Fundamentals

When you begin a protocol involving therapeutic peptides, you are placing immense trust in the unseen science that delivers that molecule to you. You trust that the peptide in your hand is pure, potent, and precisely what your body needs to recalibrate and heal. This trust is the bedrock of any therapeutic relationship.

In many parts of the world, however, the journey of a peptide from its synthesis to your syringe is fraught with complexities that can compromise this fundamental trust. The quality control challenges for peptides in developing regions are a profound human issue, one that directly impacts the potential for healing and the safety of every individual seeking to restore their biological function.

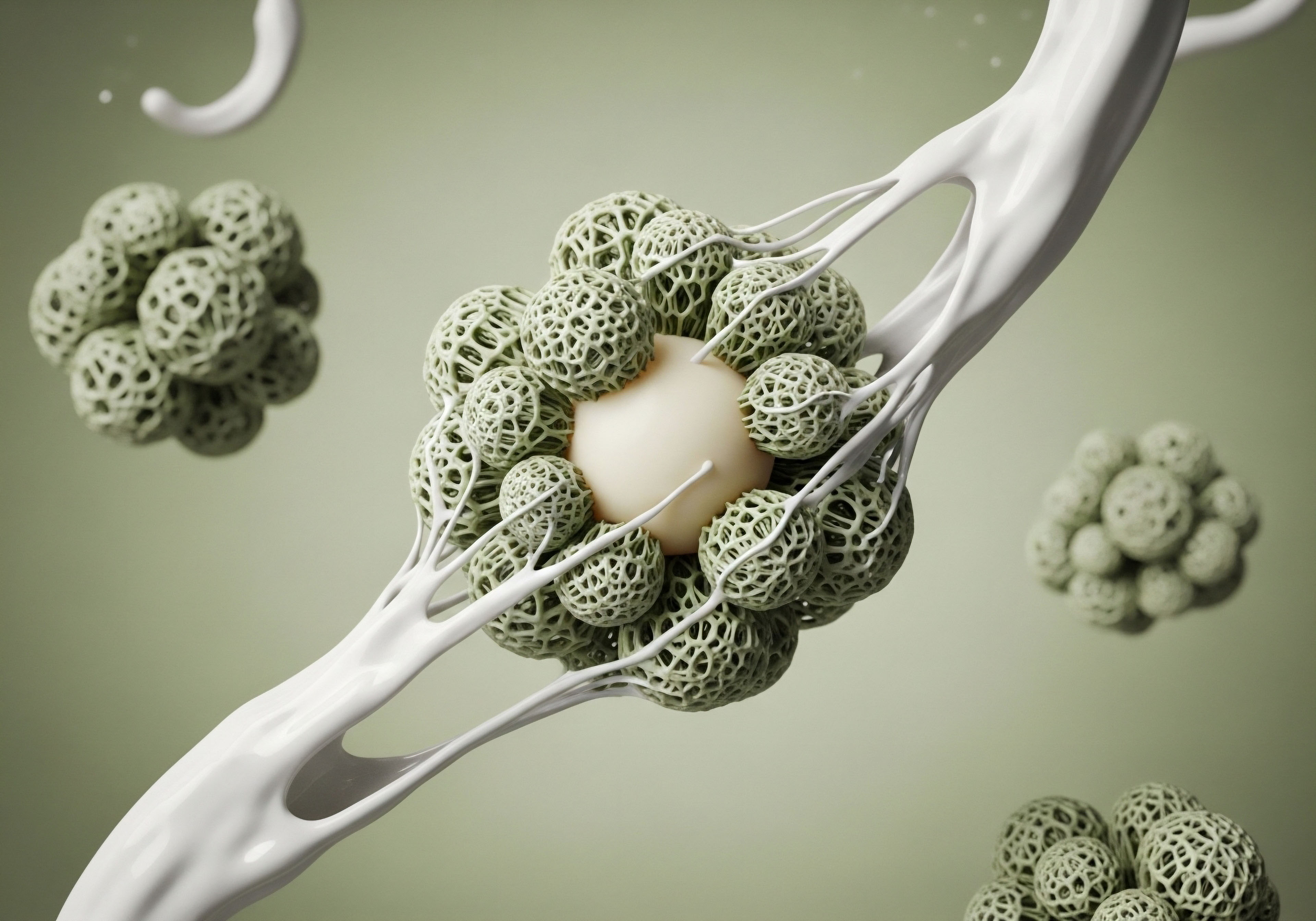

Imagine a highly specific key designed to fit a single lock in your body. A therapeutic peptide is that key, engineered to interact with a specific receptor to initiate a cascade of desired physiological responses, like signaling for tissue repair or modulating hormonal pathways.

Quality control is the rigorous process that ensures every key is perfectly cut. In regions with robust regulatory oversight and advanced analytical infrastructure, this process is meticulous. In developing regions, economic constraints, logistical hurdles, and a less established regulatory framework can lead to significant deviations. The result can be a key that is misshapen, impure, or unstable, one that fails to open the lock or, more concerningly, fits the wrong lock entirely.

The Silent Risks of Impurity

The primary challenge revolves around purity. Peptides are synthesized by linking amino acids together in a precise sequence. Any error in this process can create impurities. These are not just inert substances; they can be structurally similar peptides that may have unintended biological effects or even trigger an immune response.

The body’s surveillance system is exquisite at detecting foreign invaders. An impure peptide can be flagged as a threat, leading to inflammation or the generation of antibodies that could neutralize the therapeutic effect of the peptide itself or, in rare cases, cross-react with the body’s own proteins.

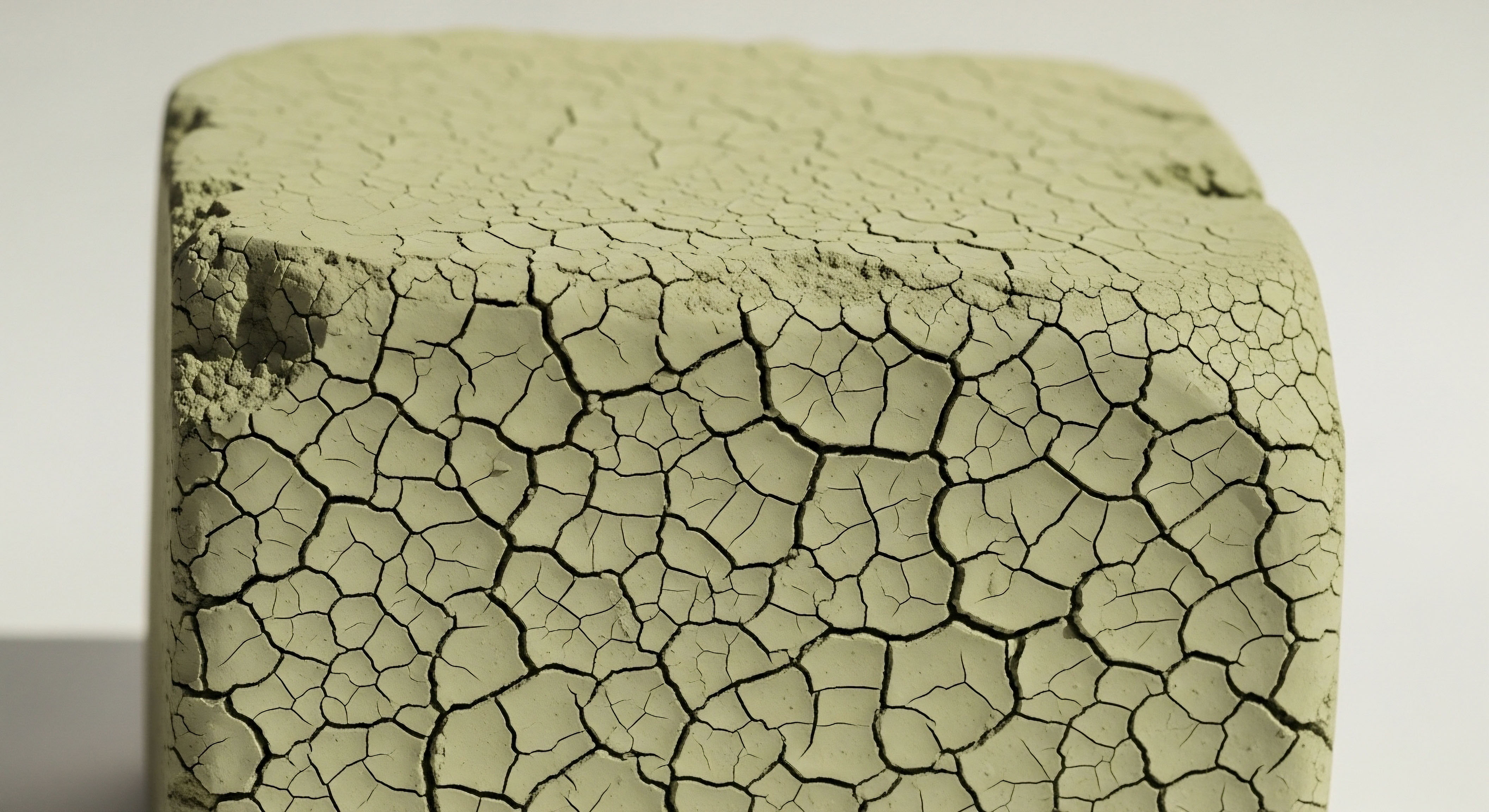

Consider the environment in which these peptides are stored and transported. Peptides are delicate molecules, sensitive to changes in temperature and light. Without an unbroken “cold chain” ∞ a refrigerated supply line from manufacturer to patient ∞ a perfectly pure peptide can degrade. It can break down into inactive fragments or clump together into aggregates.

These aggregates are particularly problematic, as they are often associated with an increased risk of an adverse immune reaction. In many developing regions, maintaining this cold chain across vast distances and in variable climates is a monumental logistical challenge.

A peptide’s journey through a compromised supply chain can fundamentally alter its structure, turning a therapeutic key into a source of biological confusion.

The absence of stringent, localized regulatory oversight creates a vacuum where substandard products can proliferate. While global standards exist, their enforcement can be inconsistent. This leaves patients and clinicians in a vulnerable position, often without the means to verify the quality of the peptides they are using.

The physical and chemical tests required to confirm a peptide’s identity, purity, and potency are sophisticated and expensive, involving techniques like high-performance liquid chromatography (HPLC) and mass spectrometry. Access to this level of analytical technology is limited in many developing nations, making independent verification nearly impossible. This is where the human element becomes most critical; the patient’s body becomes the final, and most vulnerable, testing ground.

Intermediate

To truly appreciate the quality control predicament in developing regions, we must look at the specific technical failures that can occur during a peptide’s lifecycle. These are not abstract risks; they are concrete deviations in chemistry and handling that have direct physiological consequences. The core of the issue lies in the gap between established best practices in pharmaceutical manufacturing and the realities of implementing them in resource-limited settings.

The synthesis of a peptide is a complex dance of chemical reactions. The most common method, Solid-Phase Peptide Synthesis (SPPS), involves building the peptide one amino acid at a time on a solid resin support. Each step ∞ coupling a new amino acid, deprotecting it so the next one can be added ∞ must be nearly perfect.

Incomplete reactions can lead to the formation of deletion sequences (missing an amino acid) or truncated sequences (incomplete chains). Side reactions can cause unintended modifications to amino acid side chains. While advanced purification techniques like HPLC can remove many of these impurities, the effectiveness of purification is dependent on the quality of the initial synthesis. A poorly controlled synthesis produces a complex mixture of closely related impurities that are difficult and costly to separate.

Analytical Hurdles and Regulatory Gaps

How do we know a peptide is what it claims to be? The answer lies in a suite of analytical tests. In a well-equipped lab, HPLC is used to determine purity by separating the target peptide from impurities. Mass spectrometry confirms the molecular weight, verifying the correct amino acid sequence.

Amino acid analysis quantifies the amount of each amino acid, ensuring the composition is correct. These methods are the gold standard, yet their implementation is a significant challenge in many developing countries.

- Equipment Costs and Maintenance ∞ An HPLC machine is a significant capital investment, and its maintenance requires specialized technicians and a steady supply of expensive consumables like solvents and columns.

- Reference Standards ∞ Accurate analysis requires comparison to a highly purified, well-characterized reference standard. These standards are costly and must be stored under strict conditions to prevent degradation. Their availability and proper use can be a major bottleneck.

- Human Expertise ∞ Operating the equipment and interpreting the complex data generated requires highly trained analytical chemists. A shortage of this specialized expertise can lead to improper analysis and unreliable results.

The regulatory environment compounds these technical challenges. In North America and Europe, regulatory bodies like the FDA and EMA provide detailed guidance on the quality attributes expected for therapeutic peptides, including strict limits on impurities. Many developing nations may lack a similarly robust and specialized regulatory framework for peptides. They might adopt guidelines from other regions, but lack the resources for rigorous enforcement and market surveillance. This can create an environment where products of unverifiable quality can enter the market.

The integrity of a therapeutic peptide is not a single property, but a composite of its identity, purity, strength, and stability, each of which can be compromised by a lack of resources.

The table below illustrates the stark contrast between the ideal quality control pathway and the challenging reality often faced in developing regions.

| QC Stage | Ideal Scenario (Developed Regions) | Common Reality (Developing Regions) |

|---|---|---|

| Raw Material Sourcing | Sourcing of amino acids and reagents from validated suppliers with certificates of analysis. | Use of lower-cost materials from unverified sources, introducing impurities from the very start. |

| Synthesis and Purification | Automated synthesis with real-time monitoring, followed by multi-step HPLC purification. | Manual or semi-automated synthesis with limited process control, leading to a higher impurity load. |

| Analytical Testing | Comprehensive testing (HPLC, MS, AAA) against a certified reference standard. | Basic or no testing; reliance on manufacturer’s claims without independent verification. |

| Storage and Distribution | Unbroken, monitored cold chain from production to pharmacy. | Potential for temperature fluctuations during shipping and storage, causing degradation. |

| Regulatory Oversight | Strict enforcement of cGMP (current Good Manufacturing Practices) and post-market surveillance. | Inconsistent regulatory enforcement and lack of resources for market monitoring. |

Academic

The most profound and clinically significant consequence of inadequate peptide quality control is the potential for increased immunogenicity. This response, where the body’s immune system recognizes the therapeutic peptide or its contaminants as a foreign threat, is a complex biological event with serious implications. The challenges in developing regions, from compromised synthesis to unstable storage conditions, directly amplify this risk. A deep examination of the molecular triggers of immunogenicity reveals why stringent quality control is an absolute biological necessity.

Immunogenicity of therapeutic peptides is primarily driven by the activation of CD4+ T-helper cells. This process is initiated when an antigen-presenting cell (APC), such as a dendritic cell, engulfs the peptide product. Inside the APC, the peptide is processed into smaller fragments.

These fragments can then be loaded onto Major Histocompatibility Complex class II (MHC-II) molecules and presented on the APC’s surface. If a circulating T-helper cell has a T-cell receptor (TCR) that recognizes this specific peptide-MHC-II complex, the T-cell becomes activated. This activation is the central event that can lead to the production of anti-drug antibodies (ADAs) by B-cells, potentially neutralizing the drug, accelerating its clearance, or causing adverse hypersensitivity reactions.

How Do Impurities Increase Immunogenicity?

Synthesis-related impurities represent a significant source of immunogenic risk. These impurities are often novel peptide sequences that the body has never encountered. An impurity containing a single amino acid substitution, insertion, or deletion can create a new, potent T-cell epitope ∞ a sequence fragment with high binding affinity for MHC-II molecules.

Regulatory guidance from the FDA, for example, now suggests that any new impurity present at a level above 0.1% should be assessed for immunogenicity potential. This highlights the minute quantities at which these impurities can become clinically relevant.

Another critical factor is the formation of aggregates. Peptides, especially when subjected to thermal stress or pH changes common in a broken cold chain, have a tendency to aggregate. These aggregates can be taken up more efficiently by APCs than monomeric peptides.

Furthermore, the repetitive structure of an aggregate can cross-link B-cell receptors, providing a powerful activation signal that can bypass the need for T-cell help in some cases, leading to a rapid and robust antibody response. The physical stress of transportation and improper storage in developing regions is a direct contributor to the formation of these highly immunogenic aggregates.

What Is the Role of Post-Translational Modifications?

Chemical degradation of peptides also introduces immunogenic risk. Deamidation (the conversion of asparagine or glutamine to aspartic or glutamic acid) and oxidation (of methionine or tryptophan) are common degradation pathways. These modifications can occur during synthesis or storage.

A deamidated peptide sequence can create a negatively charged residue that enhances binding to certain MHC-II alleles, turning a previously non-immunogenic sequence into a T-cell epitope. The lack of controlled environmental conditions during shipping and storage in many developing nations accelerates these chemical modifications, silently increasing the immunogenic potential of the product.

The following table outlines the specific mechanisms by which common quality control failures contribute to immunogenicity, based on current immunological understanding.

| Quality Control Failure | Molecular Mechanism | Potential Clinical Outcome |

|---|---|---|

| Synthesis Errors | Creation of new peptide sequences (impurities) that act as potent T-cell epitopes. | Generation of neutralizing antibodies, loss of efficacy, hypersensitivity reactions. |

| Aggregation | Enhanced uptake by APCs and potential for T-cell independent B-cell activation. | Strong antibody response, potential for infusion reactions and anaphylaxis. |

| Chemical Degradation | Formation of neo-epitopes through deamidation or oxidation that increase MHC-II binding affinity. | Breakdown of immune tolerance, leading to ADA formation against the therapeutic. |

| Host-Cell Proteins (HCPs) | If peptides are produced recombinantly, contaminating proteins from the production host can act as adjuvants, boosting the immune response. | Broad immune activation, increased likelihood of ADA response to the peptide itself. |

The confluence of these factors creates a precarious situation in developing regions. The very conditions that make quality control difficult ∞ economic pressures, logistical instability, and regulatory gaps ∞ are the same conditions that systematically increase the risk of administering an immunogenic product. This transforms the challenge of quality control from a simple matter of chemical purity into a critical issue of immunological safety.

References

- De Groot, A. S. & Robe, B. (2023). Immunogenicity risk assessment of synthetic peptide drugs and their impurities. Drug Discovery Today, 28(10), 103714.

- Abbood, A. (2024). Insights into Therapeutic Peptides and their Quality Control. International Journal of Advanced Pharmaceutical Sciences and Research (IJAPSR).

- USP. (2023). Reference Standards to Support Quality of Synthetic Peptide Therapeutics. Journal of Pharmaceutical Sciences.

- Kuril, A. K. (2024). Identifying Trending Issues in Assay of Peptide Therapeutics During Stability Study. American Journal of Biomedical Science and Research, 22(5).

- Teva Pharmaceutical Industries Ltd. (2022). Challenges in the Changing Peptide Regulatory Landscape. TAPI.

- Gomes, A. C. et al. (2025). Regulatory Guidelines for the Analysis of Therapeutic Peptides and Proteins. Journal of Peptide Science, 31(3).

- ResolveMass Laboratories Inc. (2025). Case study ∞ Challenges Faced in Peptide Impurities Characterization.

Reflection

Your Personal Health Equation

The information presented here about the quality control of therapeutic peptides is more than an academic exercise. It is a framework for understanding the profound importance of the invisible systems that support your health journey. Every protocol you consider, every therapeutic agent you use, exists at the end of a long chain of events.

The integrity of that chain is directly linked to the integrity of the clinical outcomes you seek. Your body is a finely tuned biological system, and the signals you introduce to it must be clear and precise.

As you move forward, consider the source of the tools you use to recalibrate your health. Ask questions about sourcing, purity, and stability. Recognizing the complexity of these challenges is the first step toward making informed decisions. Your path to optimized function is a partnership between you, your clinical guide, and the science that underpins your protocols.

Ensuring the quality of that science is a shared responsibility, and your awareness is a powerful part of that equation. What does it mean for you to trust the process? And how can that trust be built on a foundation of verifiable quality?

Glossary

therapeutic peptides

quality control

regulatory oversight

cold chain

many developing nations

immunogenicity