Fundamentals

You may have held in your hand a vial or cream prescribed by your physician that did not come in the familiar packaging of a large pharmaceutical brand. This experience, the delivery of a medication formulated for your specific biological requirements, is a direct connection to the world of pharmaceutical compounding.

It is a deliberate and precise medical practice, grounded in the understanding that your body’s needs are unique. The journey to reclaim your vitality, especially when navigating the complexities of hormonal or metabolic health, often begins with such a personalized therapeutic agent. Understanding the origins of these custom formulations is a foundational step in becoming an informed, empowered participant in your own wellness protocol.

The legal framework that ensures the safety and integrity of these specialized medications is rooted in federal law, specifically the Drug Quality and Security Act (DQSA) of 2013. This legislation created two distinct categories of compounding facilities, known as 503A and 503B.

Appreciating the roles of these two types of facilities is essential for anyone engaged in a sophisticated health protocol, such as hormone optimization or peptide therapy. Each designation represents a different model of production, regulation, and distribution, tailored to meet different needs within the healthcare system. The law distinguishes them to provide clear pathways for both highly individualized patient care and the broader needs of medical practices for reliable, sterile medications.

The Patient-Specific Focus of 503a Facilities

A 503A compounding pharmacy functions as a direct extension of the relationship between you and your prescribing physician. These facilities are authorized to create a drug product based on a valid, patient-specific prescription. Think of this as a truly bespoke formulation.

For instance, if your hormonal panel indicates a need for a precise, non-standard dose of Testosterone Cypionate, or if you require a formulation free of a specific allergen or preservative, a 503A pharmacy is the designated entity to prepare it. Their work is tailored to the individual.

The oversight for these pharmacies is primarily handled at the state level by State Boards of Pharmacy. They operate under guidelines set forth by the United States Pharmacopeia (USP), particularly chapters like USP <795> for non-sterile preparations and USP <797> for sterile ones.

This regulatory structure is designed to ensure safety and quality for medications that are prepared one-by-one, for one person at a time. It is a system built on the premise of personalization, directly serving the nuanced requirements that emerge from a thorough clinical evaluation of your individual physiology.

Federal law categorizes compounding facilities to ensure a safe, reliable supply of both individualized prescriptions and larger-scale sterile medications for clinical use.

The Scale and Scope of 503b Outsourcing Facilities

In contrast, 503B facilities operate on a different scale and for a different purpose. These are designated as “outsourcing facilities” and are permitted to produce large batches of compounded drugs without first receiving patient-specific prescriptions. Your physician’s clinic might, for example, source its entire stock of a specific peptide combination, like CJC-1295/Ipamorelin, or vials of Gonadorelin from a 503B facility.

This allows healthcare providers to maintain a supply of commonly used sterile medications for in-office administration, ensuring that treatments are available to patients when they are needed.

Because they produce medications in bulk, 503B facilities are held to a more stringent federal standard of regulation. They must register directly with the Food and Drug Administration (FDA) and adhere to Current Good Manufacturing Practices (cGMP). These are the same rigorous standards that large pharmaceutical manufacturers must follow.

This heightened level of oversight is a direct acknowledgment of the increased potential risk associated with large-batch production. The cGMP framework provides a robust system of quality control, process validation, and testing to ensure that every vial in a batch is consistent, pure, and safe. This distinction is what provides the confidence for hospitals and clinics to use these products on a broad scale.

Intermediate

Understanding the fundamental distinction between 503A and 503B facilities lays the groundwork for a more sophisticated appreciation of how your therapeutic protocols are managed. The choice between these facility types is a clinical decision made by your healthcare provider, based on the specific medication, the context of its use, and the overarching goals of your health protocol.

The legal and regulatory differences are directly tied to the concepts of sterility, stability, and quality assurance, which are paramount when dealing with sensitive biochemical agents like hormones and peptides.

The regulatory pathways for 503A and 503B facilities diverge significantly, and these differences have tangible consequences for the medications you receive. A 503A pharmacy operates under the immediate jurisdiction of a state board, focusing on compliance with USP chapters. A 503B outsourcing facility, however, is under the direct and continuous oversight of the FDA.

This federal supervision mandates a much more intensive quality system, which is reflected in the facility’s operations, testing protocols, and the data it must provide about its products.

What Are the Key Regulatory and Operational Distinctions?

The primary divergence in regulatory standards is the mandate for 503B facilities to comply with Current Good Manufacturing Practices (cGMP), while 503A facilities adhere to USP standards. While both frameworks prioritize safety, cGMP is a comprehensive system designed for industrial-scale manufacturing.

It governs every aspect of production, from the sourcing and testing of raw ingredients to the validation of every manufacturing process and the final product’s stability testing. USP standards, while rigorous, are designed to guide the professional practice of pharmacy for preparing individual prescriptions.

A Comparative Look at 503a and 503b Standards

To truly grasp the implications, consider how each type of facility approaches key aspects of medication preparation. The following table illustrates these operational differences, which are dictated by the federal legal framework.

| Attribute | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Regulation | State Boards of Pharmacy | U.S. Food and Drug Administration (FDA) |

| Governing Standard | USP Chapters (e.g. <795>, <797>) | Current Good Manufacturing Practices (cGMP) |

| Production Basis | Requires a patient-specific prescription | Can produce large batches without prescriptions (“for office use”) |

| Batch Size | Limited, based on individual prescription needs | Large, industrial scale |

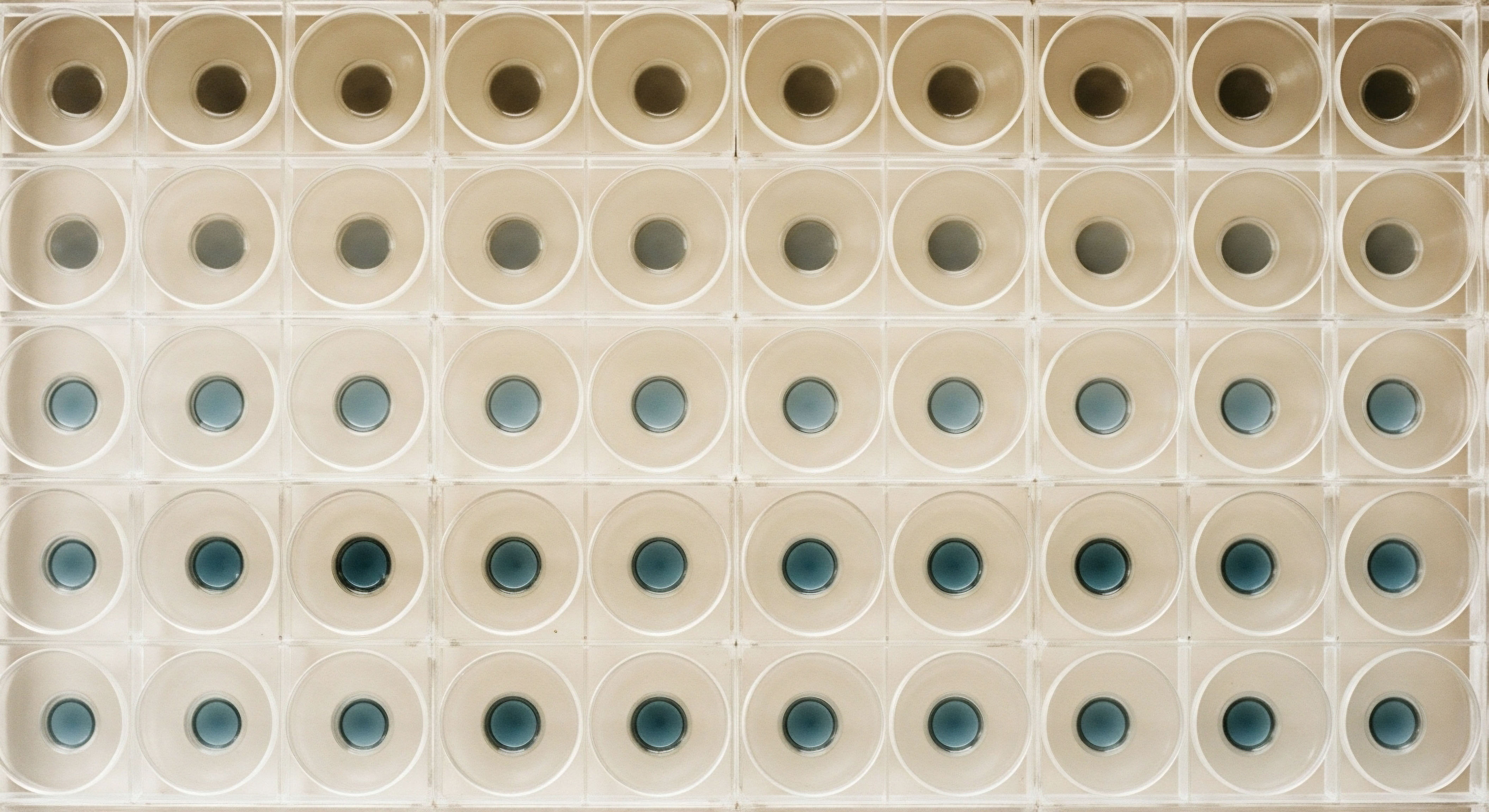

| Sterility Testing | Performed on small batches as required by USP <797> | Mandatory, rigorous testing of every batch produced |

| Beyond-Use Dating (BUD) | Determined by USP guidelines, often shorter durations | Determined by extensive, real-time stability testing, often allowing for longer dating |

Implications for Hormonal and Peptide Therapies

These regulatory distinctions are particularly relevant in the context of hormonal optimization and peptide therapies. The agents used in these protocols, such as Testosterone Cypionate, Anastrozole, Gonadorelin, or peptide blends like Ipamorelin/CJC-1295, are sterile injectables that directly interact with the body’s most sensitive signaling systems. The purity, potency, and sterility of these compounds are therefore of utmost importance.

The federal distinction between compounding facilities directly impacts the quality assurance, stability, and accessibility of personalized medications like hormones and peptides.

A 503B facility’s adherence to cGMP provides a high degree of assurance regarding the quality and consistency of these medications from batch to batch. The mandatory stability testing also means that products from a 503B often have a longer beyond-use date (BUD), which can be a practical advantage for both clinics and patients. This makes 503B-sourced products a reliable choice for clinics that administer these therapies regularly.

Conversely, a 503A pharmacy offers unparalleled customization. If a therapeutic protocol calls for a highly specific dosage that is not available from a 503B, or if a patient has a sensitivity to a preservative used in a batch-produced product, the 503A is the essential partner in care. This facility can create the exact formulation needed, guided by the physician’s prescription and USP standards. This adaptability is critical for true personalization of care.

- Testosterone Replacement Therapy (TRT) for Men ∞ A standard protocol might involve weekly injections of Testosterone Cypionate. A clinic may stock cGMP-produced testosterone from a 503B facility for its consistency and reliability. If a patient requires a specific concentration unavailable from the 503B, a 503A pharmacy would compound it based on his individual prescription.

- Hormone Therapy for Women ∞ A woman on a protocol involving low-dose testosterone and progesterone might receive her medications from a 503A pharmacy. This allows for precise, micro-dosed adjustments as her symptoms and lab values change over time, offering a level of fine-tuning that is the hallmark of personalized medicine.

- Growth Hormone Peptide Therapy ∞ Peptides like Sermorelin or Ipamorelin/CJC-1295 are often used to optimize metabolic function and recovery. Because these are sterile injectables, many clinics prefer to source them from FDA-registered 503B facilities to ensure the highest level of sterility and purity assurance provided by cGMP standards.

Academic

A deep analysis of the federal legal distinction between 503A and 503B compounding facilities reveals more than a simple regulatory division. It reflects a sophisticated public health strategy designed to balance medical innovation with patient safety.

The genesis of the Drug Quality and Security Act (DQSA) in 2013 was a direct response to safety events that highlighted the risks inherent in large-scale sterile compounding without adequate oversight. From a systems-biology perspective, this legal framework can be viewed as an external control system designed to protect the integrity of the most sensitive internal biological systems of the human body, particularly the endocrine system.

The introduction of any exogenous substance, especially a bioactive molecule like a hormone or peptide, represents a significant input into a complex, self-regulating biological circuit. The body’s endocrine system, governed by intricate feedback loops like the Hypothalamic-Pituitary-Gonadal (HPG) axis, is designed to maintain a precise state of homeostasis.

The legal requirement for 503B facilities to adhere to Current Good Manufacturing Practices (cGMP) is a direct acknowledgment of this biological reality. It ensures that the chemical signals being introduced into the body are exactly what they purport to be, in both identity and concentration.

The Molecular Imperative of Current Good Manufacturing Practices (cGMP)

The cGMP regulations detailed in the Code of Federal Regulations (21 CFR Parts 210 and 211) constitute a rigorous quality assurance discipline. This system is designed to prevent harm by minimizing all potential risks in the manufacturing process. For a 503B outsourcing facility producing sterile hormonal preparations, cGMP is a mandate that governs the entire lifecycle of the product.

How Does cGMP Protect Endocrine Function?

The integrity of a hormonal therapy protocol depends entirely on the molecular quality of the therapeutic agent. Deviations in potency, the presence of impurities, or microbial contamination can have cascading negative effects on the endocrine system. The cGMP framework directly mitigates these risks through several key requirements.

- Raw Material Validation ∞ cGMP requires that all raw active pharmaceutical ingredients (APIs) and excipients be rigorously tested for identity, purity, and quality before they are ever used in production. For a patient on TRT, this means the Testosterone Cypionate API has been verified, ensuring it is not a different ester and is free from contaminants that could cause an inflammatory response or disrupt other metabolic pathways.

- Process Validation ∞ Every step of the manufacturing process, from weighing and mixing to sterilization and filling, must be validated. This means the facility must prove that its processes consistently produce a product of a specified quality. This ensures that the 200mg/mL concentration of Testosterone Cypionate in one vial is identical to the next, preventing unintended under-dosing or over-dosing that could destabilize the HPG axis.

- Finished Product and Stability Testing ∞ Every batch of a drug produced by a 503B facility must undergo comprehensive testing for sterility, potency, and purity before it can be released. Furthermore, stability testing is performed to scientifically determine the product’s beyond-use date (BUD). This data provides clinical confidence that the hormone or peptide will remain stable and effective throughout its shelf life, a critical factor for ensuring consistent therapeutic outcomes.

The stringent cGMP standards governing 503B facilities are a direct regulatory extension of the biological need for precision in modulating the endocrine system.

The Hypothalamic-Pituitary-Gonadal Axis as a Case Study

The HPG axis is a prime example of a biological system that demands the precision that cGMP-level manufacturing provides. This axis governs reproductive function and steroidogenesis through a delicate negative feedback loop. The hypothalamus releases Gonadotropin-Releasing Hormone (GnRH), which signals the pituitary to release Luteinizing Hormone (LH) and Follicle-Stimulating Hormone (FSH). LH then signals the gonads to produce testosterone. Rising testosterone levels, in turn, signal the hypothalamus and pituitary to decrease their output, thus maintaining equilibrium.

When a patient begins a TRT protocol, the introduction of exogenous testosterone disrupts this natural loop. The body senses sufficient testosterone and reduces its own production of GnRH and LH. This is why protocols often include agents like Gonadorelin (a GnRH analog) or Clomiphene to maintain the function of the natural signaling pathway.

The success of such a multi-component protocol rests on the absolute accuracy of each compounded drug. An inaccurately dosed vial of testosterone or an impure batch of Gonadorelin could lead to either insufficient therapeutic effect or an excessive shutdown of the natural system, producing a host of undesirable clinical outcomes. The federal legal distinction, by mandating cGMP for large-batch producers, creates a reliable supply chain for the very tools needed to safely and effectively modulate these intricate systems.

| cGMP Control Requirement | Biological Rationale within TRT Protocol |

|---|---|

| Potency Assay of Finished Product | Ensures the dose of exogenous testosterone is precise, allowing for predictable suppression of the HPG axis and stable serum levels. Prevents symptoms of under or over-dosing. |

| Sterility and Endotoxin Testing | Prevents injection-site reactions and systemic inflammation. Inflammatory cytokines can disrupt hormonal signaling and overall metabolic health, confounding the goals of therapy. |

| Impurity Profiling | Guarantees the absence of unknown related compounds or synthetic byproducts that could have unintended biological activity, potentially interacting with other receptors or metabolic enzymes. |

| Identity Testing of API | Confirms the therapeutic agent is exactly what is specified (e.g. Testosterone Cypionate vs. Enanthate), which have different pharmacokinetic profiles. This is crucial for maintaining steady-state hormone levels. |

References

- Kaylor, Alivia. “Understanding the differences between 503A, 503B compounding pharmacies.” TechTarget, 10 June 2024.

- Revelation Pharma. “Understanding the Differences Between 503A and 503B Compounding Pharmacies.” Revelation Pharma Corporation, 26 July 2024.

- “503A vs. 503B ∞ A Quick-Guide to Compounding Pharmacy Designations & Regulations.” American Pharmaceutical Review, 16 November 2021.

- “503A Vs. 503B Compounding Pharmacies ∞ Similarities & Differences.” Fagron, Accessed July 2024.

- U.S. Food and Drug Administration. “FD&C Act Provisions that Apply to Human Drug Compounding.” FDA.gov, 13 August 2021.

- U.S. Food and Drug Administration. “Guidance for Entities Considering Whether to Register As Outsourcing Facilities Under Section 503B.” FDA.gov, August 2021.

- United States Pharmacopeia. “General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations.” USP.org.

- Gudeman, Jennifer, et al. “Potential Risks of Pharmacy Compounding.” Drugs in R&D, vol. 13, no. 1, 2013, pp. 1-8.

- Ashcroft, Richard E. “The Troubled Relationship Between Therapeutic Need and the Regulation of Compounded Drugs.” The Journal of Law, Medicine & Ethics, vol. 42, no. 3, 2014, pp. 273-280.

Reflection

The knowledge of how federal law distinguishes compounding facilities is more than an academic exercise. It is a practical tool for navigating your own health. This framework, born from a need to protect public health, provides the structure within which your personalized medical protocols exist.

It offers a way to understand the origins and quality assurances behind the very therapies designed to recalibrate your biological systems. As you move forward, this understanding becomes a critical component of your dialogue with your clinical team.

Consider the journey you are on. It is a collaborative process between you and your physician, built on data, trust, and a shared goal of optimizing your function and vitality. How can this new layer of knowledge enhance that partnership?

When you understand the difference between a patient-specific compound from a 503A pharmacy and a cGMP-verified product from a 503B facility, you are better equipped to ask insightful questions. You can discuss the clinical reasoning behind why one source is chosen over another for a specific part of your protocol.

This deeper engagement transforms you from a passive recipient of care into an active, informed steward of your own health. The ultimate goal is a body that functions with resilience and a life lived with vitality. This understanding is a step toward that outcome.

Glossary

peptide therapy

patient-specific prescription

503a compounding pharmacy

testosterone cypionate

503a pharmacy

503b facilities

503b facility

current good manufacturing practices

food and drug administration

process validation

503b outsourcing facility

good manufacturing practices

stability testing

hormonal optimization

sterile injectables

503b compounding

sterile compounding

endocrine system

hypothalamic-pituitary-gonadal (hpg) axis

503b outsourcing