Fundamentals

You may be standing at a point in your health journey where the language of your own body has started to feel unfamiliar. The energy that once defined your days may have diminished, your sleep may be less restorative, or you might sense a subtle but persistent shift in your overall vitality. These experiences are valid and deeply personal. They often originate from the complex and delicate communication network within your body known as the endocrine system.

The messengers in this system, hormones and peptides, are the biological architects of your well-being. When considering therapeutic peptides, which are potent molecules designed to support and recalibrate this internal communication, a foundational question arises ∞ how can we trust their quality? This question becomes particularly relevant when we look at the global supply chain, where many active pharmaceutical ingredients originate from China. Understanding the regulatory framework governing these substances is the first step in transforming apprehension into empowered knowledge.

The journey to ensuring the quality of a therapeutic peptide begins with recognizing it as an Active Pharmaceutical Ingredient Meaning ∞ The Active Pharmaceutical Ingredient, often abbreviated as API, refers to the biologically active component within a drug product responsible for its intended therapeutic effect. or API. An API is the core component of any medication that produces the intended health effect. In China, the National Medical Products Administration National growth hormone therapy reimbursement policies vary by strict clinical criteria, quality of life metrics, and health system funding models. (NMPA) is the principal government authority tasked with overseeing the safety, efficacy, and quality control of all drugs and APIs, including peptides. The NMPA’s role is to establish a rigorous set of standards and a comprehensive review process that every manufacturer must adhere to.

This process is designed to build a foundation of trust, ensuring that the peptide that eventually becomes part of a therapeutic protocol is precisely what it claims to be. The concept of purity is central to this entire framework. A peptide’s purity is a direct measure of its identity and safety. It confirms that the molecule in the vial is the correct one, and that it is free from contaminants, byproducts, or structural variations that could alter its function or, more critically, cause harm.

The Biological Importance of Purity

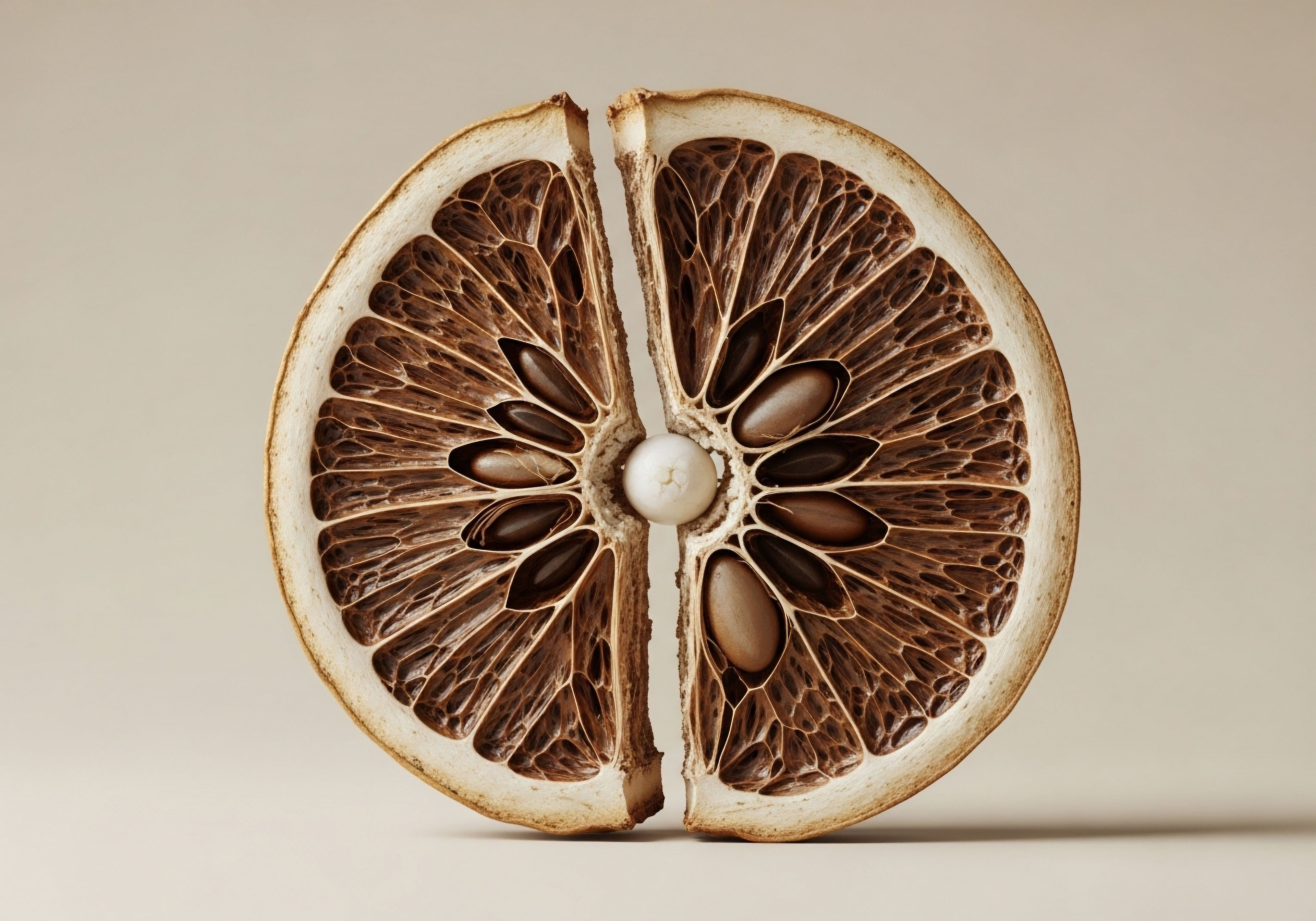

To appreciate the NMPA’s focus on purity, we must first understand the exquisite specificity of biological systems. Peptides function by binding to specific receptors on the surface of cells, much like a key fits into a lock. This binding action initiates a cascade of signals inside the cell, leading to a desired physiological response, such as the release of growth hormone or the modulation of an inflammatory process. For this to occur correctly, the peptide’s structure, a precise sequence of amino acids folded into a specific three-dimensional shape, must be perfect.

Any deviation, any impurity, can have significant consequences. A structurally incorrect peptide might fail to bind to its target receptor, rendering it ineffective. Worse, it could potentially bind to the wrong receptor, triggering unintended and potentially adverse biological effects. It is this potential for off-target activity that makes purity a non-negotiable aspect of peptide therapy.

Impurities can arise from various stages of the complex chemical synthesis process used to manufacture peptides. These can include residual solvents, reagents, or even incomplete or incorrectly formed peptide chains. The NMPA’s regulations mandate that manufacturers develop and validate sensitive analytical methods Meaning ∞ Analytical Methods refer to systematic, standardized procedures employed in scientific and clinical laboratories to identify, quantify, and characterize biological substances or processes. to detect and quantify these impurities. The goal is to ensure that any detected impurities are below stringent, predefined thresholds that have been established as safe.

This meticulous attention to what is removed from the final product is just as important as the verification of the peptide itself. It provides the assurance that when you embark on a personalized wellness protocol, the therapeutic agents you use are working with your body’s systems as intended, creating a predictable and positive outcome. This regulatory oversight is the silent, steadfast guardian of your biological journey back to optimal function.

A peptide’s purity is a direct measure of its identity and safety, confirming the molecule is correct and free from harmful contaminants.

The Role of the National Medical Products Administration

The NMPA Meaning ∞ NMPA, or Neuro-Modulatory Peptide Agonist, refers to a class of biological agents designed to activate specific peptide receptors located within the nervous system. operates as the central pillar of China’s pharmaceutical regulatory landscape. Its authority extends across the entire lifecycle of a drug, from preclinical research and development to post-market surveillance. For peptide APIs, the NMPA, through its Center for Drug Evaluation Meaning ∞ The Center for Drug Evaluation is a pivotal regulatory body responsible for the thorough assessment and approval of pharmaceutical products intended for human use. (CDE), has established a clear and structured registration pathway.

This pathway requires manufacturers, both domestic and foreign, to submit a comprehensive dossier of information for review and approval before their API can be legally manufactured and sold. This process, often referred to as API registration or obtaining a Drug Master File Meaning ∞ A Drug Master File (DMF) is a confidential document submitted to a regulatory authority. (DMF) number, is the formal mechanism through which the NMPA exerts its control and ensures compliance with its standards.

Foreign manufacturers seeking to supply their peptides to the Chinese market must appoint a Chinese legal entity to manage their registration process with the CDE. This ensures that there is a local, accountable party responsible for all communications and regulatory submissions. The NMPA’s framework has evolved significantly, aligning more closely with international standards, such as those from the International Council for Harmonisation Meaning ∞ The International Council for Harmonisation (ICH) is a global initiative uniting regulatory authorities and pharmaceutical industry associations. of Technical Requirements for Pharmaceuticals for Human Use (ICH). This harmonization facilitates a more transparent and predictable regulatory environment.

It also reflects a deep understanding that in a globalized world, the safety of therapeutic agents is a shared international responsibility. The NMPA’s requirements are designed to be thorough, demanding a level of detail that leaves no room for ambiguity regarding a peptide’s quality, with purity being the most scrutinized characteristic.

Intermediate

For those already familiar with the foundational concepts of hormonal health and the role of regulatory bodies, the next logical step is to understand the specific mechanisms by which peptide purity Meaning ∞ Peptide purity defines the percentage of the desired, correctly synthesized peptide molecule in a sample, free from related impurities like truncated sequences or chemical byproducts. is enforced in China. This involves a deeper examination of the administrative and technical procedures that a manufacturer must navigate. The process is anchored in the submission of a Drug Master File (DMF) to the NMPA’s Center for Drug Evaluation (CDE).

This dossier is a comprehensive document that contains complete information on the chemistry, manufacturing, and controls (CMC) of an Active Pharmaceutical Ingredient (API). The review of this file is the NMPA’s primary tool for assessing the quality and purity of a peptide before it can be used in a finished pharmaceutical product.

The Chinese regulatory system has transitioned to a binding review process. This means the API’s DMF is directly linked to the application for a finished drug product. The CDE reviews both dossiers concurrently. This integrated approach ensures that the quality of the peptide API Meaning ∞ A Peptide API denotes a synthesized or isolated peptide compound intended as the sole active constituent within a pharmaceutical formulation. is evaluated in the specific context of its intended use.

For instance, the purity requirements for a peptide used in a daily subcutaneous injection might be evaluated with different considerations than one used in a long-acting implantable pellet. This system creates a direct line of accountability, linking the peptide manufacturer’s quality systems directly to the safety and efficacy of the final medication that reaches a patient. The successful review of a DMF results in the API being assigned an “Active” or “A” status on the NMPA’s registration platform, signaling to finished drug manufacturers that the API has met the requisite quality standards and is approved for use.

The Drug Master File and Purity Verification

The DMF is the technical heart of the regulatory submission. Within this document, the section on “Characterization and Control of the Drug Substance” is where the evidence of a peptide’s purity is presented. Manufacturers must provide a detailed narrative of their entire manufacturing process, from the starting materials to the final purified peptide. They must also provide robust data from validated analytical methods that confirm the peptide’s identity, structure, and, most critically, its purity profile.

This is not a mere formality; it is a rigorous scientific exercise that demonstrates a profound understanding and control over the production process. The NMPA requires this data to be generated using established and validated analytical techniques Meaning ∞ Analytical techniques refer to the precise methodologies employed to identify, quantify, and characterize specific substances within biological matrices, such as blood, urine, or saliva, providing crucial data for clinical assessment and research. capable of separating the main peptide from any potential impurities.

The two most critical analytical methods for this purpose are High-Performance Liquid Chromatography Meaning ∞ High-Performance Liquid Chromatography, commonly known as HPLC, is an advanced analytical chemistry technique used to separate, identify, and quantify individual components within a complex liquid mixture. (HPLC) and Mass Spectrometry (MS). HPLC is the workhorse for quantifying purity. It separates components in a mixture based on their chemical properties, allowing for the precise measurement of the main peptide peak relative to any impurity peaks. The NMPA requires manufacturers to report the purity level, typically as a percentage, and to identify and quantify any significant impurities.

Mass Spectrometry complements HPLC by providing an exact measurement of the peptide’s molecular weight, which confirms its identity and elemental composition. Together, these methods provide a detailed chemical fingerprint of the peptide, offering a high degree of confidence in its quality. The table below outlines the roles of these key analytical techniques in the purity verification process.

| Analytical Technique | Primary Function in Purity Assessment | Information Provided to the NMPA |

|---|---|---|

| High-Performance Liquid Chromatography (HPLC) | Quantifies the percentage of the desired peptide and separates it from process-related and degradation impurities. |

Provides a chromatogram showing the main peptide peak and impurity peaks. The purity is reported as a percentage of the total peak area. It also establishes a unique “fingerprint” for a given peptide batch. |

| Mass Spectrometry (MS) | Confirms the molecular identity of the peptide by measuring its precise mass-to-charge ratio. |

Delivers a mass spectrum that verifies the molecular weight of the peptide, confirming the correct amino acid sequence was synthesized. It is also used to identify the structure of unknown impurities. |

Good Manufacturing Practices a Pillar of Quality

While analytical testing confirms the purity of the final product, the NMPA’s regulations also extend to the environment and processes used to create it. Good Manufacturing Practices Meaning ∞ Good Manufacturing Practices (GMP) represent a regulatory framework and a set of operational guidelines ensuring pharmaceutical products, medical devices, food, and dietary supplements are consistently produced and controlled according to established quality standards. (GMP) are a set of principles and procedures that, when followed, help ensure that a product is consistently produced and controlled to the quality standards appropriate for its intended use. China has its own GMP guidelines, which have been progressively updated to align with international standards, such as those of the World Health Organization and the Pharmaceutical Inspection Co-operation Scheme (PIC/S). Adherence to GMP is mandatory for all API manufacturers in China and is verified through on-site inspections by the NMPA or its provincial authorities.

Adherence to Good Manufacturing Practices is mandatory and ensures that peptides are consistently produced and controlled according to strict quality standards.

GMP for peptide manufacturing covers every aspect of production, from the quality of the raw materials and the training of personnel to the design and maintenance of the facility and equipment. The objective is to minimize the risk of contamination, cross-contamination, and human error. For peptides, which are large, complex molecules susceptible to degradation and contamination, a robust GMP system is paramount.

It provides the procedural backbone that ensures the purity demonstrated in analytical tests is a consistent and reproducible outcome of a well-controlled process. A failure in GMP can introduce impurities that may be difficult to detect, making process control an essential complement to final product testing.

- Personnel ∞ All staff involved in manufacturing must have the necessary training and experience. They must follow detailed standard operating procedures (SOPs) for every task to ensure consistency and prevent errors.

- Facility and Equipment ∞ Manufacturing facilities must be designed to prevent cross-contamination. This includes controlled air quality (HVAC systems), smooth and cleanable surfaces, and logical workflow. All equipment must be properly calibrated, cleaned, and maintained.

- Raw Materials ∞ All starting materials and reagents must be of high quality and tested for identity and purity before use. A secure and documented supply chain is essential.

- Process Controls ∞ Critical steps in the peptide synthesis, cleavage, and purification process must be monitored and controlled to ensure the desired outcome. This includes monitoring reaction times, temperatures, and pH levels.

- Documentation ∞ Every step of the manufacturing process must be documented in real-time. This creates a complete batch record that provides a traceable history of how a specific batch of peptide was made, from raw materials to final release.

What Are the Specific Purity Thresholds Required?

A common question that arises is what specific purity level is considered acceptable by the NMPA. The required purity threshold for a peptide API is not a single, universal number. It is determined on a case-by-case basis and is typically specified in the Chinese Pharmacopoeia Meaning ∞ The Chinese Pharmacopoeia serves as the official compilation of standards for drugs in China, encompassing both traditional Chinese medicines and Western pharmaceuticals. or established by the manufacturer and justified within their DMF. Generally, for synthetic peptides used in therapies, purity levels are expected to be very high, often greater than 98% or 99% as measured by HPLC.

The acceptable level depends on several factors, including the peptide’s therapeutic indication, its dosage, and the nature of its impurities. The focus is less on achieving a perfect 100% purity, which is practically impossible, and more on ensuring that any impurities present are identified, characterized, and proven to be safe at the levels they exist.

The NMPA requires a thorough impurity profile. This means manufacturers must not only report the total percentage of impurities but also identify individual impurities that are present above a certain threshold (e.g. 0.1%). They must then provide data on the chemical structure of these impurities and, for any significant impurity, assess its potential biological activity and toxicity.

This detailed approach ensures that the safety of the peptide is not just assumed from its high purity value but is supported by a deep scientific understanding of its minor components. This rigorous, evidence-based approach to purity and impurity control is the hallmark of a mature and robust regulatory system, providing a strong assurance of quality for any peptide that successfully navigates the NMPA’s review process.

Academic

An academic exploration of China’s regulatory requirements for peptide purity moves beyond procedural descriptions into the scientific rationale and systemic philosophies that underpin them. At this level, the conversation shifts to a detailed analysis of impurity characterization, the application of orthogonal analytical methods, and the adoption of advanced quality paradigms like Quality by Design Meaning ∞ Quality by Design represents a systematic, proactive approach to product and process development, ensuring that desired quality attributes are inherent to the output from the outset. (QbD). The NMPA’s framework, particularly its alignment with ICH guidelines such as ICH Q3A (Impurities in New Drug Substances) and ICH Q11 (Development and Manufacture of Drug Substances), provides the basis for this sophisticated approach. The core principle is that product quality and purity are not merely confirmed by final testing but are built into the product and process from the very beginning.

This perspective reframes the regulatory submission as a scientific dissertation on the peptide itself. The manufacturer must demonstrate a comprehensive mastery of the molecule’s chemical and physical properties, its synthetic pathway, and its degradation products. The focus is on creating a robust “control strategy,” a planned set of controls derived from both product and process understanding that assures process performance and product quality.

For peptides, which are significantly more complex than small-molecule drugs, this strategy must account for a wider range of potential impurities, including those related to the solid-phase synthesis process, diastereomers, and aggregations. The NMPA’s CDE reviewers, who possess deep scientific expertise, scrutinize this control strategy to ensure it is scientifically sound and sufficient to guarantee the consistent production of a high-purity peptide.

The Science of Impurity Profiling

Impurity profiling is the cornerstone of a modern CMC submission for a peptide API. It involves a systematic scientific investigation to detect, identify, and quantify all potential impurities in the drug substance. These impurities are generally categorized based on their origin.

Understanding these categories is essential for developing a targeted analytical control strategy. The NMPA expects manufacturers to address each of these potential sources of impurity with specific data and risk assessments.

The complexity of peptide synthesis, particularly solid-phase peptide synthesis (SPPS), can generate a unique constellation of related impurities. These are not random contaminants but are structurally similar to the desired peptide. For example, incomplete deprotection of an amino acid during a synthesis cycle can lead to a “deletion sequence,” where one amino acid is missing. Alternatively, a “double coupling” event can lead to an “insertion sequence.” Because these related impurities often have similar chemical properties to the final peptide, they can be particularly challenging to separate and quantify.

This is why the NMPA requires the use of high-resolution analytical techniques and extensive method validation to prove that the chosen methods are capable of detecting these specific, process-related impurities. The control of these related substances is critical, as they may possess altered biological activity or immunogenicity.

How Are Different Impurity Types Classified and Controlled?

The classification of impurities is a critical exercise that dictates the level of control and qualification required. The NMPA, following ICH guidelines, has specific expectations for how different types of impurities are managed. This systematic approach ensures that the greatest scrutiny is applied to the impurities that pose the highest potential risk to patient safety. A deep understanding of these classifications is what separates a routine quality control operation from a truly science-driven pharmaceutical development program.

| Impurity Category | Origin and Examples | Regulatory Expectation and Control Strategy |

|---|---|---|

| Organic Impurities (Process-Related) |

Arise during the manufacturing process. Examples include starting materials, by-products (e.g. deletion/insertion sequences), and intermediates. |

Must be controlled through optimization of the synthesis and purification process. A comprehensive impurity profile is required, with specific acceptance criteria for known and unknown impurities in the final API specification. |

| Organic Impurities (Degradation-Related) |

Form during storage or transport due to chemical changes like deamidation, oxidation, or aggregation. |

Evaluated through rigorous stability studies under various conditions (temperature, humidity, light). The results are used to define the re-test period or shelf life and appropriate storage conditions for the peptide. |

| Inorganic Impurities |

Derived from the manufacturing process, such as reagents, ligands, catalysts, or heavy metals. |

Controlled by established pharmacopoeial limits (e.g. from the Chinese Pharmacopoeia or USP/Ph. Eur.). Specific tests for heavy metals and residual catalysts are often required. |

| Residual Solvents |

Organic solvents used during synthesis or purification that are not completely removed. |

Controlled according to ICH Q3C guidelines, which classify solvents based on their toxicity. Gas Chromatography (GC) is the standard method for quantification. Limits are set to ensure patient safety. |

Orthogonal Analytical Methods for Robust Verification

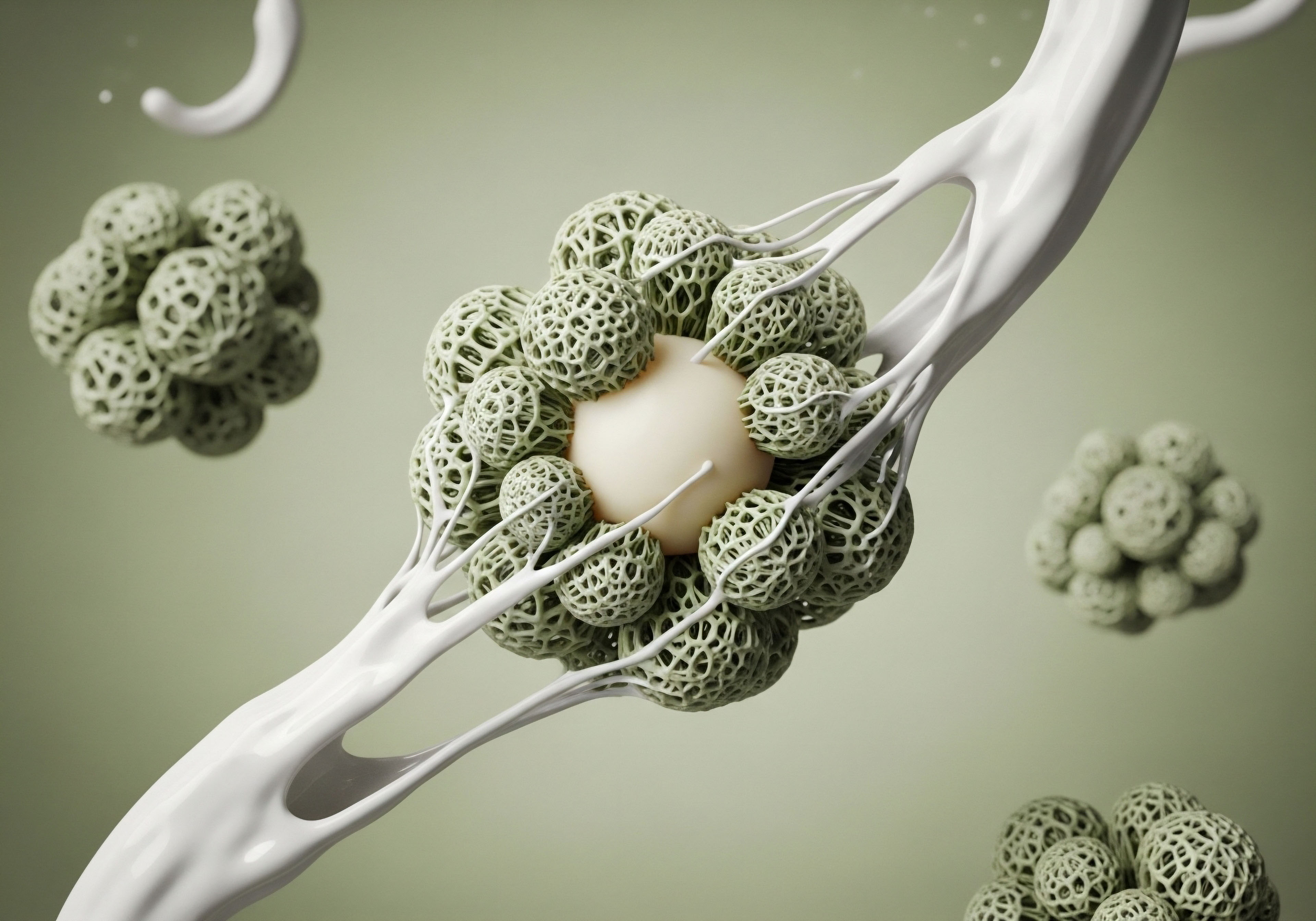

Given the complexity of peptides, relying on a single analytical method, even one as powerful as HPLC, is insufficient to fully characterize purity. Regulatory bodies like the NMPA expect manufacturers to employ a suite of “orthogonal” methods. Orthogonal methods are analytical techniques that measure the same attribute (like purity) using different underlying physical or chemical principles.

This approach provides a much more comprehensive and reliable picture of the peptide’s quality. If multiple, distinct methods all confirm a high level of purity, it builds a powerful and convincing case for the quality of the API.

Employing a suite of orthogonal analytical methods provides a comprehensive and reliable assessment of a peptide’s quality and purity.

For example, while a reverse-phase HPLC (RP-HPLC) method might be the primary tool for purity analysis, it could be complemented by other techniques. Capillary Electrophoresis (CE) separates molecules based on their mass-to-charge ratio in an electric field, offering a different separation mechanism that might resolve impurities that co-elute with the main peak in HPLC. Similarly, Size-Exclusion Chromatography (SEC) can be used specifically to detect and quantify aggregates, which are a critical quality attribute for peptides as they can be immunogenic.

The use of this multi-faceted analytical approach demonstrates a manufacturer’s commitment to rigorous quality control and provides the CDE with a high degree of confidence that the purity value is accurate and that no significant impurities have been missed. This is the level of scientific diligence required to support therapies like Gonadorelin or Ipamorelin, where precise biological signaling is the goal.

- Primary Method (Quantification) ∞ A validated, stability-indicating Reverse-Phase High-Performance Liquid Chromatography (RP-HPLC) method is typically used to determine the main purity value and quantify known and unknown impurities.

- Identity Confirmation ∞ High-resolution Mass Spectrometry (MS) and Amino Acid Analysis (AAA) are used to confirm the primary structure (the amino acid sequence) and overall composition of the peptide, verifying its identity beyond doubt.

- Higher-Order Structure ∞ For larger peptides where folding is critical, techniques like Circular Dichroism (CD) may be used to provide information about the peptide’s secondary structure (e.g. alpha-helices or beta-sheets).

- Aggregate and Oligomer Analysis ∞ Size-Exclusion Chromatography (SEC-HPLC) is employed to specifically look for dimers, trimers, and larger aggregates that would not be properly quantified by RP-HPLC.

- Chiral Purity ∞ Chiral chromatography or other specialized methods are used to ensure the correct stereochemistry of the amino acids, as the presence of D-isomers in an L-peptide can significantly impact its biological activity and safety.

References

- National Medical Products Administration. “Announcement No. 129 of 2023 on Matters Concerning the Renewal of the Registration of Active Pharmaceutical Ingredients.” NMPA, 13 Oct. 2023.

- Center for Drug Evaluation, NMPA. “Notice on Improving the Relevant Functions of the API Registration System.” CDE, 17 Jan. 2020.

- International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use. “ICH Harmonised Guideline Q11 ∞ Development and Manufacture of Drug Substances (Chemical Entities and Biotechnological/Biological Entities).” ICH, 2 May 2012.

- International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use. “ICH Harmonised Guideline Q3A(R2) ∞ Impurities in New Drug Substances.” ICH, 25 Oct. 2006.

- Chinese Pharmacopoeia Commission. “Chinese Pharmacopoeia (ChP) 2020 Edition.” China Medical Science Press, 2020.

- Blanco, M. and I. Villarroya. “HPLC for the Separation of Peptides.” Separation & Purification Reviews, vol. 31, no. 1, 2002, pp. 1-63.

- Rathore, Anurag S. “Quality by design (QbD) for biotechnology products.” Trends in Biotechnology, vol. 27, no. 9, 2009, pp. 546-553.

Reflection

Calibrating Your Internal Compass

The intricate details of China’s regulatory landscape for peptide purity, from the technical specifications of High-Performance Liquid Chromatography Meaning ∞ Liquid Chromatography is an analytical chemistry technique used to separate, identify, and quantify components in a mixture. to the procedural rigor of Good Manufacturing Practices, may seem distant from the personal experience of seeking better health. Yet, within this complex system of controls and validations lies a profound affirmation. It affirms that the desire for vitality is matched by a global system of scientific diligence aimed at ensuring the tools you might use on your journey are trustworthy. Understanding this framework does more than just answer a question; it equips you with a new lens through which to view your own health protocols.

This knowledge becomes a part of your personal toolkit. It transforms you from a passive recipient of a therapy into an active, informed participant in your own wellness. It empowers you to ask more precise questions, to evaluate the quality of information you receive, and to appreciate the deep science that supports every therapeutic choice you consider.

The path to reclaiming your optimal function is a deeply personal one, a unique calibration of your own biological systems. The knowledge that there are robust systems in place to ensure the purity and quality of the very molecules designed to aid in that recalibration can provide a quiet confidence as you move forward, step by intentional step.