Fundamentals

Your journey toward hormonal balance is an intimate and significant one. When you and your clinician decide that a compounded hormonal cream Recode your biology from the inside out; your fork is the most powerful anti-aging instrument you own. is the right path, you are placing immense trust in the medication designed specifically for your body’s needs. Understanding the systems that protect you is a vital part of this process.

The sensation of renewed vitality or the stabilization of your internal rhythms is directly connected to the molecular integrity of the therapy you are using. This is where the role of a regulatory body becomes deeply personal.

In China, the National Medical Products Administration National growth hormone therapy reimbursement policies vary by strict clinical criteria, quality of life metrics, and health system funding models. (NMPA) is the entity entrusted with overseeing the safety and quality of all drugs, including the hormonal cream you may hold in your hand. Its purpose is to ensure that the therapeutic promise of a medication is delivered with unwavering consistency and purity.

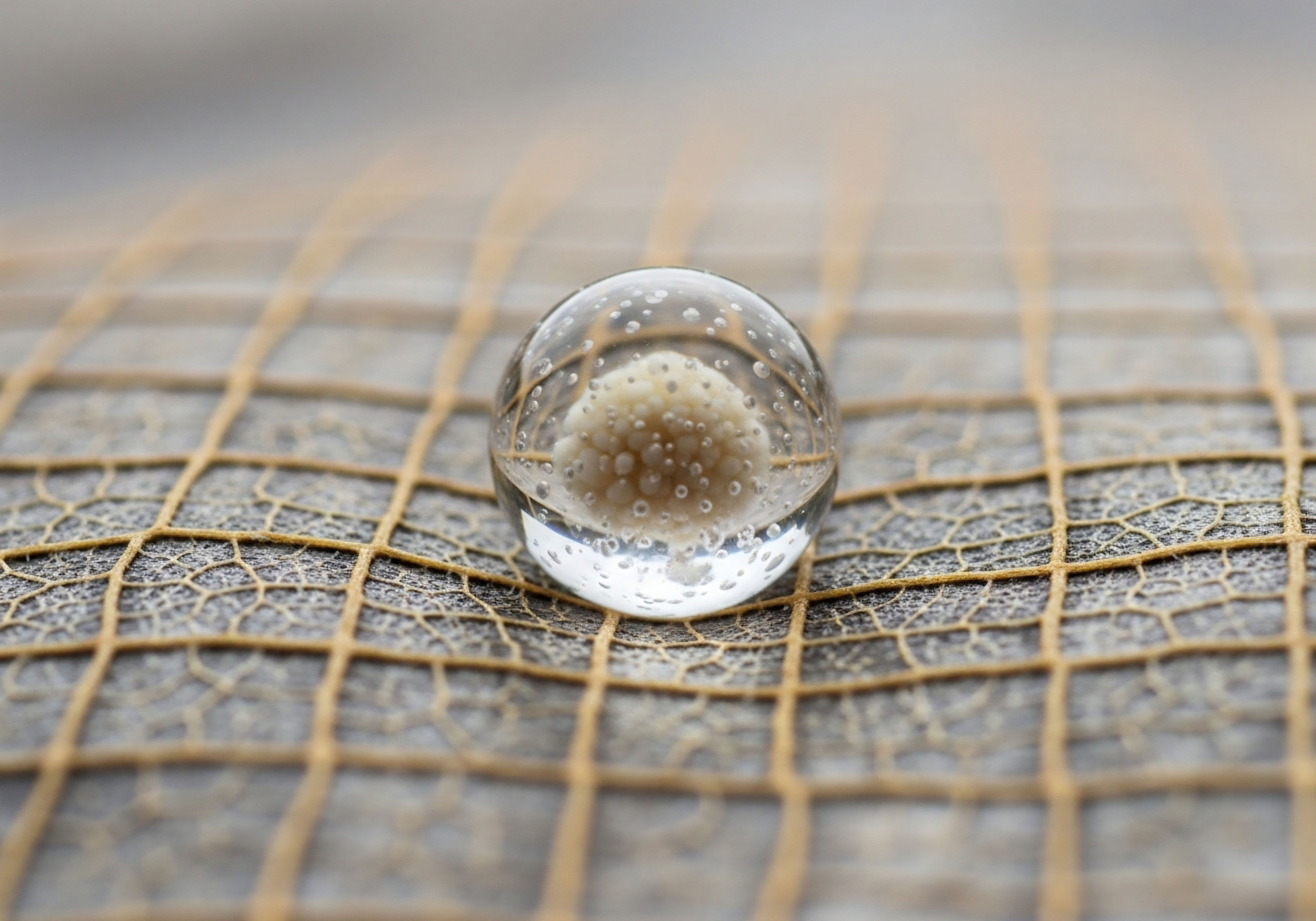

At its heart, quality control Meaning ∞ Quality Control, in a clinical and scientific context, denotes the systematic processes implemented to ensure that products, services, or data consistently meet predefined standards of excellence and reliability. for a compounded hormonal cream is about ensuring that what is on the label is precisely what is in the product, from the first dose to the last. For hormones, this is of paramount importance.

The endocrine system operates on a principle of exquisite sensitivity; minute changes in hormone concentrations can lead to profound shifts in your physical and emotional state. A cream with too little of its active ingredient may fail to alleviate your symptoms, leaving you to question the entire therapeutic approach.

Conversely, a cream with too much could introduce a new cascade of unwanted effects, disrupting the very equilibrium you seek. The NMPA’s framework is designed to prevent such deviations, transforming the art of compounding into a rigorous, reproducible science.

The NMPA’s primary function is to establish and enforce a unified standard of quality, ensuring every dose of your medication is both safe and effective.

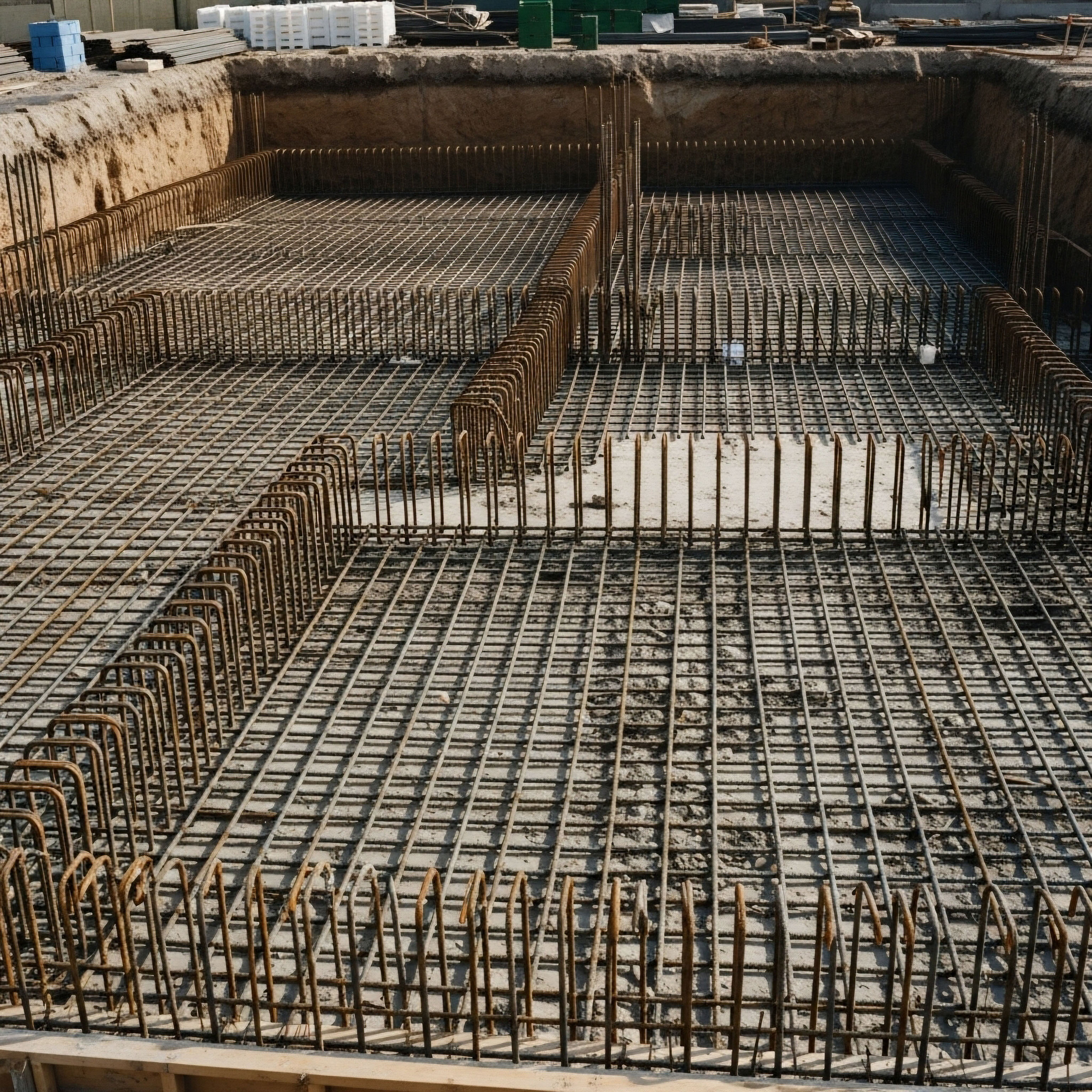

The core of this regulatory oversight is a set of principles known as Good Manufacturing Practice Meaning ∞ Good Manufacturing Practice (GMP) defines a system of regulations for manufacturing processes and facilities. (GMP). Think of GMP as a comprehensive blueprint for quality, dictating every step of the manufacturing process. It governs the raw materials, the environment in which the cream is made, the training of the technicians, and the testing of the final product.

For your hormonal cream, this means the base ingredients must be pure, the active hormones must be of a specific grade and potency, and the process of mixing them must be meticulously controlled to ensure a homogenous blend. Each step is documented, creating a transparent record that allows for accountability and verification.

This systematic approach provides a powerful assurance that the personalized medicine you rely on is a product of precision engineering, not guesswork. It validates the trust you place in your wellness protocol, grounding your journey in a foundation of verifiable quality.

Intermediate

To truly appreciate the NMPA’s role in safeguarding your hormonal therapy, we must look deeper into the architecture of its primary quality control instrument ∞ the Good Manufacturing Practice (GMP) guidelines. These are not mere suggestions; they are enforceable regulations that form the bedrock of pharmaceutical manufacturing in China.

The GMP framework is built upon the concept of a holistic Quality Management System Meaning ∞ A Quality Management System, within biological regulation and clinical practice, represents structured processes ensuring consistent physiological states and therapeutic outcomes. (QMS), an organizational structure designed to maintain a continuous state of control over all processes that influence the quality of your compounded cream. This system is proactive, designed to prevent errors before they occur, rather than simply detecting them after the fact.

The Pillars of Good Manufacturing Practice

The NMPA’s GMP regulations are extensive, but they can be understood through several key pillars that directly impact the quality of compounded hormonal creams. Each pillar works in concert with the others to create a multi-layered defense against inconsistency and contamination.

- Personnel ∞ The individuals responsible for compounding your medication must be appropriately qualified and extensively trained. GMP requires that personnel understand the specific procedures they perform, the principles of hygiene, and the potential consequences of deviation. Their training is documented, and their competency is regularly assessed. This ensures that a human touch, when required, is guided by expertise and precision.

- Premises and Equipment ∞ The physical environment of a compounding facility is a critical control point. GMP dictates requirements for facility design, maintenance, and cleaning to prevent cross-contamination between different formulations. Equipment used in the compounding process must be suitable for its intended use, calibrated regularly, and meticulously cleaned according to validated procedures. For a hormonal cream, this prevents the introduction of impurities or allergens and ensures that the sensitive hormonal molecules are not degraded by environmental factors.

- Materials Management ∞ The quality of the final product begins with the quality of its components. GMP mandates strict control over starting materials, including the active pharmaceutical ingredients (APIs) like testosterone or progesterone, and the excipients that form the cream base. Suppliers must be qualified, materials must be tested upon receipt to verify their identity and purity, and everything must be stored under appropriate conditions to maintain stability.

- Process Validation ∞ How can a facility be certain its compounding process consistently produces a homogenous cream at the target potency? The answer is process validation. GMP requires manufacturers to conduct studies that prove their specific methods and procedures will reliably yield a product that meets all quality specifications. This involves rigorous testing of multiple batches to demonstrate consistency and reproducibility, removing any element of chance from the production of your medication.

What Are the Core Responsibilities in Quality Assurance?

Within the GMP framework, the Quality Assurance Meaning ∞ Quality Assurance refers to the systematic process of verifying that a product, service, or process meets specified requirements and established standards. (QA) department holds a unique and powerful position. It operates independently of production and is responsible for ensuring that all aspects of the QMS are functioning correctly. The table below outlines some of the distinct responsibilities within a GMP-compliant facility, illustrating the system of checks and balances that protects the end user.

| Department | Core Responsibilities |

|---|---|

| Production |

Manufactures the product according to the master manufacturing documents. Ensures equipment is maintained and that all production steps are documented in the batch record. Responsible for in-process controls and adherence to standard operating procedures. |

| Quality Control (QC) |

Conducts all testing of raw materials, packaging components, and the final compounded product. This includes assays for potency, tests for microbial contamination, and other specifications. QC is responsible for generating the laboratory data that confirms the product meets its release criteria. |

| Quality Assurance (QA) |

Oversees the entire quality system. QA reviews and approves all procedures, audits the facility for GMP compliance, manages the investigation of any deviations or out-of-specification results, and has the final authority to release a batch of product for distribution. |

This separation of duties is a cornerstone of GMP. It ensures that the team responsible for making the product is not the same team that gives the final approval for its release. This objective oversight is a powerful guarantee that every batch of your compounded hormonal cream has been scrutinized from multiple angles, all with the singular goal of ensuring its quality, safety, and efficacy.

Academic

The NMPA’s regulatory apparatus for ensuring the quality of compounded hormonal creams is best understood as a dynamic, multi-layered system of risk mitigation, grounded in the legal framework of the Drug Administration Law of the People’s Republic of China.

The 2010 revision of the Good Manufacturing Practice (GMP) for Drugs serves as the foundational regulatory text, establishing a comprehensive quality management system that is both preventative and prescriptive. This system is designed to address the inherent variability of compounding pharmacy, where products are often prepared in small batches for specific patient needs, a stark contrast to the industrial scale of conventional pharmaceutical manufacturing.

A Systems-Based Approach to Quality Management

The NMPA’s enforcement of GMP principles reflects a sophisticated systems-biology perspective on pharmaceutical quality. The regulations compel manufacturers to view the production process not as a series of discrete steps, but as an interconnected ecosystem where each component influences the final therapeutic article.

The core tenet is that quality cannot be tested into a product; it must be designed and built into the manufacturing process from its inception. This is achieved through a rigorous Quality Management System (QMS), which integrates Quality Assurance, GMP, and Quality Risk Management.

The regulatory framework treats product quality as an emergent property of a well-controlled manufacturing system.

Quality Risk Management (QRM) is a particularly advanced component of this system. It requires the compounding facility to proactively identify, analyze, and control potential risks to product quality throughout the lifecycle of the product. For a hormonal cream, this involves a deep analysis of potential failure modes.

For instance, what is the risk of phase separation in the cream base over time, and how would that affect dose uniformity? What is the risk of microbial proliferation in a multi-use container, and what preservative systems are most effective? The NMPA Meaning ∞ NMPA, or Neuro-Modulatory Peptide Agonist, refers to a class of biological agents designed to activate specific peptide receptors located within the nervous system. expects these questions to be answered with scientific data, leading to the implementation of robust control strategies that are commensurate with the level of risk.

How Does the NMPA Differentiate Its Regulatory Focus?

The NMPA’s regulatory focus adapts to the specific nature of the pharmaceutical product. While the foundational GMP principles apply universally, their application is tailored. The table below contrasts the quality control focus for a mass-produced chemical drug versus a compounded hormonal cream, illustrating the nuanced application of NMPA guidelines.

| Quality Control Aspect | Mass-Produced Chemical Drug (e.g. Tablet) | Compounded Hormonal Cream |

|---|---|---|

| Batch Size |

Very large (millions of units). Focus is on statistical process control and high-throughput testing to ensure uniformity across the entire batch. |

Small to very small (often a single unit for one patient). Focus is on the meticulous control of the compounding process itself, as extensive final product testing may not be feasible for a single unit. |

| Stability Testing |

Extensive, long-term stability studies are required for regulatory approval, establishing a multi-year shelf life under various conditions. |

A Beyond-Use Date (BUD) is assigned based on established data for similar formulations or limited stability studies. The focus is on ensuring stability for the intended duration of use. |

| Validation |

Process validation is performed on multiple large-scale commercial batches before the product is ever marketed. |

The specific compounding process is validated to ensure it can reliably produce a quality product. This relies heavily on the validation of equipment and the demonstrated competency of the compounding personnel. |

| Regulatory Submission |

Requires a comprehensive New Drug Application with extensive pre-clinical and clinical trial data. Recent NMPA guidelines have tightened requirements for electronic submissions (eCTD) and patent declarations. |

Operates under the regulations for pharmacy compounding, which focus on the integrity of the compounding facility and its processes rather than on pre-market approval of each specific formulation. |

The Convergence of GMP and Clinical Oversight

The NMPA’s authority extends beyond the manufacturing facility into the clinical realm. The recent updates to guidelines concerning clinical trials and safety reporting for chemical compound drugs, while not directly aimed at compounding, signal a broader regulatory trend toward data-driven oversight and post-market surveillance. This creates a feedback loop.

The quality control established by GMP ensures that any clinical outcomes observed are the result of the intended formulation, providing clean data for evaluating the therapy’s efficacy and safety. Should adverse events be reported, the robust documentation required by GMP allows for a thorough investigation to determine if a quality defect was the root cause.

This integration of manufacturing quality control with clinical safety monitoring forms a powerful, continuous cycle of improvement and patient protection, ensuring that your personalized hormonal therapy is supported by a system of uncompromising scientific rigor.

References

- National Medical Products Administration. “Good Manufacturing Practice for Drugs (2010 Revision).” Ministry of Health Decree No. 79, 17 Jan. 2011.

- ClinRegs. “China Profile Updated to Include New NMPA Guidelines.” National Institute of Allergy and Infectious Diseases, 6 Apr. 2023.

- CISEMA. “New NMPA Guidelines for Chemical Drug Registration in China.” 9 Apr. 2025.

- China Med Device. “Full List of 181 Guidelines Issued by NMPA in 2022.” 13 Jan. 2023.

- ClinRegs. “China Profile Updated.” National Institute of Allergy and Infectious Diseases, 30 Nov. 2023.

Reflection

You have now seen the intricate systems and deliberate protocols that stand behind the formulation of a compounded hormonal cream. This knowledge demystifies the process, transforming a simple container of medication into a testament to regulatory science and meticulous control.

Your body’s endocrine system is a finely tuned instrument, and the therapy designed to support it must be equally precise. Understanding the framework that ensures this precision is the first step in becoming an active, informed participant in your own health narrative.

The journey to reclaiming your vitality is yours alone, yet it is supported by this invisible architecture of quality. Let this understanding be a source of confidence as you move forward, empowering you to ask meaningful questions and make choices that are in true alignment with your wellness goals.