Fundamentals

The journey toward hormonal balance often leads to personalized solutions, among which low-dose hormonal creams represent a subtle yet powerful tool. Your experience with symptoms like fatigue, mood shifts, or changes in metabolic function is a direct reflection of your body’s intricate internal communication system.

When we introduce a therapeutic agent like a hormonal cream, the expectation is one of precise, gentle recalibration. The physical reality of that cream ∞ its texture, its consistency, the very molecules within it ∞ becomes the conduit for that change. It is here, at the intersection of your biology and the pharmacy’s science, that the first and most personal challenge arises.

The quality of that cream is paramount, as its formulation directly influences the stability and delivery of its active ingredient, shaping your therapeutic outcome.

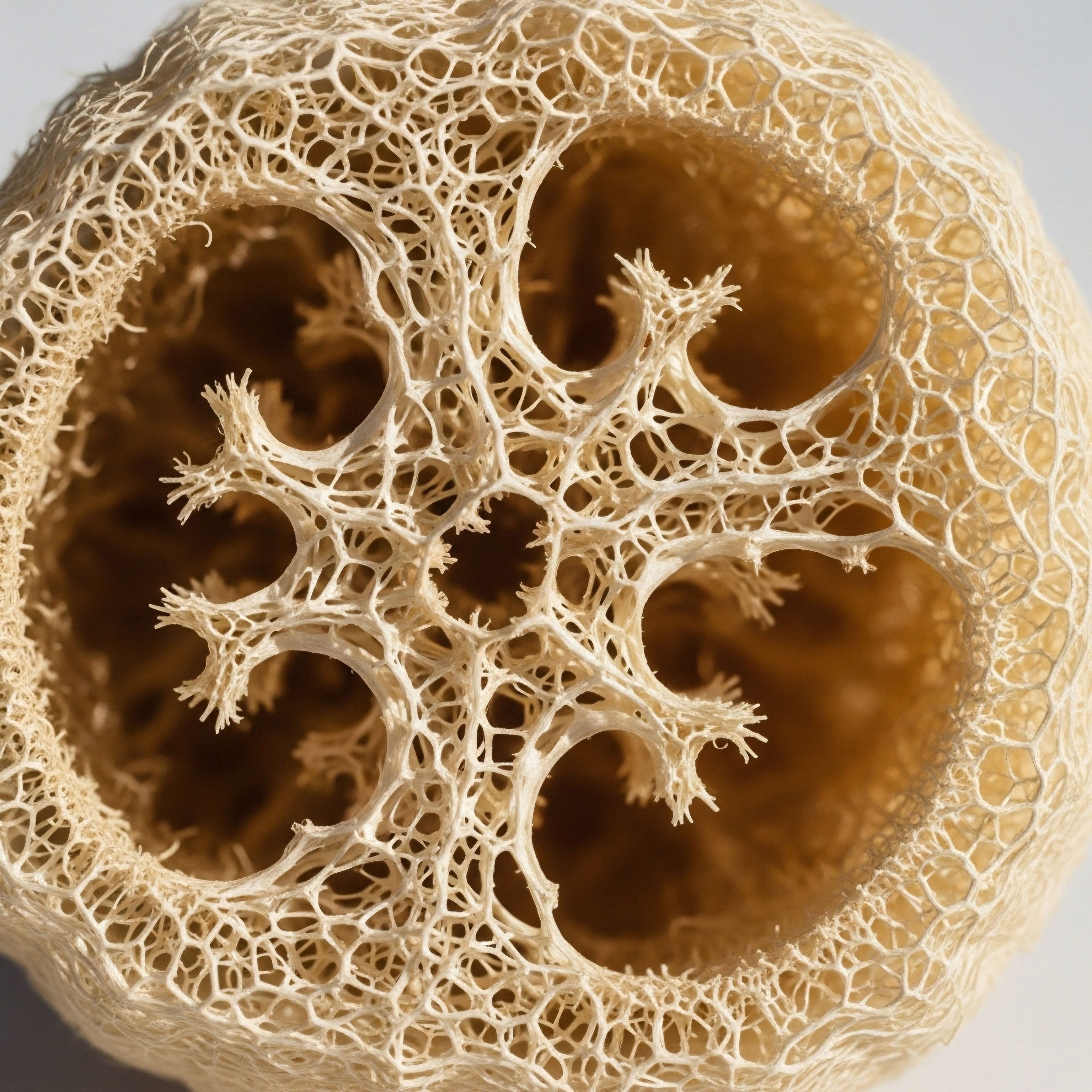

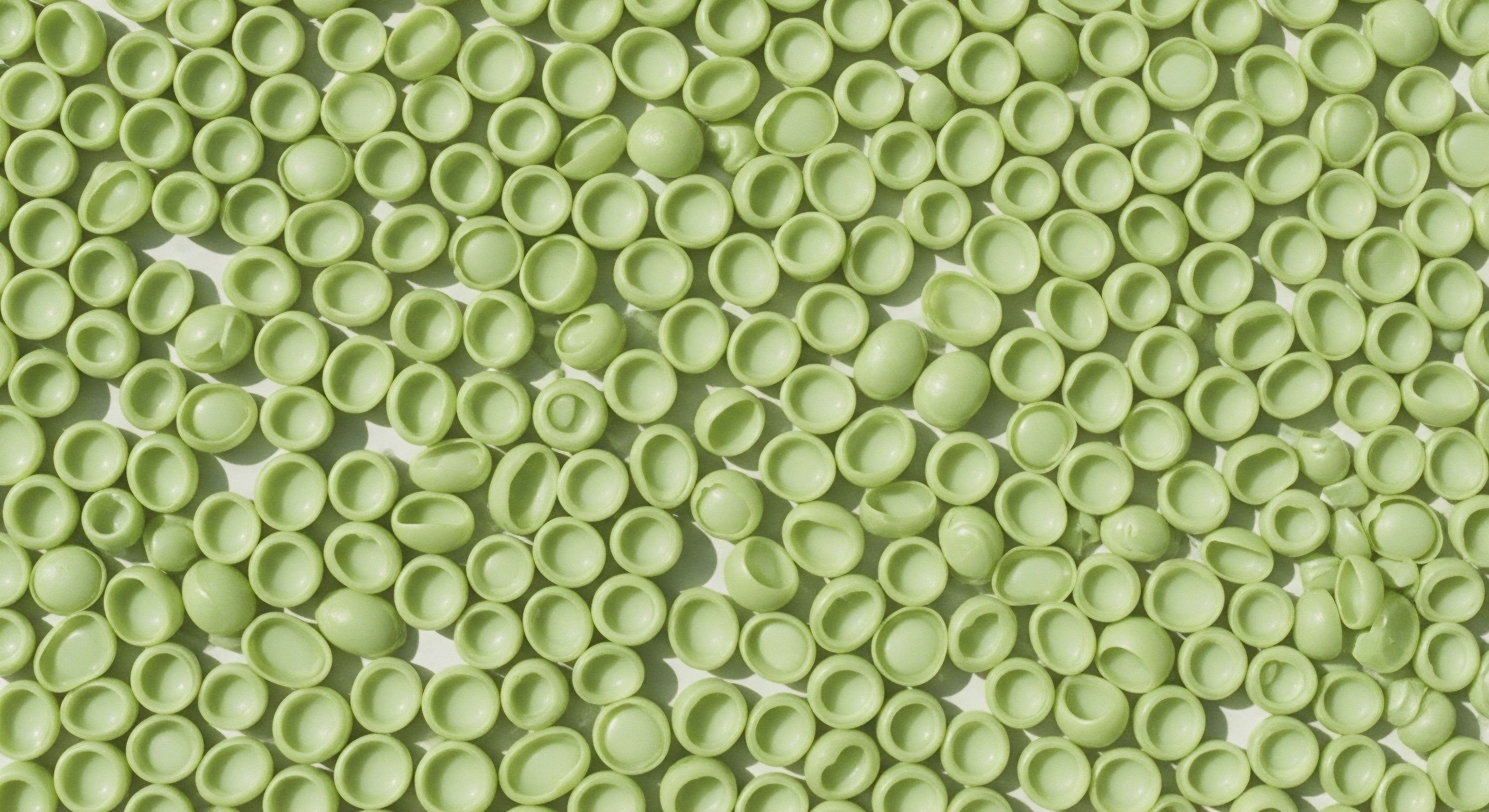

Imagine the active hormone as a single drop of potent ink in a large vessel of water. The objective is to ensure that every single milliliter of that water contains the exact same concentration of ink. In the context of a cream, the active pharmaceutical ingredient (API) must be perfectly and evenly distributed throughout the base.

This concept, known as homogeneity, is a cornerstone of pharmaceutical quality. For low-dose preparations, achieving this uniformity is a significant operational hurdle. Any inconsistency means that one application might deliver a slightly different amount of the hormone than the next. This variability can translate into fluctuating responses within your own body, creating a sense of unpredictability when the entire goal is to restore a steady, reliable state of well-being.

A consistent hormonal cream formulation is the foundation of a predictable and effective therapeutic response.

The base of the cream itself, composed of various excipients, is far from inert. These ingredients are selected to create a specific texture and, most importantly, to facilitate the absorption of the hormone through the skin. The operational challenge lies in selecting a base that is both stable and compatible with the specific hormone it carries.

The chemical properties of the base can influence the hormone’s molecular structure over time, potentially reducing its potency. The journey of the hormone from the cream to your bloodstream is a complex event, and the vehicle for that journey must be engineered with precision. Every element of the cream’s design and production is a deliberate choice aimed at protecting the integrity of its precious cargo, ensuring that what is prescribed is what is ultimately delivered to your system.

What Is the Primary Hurdle in Formulation?

The primary hurdle in formulating low-dose hormonal creams is achieving and maintaining the uniform dispersion of a very small amount of active ingredient within a complex semi-solid medium. The chemical and physical properties of the cream base must be perfectly matched to the hormone to prevent degradation and ensure consistent delivery with each application.

This requires a deep understanding of the molecular interactions between the hormone and the various components of the cream. The process is a delicate balance of science and artistry, where even minor variations in temperature or mixing technique can have a substantial impact on the final product’s quality and efficacy.

Furthermore, the manufacturing process itself introduces another layer of complexity. The equipment used, the order in which ingredients are added, and the environmental conditions of the laboratory all play a role in the final product’s quality. For instance, the mixing speed and duration must be carefully controlled.

Insufficient mixing can lead to a non-uniform product, while excessive shear force can alter the physical structure of the cream or even degrade the sensitive hormone molecules. Each step, from sourcing raw materials to the final packaging, is a critical control point that must be managed to ensure the consistency and stability of the cream over its entire shelf life. This meticulous attention to detail is what separates a high-quality therapeutic preparation from a product with unpredictable performance.

Intermediate

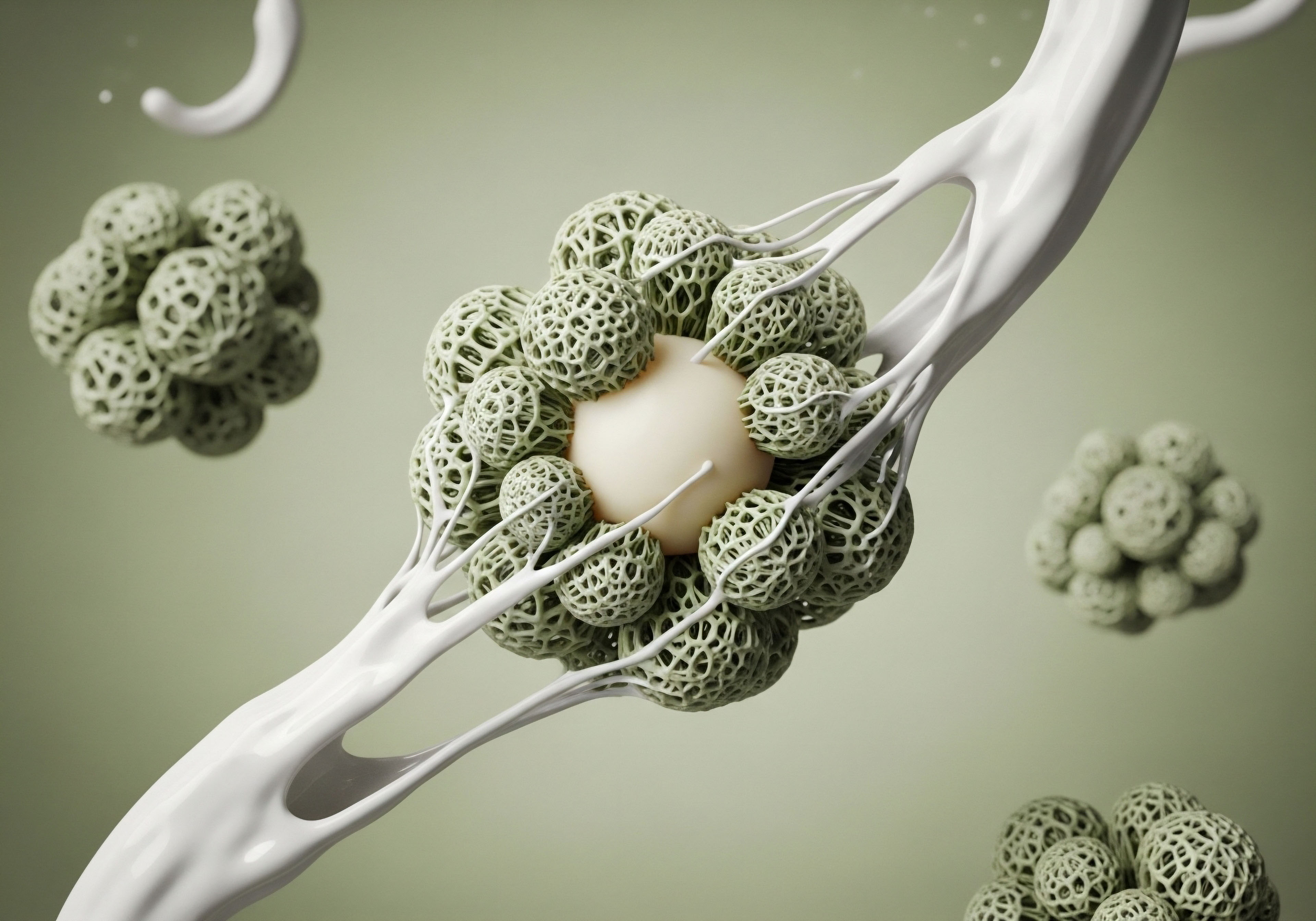

In the realm of pharmaceutical manufacturing, creating a low-dose hormonal cream is a study in precision. The operational challenges extend far beyond simple mixing and packaging; they involve a sophisticated understanding of thermodynamics, fluid dynamics, and materials science. The very act of creating a stable emulsion ∞ the basis of most creams ∞ is a process of controlling thermodynamically unstable systems.

The goal is to create a homogenous product where the tiny droplets of the oil phase are evenly suspended within the water phase, and the active hormone is uniformly dissolved or suspended within this intricate matrix. This requires precise control over manufacturing parameters, as even slight deviations can lead to a product that is ineffective or, worse, delivers an inconsistent dose.

One of the most significant operational challenges is managing the particle size of the active pharmaceutical ingredient (API). For a hormone to be effectively absorbed through the skin, its particle size must be optimized. In many formulations, the hormone is present as a suspension of microscopic crystals within the cream base.

The size and distribution of these crystals directly influence the rate of dissolution and subsequent absorption. An operationally robust process must ensure that the crystal size is uniform throughout the batch and remains stable over time. This involves carefully controlled crystallization processes and milling techniques. Any failure in this area can lead to a product where the bioavailability of the hormone changes as the product ages, leading to inconsistent therapeutic effects for the patient.

The manufacturing process for a topical cream directly dictates the stability and performance of the final product.

The table below outlines some of the critical process parameters that must be meticulously controlled during the manufacturing of low-dose hormonal creams to ensure quality and consistency.

| Parameter | Operational Challenge | Impact on Quality |

|---|---|---|

| Temperature Control |

Maintaining precise temperatures during heating and cooling phases. Overheating can degrade the API, while improper cooling can cause precipitation or unwanted changes in viscosity. |

Affects API stability, product consistency, and viscosity. |

| Mixing Speed and Shear |

Applying the optimal amount of shear to create a stable emulsion without damaging the API or the cream’s structure. High shear is needed for emulsification, but low shear may be required for gels. |

Determines droplet size, homogeneity, and physical stability of the cream. |

| Order of Ingredient Addition |

Adding components in a specific sequence to ensure proper dispersion and hydration of polymers and to protect sensitive ingredients like preservatives and the API. |

Crucial for preventing the formation of clumps or “fish eyes” and for overall product stability. |

| Scale-Up and Technology Transfer |

Reproducing the exact same product characteristics when moving from a small laboratory batch to a large commercial production run. Equipment differences can significantly alter the final product. |

Ensuring batch-to-batch consistency and maintaining product quality at a commercial scale. |

How Does Quality by Design Address These Challenges?

The modern pharmaceutical approach to these challenges is rooted in the concept of Quality by Design (QbD). QbD is a systematic, science-based methodology that begins with predefined objectives and emphasizes product and process understanding and process control.

It involves identifying the critical quality attributes (CQAs) of the product ∞ the physical, chemical, and biological characteristics that must be within an appropriate limit to ensure the desired product quality. For a low-dose hormonal cream, CQAs would include potency, content uniformity, particle size, viscosity, and microbial limits.

Once the CQAs are defined, the next step is to identify the critical process parameters (CPPs) that affect them. As detailed in the table above, these are the manufacturing variables that must be tightly controlled.

The QbD framework uses risk assessment and experimental design to establish a “design space” ∞ a multidimensional combination and interaction of input variables and process parameters that has been demonstrated to provide assurance of quality.

Operating within this design space is not just a matter of following a recipe; it is a dynamic process of control and verification that ensures the final product meets all its quality targets. This approach is fundamental to creating reliable and effective low-dose hormonal creams, transforming the manufacturing process from an art into a reproducible science.

Academic

The assurance of quality in low-dose hormonal creams presents a formidable analytical and manufacturing challenge, centered on the principle of content uniformity. At therapeutic concentrations often measured in fractions of a percent, the analytical validation required to confirm the homogeneity of the active pharmaceutical ingredient (API) within a semi-solid matrix is exceptionally complex.

The very nature of a cream, being an opaque, viscous emulsion, complicates sampling and analysis, making it difficult to ascertain with statistical confidence that the API is evenly distributed throughout the entire batch. This issue is magnified in compounded preparations, which may lack the rigorous validation and process controls inherent in large-scale commercial manufacturing.

From a pharmaceutical science perspective, the challenge is twofold. First, the physical chemistry of the formulation must be optimized to ensure the API remains uniformly dispersed and does not agglomerate, crystallize, or degrade over time.

This involves a deep understanding of the phase behavior of the emulsion, the solubility of the API in the chosen vehicle, and the potential for interactions between the API and the various excipients. Second, robust analytical methods must be developed and validated to accurately quantify the API in small samples taken from multiple locations within a batch.

These methods must be sensitive enough to detect minute variations in concentration and specific enough to distinguish the API from any potential degradation products or interfering substances from the cream base.

What Analytical Techniques Can Verify Homogeneity?

Verifying the homogeneity of low-dose hormonal creams requires a suite of advanced analytical techniques. High-Performance Liquid Chromatography (HPLC) is the gold standard for potency and content uniformity testing, but its application to semi-solid dosage forms is challenging.

The extraction of the API from the cream matrix must be complete and reproducible, a non-trivial task given the complex and often proprietary nature of cream bases. The development of an effective extraction method is a critical step that must be rigorously validated to ensure it does not introduce variability into the results.

Beyond traditional HPLC, other techniques are being explored to provide a more comprehensive picture of product quality. Raman spectroscopy and Near-Infrared (NIR) spectroscopy are powerful process analytical technology (PAT) tools that can be used for non-destructive, real-time monitoring of content uniformity during the manufacturing process.

These spectroscopic methods can provide a spatial map of the API distribution within the cream, offering a much more detailed assessment of homogeneity than can be achieved by testing a few discrete samples. The implementation of these advanced analytical technologies is a key component of a modern, QbD-based approach to manufacturing high-quality topical products.

The following list details some of the key analytical considerations for ensuring the quality of low-dose hormonal creams:

- Method Specificity ∞ The analytical method must be able to unequivocally assess the analyte in the presence of components that may be expected to be present, including impurities, degradants, and matrix components.

- Accuracy and Precision ∞ The method must be demonstrated to be accurate (close to the true value) and precise (reproducible) over the specified range of concentrations. This is particularly challenging at very low dose levels.

- Linearity and Range ∞ The analytical procedure must be able to obtain test results that are directly proportional to the concentration of the analyte in samples within a given range.

- Robustness ∞ The method’s capacity to remain unaffected by small, but deliberate variations in method parameters provides an indication of its reliability during normal usage.

The table below summarizes the challenges and solutions related to the bioequivalence of topical dermatological products, a concept closely related to quality and efficacy.

| Challenge | Description | Potential Solution |

|---|---|---|

| In Vivo Assessment |

Traditional pharmacokinetic studies involving blood draws are often not sensitive enough for locally acting topical drugs with low systemic absorption. |

Methods like skin stripping to measure drug concentration in the stratum corneum, or pharmacodynamic endpoints like skin blanching for corticosteroids. |

| In Vitro-In Vivo Correlation (IVIVC) |

Establishing a predictive relationship between in vitro drug release from the formulation and its in vivo performance is notoriously difficult for semi-solids. |

Development of sophisticated in vitro release testing (IVRT) models that can mimic the skin barrier and correlate with in vivo data. |

| Product “Sameness” |

Demonstrating that a generic or compounded product is equivalent to a reference product in terms of its physicochemical characteristics and clinical effect. |

A “whole toolkit” approach combining advanced analytical characterization (Q3), IVRT, and potentially limited clinical studies. |

References

- National Academies of Sciences, Engineering, and Medicine. “The Safety and Effectiveness of Compounded Topical Pain Creams.” The National Academies Press, 2020.

- Thomas, J. “Challenges in Topical Drug Manufacturing.” Pharmaceutical Technology, vol. 36, no. 9, 2012.

- Thomas, J. “Challenges in Topical Drug Manufacturing.” Pharmaceutical Technology, vol. 36, no. 10, 2012.

- Asbill, S. “Topical products ∞ Aiming for quality, simplicity, and cost-efficiency in their development, scale-up, and manufacturing.” Pharmaceutical Technology, vol. 47, no. 1, 2023.

- Shah, V. P. et al. “Challenges in Evaluating Bioequivalence of Topical Dermatological Drug Products.” Pharmaceutical Research, vol. 12, 1995, pp. 1547-1553.

Reflection

Your body is a finely tuned instrument, and the path to hormonal wellness is one of subtle adjustments and careful listening. The information presented here illuminates the profound technical complexities involved in creating a seemingly simple low-dose hormonal cream. This knowledge serves a distinct purpose.

It transforms you from a passive recipient of care into an informed partner in your own health journey. Understanding the meticulous science required to produce a high-quality therapeutic agent allows you to ask more precise questions and appreciate the deep connection between the product in your hand and the biological response you seek.

The ultimate goal is a state of vitality, and that begins with a foundation of trust ∞ trust in the process, trust in the product, and most importantly, trust in your own capacity to navigate the path toward optimal function.

Glossary

low-dose hormonal creams

active pharmaceutical ingredient

homogeneity

low-dose hormonal cream

critical process parameters

quality by design

content uniformity

high-performance liquid chromatography

semi-solid dosage forms

process analytical technology

bioequivalence