Fundamentals

Your wellness journey is a deeply personal one, grounded in the dialogue between how you feel and the biological realities within your body. When you begin a personalized wellness protocol, such as Testosterone Replacement Therapy (TRT) or Growth Hormone Peptide Therapy, you are taking a definitive step toward recalibrating your body’s internal systems.

The arrival of a small, temperature-controlled package at your doorstep represents a physical manifestation of this commitment. Contained within that package is more than just a medication; it holds a set of molecular instructions designed to restore balance and function to your endocrine system.

The careful handling of this package, from the moment it leaves the pharmacy to the moment you administer your dose, is a foundational element of your therapeutic success. The commercial apparatus that ensures this delivery is a direct extension of the clinical science that informs your protocol.

The medications used in hormonal optimization, like Testosterone Cypionate or peptides such as Sermorelin and Ipamorelin, are complex, precisely structured molecules. Testosterone Cypionate is a bioidentical hormone attached to an ester, suspended in a carrier oil. This structure is designed for stable, slow release into your system.

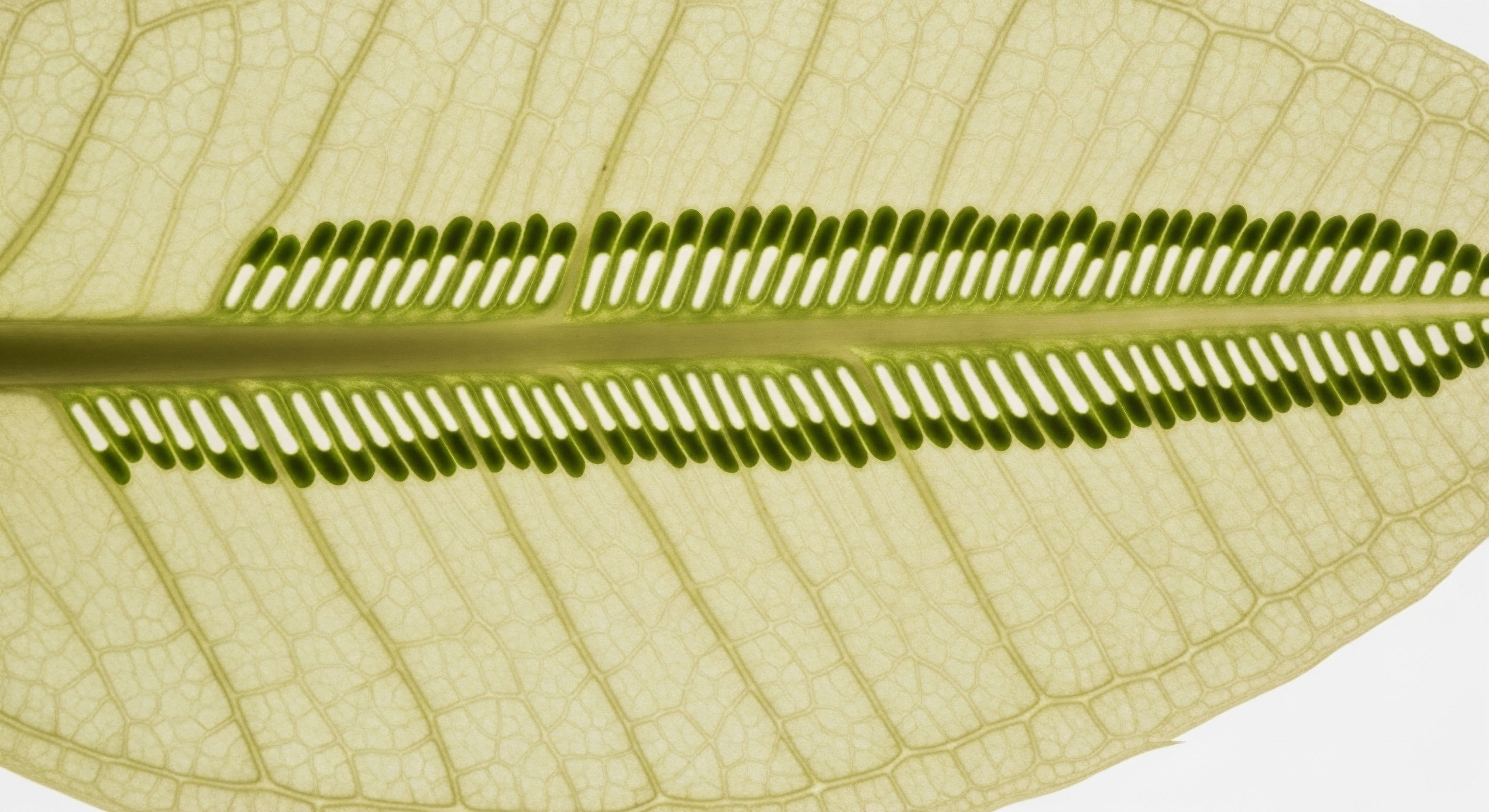

Peptides are short chains of amino acids, delicate by nature, akin to intricate keys designed to fit specific cellular locks. The integrity of these molecular structures is directly dependent on their environment, with temperature being a primary determinant of their stability.

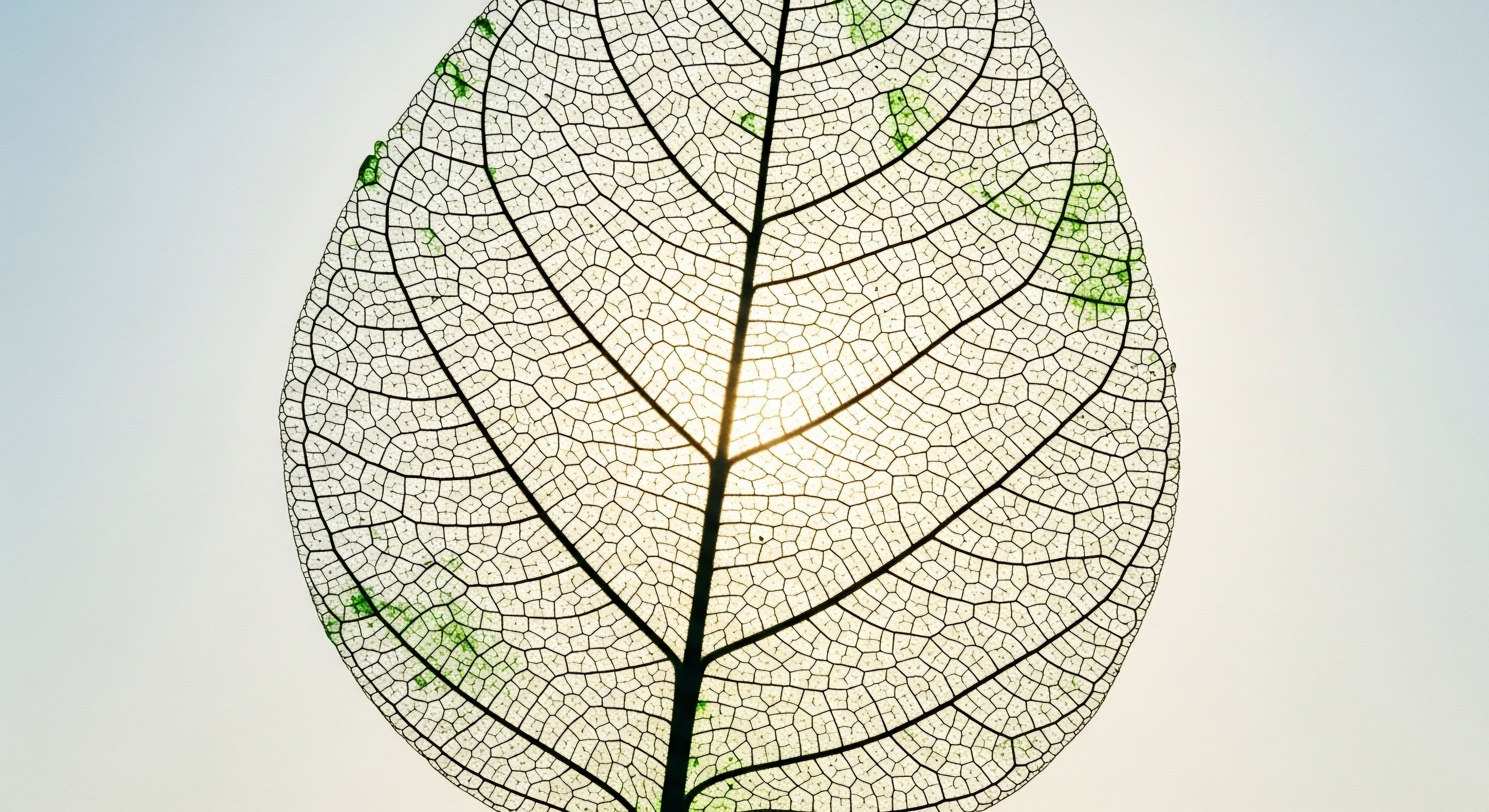

A deviation from the prescribed temperature range can initiate a cascade of molecular changes that may render the therapy ineffective or, in some cases, unsafe. This is the central reason for the existence of the pharmaceutical cold chain, a continuous, temperature-controlled supply line that protects the product’s viability.

The Biology of Temperature Sensitivity

To understand the commercial implications of distributing these therapies, one must first appreciate the underlying biochemistry. The hormones and peptides in your protocol are not inert substances; they are biologically active molecules whose three-dimensional shape dictates their function. Think of a key and a lock.

The peptide or hormone is the key, and the cellular receptor is the lock. If the key is bent or broken, it can no longer open the lock. Temperature excursions, both hot and cold, are a primary force that can bend or break these molecular keys.

For instance, Testosterone Cypionate, which should be stored at a controlled room temperature of 20°C to 25°C (68°F to 77°F), is susceptible to crystallization if it gets too cold. Crystallization occurs when the testosterone molecule separates from the carrier oil, forming solid, needle-like crystals.

Injecting a crystallized solution can cause pain and inflammation at the injection site and, more importantly, leads to inconsistent dosing. The body cannot properly absorb the hormone in this solidified state, disrupting the steady physiological levels your protocol is designed to achieve. Conversely, exposure to excessive heat can accelerate the degradation of the testosterone molecule and the cypionate ester, reducing the medication’s potency. A therapy’s effectiveness diminishes with each degree outside its stable range.

The stability of your therapeutic molecules is directly linked to maintaining a precise temperature from production to administration.

Peptide therapies face similar, and often more pronounced, vulnerabilities. Peptides are held together by fragile bonds, and their function relies on a specific folded structure. Heat can cause these bonds to break and the peptide to unfold, a process called denaturation. Once denatured, the peptide loses its biological activity permanently.

It can also lead to aggregation, where the unfolded molecules clump together. These aggregates are not only inactive but can potentially trigger an immune response in the body. The commercial systems for distributing these molecules are built around mitigating these inherent physical vulnerabilities. Every dollar spent on specialized packaging, monitoring, and logistics is an investment in preserving the molecular structure that makes your therapy work.

From the Pharmacy to Your Refrigerator

The journey of your medication is a carefully choreographed sequence of events. It begins at a compounding pharmacy, where your specific prescription is prepared under sterile conditions. From there, it is placed into a qualified shipping container.

This container is a sophisticated piece of equipment, often insulated with materials like expanded polystyrene or advanced vacuum insulated panels, and includes cooling elements such as gel packs that are conditioned to a specific temperature.

The size of the container, the type of insulation, and the number and placement of coolant packs are all calculated based on the medication, the transit time, and the anticipated external temperatures. This is a scientific process, validated through rigorous testing, to ensure the package can maintain its target temperature range (for example, 2°C to 8°C for most peptides) for the duration of its journey.

The commercial cost of this single shipment reflects the sum of these materials, the expertise required to assemble them correctly, and the risk associated with potential failure.

The implications are therefore deeply personal. A failure in this chain, such as a delivery truck being delayed on a hot day or a package left on a sun-drenched porch, is a direct threat to your health protocol.

It means a potential delay in your treatment, a financial loss for the pharmacy or manufacturer, and a disruption to the physiological balance you are working to restore. The meticulous instructions you receive for storing your medication upon arrival are the final, critical link in this extensive chain.

Your refrigerator, for a vial of Ipamorelin, or your cool, dark cabinet, for a vial of Testosterone Cypionate, becomes the last outpost of a global logistics network dedicated to the stability of that single molecule.

Intermediate

Understanding the commercial implications of distributing temperature-sensitive drugs requires moving beyond the individual vial and examining the entire system as a whole. This system, known as the pharmaceutical cold chain, is a sequence of refrigerated production, storage, and distribution activities. Its purpose is to maintain the quality and efficacy of products like your hormone or peptide therapy.

Every step is a potential point of failure, and the commercial costs of such failures are substantial, extending from direct financial loss to significant clinical consequences for the patient. The industry quantifies these risks and invests heavily in technologies and processes designed to ensure an unbroken chain of custody and temperature integrity.

The financial architecture of cold chain logistics is built upon risk mitigation. A single international shipment of a biologic drug can be valued in the millions of dollars. While a single patient’s prescription has a lower monetary value, the principle is the same.

The cost of a single temperature excursion ∞ a deviation from the required storage conditions ∞ can be immense. According to industry estimates, the pharmaceutical industry loses over $35 billion annually due to failures in temperature-controlled logistics.

This figure includes the cost of the product itself, the logistics costs of the failed shipment, the expense of shipping a replacement, and the administrative costs of investigating the failure. For the patient, the cost is measured in treatment delays and the physiological disruption of inconsistent therapy, which can undermine months of progress.

The Anatomy of a Cold Chain Shipment

When your therapy is dispatched from the pharmacy, it enters a complex logistical network. The choice between different shipping configurations is a primary commercial decision based on the product’s value, stability, and the duration of transit. These configurations fall into two main categories ∞ passive and active systems.

- Passive Shippers ∞ These are the most common for direct-to-patient shipments. A passive shipper is an insulated container, like the ones described previously, that uses frozen or refrigerated gel packs or phase change materials (PCMs) to maintain temperature. PCMs are advanced materials that absorb or release thermal energy to maintain a specific temperature for a prolonged period. The commercial calculation here is a balance of cost and performance. The shipper must be “qualified” through rigorous testing to prove it can hold its temperature range for a specified duration (e.g. 48 or 72 hours) under simulated real-world conditions.

- Active Systems ∞ For larger, high-value bulk shipments, active systems are often employed. These are essentially mobile refrigeration or freezer units. They use mechanical or electric systems powered by batteries or connected to an external power source to heat or cool the payload compartment, maintaining a precise temperature setpoint. These containers are significantly more expensive to purchase, lease, and operate, but they provide a much higher level of security and are capable of longer transit times. The decision to use an active system is a direct commercial response to the high value and extreme temperature sensitivity of the product being transported.

The Role of Data in Assuring Integrity

You cannot control what you cannot measure. This principle is central to modern cold chain management. To ensure that a product has remained within its specified temperature range, shipments are increasingly accompanied by digital data loggers. These small electronic devices are placed inside the shipping container alongside the product. They record the internal temperature at regular intervals throughout the entire journey.

Upon arrival, the data can be downloaded and reviewed. A temperature graph provides an unbroken record of the shipment’s thermal history. This data is the ultimate arbiter of a shipment’s viability. If the logger shows a temperature excursion beyond the product’s stability limits, the shipment is flagged.

A quality assurance team will then conduct a formal investigation, reviewing the extent and duration of the deviation against the known stability data for that specific drug. The product may be deemed unusable and destroyed, triggering a replacement shipment.

The commercial implications are clear ∞ the cost of the data logger and the system to manage its data is a small price to pay compared to the cost of either administering a compromised drug or unnecessarily destroying a perfectly good one. Real-time monitors that use cellular or GPS technology to transmit temperature data during transit represent the next evolution, allowing for intervention before a shipment is lost.

Every data point from a temperature logger is a piece of evidence that validates the safety and efficacy of the medication you receive.

This reliance on data brings us to the concept of regulatory compliance. Health authorities like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established strict guidelines for the distribution of pharmaceutical products, known as Good Distribution Practices (GDP).

These regulations mandate that all parties involved in the supply chain must be able to demonstrate that the quality and integrity of medicines are maintained. This includes requirements for temperature mapping of storage areas, calibration of monitoring equipment, and qualification of shipping containers.

Failure to comply can result in severe commercial penalties, including fines and the loss of a license to distribute. The entire commercial framework of temperature-sensitive distribution is therefore built on a foundation of regulatory adherence and verifiable data.

| Technology | Mechanism | Typical Use Case | Relative Cost | Key Advantage |

|---|---|---|---|---|

| Passive Shipper (EPS/PUR) | Insulated box with frozen/refrigerated gel packs. | Direct-to-patient, short-duration shipments. | Low | Simplicity and low unit cost. |

| Passive Shipper (VIP/PCM) | Vacuum Insulated Panels with Phase Change Materials. | Longer duration or shipments with higher value/sensitivity. | Medium | Higher thermal performance and duration. |

| Active Container | Battery-powered heating/cooling system. | Bulk pharmaceutical shipments, clinical trials. | High | Precise temperature control, long duration. |

| Data Logger (Historical) | Records temperature data for download upon arrival. | Standard practice for most qualified shipments. | Low | Provides a full thermal history for compliance. |

| Data Logger (Real-Time) | Uses cellular/GPS to transmit live temperature data. | High-value, highly sensitive shipments. | Medium-High | Allows for real-time intervention to prevent loss. |

Academic

The commercial framework for distributing temperature-sensitive pharmaceuticals is a direct consequence of the molecular fragility of modern therapeutics, particularly biologics, peptides, and certain hormonal agents. From an academic perspective, the entire cold chain is an applied science, translating principles of biochemistry, thermodynamics, and risk management into a complex operational system.

The financial and logistical architecture of this system is dictated by the chemical degradation pathways of the molecules it is designed to protect. A deeper analysis reveals that the commercial implications are intrinsically linked to regulatory frameworks like Good Distribution Practices (GDP), the physics of thermal packaging, and the economic calculus of failure analysis.

At the core of the issue is the inherent instability of large molecules. Unlike small-molecule drugs, which are often chemically robust, biologics and peptides derive their function from a precise, three-dimensional conformational structure, or tertiary structure. This conformation is maintained by a delicate balance of relatively weak non-covalent bonds, such as hydrogen bonds and van der Waals forces.

Thermal energy introduced into the system (heat) can disrupt these bonds, causing the molecule to unfold (denature) and lose its function. This process can be irreversible. Furthermore, unfolded peptides can expose hydrophobic regions that cause them to aggregate, forming biologically inactive and potentially immunogenic clumps.

Cold temperatures can also be damaging, leading to the formation of ice crystals that can physically stress the molecule or cause cryoconcentration of solutes, altering pH and buffer capacity, which in turn destabilizes the drug. For oil-based depots like Testosterone Cypionate, cold induces phase separation and crystallization, altering the drug’s release kinetics and bioavailability.

Quantifying Risk through Qualification and Validation

The commercial enterprise of cold chain logistics is fundamentally about managing and mitigating the risks of these molecular degradation pathways. The primary tool for this is the rigorous process of qualification and validation. Regulatory bodies mandate that any equipment or process used in the storage and transport of pharmaceuticals must be proven fit for its intended purpose. This is a multi-stage process.

- Installation Qualification (IQ) ∞ This step verifies that the equipment ∞ be it a warehouse refrigeration unit or a parcel-sized insulated shipper ∞ is installed correctly and matches the design specifications.

- Operational Qualification (OQ) ∞ Here, the equipment is tested to ensure it operates correctly under controlled conditions. For a shipping container, this involves running empty tests to demonstrate that it can maintain its target temperature range.

- Performance Qualification (PQ) ∞ This is the most critical stage. The system is tested under real-world or simulated real-world conditions. For a shipping container, this means loading it with a simulated product mass and placing it in a programmable environmental chamber. The chamber will run a temperature profile that mimics the anticipated transit route, including extreme summer and winter temperatures. These profiles are often standardized, such as those developed by the International Safe Transit Association (ISTA). The data loggers inside the shipper must prove that the internal temperature remained within specification for the entire test duration.

The commercial implication of this process is significant. A full PQ can be expensive and time-consuming. Pharmaceutical manufacturers and distributors invest heavily in this testing to create a portfolio of pre-qualified shipping solutions for different products, transit lanes, and seasons. This investment is a prerequisite for commercial distribution and is factored into the overall cost of the therapy. It is a scientifically-defensible method of demonstrating control over the distribution process to regulators.

What Are the Commercial Consequences of a System Failure?

When a temperature excursion occurs, a formal investigation is initiated. This process, known as a root cause analysis (RCA), is a systematic method of identifying the source of the failure. Was it human error (e.g. improper packaging)? Equipment failure (e.g. a faulty data logger or a refrigeration unit malfunction)?

Or a process failure (e.g. selecting the wrong shipping solution for the transit lane)? The findings of the RCA are used to implement Corrective and Preventive Actions (CAPAs) to prevent a recurrence. This entire quality management system is a significant operational expense, but it is commercially necessary to maintain regulatory compliance and prevent much larger losses.

The disposition of the affected product is a complex decision. It requires deep knowledge of the drug’s specific stability profile. Manufacturers conduct extensive stability studies to understand how their product degrades under various temperature stress conditions. This data determines the allowable excursion limits.

For example, a peptide might be able to tolerate a brief spike to 10°C for two hours without significant loss of potency, but be completely degraded after 30 minutes at 25°C. If a shipment experiences an excursion, the quality assurance team will compare the time and temperature data from the logger against this stability budget.

If the excursion is within allowable limits, the product can be released. If it exceeds the limits, the product must be destroyed. The commercial loss is not just the cost of goods sold; it is the full market value of the product, as a replacement must be provided.

For high-value biologics, this can be catastrophic. For a patient on a carefully titrated hormone protocol, the clinical impact of a missed or ineffective dose due to a distribution failure can disrupt the hypothalamic-pituitary-gonadal (HPG) axis, leading to a resurgence of symptoms and setting back the therapeutic progress.

The stability budget of a drug is a finite, scientifically determined resource that is consumed by any deviation from ideal storage conditions.

The future of this field lies in developing more robust solutions. This includes advancements in formulation science to create more thermostable versions of drugs, potentially reducing the reliance on the cold chain. It also involves the wider adoption of real-time monitoring and predictive analytics.

By using AI to analyze historical shipping data, weather patterns, and carrier performance, logistics companies can proactively identify high-risk routes and implement mitigation strategies before a shipment is even dispatched. These technological advancements represent new commercial opportunities, promising a future of more resilient and efficient pharmaceutical distribution.

| Potential Failure Mode | Potential Effects of Failure | Potential Cause(s) | Current Controls | Recommended Actions |

|---|---|---|---|---|

| Temperature excursion (Too Hot) | Product degradation, loss of efficacy, potential for aggregation. Financial loss. | Delay in transit; exposure to sun on tarmac or doorstep; incorrect packaging (insufficient coolant). | Qualified thermal shipper; use of data loggers; SOPs for seasonal packaging configurations. | Implement real-time monitoring; select premium carriers with temperature control options. |

| Temperature excursion (Too Cold) | Crystallization of product (e.g. Testosterone); phase separation; damage from ice formation. | Use of dry ice for a refrigerated product; exposure during transit in winter; incorrect coolant placement. | SOPs prohibiting use of dry ice for 2-8°C products; qualified shippers with thermal buffering. | Enhanced training for packaging personnel on seasonal risks and proper gel pack conditioning. |

| Physical Damage to Shipper | Compromised insulation; breach of product sterility. | Improper handling by carrier; inadequate packaging. | Use of robust, validated shipping containers; carrier quality agreements. | Conduct drop testing as part of shipper qualification; add “shock watch” indicators. |

| Data Logger Failure | Inability to verify temperature integrity; shipment must be assumed compromised. | Battery failure; device malfunction; user error in activation/readout. | Use of reliable, calibrated loggers; redundant loggers for high-value shipments; SOPs for operation. | Transition to loggers with longer battery life and simpler user interfaces. |

References

- Defy Medical. “Testosterone Cypionate Storage Warning.” Defy Medical, Accessed July 2024.

- Kerali, Henry. “The Implications of Cold Chain failure.” Clinical Trials Arena, 3 Mar. 2017.

- HRT Doctors Group. “How to Store Testosterone Cypionate Medication.” HRT Doctors Group, 10 Feb. 2023.

- U.S. Food and Drug Administration. “NDA 216318 Approval Letter.” 2 June 2022.

- European Medicines Agency. “Guidelines of 5 November 2013 on Good Distribution Practice of medicinal products for human use (2013/C 343/01).” Official Journal of the European Union, 2013.

- World Health Organization. “WHO Technical Report Series, No. 937, 2006 Annex 5 Good distribution practices for pharmaceutical products.” WHO, 2006.

- Chirmade, Dhanshri. “Safeguarding Biologics ∞ Strategies to Prevent Cold Chain Failures.” PharmaFeatures, 29 Jan. 2025.

- Singh, Satish K. et al. “Grand Challenges in Pharmaceutical Research Series ∞ Ridding the Cold Chain for Biologics.” Journal of Pharmaceutical Sciences, vol. 110, no. 6, 2021, pp. 2259-2262.

- Chien, David, et al. “Accelerated Forced Degradation of Therapeutic Peptides in Levitated Microdroplets.” Pharmaceutical Research, vol. 37, no. 8, 2020, p. 138.

- MacKay, J. Andrew, and Ashutosh Chilkoti. “Temperature sensitive peptides ∞ Engineering hyperthermia-directed therapeutics.” International Journal of Hyperthermia, vol. 24, no. 6, 2008, pp. 483-95.

Reflection

Calibrating Your Internal System

The information presented here details a complex, global system of logistics, regulation, and science. Yet, its entire purpose comes down to a single, personal outcome ∞ ensuring the molecule that arrives at your door is the exact molecule you need to recalibrate your internal world.

Your body is a system of immense complexity, governed by intricate feedback loops and hormonal cascades. Your decision to engage in a personalized therapy is a decision to actively participate in the stewardship of that system. Understanding the journey of your medication illuminates the care and precision required at every stage.

This knowledge is a tool. It allows you to be a more informed partner in your own health, to appreciate the final, critical steps of proper storage and administration, and to recognize that your personal wellness journey is supported by a vast, unseen network dedicated to the integrity of that process.