Fundamentals

Understanding the architecture of safety and consistency in therapeutic peptides begins with appreciating the systems designed to protect you. When we consider the medications that interact so intimately with our body’s signaling systems, the question of their origin and quality becomes deeply personal.

The core principles of the National Medical Products Administration’s (NMPA) Good Manufacturing Practices (GMP) represent a foundational promise of safety and reliability. These regulations are a meticulously designed framework that governs the entire lifecycle of a pharmaceutical product, ensuring that every single vial of a therapeutic peptide is created with precision and integrity.

The system is built to minimize the inherent risks in pharmaceutical production, such as contamination, mix-ups, or errors, which could compromise the very function and safety of these sensitive molecules.

The NMPA, as the regulatory body in China, establishes these guidelines to align with international standards, creating a universal language of quality control. This framework is built upon the establishment of a comprehensive Quality Management System (QMS). A QMS is the central nervous system of a manufacturing facility.

It is an organized structure of procedures and responsibilities designed to ensure that every product consistently meets its intended specifications for safety, efficacy, and quality. This system ensures that from the moment raw materials arrive at a facility to the final release of a product, every step is defined, controlled, and documented. The integrity of this process is paramount, as the biological messages that peptides deliver to your cells depend entirely on their structural purity and correct formulation.

The NMPA’s Good Manufacturing Practices establish a required system of control to ensure therapeutic peptides are consistently produced to meet quality and safety standards for their intended use.

What Is the Role of a Quality Management System?

A Quality Management System is the operational blueprint for excellence within a pharmaceutical manufacturing environment. It encompasses all planned activities and systems with the objective of guaranteeing that the drugs produced meet all requirements for their intended use. This begins with a clear definition of manufacturing processes, which are systematically reviewed and validated to prove their capability.

Validation is a critical concept; it is the process of generating documented evidence that a procedure, process, or activity consistently produces the expected result. For peptide therapies, this means confirming that the synthesis and purification processes reliably create the correct molecule at the required purity, batch after batch. The QMS provides the necessary resources to achieve this, including appropriately trained personnel, suitable facilities and equipment, and correctly specified materials.

The system also holds the manufacturer accountable for integrity. The NMPA regulations explicitly forbid any form of falsification or fraud, demanding a culture of transparency and responsibility. This ensures that the data supporting the quality of a peptide is real and trustworthy.

Every aspect of the manufacturing journey, from production and quality control to product release and distribution, is managed under this umbrella of quality. This creates a predictable environment where the potential for human error is minimized and the final product that reaches a patient is one that can be trusted to interact with their physiology as intended.

Intermediate

Moving beyond the foundational concept of a quality system, the NMPA’s Good Manufacturing Practices are built upon several key operational pillars. These principles translate the philosophy of quality into concrete, auditable actions that govern every facet of peptide production.

The regulations are designed to build quality into the product at every stage, recognizing that a final test on a batch is only a snapshot. True quality assurance comes from a state of continuous control over materials, personnel, equipment, and the environment itself.

A central tenet of NMPA GMP is the rigorous management of all inputs to the manufacturing process. This starts with the people involved. Personnel must be appropriately qualified and receive ongoing training for their specific roles. In the context of sterile peptide production, this training is intense, covering aseptic techniques, cleanroom behavior, and hygiene protocols to prevent the introduction of microbial contaminants.

The facility itself is another critical input. The premises must be designed and maintained to prevent cross-contamination, with logical flows of materials and personnel. For injectable peptides, this involves the use of cleanrooms with validated air filtration systems and controlled environmental parameters like temperature and humidity to ensure product stability and sterility.

NMPA GMP mandates strict control over personnel, facilities, equipment, and materials to build quality directly into the manufacturing process from start to finish.

Pillars of Manufacturing Control

The NMPA framework specifies several areas of non-negotiable control for any facility producing pharmaceuticals, including therapeutic peptides. These pillars work together to create a robust manufacturing environment.

- Supplier and Raw Material Management ∞ The quality of a peptide is directly dependent on the quality of its starting materials. NMPA regulations mandate a stringent supplier qualification system. Manufacturers must evaluate and approve their suppliers to ensure all raw materials meet predefined quality standards. Upon arrival, these materials undergo rigorous testing for identity, purity, and potency before they are approved for use in production. This prevents substandard or contaminated substances from entering the manufacturing chain.

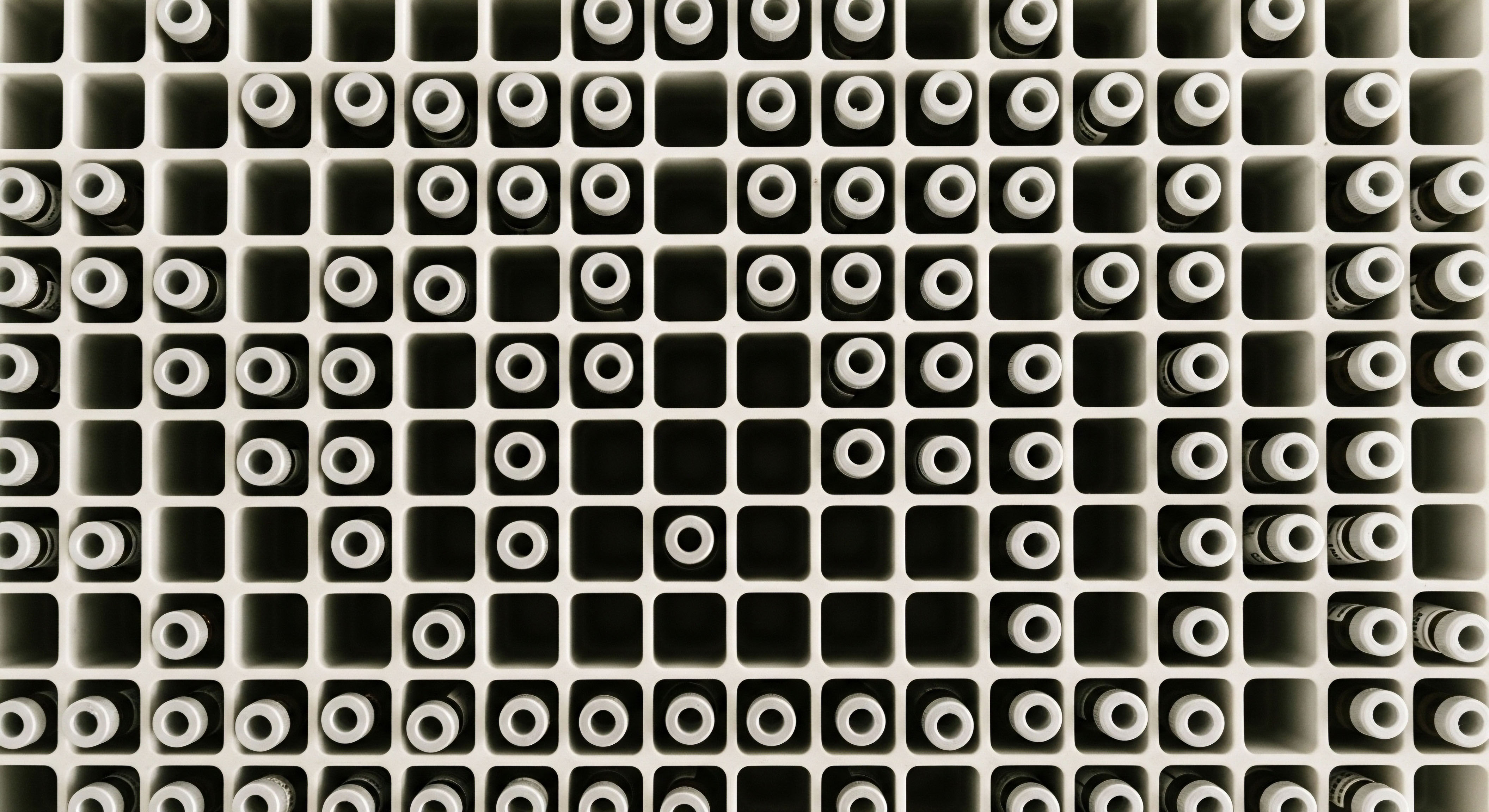

- Equipment and Facility Validation ∞ All equipment used in the manufacturing process must be suitable for its intended purpose and validated to confirm it performs as expected. This includes everything from the reactors used for peptide synthesis to the chromatography systems for purification and the filling lines for sterile vials. Cleaning procedures for all equipment must also be validated to prove they effectively remove any residues, preventing carryover between different batches or products.

- Environmental Monitoring and Control ∞ For sterile peptides, the manufacturing environment is a critical control point. GMP requires manufacturers to establish comprehensive environmental monitoring programs. These programs continuously assess factors like air quality for particulate and microbial contamination, differential pressures between cleanroom zones, temperature, and humidity. The goal is to maintain an aseptic environment that protects the product from contamination at all times.

- Documentation and Record-Keeping ∞ Every action taken during the manufacturing process must be documented. GMP requires complete and accurate records for full traceability. This “batch record” is a detailed history of a product’s creation, including the specific lots of raw materials used, the equipment utilized, the personnel involved, and the results of all in-process tests. This documentation is essential for investigating any deviations and for confirming that the batch was made according to its validated process.

Key Personnel Responsibilities under NMPA GMP

The regulations define specific roles and responsibilities to ensure accountability. The Qualified Person (QP), for instance, holds a unique and critical position.

| Role | Core Responsibilities | Impact on Peptide Quality |

|---|---|---|

| Head of Production | Ensures that products are produced and stored according to appropriate documentation to meet the required quality standards. Manages production resources and ensures that all personnel are trained. | Directly oversees the synthesis and handling of the peptide, ensuring the validated process is followed precisely to achieve the correct molecular structure and prevent degradation. |

| Head of Quality Control | Responsible for approving specifications, sampling instructions, and test methods. Ensures that all necessary testing on materials and products is carried out before release. | Guarantees that the analytical methods used, such as HPLC and mass spectrometry, are capable of accurately measuring the peptide’s purity, identity, and any impurities. |

| Qualified Person (QP) | Personally responsible for certifying that each batch of a drug has been manufactured and checked in compliance with regulations and the product’s marketing authorization. Reviews the batch record before releasing the product to the market. | Acts as the final gatekeeper of quality, providing an independent review of all manufacturing and testing data to confirm the peptide batch is safe and effective for patient use. |

Academic

A sophisticated examination of China’s NMPA Good Manufacturing Practices, particularly concerning advanced therapeutics like peptides, reveals a deliberate evolution toward a risk-based and holistic framework. This progression is exemplified by the introduction of the Contamination Control Strategy (CCS) in recent draft guidelines for sterile products.

The CCS is a comprehensive, facility-wide philosophy that requires manufacturers to critically assess and proactively manage all potential sources of contamination. It formalizes the understanding that product sterility and purity are the result of an integrated system, where every element from facility design and personnel flow to material handling and process parameters contributes to the final state of control.

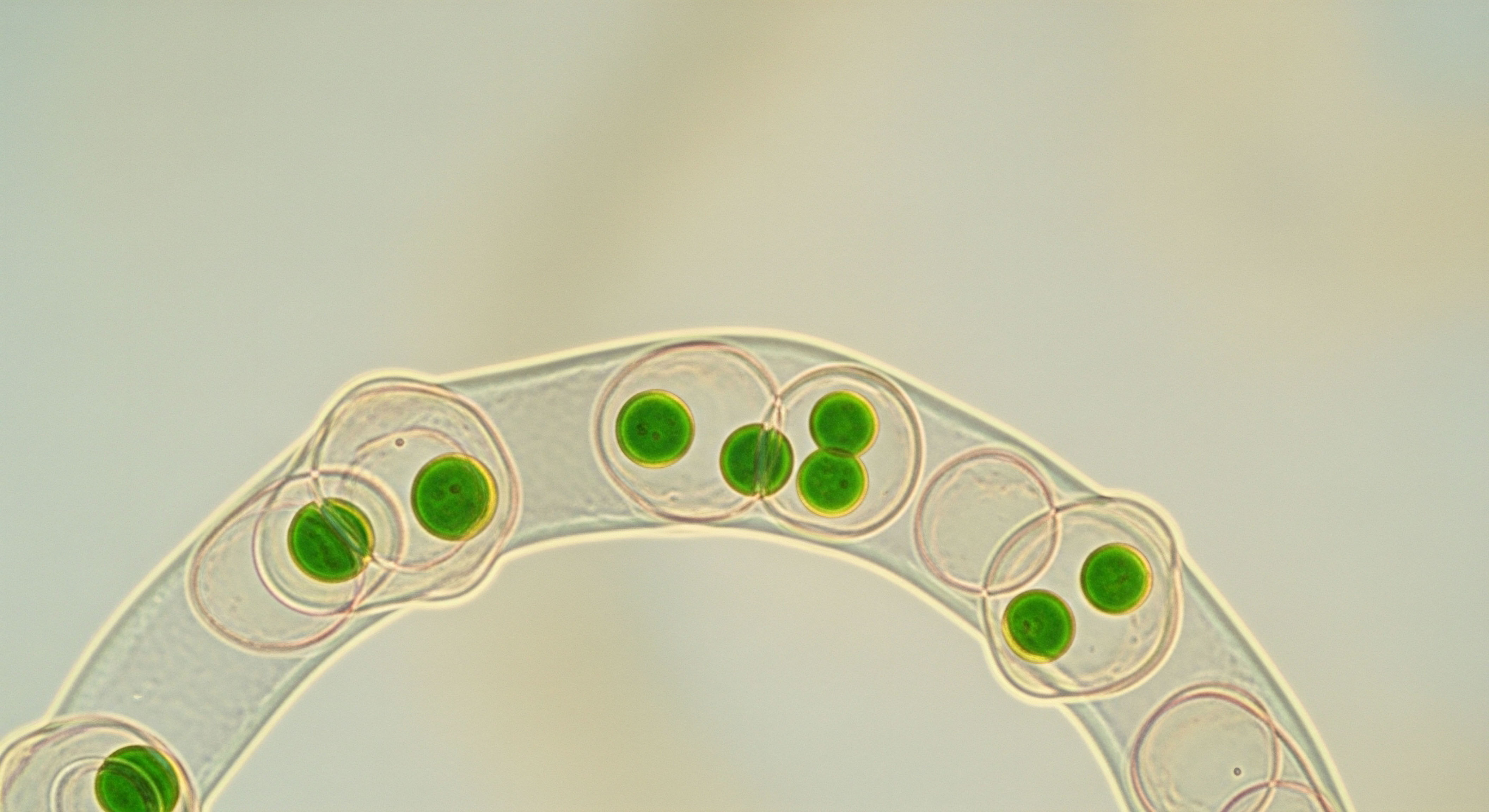

This approach requires a deep, scientific understanding of potential failure modes. For peptide manufacturing, the risks are numerous and complex. Peptides are large, intricate molecules susceptible to degradation from microbial enzymes, pH shifts, or temperature fluctuations. They can also be contaminated by endotoxins (pyrogens), which are components of bacterial cell walls that can cause a severe immune response if injected.

The CCS compels a manufacturer to identify every point where microbial or particulate contamination could be introduced and to implement scientifically sound control measures. This involves extensive validation of airflows in cleanrooms, the effectiveness of sterilization processes for equipment, and the integrity of barrier systems like isolators or Restricted Access Barrier Systems (RABS).

The Contamination Control Strategy required by NMPA GMP represents a shift towards a proactive, science-driven analysis of all potential contamination vectors throughout the peptide manufacturing lifecycle.

How Does Risk Management Reshape Manufacturing?

The principle of risk-based quality management is now a central axis of modern GMP, including the NMPA’s updated standards. This methodology requires a manufacturer to use scientific knowledge and data to evaluate the risk to product quality across the entire lifecycle. Control measures are then applied in a manner proportionate to the level of risk.

In the context of peptide synthesis, a critical risk assessment might focus on the purification steps. High-Performance Liquid Chromatography (HPLC) is a standard technique for purifying peptides, but the process itself carries risks. A risk analysis would examine factors like column integrity, buffer quality, potential for microbial growth in the system, and the possibility of carryover between runs.

Based on this analysis, the manufacturer would define control measures, such as stringent column cleaning validation, bioburden limits for buffers, and dedicated equipment for certain products.

This risk-based approach extends to the entire quality system. Instead of a one-size-fits-all checklist, manufacturers are expected to demonstrate a deep understanding of their specific products and processes. The table below outlines how this risk-based thinking is applied to different domains within peptide manufacturing, aligning with NMPA’s expectations for a modern, compliant facility.

| Manufacturing Domain | Potential Risk Identified | Example of a Risk-Based Control Measure |

|---|---|---|

| Aseptic Process Simulation | Human error during sterile filling operations can introduce microbial contamination that is not detected by finished product sterility testing. | Conducting regular “media fills,” where a sterile microbiological growth medium is passed through the entire aseptic filling process in place of the actual peptide. This simulates the process to validate that the controls are effective at preventing contamination. |

| Raw Material Sourcing | The use of amino acid derivatives (the building blocks of peptides) from a poorly qualified supplier could introduce impurities that are difficult to remove and may have unknown biological activity. | Implementing a multi-tiered supplier management program that includes on-site audits of the supplier’s facility, independent testing of their materials, and a documented history of quality performance. |

| Analytical Method Validation | An analytical method for purity (e.g. HPLC) may not be sensitive enough to detect a specific, potentially harmful impurity that forms during synthesis. | Performing forced degradation studies on the peptide to intentionally create degradation products. The analytical method is then challenged to prove it can separate and quantify these specific impurities, ensuring its suitability. |

| Data Integrity | Electronic data from laboratory equipment could be altered or deleted, obscuring an out-of-specification result. | Implementing a 21 CFR Part 11 compliant data system with full audit trails, secure user access controls, and electronic signatures to ensure all data is attributable, legible, contemporaneous, original, and accurate (ALCOA+). |

This academic application of GMP principles demonstrates that compliance is an active, intellectual process. It requires a continuous cycle of risk assessment, mitigation, and review, all supported by robust scientific data and a culture of quality that permeates the entire organization. The ultimate goal is to create a state of control so thorough that the safety and efficacy of every peptide molecule are an assured outcome of the process itself.

References

- China. National Medical Products Administration. Good Manufacturing Practice for Drugs (2010 Revision). MOH Decree No. 79, 17 Jan. 2011.

- “China’s GMP for Pharmaceuticals.” Pacific Bridge Medical, 1 May 2023.

- “Update of the GMP Guideline for Sterile Medicinal Products in China.” ECA Academy, 1 Apr. 2025.

- “China’s New GMP Standards ∞ Elevating Medical Device Manufacturing to Global Excellence.” BradyKnows Medical, 24 Jan. 2025.

- “Understanding GMP Standards in Peptide Manufacturing.” NEX Bio, 20 Feb. 2025.

Reflection

Having explored the structured world of Good Manufacturing Practices, you now possess a clearer lens through which to view therapeutic peptides. The journey from a chemical blueprint to a sterile vial is governed by a profound commitment to quality and safety. This knowledge is the first step.

The next is to consider how this assurance of quality connects to your own personal health objectives. Understanding the ‘what’ and ‘why’ behind manufacturing standards allows you to engage in more informed conversations about your own wellness protocols.

It provides a foundation of confidence, allowing you to focus on the biological purpose of these therapies and how they align with your body’s unique needs. Your path forward is a personal one, built on the bedrock of this shared standard of excellence.

Glossary

therapeutic peptides

good manufacturing practices

nmpa

quality management system

nmpa gmp

raw material management

environmental monitoring

batch record

qualified person

peptide manufacturing