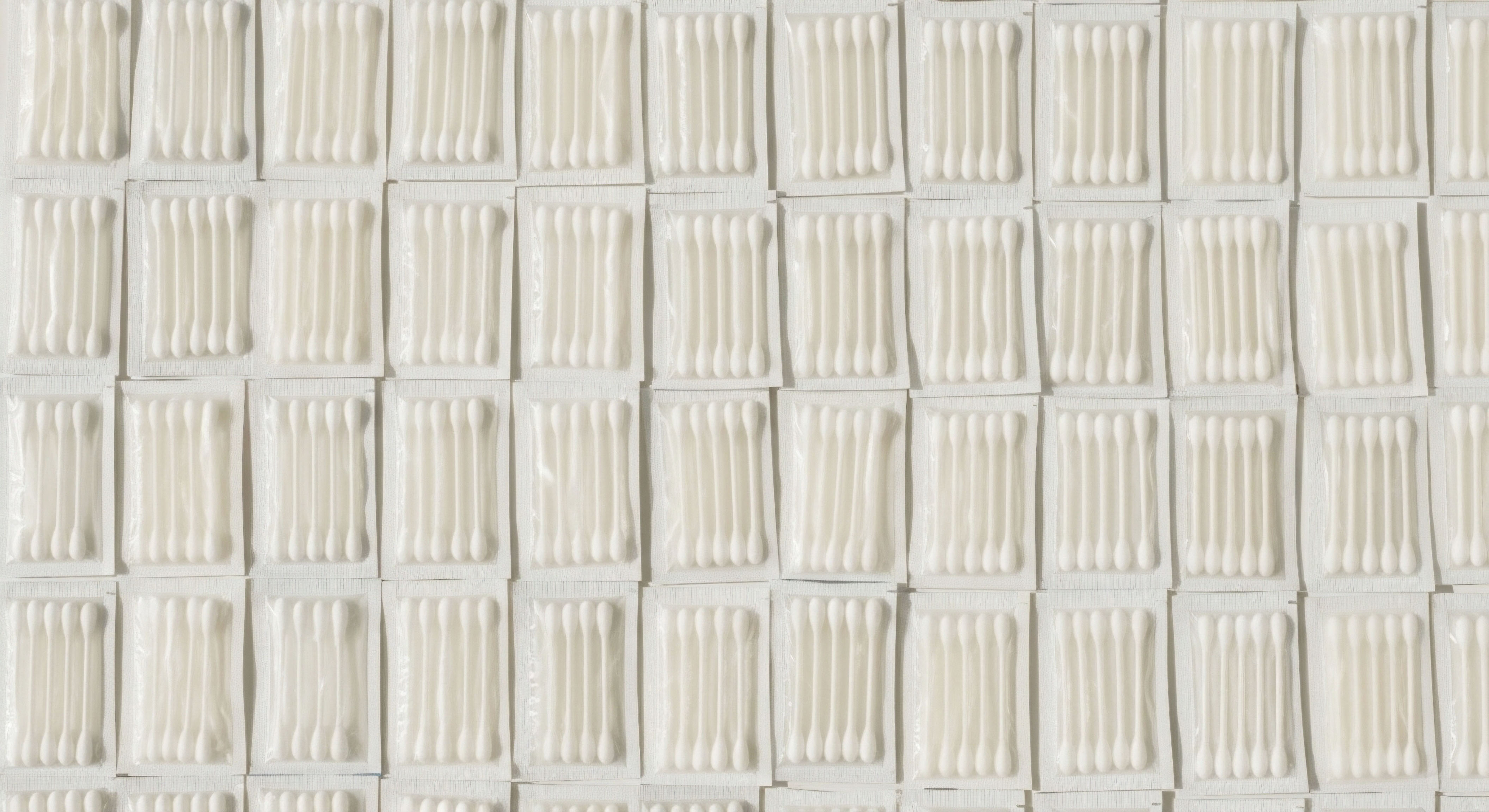

Even in a perfectly designed facility, the personnel who perform the compounding are a critical factor. CGMP places significant emphasis on their training, hygiene, and technique. Aseptic processing is the technique of handling sterilized materials in a highly controlled, sterile environment to prevent microbial contamination of the final product. This is a skill that requires extensive training and qualification.

Personnel must follow strict gowning procedures before entering the cleanroom suite. This involves covering street clothes with sterile garments, including coveralls, hoods, gloves, goggles, and booties. The process itself is highly procedural to minimize the transfer of contaminants. Once inside, their movements are deliberate and slow to avoid creating air currents that could disturb the controlled environment.

The quality control unit is responsible for monitoring personnel to ensure they adhere to these procedures and demonstrate proficient aseptic technique through process simulations known as media fills. A media fill involves using a sterile microbiological growth medium to simulate the entire compounding process. If no microbial growth occurs after incubation, it provides evidence that the process and the personnel are capable of producing a sterile product.

Aseptic technique is the disciplined human performance that bridges the gap between a sterile environment and a sterile product.

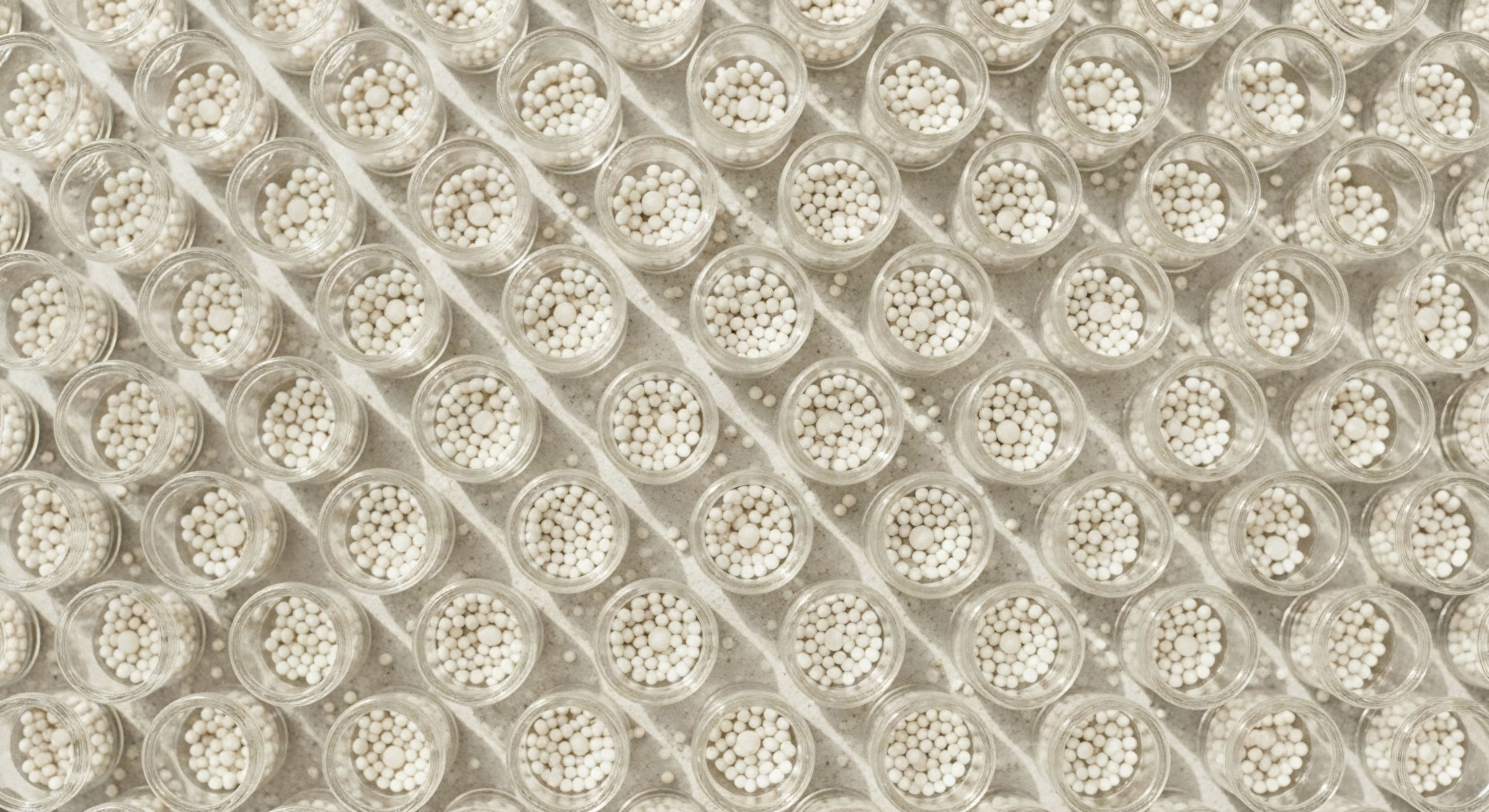

From Raw Materials to Final Release

The journey of a compounded medication is tracked and verified from beginning to end. This meticulous process ensures the final product is precisely what it claims to be. The table below outlines the key stages of quality control that a batch of medication, such as Testosterone Cypionate, undergoes in a 503B facility.

| Process Stage | CGMP Requirement | Impact on Hormonal Therapy |

|---|---|---|

| Component Receipt | Active pharmaceutical ingredients (APIs) and other components must be sourced from reputable suppliers and tested for identity, purity, and quality upon arrival. All components are quarantined until approved by the quality control unit. | Ensures the foundational testosterone molecule is pure and free from contaminants before the compounding process even begins. |

| Production and Processing | All processes must be validated to ensure they are reproducible and effective. This includes validating the sterilization process for equipment and containers and ensuring the mixing process results in a homogenous product. | Guarantees that every vial in a batch has a consistent and uniform concentration of the active hormone, ensuring predictable dosing. |

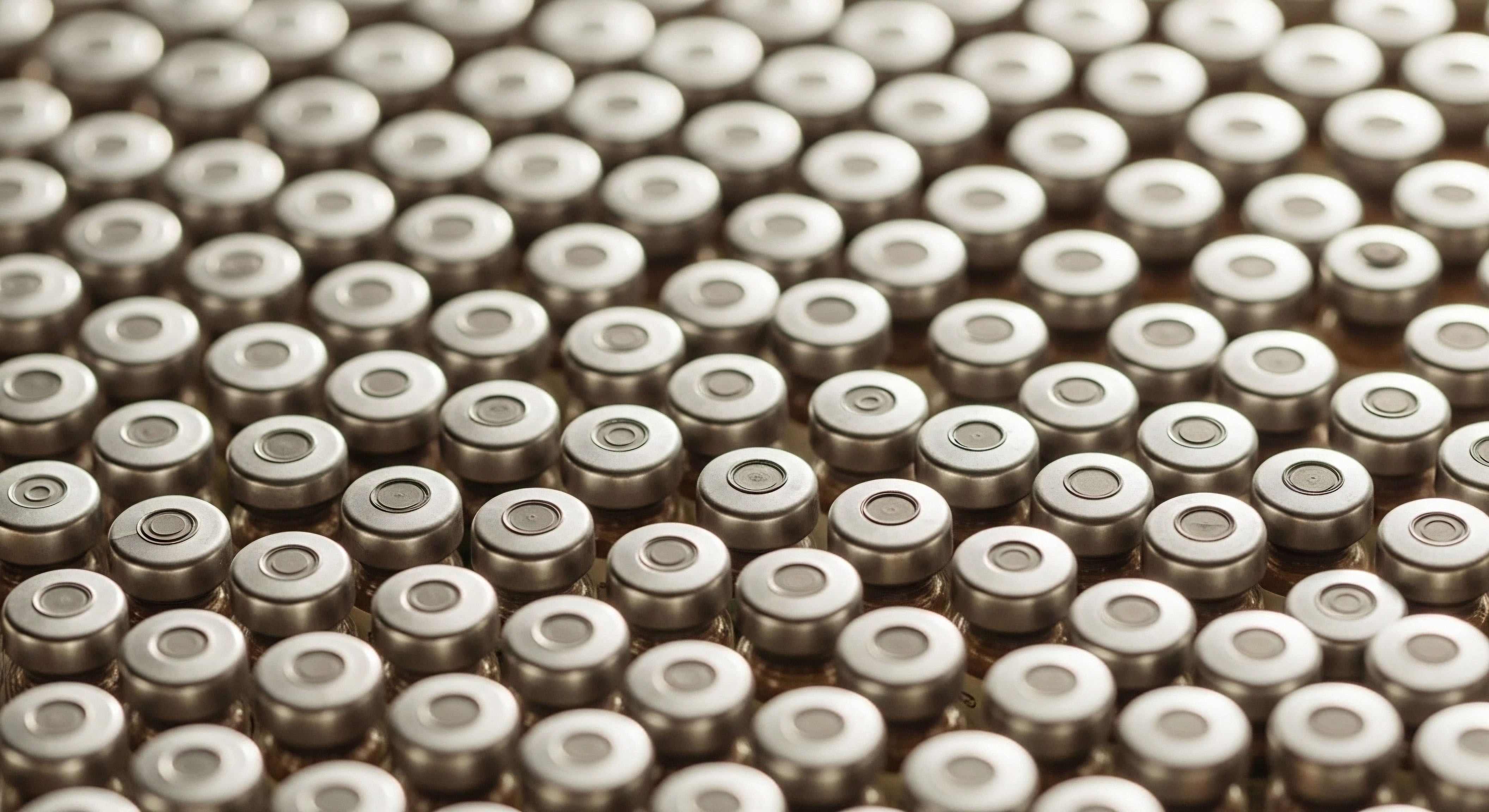

| Finished Product Testing | Every batch of a sterile drug product must be tested for sterility and the identity and strength of its active ingredients before it can be released for distribution. It must also be tested for bacterial endotoxins. | This is the final verification that the vial is free from microbes and contains the exact dosage prescribed, ensuring both safety and therapeutic efficacy. |

| Labeling and Packaging | Strict controls are in place to prevent label mix-ups. The label must accurately reflect the contents, strength, and expiration date. Packaging must protect the product from degradation during storage and shipping. | Provides clear and accurate information, preventing dosing errors and ensuring the medication remains stable until its beyond-use date. |

This multi-layered system of controls, checks, and validations is the essence of CGMP in a 503B outsourcing facility. It provides the assurance that the sophisticated hormonal therapies prescribed for your well-being are prepared under the most stringent standards for safety and quality.

Academic

The regulatory framework governing 503B outsourcing facilities, specifically the mandates within 21 CFR Parts 210 and 211, represents a sophisticated application of risk management science to pharmaceutical production. For those engaged in hormonal optimization protocols, where sterile injectable products are the primary delivery vector, these regulations are the principal mechanism ensuring that therapeutic interventions support physiological goals without introducing iatrogenic harm.

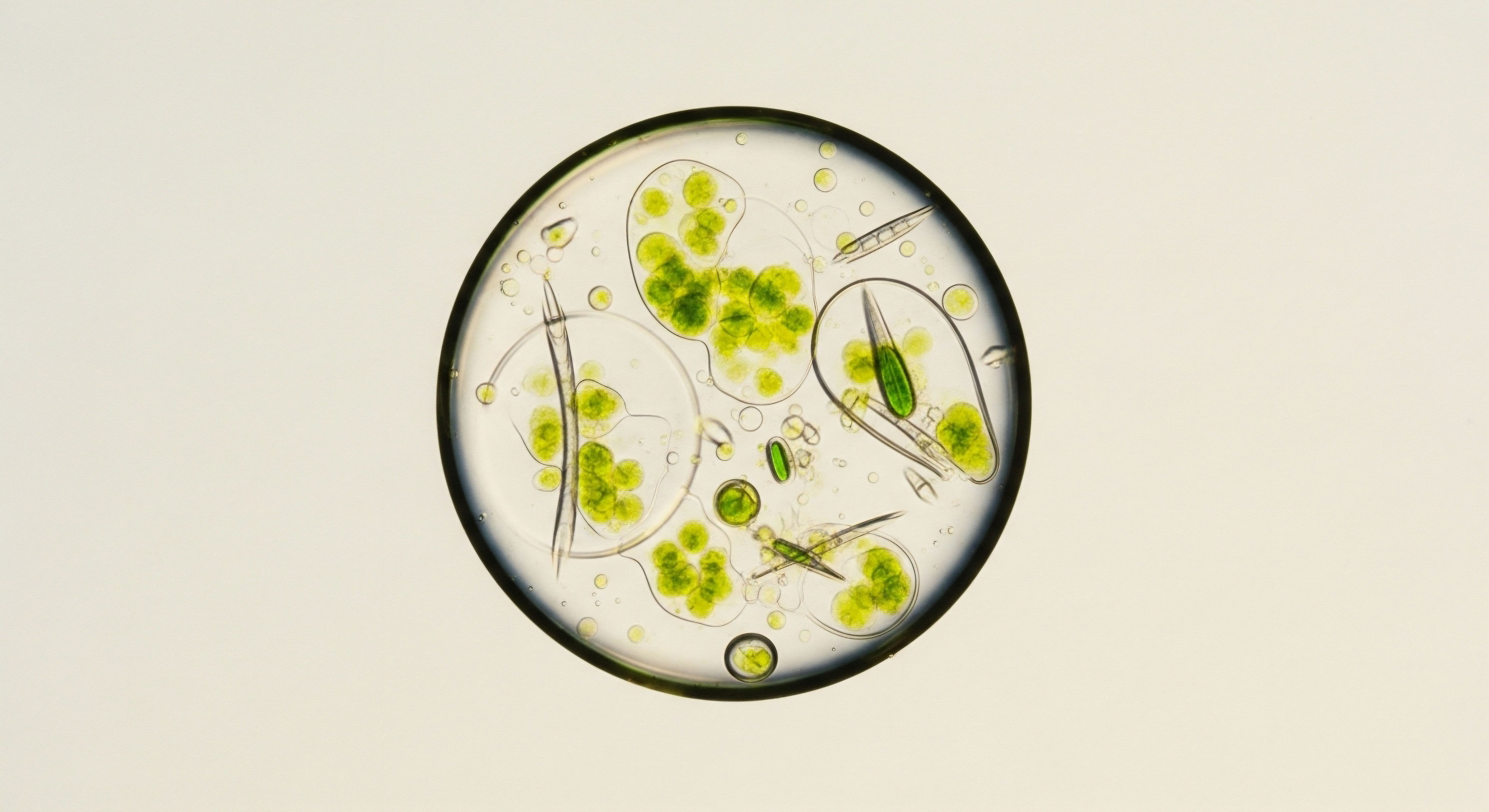

The entire edifice of Current Good Manufacturing Practices (CGMP) is built upon the objective of achieving and maintaining a state of control over processes and environments to produce products of consistent quality and purity. This state of control is particularly acute in the context of aseptic processing, the methodology used for most compounded sterile preparations like testosterone, progesterone, and peptide therapies.

Aseptic processing is a system of producing a sterile product by bringing together previously sterilized components within a meticulously controlled environment. The objective is to achieve a defined Sterility Assurance Level (SAL), which is the probability of a single unit being non-sterile after sterilization.

For terminally sterilized products, an SAL of 10^-6 (a one-in-a-million probability of a non-sterile unit) is the standard. While this specific SAL is mathematically demonstrated for terminal sterilization, the goal of an aseptic process is to achieve a comparable level of sterility assurance through procedural and environmental controls.

The FDA’s guidance on the matter provides a roadmap for establishing and validating these controls, creating a system where sterility is the logical outcome of a well-designed and rigorously executed process.

The CGMP framework transforms the abstract concept of sterility into a series of measurable, verifiable, and reproducible actions.

What Is the Role of the Quality Control Unit?

Within the CGMP paradigm, the quality control unit holds a unique and powerful position. As defined in 21 CFR 211.22, this unit has the authority and responsibility for all functions that may affect product quality. It has the power to approve or reject all components, drug product containers, closures, in-process materials, and finished products.

This organizational independence ensures that its decisions are based solely on scientific and quality-related criteria, free from any production pressures. For a patient receiving a compounded hormone, this unit is their ultimate advocate within the facility.

The quality control unit’s responsibilities are extensive and form the backbone of CGMP compliance. They are responsible for reviewing and approving all procedures, from cleaning and maintenance to production and process controls. They must review all production records to confirm that no errors occurred and that any deviations were properly documented and investigated.

This meticulous record review ensures that the validated state of control was maintained throughout the compounding of a specific batch. The unit also oversees the environmental monitoring program, analyzing the data to detect any trends that might indicate a loss of control, allowing for corrective action before product quality is compromised.

Validation the Scientific Proof of Process Control

A core tenet of modern pharmaceutical quality assurance is process validation. Validation is the documented evidence that a process will consistently produce a result meeting pre-determined specifications. For sterile compounding, several validation processes are critical.

- Process Simulation (Media Fills) ∞ This is the primary method for validating an aseptic process. As described in FDA guidance, a media fill involves substituting a sterile microbiological growth medium for the drug product and performing the entire compounding process from start to finish. The number of units filled should mimic the size of a typical production run. The sealed units are then incubated under specific conditions. The target acceptance criterion is zero growth. A successful media fill provides powerful evidence that the facility’s procedures, personnel, and environmental controls are collectively capable of producing a sterile product.

- Container Closure Integrity Testing (CCIT) ∞ The vial and stopper that contain your medication are its primary barrier against contamination after it leaves the facility. CCIT is a set of methods used to validate that this seal is intact and will prevent microbial ingress. Methods can include dye immersion tests, vacuum decay, or high-voltage leak detection. This testing is crucial for establishing the beyond-use date of a product, as it ensures the container can maintain sterility throughout its shelf life.

- Bacterial Endotoxin Testing ∞ Endotoxins are lipopolysaccharides from the cell walls of Gram-negative bacteria. They are pyrogenic, meaning they can induce a fever and a potent inflammatory response if injected. Because sterilization processes like filtration do not remove endotoxins, it is a critical quality attribute that must be tested in the final product. The standard method is the Limulus Amebocyte Lysate (LAL) test, which is highly sensitive to the presence of endotoxins. For anyone on a therapy designed to manage inflammation and optimize metabolic health, avoiding an endotoxin-induced inflammatory cascade is paramount.

The Legal and Scientific Basis of CGMP

The table below breaks down specific sections of 21 CFR Part 211, connecting the legal requirement to the scientific principle and its direct relevance to a patient’s hormonal therapy protocol.

| Regulation (21 CFR Part 211) | Scientific Principle | Relevance to Patient Safety and Efficacy |

|---|---|---|

| § 211.84 – Testing and approval or rejection of components | Analytical Chemistry & Material Science | Verifies that the raw hormonal ingredient (e.g. Testosterone USP) is chemically pure and potent before it is used. This prevents the use of substandard or contaminated materials from the outset. |

| § 211.113 – Control of microbiological contamination | Microbiology & Aseptic Technique | This section legally mandates the procedures to prevent microbial contamination in sterile products. It is the basis for requiring validated sterilization, media fills, and environmental monitoring, directly protecting the patient from infection. |

| § 211.165 – Testing and release for distribution | Quality Assurance & Statistical Process Control | Requires that a scientifically sound specification and test procedure is in place for every batch. This final checkpoint confirms the product is sterile, potent, and pure before it can be sent to a clinic, ensuring the dose is therapeutically active. |

| § 211.166 – Stability testing | Chemical Kinetics & Degradation Pathways | Mandates a program to determine the appropriate storage conditions and expiration dates. This ensures the hormone remains potent and does not degrade into potentially harmful substances throughout its shelf life, guaranteeing consistent therapeutic effect. |

The FDA’s requirements for outsourcing facilities are a direct application of established scientific principles to protect public health. They create a system where every critical parameter of the compounding process is controlled, monitored, and verified. For the individual seeking to optimize their endocrine function, this regulatory science provides a foundation of trust, ensuring that the powerful molecules they introduce into their system are precisely what they are intended to be ∞ pure, potent, and safe.

References

- U.S. Food and Drug Administration. “Guidance for Industry ∞ Sterile Drug Products Produced by Aseptic Processing ∞ Current Good Manufacturing Practice.” September 2004.

- U.S. Food and Drug Administration. “Current Good Manufacturing Practice ∞ Guidance for Human Drug Compounding Outsourcing Facilities Under Section 503B of the FD&C Act.” January 2020.

- Code of Federal Regulations, Title 21, Part 210, “Current Good Manufacturing Practice in Manufacturing, Processing, Packing, or Holding of Drugs; General.”

- Code of Federal Regulations, Title 21, Part 211, “Current Good Manufacturing Practice for Finished Pharmaceuticals.”

- Drug Quality and Security Act, Public Law 113-54, 127 Stat. 587, enacted November 27, 2013.

- Sutton, Scott. “The Contamination Control Plan in the GMP Environment.” Journal of GXP Compliance, vol. 14, no. 3, 2010, pp. 62-71.

- Agalloco, James P. and James E. Akers. “Aseptic Processing ∞ A Review of Current Industry Practice.” PDA Journal of Pharmaceutical Science and Technology, vol. 59, no. 2, 2005, pp. 80-94.

Reflection

Your Role in a System of Quality

You have now seen the intricate architecture of safety and quality that stands behind your prescribed hormonal therapies. This framework of regulation, validation, and control is designed to be a silent partner in your health journey, providing a constant assurance of product integrity.

The knowledge of this system shifts your position from a passive recipient of care to an active, informed participant. Understanding the ‘why’ behind the sterile vial, the beyond-use date, and the very existence of a 503B facility empowers you.

How does this understanding reshape your dialogue with your clinical team? It equips you to ask questions that are rooted in a deeper comprehension of the treatment process. It allows you to appreciate the quality standards that your provider upholds by selecting a reputable outsourcing partner.

Your personal wellness protocol is a collaborative effort. Your physiological system provides the feedback, your clinician provides the expertise, and the outsourcing facility provides the precisely formulated, quality-assured tool. Recognizing the profound importance of that third element is a vital step in navigating your path to optimized health with confidence and clarity. The journey is yours, and the knowledge of the systems that support it is your most valuable asset.

Glossary

food and drug administration

503b outsourcing facility

current good manufacturing practices

testosterone replacement therapy

outsourcing facility

section 503b

quality control

good manufacturing practices

prevent microbial contamination

current good manufacturing

503b outsourcing

outsourcing facilities

hormonal optimization

quality control unit

sterile compounding

environmental monitoring

microbial contamination

aseptic processing

sterile microbiological growth medium

aseptic technique

process validation

container closure integrity

bacterial endotoxin testing