Fundamentals

Your body operates as a finely tuned biological orchestra, with hormones acting as the conductors of this complex symphony. These chemical messengers regulate everything from your energy levels and mood to your metabolic rate and reproductive cycles. When a specific hormonal instrument plays out of tune, the entire composition of your well-being can be affected.

This is a lived reality for many who experience the profound shifts of andropause or perimenopause, where the body’s natural production of hormones like testosterone, estrogen, and progesterone declines. It is this personal, tangible experience of feeling “off” that leads many to explore hormonal optimization protocols.

Compounded hormones are presented as a personalized solution, tailored to your unique biochemical needs. The core idea is to create a preparation with the exact dosage and combination of hormones prescribed for you, something unavailable in mass-produced pharmaceuticals.

The journey toward hormonal recalibration begins with understanding the fundamental promise and challenge of compounded preparations. A physician, after carefully interpreting your lab results and discussing your symptoms, writes a specific prescription. This could be for Testosterone Cypionate to address low testosterone, perhaps combined with Anastrozole to manage its conversion to estrogen.

For a woman, it might be a delicate balance of Bi-Est (a combination of two estrogens, estriol and estradiol) and progesterone in a transdermal cream. This prescription is then sent to a compounding pharmacy, a specialized facility that creates the medication from scratch.

The pharmacist’s role is to take the raw, active pharmaceutical ingredients (APIs) and combine them into the final dosage form ∞ be it a cream, capsule, or injectable oil. This process is where the first procedural challenges in quality control emerge. The precision of this craft directly determines the safety and effectiveness of the therapy you receive.

The core challenge in compounded hormones lies in ensuring that the personalized dose prescribed is the exact dose delivered in every single preparation.

Ensuring that every dose is identical in potency and purity is the central procedural hurdle. Unlike large pharmaceutical manufacturers that produce millions of identical pills and are subject to rigorous oversight by the Food and Drug Administration (FDA), compounding pharmacies create bespoke medications in much smaller batches.

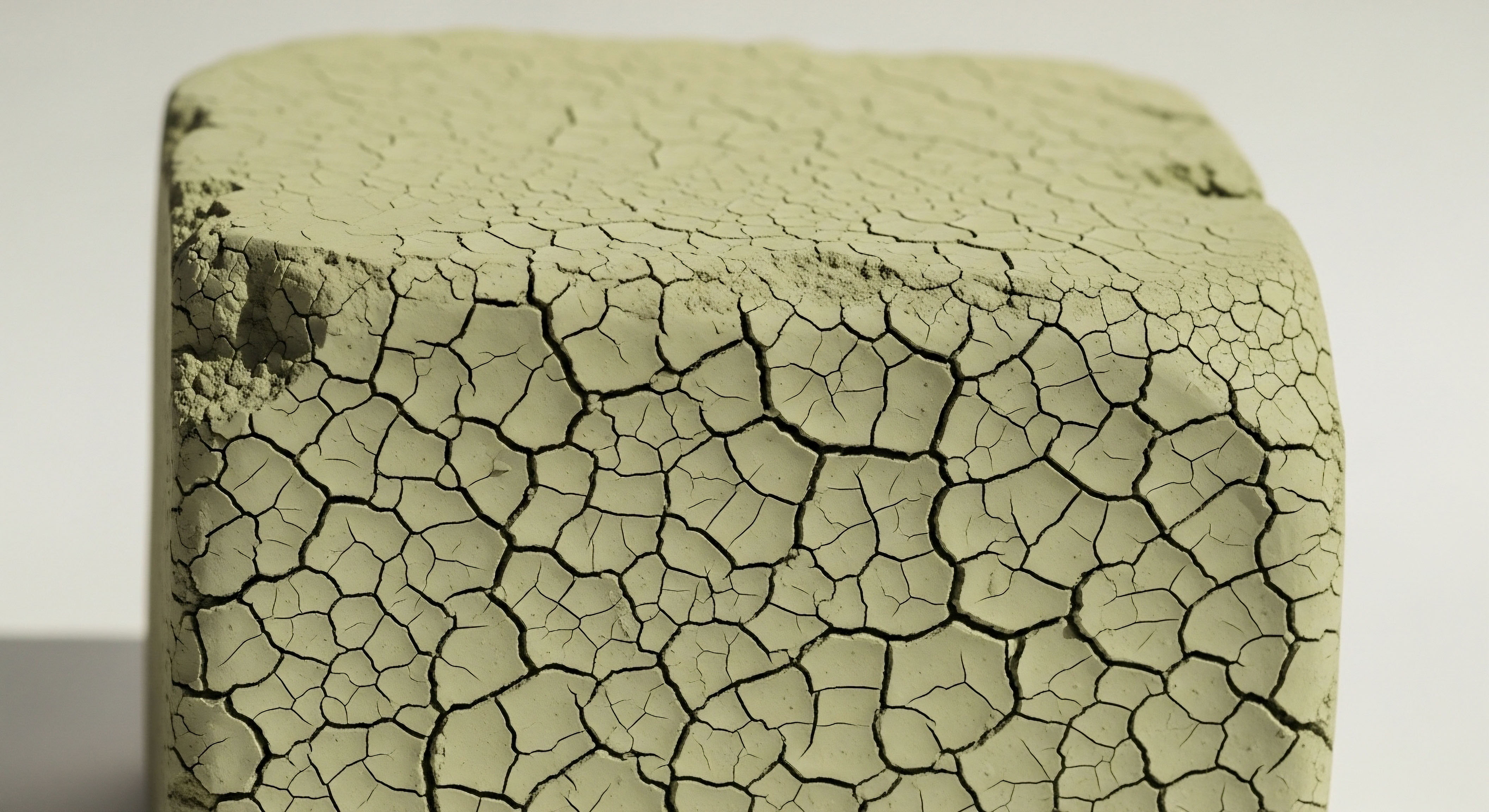

This artisanal approach, while offering personalization, introduces significant variability. The quality of the final product depends heavily on the pharmacy’s internal procedures, the skill of the pharmacist, and the quality of the raw ingredients they source. A slight miscalculation in weighing a powdered hormone, improper mixing of a cream, or the use of a lower-quality base can dramatically alter the final product.

These inconsistencies can mean you might receive a dose that is either too high, leading to potential side effects, or too low, rendering the treatment ineffective and leaving you to question why you still feel the persistent symptoms that brought you to the doctor in the first place.

This variability is not merely a theoretical concern; it is a tangible factor that can impact your personal health journey. The goal of hormonal optimization is to restore your body’s intricate balance, and this requires a consistent, predictable therapeutic dose. When quality control is inconsistent, it introduces a disruptive variable into your protocol.

Your body may respond differently from one refill to the next, making it difficult for you and your clinician to accurately assess your progress and make informed adjustments. This is why understanding the procedural challenges in quality control is so important. It empowers you to ask informed questions about where your medications are made and what steps are taken to ensure you are receiving a safe, accurate, and effective therapy designed to help you reclaim your vitality.

Intermediate

When we move beyond the foundational understanding of compounded hormones, we enter the intricate world of pharmaceutical science, where procedural precision is paramount. The quality of a compounded hormone preparation is not a single attribute but a composite of several critical factors ∞ potency, purity, stability, and bioavailability.

Each of these presents a distinct set of challenges within the compounding process. Potency, or the concentration of the active hormone, is perhaps the most discussed aspect of quality control. For a man prescribed Testosterone Cypionate at 200mg/ml, or a woman using a 10mg/ml testosterone cream, receiving a preparation that is even 10% under or over the prescribed dose can have significant clinical implications.

Overdosing can heighten the risk of side effects like fluid retention or mood changes, while underdosing can stall therapeutic progress.

The challenge of ensuring accurate potency begins with the sourcing of Active Pharmaceutical Ingredients (APIs). Compounding pharmacies must procure these raw hormone powders from reputable suppliers who can provide a Certificate of Analysis (C of A) for each batch, verifying its identity and purity. However, the C of A itself is just the starting point.

The next procedural hurdle is the geometric dilution required for creating a homogenous mixture, especially for low-dose formulations. When dealing with potent hormones, a tiny amount of powder must be evenly dispersed throughout a large volume of cream or oil.

An uneven mixture, known as a “hot spot,” can result in some doses containing a much higher concentration of the hormone than others. This is a critical concern in transdermal creams, where a patient could unknowingly apply a super-potent dose one day and an inert one the next.

The Compounding Environment and Formulation Variables

The physical environment and the equipment used in the compounding process introduce another layer of complexity. Nonsterile compounding, such as for oral capsules and topical creams, must be performed in a controlled environment to prevent cross-contamination between different hormones or with other substances.

For sterile compounding, which includes injectable hormones like Testosterone Cypionate or peptide therapies like Sermorelin, the requirements are far more stringent. These preparations must be made in a cleanroom environment using aseptic techniques to eliminate the risk of microbial contamination, which could lead to serious infections. The validation of these environmental controls and techniques is a continuous procedural challenge for any compounding facility.

Furthermore, the choice of the base, or excipient, in which the hormone is delivered can profoundly impact its performance. In transdermal creams, the base affects not only the texture and feel of the product but also the skin penetration and absorption of the hormone.

Different bases have different release characteristics, meaning that two creams with the exact same potency of progesterone could result in different absorption rates and, therefore, different clinical effects. This is a crucial variable that is not always standardized across pharmacies.

A patient who switches from one compounding pharmacy to another may receive a product with the same label but a different formulation, leading to an unexpected change in their therapeutic response. This highlights the procedural challenge of ensuring consistency not just in the active ingredient but in the entire formulation.

Inconsistent bioavailability from one compounded batch to the next can mimic hormonal fluctuation, complicating clinical assessment and adjustment.

Testing and the Lack of Standardization

The ultimate verification of quality control is through analytical testing of the final product. However, this presents one of the most significant procedural and financial challenges for many compounding pharmacies. While large drug manufacturers test every batch of a product they produce, routine end-product testing is not always feasible for small-batch compounded preparations.

The cost of High-Performance Liquid Chromatography (HPLC), the gold-standard method for verifying potency, can be prohibitive for a single prescription. As a result, many pharmacies rely on procedural quality assurance ∞ following standardized recipes and procedures ∞ rather than testing every batch.

While some high-volume compounding pharmacies do engage in routine third-party testing of random samples to validate their processes, this is not a universal practice. This lack of a standardized, mandatory testing protocol across the industry means that the quality assurance behind a compounded hormone prescription can vary significantly from one pharmacy to the next.

This procedural gap underscores the importance of choosing a compounding pharmacy that can provide documentation of its quality control measures, including evidence of routine potency testing.

This table illustrates the different layers of quality control and the associated challenges in a compounding pharmacy setting.

| Quality Control Area | Procedural Challenge | Impact on Patient |

|---|---|---|

| API Sourcing | Verifying the purity and identity of raw hormone powders from suppliers. | Risk of receiving an impure or incorrect substance. |

| Potency and Dosing | Ensuring accurate measurement and homogenous mixing to achieve the prescribed dose. | Potential for underdosing (ineffective therapy) or overdosing (increased side effects). |

| Formulation and Excipients | Selecting appropriate bases that ensure stability and consistent bioavailability. | Variability in hormone absorption and clinical response, even with the same prescribed potency. |

| Purity and Sterility | Preventing cross-contamination in nonsterile products and microbial contamination in sterile injectables. | Risk of allergic reactions, skin irritation, or serious infections. |

Academic

From a clinical and pharmaceutical science perspective, the procedural challenges in quality control for compounded hormones are rooted in the fundamental tension between personalized medicine and scalable, verifiable production standards.

The regulatory framework distinguishes between 503A compounding pharmacies, which prepare medications for individual patients based on a prescription, and 503B outsourcing facilities, which can produce larger batches of compounded drugs and are held to a higher standard of Current Good Manufacturing Practices (CGMP). This distinction is central to understanding the landscape of quality control.

While 503B facilities are subject to more rigorous FDA oversight, including batch testing for potency and sterility, the majority of patient-specific hormone therapies originate from 503A pharmacies, where such stringent requirements are not mandated. This regulatory bifurcation creates a significant gap in quality assurance across the market.

The chemical stability of the hormone within its compounded matrix is a critical and often overlooked procedural challenge. Hormones, particularly estrogens and testosterone, can degrade over time, especially when exposed to light, heat, or incompatible excipients.

A stability-indicating assay is a sophisticated analytical method used to determine the shelf life of a product by measuring the concentration of the active ingredient as well as any degradation products. Performing such studies is a complex and expensive undertaking, far beyond the capabilities of most 503A pharmacies.

As a result, the “beyond-use dates” assigned to compounded preparations are often based on general guidelines from the United States Pharmacopeia (USP) rather than on specific stability testing of that particular formulation. This means that a cream or injectable could lose potency over its intended shelf life, leading to a gradual decline in therapeutic efficacy for the patient.

What Are the Pharmacokinetic Variabilities in Compounded Hormones?

The pharmacokinetic profile of a compounded hormone ∞ how it is absorbed, distributed, metabolized, and excreted by the body ∞ is another area of significant procedural challenge. For transdermal preparations, the particle size of the hormone powder can dramatically influence its absorption through the skin.

Micronization, the process of reducing the average diameter of a solid material’s particles, is often used to improve the bioavailability of transdermal drugs. However, the degree of micronization can vary between API suppliers and even between different batches from the same supplier.

A compounding pharmacy may not have the analytical equipment to verify particle size, leading to inconsistent bioavailability from one prescription refill to the next. A patient could experience a surge in hormone levels from a batch made with finely micronized powder, followed by a drop with the next refill made from a coarser powder, all while the labeled potency of the cream remains the same.

This pharmacokinetic variability is particularly pronounced in multi-hormone preparations, which are popular in compounded bioidentical hormone therapy (cBHT). Combining multiple hormones like estradiol, estriol, and progesterone into a single cream introduces complex formulation challenges. The different hormones may have different solubility profiles in the chosen base, potentially leading to an uneven distribution within the product.

Furthermore, the presence of multiple active ingredients can create a competitive environment for absorption through the skin, potentially altering the intended therapeutic ratio of the hormones delivered to the bloodstream. The lack of clinical studies on the pharmacokinetics of these specific multi-hormone combinations means that their therapeutic effects can be unpredictable. This procedural complexity underscores the recommendation from many clinical bodies to use single-hormone preparations whenever possible to allow for more precise titration and monitoring.

The absence of standardized, end-product analytical testing in many compounding settings remains the most critical gap in quality assurance.

The Analytical Chemistry of Quality Control

At the highest level of scientific scrutiny, the analytical methods themselves present a procedural challenge. High-Performance Liquid Chromatography (HPLC) is the industry standard for potency testing, but its accuracy depends on a validated methodology specific to the drug and its matrix.

Developing and validating an HPLC method for a complex, multi-hormone cream is a non-trivial task that requires significant expertise in analytical chemistry. A pharmacy that sends a sample to a third-party lab for testing must ensure that the lab is using a validated, stability-indicating method for that specific formulation. Without this, the test results may not be reliable. This is a level of due diligence that is difficult for both patients and prescribers to verify.

The following table details some of the advanced procedural challenges and their implications for clinical practice.

| Advanced Challenge | Scientific Principle | Clinical Implication |

|---|---|---|

| Chemical Stability | Hormone degradation over time due to environmental factors or excipient incompatibility. | Decreased potency over the shelf life of the product, leading to reduced therapeutic effect. |

| Particle Size Variability | Micronization of API powders affecting the rate and extent of transdermal absorption. | Inconsistent bioavailability and fluctuating hormone levels from batch to batch. |

| Multi-Hormone Interactions | Competitive absorption and different solubility profiles of multiple hormones in a single preparation. | Unpredictable pharmacokinetic profiles and altered therapeutic ratios of absorbed hormones. |

| Analytical Method Validation | Ensuring that the testing method (e.g. HPLC) is accurate and specific for the compounded formulation. | Risk of relying on inaccurate potency data, leading to improper clinical adjustments. |

- Potency Testing ∞ This is the measurement of the actual amount of active pharmaceutical ingredient (API) in a compounded preparation. The primary challenge is the cost and complexity of performing High-Performance Liquid Chromatography (HPLC) on every batch, leading to reliance on procedural accuracy instead of end-product verification.

- Purity and Contamination ∞ This refers to the absence of unwanted substances, including microbial contaminants in sterile products and cross-contaminants from other drugs. Maintaining a sterile environment for injectables and preventing cross-contamination in non-sterile preparations are continuous procedural hurdles.

- Stability and Beyond-Use Dating ∞ This involves determining the time frame during which a compounded preparation maintains its potency and purity. The challenge is the lack of formulation-specific stability studies, leading to reliance on generalized guidelines which may not accurately reflect the true shelf life of a specific product.

References

- Gleason, C. E. et al. “The standardization of nonsterile compounding ∞ a study in quality control and assessment for hormone compounding.” International Journal of Pharmaceutical Compounding, vol. 19, no. 5, 2015, pp. 426-30.

- National Academies of Sciences, Engineering, and Medicine. “The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of Safety, Effectiveness, and Use.” The National Academies Press, 2020.

- Stanczyk, F. Z. et al. “A review of the safety and efficacy of compounded bioidentical hormone therapy for menopause.” Journal of the Endocrine Society, vol. 5, no. 5, 2021, bvaa203.

- Pluchino, N. et al. “Transdermal bioidentical hormone therapy in postmenopausal women ∞ a review of the literature.” Journal of Endocrinological Investigation, vol. 44, no. 6, 2021, pp. 1135-1145.

- Turton, P. and J. A. Woods. “Quality control of compounded medicines in Australia and New Zealand.” Journal of Pharmacy Practice and Research, vol. 48, no. 6, 2018, pp. 535-541.

Reflection

The exploration of compounded hormones reveals a landscape of immense therapeutic potential intertwined with significant procedural complexities. Your personal health journey is a dynamic process of recalibration, and the information you have gathered is a powerful tool for navigating this path.

Understanding the procedural challenges in quality control is the first step toward becoming an active, informed participant in your own wellness protocol. This knowledge equips you to engage in a more meaningful dialogue with your healthcare provider, to ask discerning questions about the source and quality of your therapies, and to advocate for the highest standards of care.

The ultimate goal is a partnership where personalized medicine is delivered with the precision and consistency your body deserves, allowing you to move forward with confidence on your path to restored vitality.