Fundamentals

When contemplating your personal journey toward hormonal equilibrium and metabolic resilience, the unseen forces shaping the availability and cost of therapeutic peptides often remain beyond immediate consideration. Yet, the stringent adherence to standards, such as those articulated within the Chinese Pharmacopoeia, fundamentally influences the landscape of personalized wellness protocols. These regulatory frameworks are not distant bureaucratic edicts; they are integral determinants of whether the precise biochemical tools necessary for reclaiming vitality are accessible and affordable for individuals seeking optimal function.

The Chinese Pharmacopoeia (ChP) stands as a comprehensive compendium, a statutory technical specification guiding drug development, production, and regulation within China. Its directives encompass the essential requirements for ensuring pharmaceutical safety, efficacy, and consistent quality. For peptides, these standards dictate everything from raw material purity to the final product’s analytical profile, establishing a baseline of quality that is non-negotiable for market entry and therapeutic application.

Stringent pharmacopoeia standards directly influence the accessibility and affordability of therapeutic peptides for individuals pursuing hormonal and metabolic optimization.

What Do Pharmacopoeia Standards Mean for Peptide Quality?

The essence of pharmacopoeial standards centers on assuring product integrity. For therapeutic peptides, which are complex biological molecules, this assurance becomes particularly vital. The ChP, especially in its 2020 edition, has significantly enhanced its general chapters, incorporating advanced analytical techniques and striving for harmonization with global benchmarks like ICH guidelines. This commitment to elevated quality control means that every peptide batch destined for human use undergoes rigorous scrutiny.

- Raw Material Purity ∞ Specifies the acceptable levels of impurities in starting materials, preventing contaminants from entering the production stream.

- Manufacturing Process Controls ∞ Outlines Good Manufacturing Practices (GMP) that dictate sterile environments, validated equipment, and documented procedures to prevent errors and contamination.

- Analytical Testing Protocols ∞ Mandates specific tests for identity, purity, potency, and the absence of harmful byproducts or elemental impurities, employing sophisticated methods such as mass spectrometry and chromatography.

Such detailed specifications, while crucial for patient safety, introduce inherent complexities and costs into the production cycle. Manufacturers must invest in state-of-the-art facilities, highly trained personnel, and advanced analytical instrumentation to meet these benchmarks. This foundational investment shapes the economic viability of peptide production, directly affecting the ultimate price point of these essential compounds.

Intermediate

Moving beyond the foundational understanding of pharmacopoeial intent, we encounter the tangible impact of these stringent requirements on the operational dynamics of peptide manufacturing. The “how” and “why” of adhering to the Chinese Pharmacopoeia’s demanding specifications translate into a cascade of economic considerations across the pharmaceutical supply chain. For those seeking to recalibrate their endocrine system with precision peptides, understanding these layers of cost illuminates the true value of quality assurance.

How Do Production Processes Adapt to Stringent Requirements?

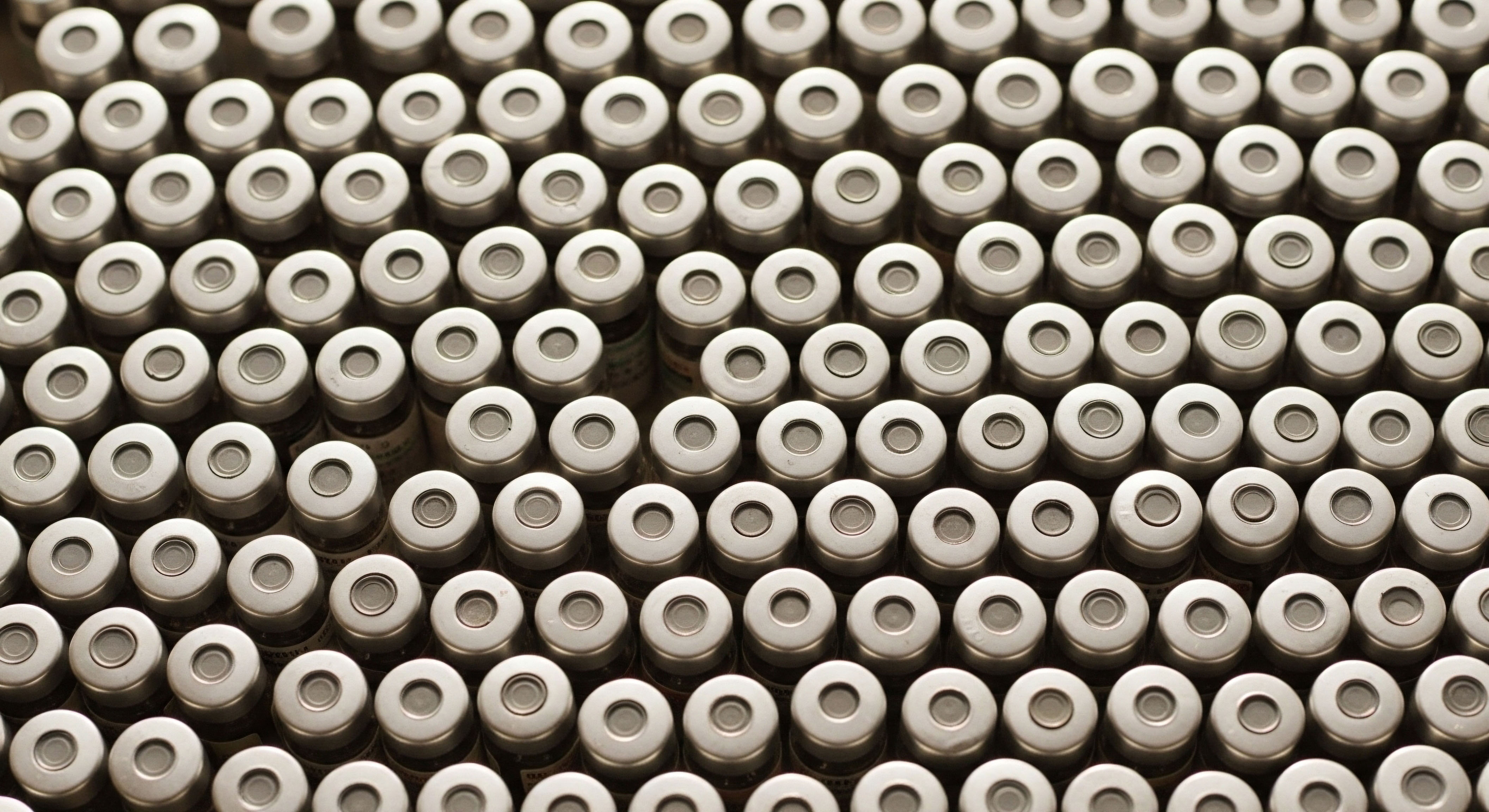

Manufacturers of therapeutic peptides, whether for testosterone replacement, growth hormone optimization, or targeted tissue repair, must fundamentally restructure their production paradigms to align with ChP mandates. This adaptation often begins with the initial synthesis, where meticulous control over reaction parameters, solvent purity, and intermediate product analysis becomes paramount. The subsequent purification steps, often involving multiple chromatography stages, demand advanced equipment and highly skilled operators to achieve the requisite purity levels.

Adherence to rigorous pharmacopoeia standards necessitates substantial investments in advanced manufacturing infrastructure, skilled labor, and sophisticated quality control measures.

Consider the example of a peptide like Sermorelin, utilized in growth hormone peptide therapy. Each step, from amino acid coupling to lyophilization, must conform to validated procedures, generating extensive documentation. This rigorous process is not merely about achieving a final product; it encompasses a continuous cycle of in-process testing, environmental monitoring, and final product release assays. The financial outlay for such an infrastructure, coupled with ongoing operational expenses, represents a significant portion of the overall cost of goods.

Supply Chain Implications and Cost Structures

The ripple effect of stringent standards extends deeply into the supply chain. Sourcing high-quality raw materials, often from certified vendors, incurs premium costs. Furthermore, the transportation and storage of temperature-sensitive peptides require specialized logistics, adding another layer of expense. The ChP’s emphasis on reducing elemental impurities and exogenous pollutants mandates enhanced vigilance at every stage, from supplier qualification to final packaging.

The economic implications can be systematically viewed through a framework of direct and indirect costs ∞

| Cost Category | Description | Impact on Peptide Therapies |

|---|---|---|

| Direct Manufacturing Costs | Investments in GMP-compliant facilities, advanced synthesis and purification equipment, and specialized analytical instruments. | Higher per-unit production cost, influencing patient pricing for compounds like Ipamorelin or PT-141. |

| Quality Control & Assurance | Extensive analytical testing, validation studies, ongoing monitoring, and robust documentation systems. | Increased overhead, ensuring therapeutic reliability for protocols such as Testosterone Cypionate injections. |

| Research & Development | Costs associated with developing and validating new analytical methods or improving existing processes to meet evolving standards. | Longer development cycles and higher initial investment for novel peptide therapeutics. |

| Regulatory Compliance | Personnel dedicated to interpreting and implementing pharmacopoeial updates, audits, and certifications. | Administrative burden and specialized expertise required to navigate complex regulatory landscapes. |

These cost drivers collectively elevate the barrier to entry for new manufacturers and compel existing ones to continuously invest in process improvements and quality systems. The ultimate aim is a product of unquestionable purity and potency, a foundational element for effective hormonal optimization protocols.

Academic

From an academic vantage, the economic implications of adhering to stringent Chinese Pharmacopoeia standards for peptide production transcend mere cost accounting, extending into complex market dynamics, strategic industry positioning, and ultimately, the global availability of critical endocrine modulators. This deep exploration requires a systems-biology perspective, understanding how regulatory stringency acts as a selective pressure on the biopharmaceutical ecosystem, shaping innovation and patient access.

Market Equilibrium and Supply Chain Resilience in Peptide Therapeutics

The ChP’s evolving requirements, particularly the drive towards international harmonization and the inclusion of more sophisticated analytical parameters for biological products, exert a significant influence on market equilibrium. When a major manufacturing hub like China elevates its quality benchmarks, it creates a bifurcated market.

Manufacturers capable of meeting these enhanced standards often incur higher production costs, which can translate into premium pricing for their peptide products. Conversely, entities unable or unwilling to invest in the necessary upgrades may face market exclusion or reduced competitiveness.

This phenomenon impacts the supply chain resilience for peptides integral to hormonal health, such as Gonadorelin for fertility stimulation or Tesamorelin for metabolic support. A reduction in the number of compliant manufacturers could, in the short term, constrict supply, leading to price volatility. However, in the long term, this consolidation can foster a more reliable global supply of high-quality peptides, mitigating risks associated with substandard products.

Stringent pharmacopoeia standards can reshape global market dynamics for peptides, potentially leading to higher initial costs but fostering long-term supply chain reliability and product quality.

Strategic Cost-Benefit Analysis for Biopharmaceutical Entities

Biopharmaceutical companies operate within a dynamic environment, constantly performing intricate cost-benefit analyses regarding regulatory compliance. Adhering to the ChP’s stringent peptide standards involves substantial upfront capital expenditure for infrastructure and technology, alongside ongoing operational costs for advanced quality control and regulatory affairs. A strategic framework for evaluating these investments considers several key variables ∞

- Market Access Expansion ∞ Compliance with globally harmonized standards, including those of the ChP, often facilitates broader market entry, particularly into high-value regulated markets. This expansion can offset increased production costs through economies of scale and enhanced market share.

- Reputational Capital ∞ Consistent production of high-quality, pharmacopoeia-compliant peptides builds significant reputational capital, a non-tangible asset that attracts partnerships and patient trust, especially critical for sensitive therapies like TRT or peptide-based anti-aging protocols.

- Risk Mitigation ∞ Robust quality systems, driven by pharmacopoeial requirements, substantially reduce the risk of product recalls, legal liabilities, and adverse patient outcomes, which carry immense financial and ethical costs.

The decision to invest in elevated compliance, therefore, becomes a strategic imperative for long-term sustainability and competitiveness. It reflects an understanding that initial economic outlays translate into sustained market presence and enhanced patient safety.

Interconnectedness with Global Health Initiatives

The economic implications extend beyond individual corporate balance sheets to influence global health initiatives. As the ChP aligns more closely with international guidelines, it contributes to a more unified global standard for pharmaceutical quality. This harmonization streamlines international trade, reduces the need for redundant testing, and lowers barriers for high-quality Chinese-produced peptides to reach global markets. This efficiency gain, over time, can contribute to greater availability and potentially more stable pricing for critical peptide therapies worldwide.

| Economic Factor | Short-Term Impact | Long-Term Impact on Health & Market |

|---|---|---|

| Production Costs | Increased due to capital investment and rigorous QC. | Stabilized supply of high-quality peptides, potential for economies of scale with broader market access. |

| Market Competition | Potential consolidation among compliant manufacturers. | Elevated overall quality benchmark, fostering trust and reducing prevalence of substandard products. |

| International Trade | Initial hurdles for non-compliant entities. | Streamlined global distribution, enhanced export opportunities for compliant manufacturers, improved access for patients. |

| Patient Access & Trust | Potentially higher prices for some therapies. | Greater confidence in therapeutic efficacy and safety, crucial for adherence to personalized wellness protocols. |

The investment in quality, driven by pharmacopoeial stringency, ultimately underpins the trust patients place in their prescribed peptide therapies, ensuring that the biochemical recalibration they seek is both safe and effective.

References

- Wang, X. et al. “Development of the General Chapters of the Chinese Pharmacopoeia 2020 Edition ∞ A Review.” Journal of Pharmaceutical Analysis, vol. 11, no. 1, 2021, pp. 1-10.

- Li, J. et al. “Analysis on the Current Quality Standards of Chinese Materia Medica Used in COVID-19 Prevention and Treatment.” Journal of Ethnopharmacology, vol. 257, 2020, Article 112876.

- Huynh-Ba, K. “Pharmacopoeia Compliance ∞ Putting it All Together; What Is on the Horizon.” Pharmaceutical Technology, vol. 44, no. 3, 2020, pp. 32-38.

- Zhang, L. et al. “Development of the Chinese Pharmacopoeia 2020 Edition General Chapters ∞ A Review.” ResearchGate, 2020. (PDF version of)

- Chinese Pharmacopoeia Commission. “Vision to Global Pharmacopeia ∞ Convergence and Upcoming Development of Biological Chapters in Chinese Pharmacopoeia.” CASSS, 2018.

Reflection

Your understanding of these intricate economic currents marks a significant step in your personal health journey. The knowledge of how global standards influence the very compounds you might consider for hormonal balance or metabolic support empowers you to approach your wellness protocols with informed discernment.

This is not merely about consuming information; it is about integrating a deeper appreciation for the complex systems that bring therapeutic innovation to your fingertips. Recognizing these layers allows you to advocate more effectively for your health and to choose pathways that resonate with a commitment to both scientific rigor and personal well-being.