Fundamentals

Your journey toward hormonal optimization begins with a conversation, a set of lab results, and a prescription. That prescription, perhaps for testosterone cypionate or a specific peptide protocol, represents a pivotal step in reclaiming your body’s functional harmony. You hold a plan designed to recalibrate your internal systems.

The next step involves turning that plan into a physical therapeutic agent. This is where the world of pharmaceutical compounding enters your life. It is the process of creating a medication tailored specifically for you. When you receive a prescription for a therapy like Testosterone Replacement Therapy (TRT) or a growth hormone peptide, the medication is often prepared by a compounding pharmacy.

Understanding the origin of your therapy is a foundational element of your wellness protocol. The United States Food and Drug Administration (FDA) defines two distinct categories of these pharmacies, designated as 503A and 503B. These designations signify profoundly different operational scopes, regulatory frameworks, and production scales. Acknowledging these differences equips you with the knowledge to understand the specific therapeutic agent you are introducing into your biological system.

A 503A facility functions as a traditional compounding pharmacy. It operates on a small, individualized scale. Think of it as a master craftsman creating a single, bespoke item for a specific individual. These pharmacies prepare medications based on a valid prescription for a particular patient.

The regulatory oversight for a 503A pharmacy is primarily managed at the state level by the respective state’s Board of Pharmacy. They follow specific standards for quality and safety, detailed in the United States Pharmacopeia (USP), particularly chapters concerning non-sterile and sterile compounding.

This pathway is designed for unique patient needs, such as requiring a medication without a specific dye or preservative due to an allergy, or needing a dosage strength that is not commercially produced. The core of the 503A model is the direct relationship between the patient, the prescriber, and the pharmacist. The medication is created for you and you alone.

A 503A pharmacy compounds patient-specific prescriptions under state-level regulation, while a 503B facility manufactures larger batches under federal FDA oversight.

The 503B designation represents a different model of pharmaceutical preparation. These facilities are known as outsourcing facilities. They were formally established by Congress through the Drug Quality and Security Act of 2013, largely in response to public health events that highlighted a need for a higher level of regulatory scrutiny for large-scale compounders.

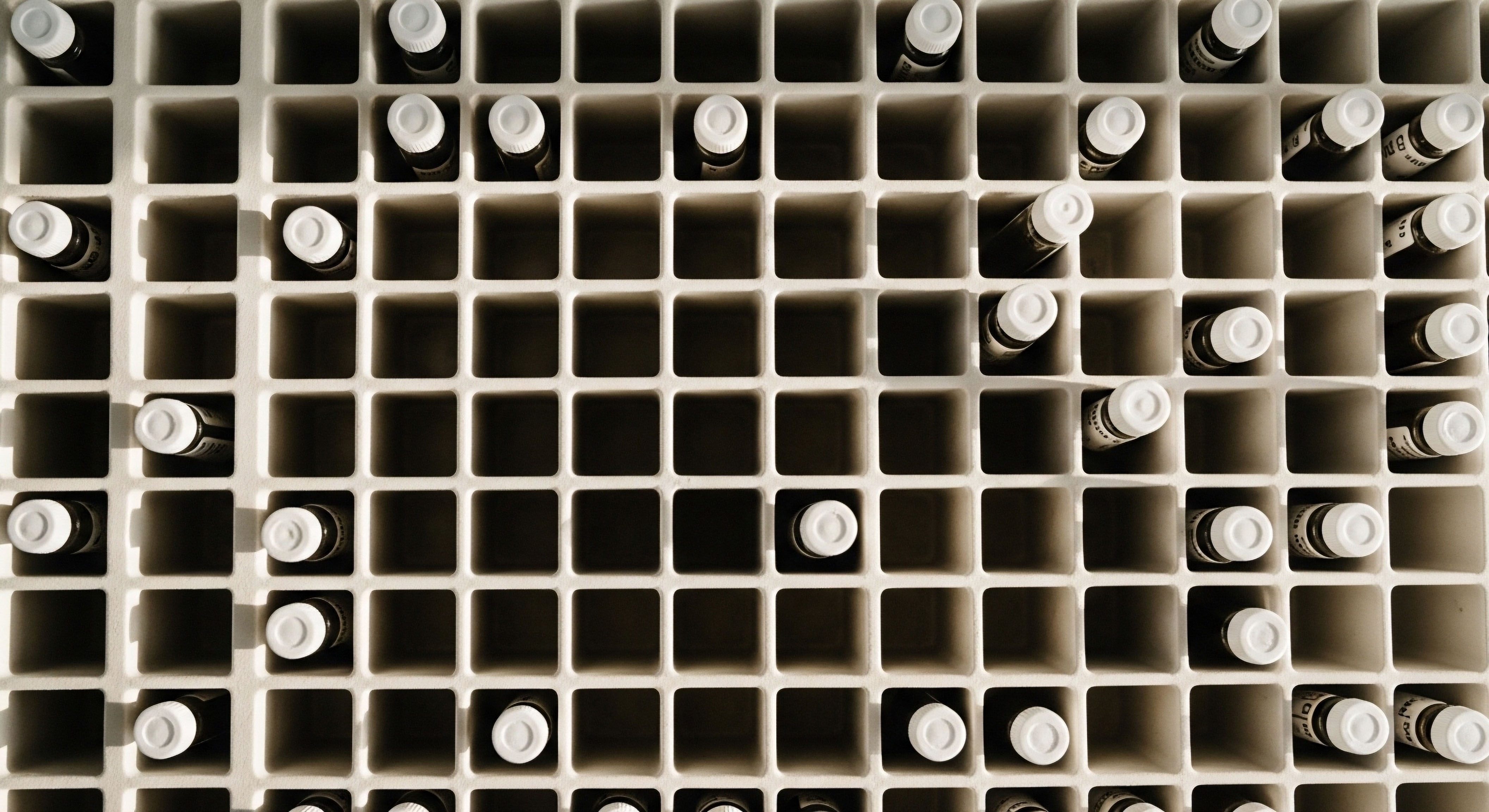

A 503B outsourcing facility can manufacture large batches of compounded drugs, which can be produced with or without patient-specific prescriptions. These batches are then sold to healthcare facilities, such as hospitals and clinics, for office use. This large-scale production capability means they operate much more like a pharmaceutical manufacturer.

Consequently, 503B facilities are held to a more stringent set of federal regulations. They must register with the FDA and adhere to Current Good Manufacturing Practices (cGMP), the same set of rigorous standards that conventional drug manufacturers must follow. This framework ensures a high degree of consistency, sterility, and quality control across entire batches of medication.

Understanding Your Hormonal Therapy Source

When you begin a protocol like weekly intramuscular injections of Testosterone Cypionate, the medication you use is a sterile preparation. Its purity and sterility are paramount to your safety and the effectiveness of the treatment. A 503A pharmacy can prepare this sterile medication for you, following the guidelines of USP Chapter <797> for sterile compounding.

A 503B facility can also produce this medication, but it does so in a large batch, with every step of the process validated and tested under the comprehensive cGMP framework. The choice between these sources has direct implications for the therapeutic agent you receive.

For therapies that form the bedrock of your long-term wellness strategy, understanding the production environment is a critical component of informed self-advocacy. The goal is a predictable, reliable, and safe therapeutic outcome, and that outcome begins with the quality of the medication itself.

Intermediate

Advancing your understanding of hormonal health requires moving from the what to the why. You comprehend that 503A and 503B facilities represent distinct pathways for creating your therapies. Now, we examine the specific regulatory and procedural architectures that define them.

These frameworks are the very systems designed to ensure the safety, stability, and potency of the medications you rely on to modulate your endocrine system. The distinctions are rooted in their operational purpose ∞ one serves the individual patient directly, while the other serves institutions that care for many patients.

This divergence in purpose necessitates different levels of oversight and quality assurance protocols. For any individual on a long-term hormonal optimization plan, from low-dose testosterone for women to complex peptide regimens for metabolic health, these details are directly relevant to the consistency and reliability of their treatment.

The regulatory environment for 503A pharmacies is built upon state-level oversight and adherence to the United States Pharmacopeia. The USP is a non-governmental organization that sets public standards for medicines. For compounding, two chapters are of primary importance. USP Chapter <795> governs non-sterile compounding, such as the preparation of oral capsules or topical creams.

USP Chapter <797> provides the standards for sterile compounding, which is critical for injectable medications like Testosterone Cypionate, Gonadorelin, or peptide therapies such as Ipamorelin. These standards dictate requirements for personnel training, cleanroom environments, and procedures to prevent microbial contamination. State Boards of Pharmacy are responsible for enforcing these standards.

A key operational aspect of 503A pharmacies is that they assign a Beyond-Use Date (BUD) to their preparations, which is determined based on scientific literature or internal data, indicating the timeframe within which the medication should be used. This system is designed to provide safe, customized medications for individual patients.

What Does cGMP Mean for Your Therapy?

The operational standard for 503B outsourcing facilities is Current Good Manufacturing Practices (cGMP). This term signifies a comprehensive and rigorous quality control system enforced by the FDA. The cGMP framework covers every aspect of production, from the moment raw ingredients arrive at the facility to the final labeling and distribution of the finished product.

It is a system designed for manufacturers producing drugs at scale, where process validation is essential to ensure that every single vial in a batch of thousands is identical in potency, purity, and sterility. For a patient, this means the Testosterone or Sermorelin you inject in week one is identical to the one you inject in week ten.

This level of quality assurance involves several key activities that are mandatory for 503B facilities but not for 503A pharmacies. Process validation, for instance, requires a facility to prove through repeated testing that its manufacturing process consistently produces a product meeting predetermined specifications.

Stability testing is another cornerstone of cGMP, where the facility must conduct rigorous tests to determine the chemical stability of their products over time, allowing them to assign a scientifically validated expiration date rather than a BUD based on general guidelines. Environmental monitoring in a 503B facility is continuous and far more extensive, ensuring the manufacturing environment remains free of contaminants. Every batch of a finished product is tested for sterility and potency before it can be released for distribution.

The cGMP standards required for 503B facilities provide a manufacturing-level quality assurance system for compounded medications.

This distinction becomes particularly meaningful when considering the nature of hormonal optimization. The goal of a protocol like TRT is to restore and maintain testosterone levels within a precise, optimal physiological range. This requires a consistent and predictable dose of the active hormone. The cGMP framework of a 503B facility is engineered to deliver that predictability.

While 503A pharmacies provide a vital service for creating unique formulations, the industrial scale and regulatory rigor of 503B facilities offer a different kind of assurance, one centered on batch-wide uniformity and extensive quality verification.

The following table provides a direct comparison of the operational and regulatory distinctions.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Purpose | Prepares customized medications for specific patients based on individual prescriptions. | Manufactures large batches of compounded drugs for healthcare facilities (hospitals, clinics) for office use. |

| Regulatory Oversight | Primarily regulated by State Boards of Pharmacy. | Registered with and regulated by the FDA at the federal level. |

| Core Quality Standard | Adherence to USP Chapters (e.g. <795>, <797>). | Adherence to FDA’s Current Good Manufacturing Practices (cGMP). |

| Prescription Requirement | Requires a valid, patient-specific prescription for compounding. | Can compound without a patient-specific prescription for office stock. |

| Production Scale | Limited to small-batch or single-prescription compounding. | Permitted to produce large, industrial-scale batches. |

| Product Testing | Product testing is not required for every batch. Quality is assured by following established procedures. | Every finished batch must be tested for sterility, potency, and purity before release. |

| Expiration Dating | Assigns a Beyond-Use Date (BUD) based on USP guidelines or available stability data. | Assigns a scientifically validated expiration date based on rigorous, product-specific stability testing. |

Academic

A sophisticated approach to personalized wellness requires an appreciation for the subtle variables that can influence biological outcomes. The distinction between 503A and 503B compounding facilities provides a compelling case study in how manufacturing and regulatory frameworks translate directly into physiological effects.

The central objective of hormonal optimization protocols, whether for managing andropause in men or perimenopausal transitions in women, is to achieve a state of biochemical equilibrium. This delicate balance depends on the precise and consistent delivery of exogenous hormones. Therefore, the pharmacokinetic and pharmacodynamic properties of the therapeutic agent are of supreme importance.

The regulatory differences between 503A and 503B facilities create two distinct universes of product consistency, which can have profound implications for clinical efficacy, safety, and the predictability of a patient’s response to treatment.

The genesis of the modern regulatory landscape was the Drug Quality and Security Act (DQSA) of 2013. This legislation was a direct congressional response to a significant public health crisis involving contaminated sterile injections from a compounding pharmacy that resulted in a nationwide fungal meningitis outbreak.

The event exposed critical gaps in the oversight of compounders that were operating at a scale far beyond that of a traditional local pharmacy. The DQSA addressed this by creating the 503B designation, establishing a clear legal pathway for large-scale compounders to register as “outsourcing facilities” and subjecting them to the FDA’s cGMP requirements.

This legislative action reflects a core principle of public health ∞ as the scale of production increases, the stringency of quality control systems must increase proportionally to mitigate risk.

How Does Compounding Source Affect Bioavailability?

The most critical variable in hormone therapy is bioavailability, the fraction of an administered dose of unchanged drug that reaches the systemic circulation. Inconsistent bioavailability leads to unpredictable serum concentrations, which can disrupt the sensitive feedback loops of the endocrine system, such as the Hypothalamic-Pituitary-Gonadal (HPG) axis.

Research into compounded preparations has highlighted significant potential for variability. For instance, studies on compounded bioidentical hormone creams have shown that they can yield significantly lower and more erratic serum estrogen levels compared to FDA-approved transdermal patches designed to deliver a similar dose.

This variability can arise from multiple factors inherent in the compounding process, such as the choice of base cream, the particle size of the hormone powder, and the mixing technique. In a 503A setting, where batch-to-batch testing for potency and uniformity is not mandated, these variables can introduce a high degree of uncertainty into the final product.

A patient may experience fluctuating symptoms not because their underlying physiology has changed, but because the potency of their medication differs from one refill to the next.

The stringent cGMP standards of 503B facilities are designed to minimize the pharmacokinetic variability that can compromise the precise calibration of hormonal systems.

This contrasts sharply with the cGMP paradigm governing 503B facilities. The cGMP framework is built to control for these exact variables. It mandates stringent qualification of raw material suppliers, validated and reproducible manufacturing processes, and, most importantly, finished product testing.

A 503B facility must analytically confirm the potency and purity of every batch of testosterone cypionate or progesterone it produces before it is released. This process provides a high degree of assurance that the concentration listed on the vial label is the precise concentration in the solution.

This assurance is fundamental to achieving therapeutic precision. It allows a clinician to make informed dose adjustments based on a patient’s lab results and subjective feedback, confident that the medication itself is a controlled, consistent variable.

What Are the Specifics of cGMP for Sterile Compounding?

For sterile injectable therapies, which include the majority of hormonal and peptide protocols, the cGMP requirements provide a multi-layered system of safety and quality assurance. This system is far more extensive than the baseline requirements of USP <797>.

- Facility Design and Environmental ControlcGMP requires a facility design that prevents contamination. This includes specific air handling systems (HVAC) to maintain pressure differentials between rooms, ensuring that air flows from cleaner areas to less clean areas. Environmental monitoring is a continuous process, with frequent testing of surfaces, air, and personnel to detect any microbial presence.

- Process ValidationA 503B facility must conduct rigorous studies to prove that its sterilization process (e.g. autoclaving or sterile filtration) is effective and that its aseptic filling procedures consistently produce a sterile product without any contamination. This validation is a proactive measure to build quality into the process itself.

- Component and Container ControlAll raw materials (active pharmaceutical ingredients) and primary packaging components (vials, stoppers) must be sourced from qualified suppliers and tested upon receipt to confirm their identity, purity, and quality. Records must trace every component to a specific batch of finished product.

- Finished Product Release TestingThis is a defining feature of 503B production. Every single batch of a sterile drug product must undergo testing for sterility (to confirm the absence of microorganisms) and potency (to confirm it contains the correct amount of active ingredient) before it can be distributed. This final check provides objective evidence of the product’s quality.

The following table details some of the specific quality assurance activities mandated under cGMP for 503B facilities, which are not required for 503A pharmacies.

| cGMP Requirement | Description and Implication for Hormonal Therapies |

|---|---|

| Formal Stability Program | Requires conducting product-specific studies to determine how a drug’s potency and purity are affected by time, temperature, and light. This provides the scientific basis for the product’s expiration date, ensuring it remains effective and safe for its entire shelf life. For a patient, this means the vial of Ipamorelin used a month after receipt is just as potent as it was on day one. |

| Process Performance Qualification (PPQ) | A series of validation studies (typically on three consecutive batches) that demonstrate the manufacturing process is reproducible and consistently delivers a product of the required quality. This ensures that batch number 100 is identical to batch number 1. |

| Supplier Qualification Program | A formal system for vetting and auditing suppliers of raw pharmaceutical ingredients. This ensures that the foundational materials of the medication are of high purity and quality, reducing the risk of contaminants that could affect patient safety or hormonal activity. |

| Formal Quality Unit | Mandates an independent quality assurance department that has the authority to approve or reject all raw materials, packaging, and finished product batches. This organizational structure creates an internal system of checks and balances focused solely on product quality. |

| Adverse Event Reporting | 503B facilities are required to report adverse events associated with their products to the FDA. This creates a post-market surveillance system that can identify potential safety issues with a particular formulation. |

In conclusion, the choice between a 503A and 503B source for compounded hormonal therapies is a choice between two distinct philosophies of quality assurance. The 503A pathway offers personalized, physician-directed preparations suitable for unique patient needs, operating under state-level oversight.

The 503B pathway offers medications produced at scale under a federal, manufacturing-grade quality system designed to ensure batch-wide consistency, stability, and sterility. For the individual engaged in a precise, data-driven recalibration of their endocrine system, understanding this distinction is a vital part of the therapeutic journey.

References

- U.S. Food and Drug Administration. (2021). 503A vs. 503B ∞ A Quick-Guide to Compounding Pharmacy Designations & Regulations.

- U.S. Food and Drug Administration. (2024). What is a Compounding Pharmacy? FDA-Regulated 503A Vs 503B Pharmacy.

- TechTarget. (2024). Understanding the differences between 503A, 503B compounding pharmacies.

- Carie Boyd Pharmaceuticals. (2024). 503A VS. 503B – What is the Difference?.

- U.S. Food and Drug Administration. (2021). Current Good Manufacturing Practice ∞ Guidance for Human Drug Compounding Outsourcing Facilities Under Section 503B of the FD&C Act Guidance for Industry.

- U.S. Food and Drug Administration. (2024). Compounding and the FDA ∞ Questions and Answers.

- National Academies of Sciences, Engineering, and Medicine. (2020). The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of the Evidence.

- Jiang, X. et al. (2017). Bioidentical compounded hormones ∞ a pharmacokinetic evaluation in a randomized clinical trial. Postgraduate Medicine, 129(1), 68-76.

- U.S. Food and Drug Administration. (2018). Compounded Drug Products That Are Essentially Copies of a Commercially Available Drug Product Under Section 503A of the Federal Food, Drug, and Cosmetic Act.

- Applied Policy. (2024). Compounding Pharmacies.

Reflection

You have now examined the architectures that govern the creation of your personalized therapies. This knowledge of 503A and 503B facilities, of USP standards and cGMP, moves you beyond the role of a passive recipient of care into the role of an informed participant in your own biological narrative.

The data points on your lab reports and the daily sensations of your own vitality are interconnected. The source and quality of your therapeutic agents form the bridge between your clinical protocol and your lived experience. This understanding is the first principle of self-advocacy.

Your path forward is one of continued inquiry, thoughtful dialogue with your clinical team, and a commitment to aligning every choice with your ultimate goal ∞ a body and mind functioning in a state of calibrated, resilient wellness.

Glossary

testosterone cypionate

hormonal optimization

compounding pharmacy

food and drug administration

sterile compounding

outsourcing facilities

503b outsourcing facility

current good manufacturing practices

503b facilities

503b facility

cgmp

endocrine system

quality assurance

503a pharmacies

good manufacturing practices

503b outsourcing

process validation

scientifically validated expiration date

facility must conduct rigorous

dqsa