Fundamentals

You have arrived at this question from a place of deep personal inquiry. The search for hormonal and metabolic balance is often born from a feeling that your body’s internal symphony is playing out of tune.

You might be experiencing a persistent lack of energy, a change in your body composition that diet and exercise cannot seem to touch, or a subtle cognitive fog that clouds your focus. These are not isolated symptoms; they are signals from a complex, interconnected system.

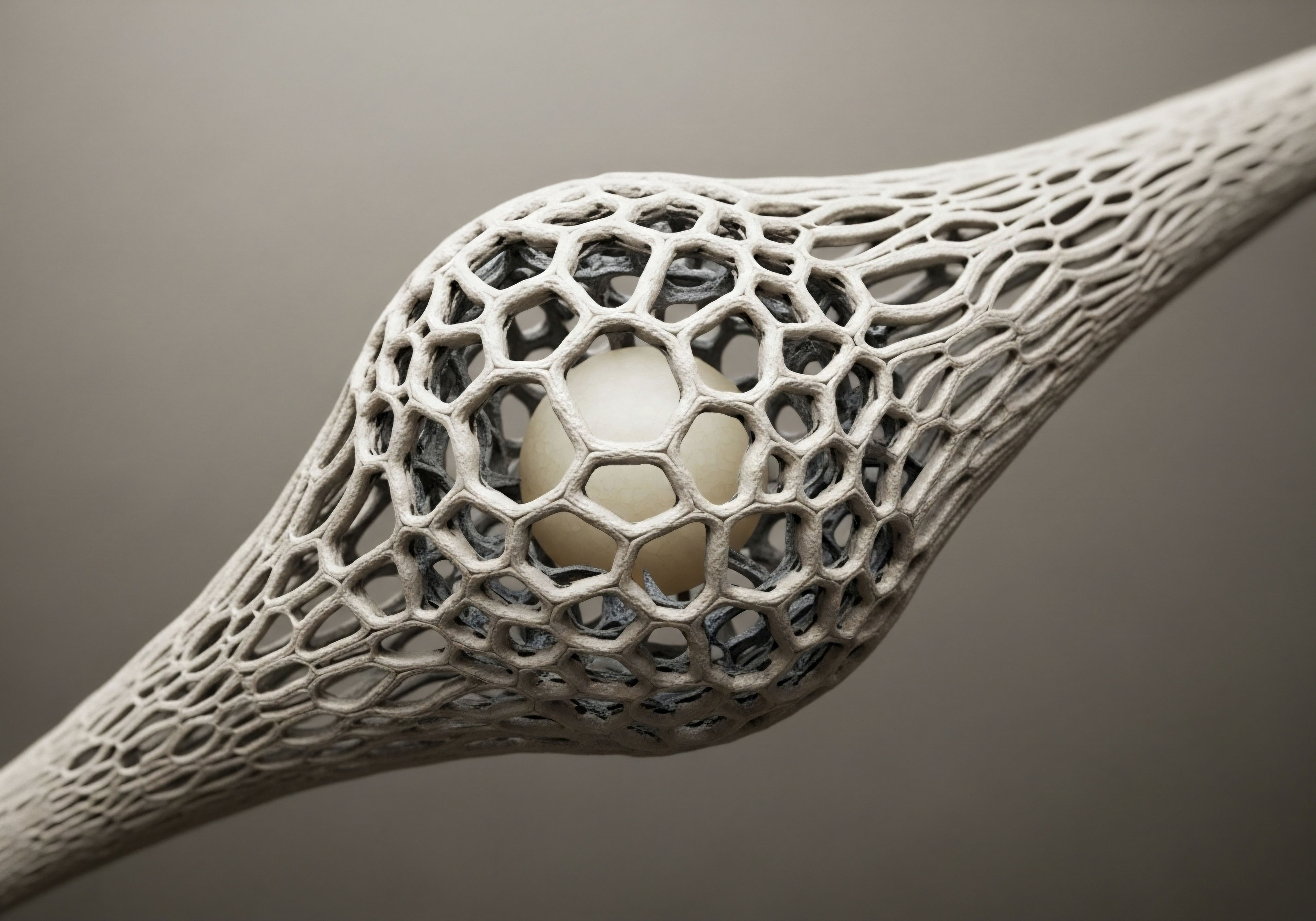

In seeking solutions like compounded peptides ∞ powerful signaling molecules such as Sermorelin, Ipamorelin, or BPC-157 ∞ you are looking to provide your body with the precise instructions it needs to restore its own inherent function. Your question about quality assurance is therefore a profound one.

You are asking if the message in the bottle will be clear, pure, and effective, or if it will be garbled, contaminated, or inert. Understanding how State Boards of Pharmacy ensure the quality of these specific compounds is central to trusting this process of biological restoration.

The primary guardians of this trust at the local level are the State Boards of Pharmacy. Each state has its own board, a regulatory body responsible for licensing pharmacists and pharmacies and enforcing the rules that govern their practice. Their mandate is to protect public health.

For compounded peptides, which are injectable and must be sterile, this responsibility is exceptionally high. They are the frontline defense, ensuring the pharmacy you use is operating safely and competently. Their authority is derived from state law, which means that the specifics of oversight can vary from one state to another, a point of significant importance for any patient.

Some states may have more stringent inspection schedules or specific requirements that go beyond the national baseline. This variability underscores the importance of understanding the framework within which your pharmacy operates.

These state boards do not operate in a vacuum. They build their regulations upon a foundation laid by federal bodies and non-governmental standards organizations. The U.S. Food and Drug Administration (FDA) sets the broad federal laws governing drugs, including the foundational distinction between manufactured drugs and compounded preparations.

Alongside the FDA, the United States Pharmacopeia (USP) creates the detailed, science-based standards for compounding. Think of the USP as the author of the technical manuals that pharmacies must follow. Chapters like USP General Chapter <797> provide the exacting protocols for sterile compounding, which is the process used for injectable peptides.

State Boards of Pharmacy typically adopt these USP standards into their own state regulations, making them legally enforceable during an inspection. Therefore, a state board inspector visiting a compounding pharmacy is there to verify, in person, that the pharmacy is adhering to these meticulous standards designed to protect you.

The Core Distinction Compounded versus Manufactured

To appreciate the role of the state board, one must first understand the unique nature of a compounded medication. A commercially manufactured drug, like a common antibiotic tablet, is produced in a large factory, undergoes a rigorous, multi-year FDA approval process for safety and efficacy, and is made in massive, identical batches. Every pill is expected to be the same.

A compounded peptide, conversely, is created in a pharmacy for a specific patient or, in some cases, for office use by a physician. This process is essential when a patient requires a specific dosage, a combination of ingredients, or a formulation free of a particular allergen ∞ needs that cannot be met by a mass-produced product.

Peptides, for instance, are often compounded to specific concentrations and may be combined with other substances to optimize their stability or therapeutic effect. This customization is a powerful tool in personalized medicine. It also places the responsibility for quality, safety, and stability squarely on the shoulders of the compounding pharmacist and their facility, which is precisely what the State Board of Pharmacy is there to regulate.

A state board’s primary function is to translate national quality standards into enforceable local rules that protect patients receiving customized medications.

The board’s oversight ensures that the pharmacist preparing your peptide therapy is not just a dispenser of medicine, but a skilled practitioner working in a controlled environment. They are verifying that the pharmacy has the proper equipment, the correct procedures, and the necessary training to create a preparation that is both sterile and potent.

This oversight is the structural framework that supports the trust you place in a personalized therapeutic protocol. It is the system designed to ensure the message your body receives from a peptide is the one your physician intended.

What Are State Boards Looking For?

When a State Board of Pharmacy inspector enters a compounding facility, their evaluation is comprehensive. They are not simply checking paperwork; they are assessing the entire ecosystem of sterile production. Their checklist is long and detailed, guided by the standards set forth in USP <797>. This includes:

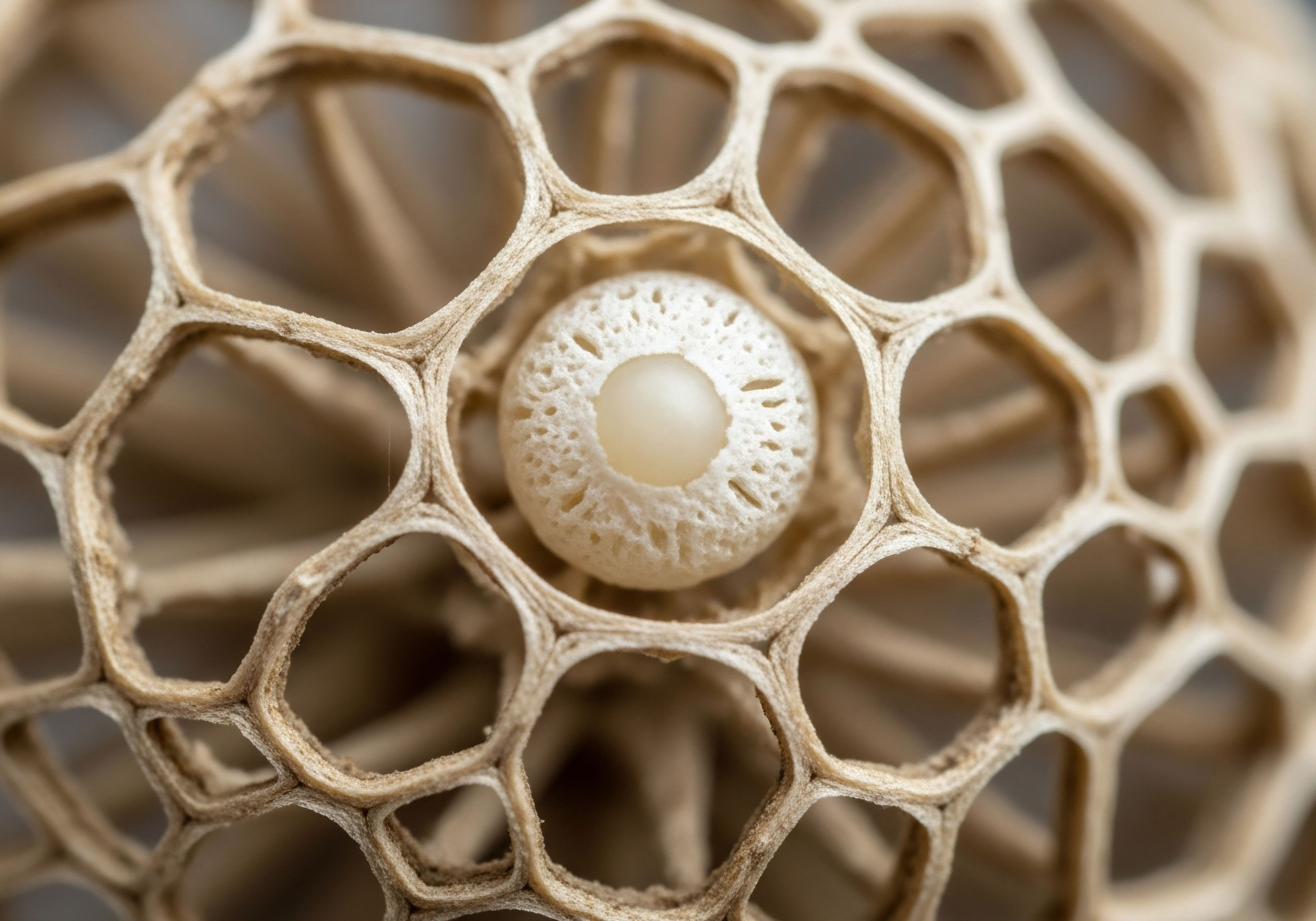

- Environmental Controls ∞ The physical space itself is the first line of defense against contamination. Inspectors verify the design and maintenance of the cleanroom, including the buffer areas and ante-rooms. They check air quality, pressure differentials between rooms, and the certification of primary engineering controls like laminar airflow hoods where the actual compounding takes place. These controls are designed to create a sterile field, minimizing the introduction of microbes or particulates into the final product.

- Personnel Training and Competency ∞ The most sophisticated cleanroom is only as good as the people working within it. Inspectors review training logs and competency assessments. They ensure that pharmacy staff have been properly trained in aseptic technique ∞ the set of practices used to prevent contamination. This includes observing proper hand hygiene, garbing procedures (donning sterile gowns, gloves, masks, and hair covers), and the meticulous, deliberate movements required to handle sterile vials, syringes, and needles without compromising their integrity.

- Standard Operating Procedures (SOPs) ∞ A well-run pharmacy operates on a set of detailed, written procedures that cover every aspect of the compounding process. Inspectors will review these SOPs to ensure they are complete, compliant with USP standards, and reviewed annually. These documents are the pharmacy’s rulebook, covering everything from how raw ingredients are received and stored to how final products are labeled and tested.

- Quality Control and Testing ∞ The board ensures the pharmacy has a robust quality assurance program. This involves verifying that the pharmacy performs necessary testing on its preparations. For sterile compounds like peptides, this can include sterility testing to confirm the absence of microbial contamination and endotoxin testing to check for fever-inducing bacterial byproducts. They also check how the pharmacy establishes beyond-use dates (BUDs), which determine how long a compounded preparation can be safely used.

This foundational level of oversight by State Boards of Pharmacy creates the baseline for safety and quality in compounded peptides. It is the system that validates the science and skill required to translate a physician’s prescription into a pure, sterile, and effective therapeutic agent, allowing you to focus on your journey toward hormonal and metabolic wellness with confidence.

Intermediate

Building upon the foundational understanding of their role, we can now examine the specific mechanisms and standards that State Boards of Pharmacy enforce to ensure peptide quality. The regulatory framework is a layered, sophisticated system designed to mitigate risk at every step of the compounding process.

For a patient embarking on a protocol involving peptides like Tesamorelin for metabolic health or Ipamorelin/CJC-1295 for growth hormone optimization, the integrity of these molecules is paramount. The body’s endocrine system operates on a principle of exquisite sensitivity; the right molecular key must fit the right lock. A state board’s enforcement of detailed compounding standards is what ensures the key is cut correctly and is free of imperfections that could jam the lock or trigger a systemic alarm.

The central pillar of this enforcement is the adoption and inspection against the United States Pharmacopeia (USP) General Chapters. Specifically, for sterile injectable peptides, USP <797> is the authoritative standard. Many state pharmacy laws explicitly reference and mandate compliance with this chapter.

When an inspector from a State Board of Pharmacy conducts an audit, they are using USP <797> as their yardstick to measure the pharmacy’s ability to prevent microbial contamination, ensure stability, and maintain the intended potency of the final preparation. This is a granular, evidence-based process that leaves little room for error.

Deep Dive into USP 797 Sterile Compounding

USP <797> organizes its guidelines around the potential for contamination, categorizing compounded sterile preparations (CSPs) into different risk levels. Most patient-specific peptide compounds fall into Category 1 or Category 2, which dictates the specific environmental controls and beyond-use dating (BUD) that must be applied. The chapter provides a comprehensive roadmap for quality.

A state board inspector will systematically verify each of the following domains:

Facility Design and Environmental Monitoring

The physical environment is a critical control point. A pharmacy is not just a room with a counter; it is a controlled airspace designed to progressively reduce particulate and microbial counts. An inspector verifies this through several checks:

- Primary Engineering Controls (PECs) ∞ This is the sterile hood (e.g. a laminar air flow workbench or biological safety cabinet) where the pharmacist handles open vials and syringes. It must be certified to meet ISO Class 5 air quality standards, meaning the air inside has an extremely low number of particles. The inspector checks the certification paperwork, which must be done every six months.

- Secondary Engineering Controls (SECs) ∞ This refers to the buffer room (the cleanroom itself) and the ante-room. The buffer room housing the PEC must maintain ISO Class 7 air quality, and the ante-room must meet ISO Class 8 standards. The inspector will review reports from air quality testing and check the pressure gauges that ensure air flows from the cleanest space to the less clean spaces, preventing contaminants from entering the sterile compounding area.

- Surface Sampling ∞ Inspectors review logs of routine environmental monitoring. The pharmacy must regularly test surfaces within the PEC, in the buffer room, and in the ante-room for microbial contamination. This active surveillance demonstrates that their cleaning and disinfection protocols are effective. If a sample shows growth, the pharmacy must have a record of their corrective action.

Personnel Garbing and Aseptic Technique

Humans are the primary source of contamination in a cleanroom. USP <797> provides, and inspectors enforce, strict protocols for gowning and sterile manipulation.

- Gloving and Garbing ∞ The inspector will review the pharmacy’s procedures and training records for garbing, which includes donning shoe covers, hair bonnets, face masks, and sterile gowns before entering the buffer room. The final step is applying sterile gloves, which are regularly sanitized with sterile alcohol during the compounding process.

- Competency Validation ∞ Pharmacists and technicians cannot just claim they know what they are doing. They must prove it. The inspector will review documentation of initial and ongoing competency testing. This includes the “gloved fingertip and thumb sampling,” where a compounder presses their gloved fingertips onto a sterile growth medium after compounding. The sample is incubated, and any microbial growth indicates a flaw in their technique. They must also pass a “media-fill test,” which involves simulating the entire compounding process using a sterile growth medium instead of actual drugs. A clear, uncontaminated media-fill test demonstrates that the person’s technique is aseptic.

The Critical Divide 503a and 503b Pharmacies

A crucial aspect of the regulatory landscape that state boards navigate is the distinction between 503A and 503B compounding facilities, established by the Drug Quality and Security Act (DQSA). This distinction directly impacts the scale, oversight, and type of compounded peptides available.

A 503A pharmacy is a traditional compounding pharmacy that formulates medications based on a prescription for an individual patient. These are primarily regulated by State Boards of Pharmacy, which enforce USP standards. They are not required to register with the FDA, though the FDA can inspect them under certain circumstances.

A 503A pharmacy is what you would use for a truly personalized prescription, such as a specific dose of Testosterone Cypionate combined with Anastrozole in a single injection, tailored to your lab results.

A 503B facility, often called an “outsourcing facility,” can manufacture large batches of compounded drugs without patient-specific prescriptions. These facilities function more like pharmaceutical manufacturers. Because they produce on a larger scale, they are subject to a higher level of federal oversight.

They must register with the FDA and are held to the FDA’s Current Good Manufacturing Practices (cGMP). cGMP requirements are more extensive than USP <797>, involving much more rigorous process validation and testing. A 503B facility might produce a large batch of a commonly prescribed peptide, like Ipamorelin, that hospitals or clinics can then purchase for office use.

The choice between a 503A and 503B pharmacy involves a trade-off between personalized formulation and large-scale quality-assured production.

State Boards of Pharmacy license and inspect both types of facilities within their borders, but their interaction with the FDA is different for each. For 503A pharmacies, the state board is the principal regulator. For 503B facilities, there is a dual oversight model, where the state board ensures compliance with state laws and pharmacy practice standards, while the FDA enforces the stricter cGMP regulations.

The following table illustrates the key differences that a state board and a patient should be aware of:

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Oversight | State Boards of Pharmacy | U.S. Food and Drug Administration (FDA) |

| Prescription Requirement | Required for each specific patient | Can produce without patient-specific prescriptions |

| Quality Standard | USP <795> (non-sterile) & <797> (sterile) | Current Good Manufacturing Practices (cGMP) |

| Batch Production | Small batches based on prescriptions | Large batches for office stock and institutional use |

| Interstate Distribution | Limited (typically <5% of total prescriptions unless an MOU with FDA exists) | Permitted nationwide |

Understanding this regulatory structure is vital. When you receive a peptide, knowing whether it came from a 503A or 503B facility gives you insight into the specific quality system under which it was produced. State Boards of Pharmacy are the linchpin in this system, ensuring that whichever type of pharmacy you use, it is held accountable to the appropriate standards, safeguarding the quality of the delicate hormonal messengers you are entrusting to your body.

Academic

The regulatory oversight provided by State Boards of Pharmacy represents a complex public health interface between pharmaceutical science and clinical practice. While the enforcement of USP standards like <797> and <800> establishes a critical framework for ensuring the sterility and safety of compounded peptides, a deeper, academic exploration reveals the profound biochemical and physiological implications of quality control failures.

The conversation must extend beyond microbial contamination to the molecular fidelity of the peptide itself and the insidious threat of non-microbial contaminants like endotoxins. For the patient, the difference between a successful therapeutic outcome and a failed cycle or an adverse inflammatory event lies at this molecular level. A state board’s ability to ensure quality is, therefore, a direct gatekeeper of biological efficacy.

The Specter of Endotoxins a Deeper Look

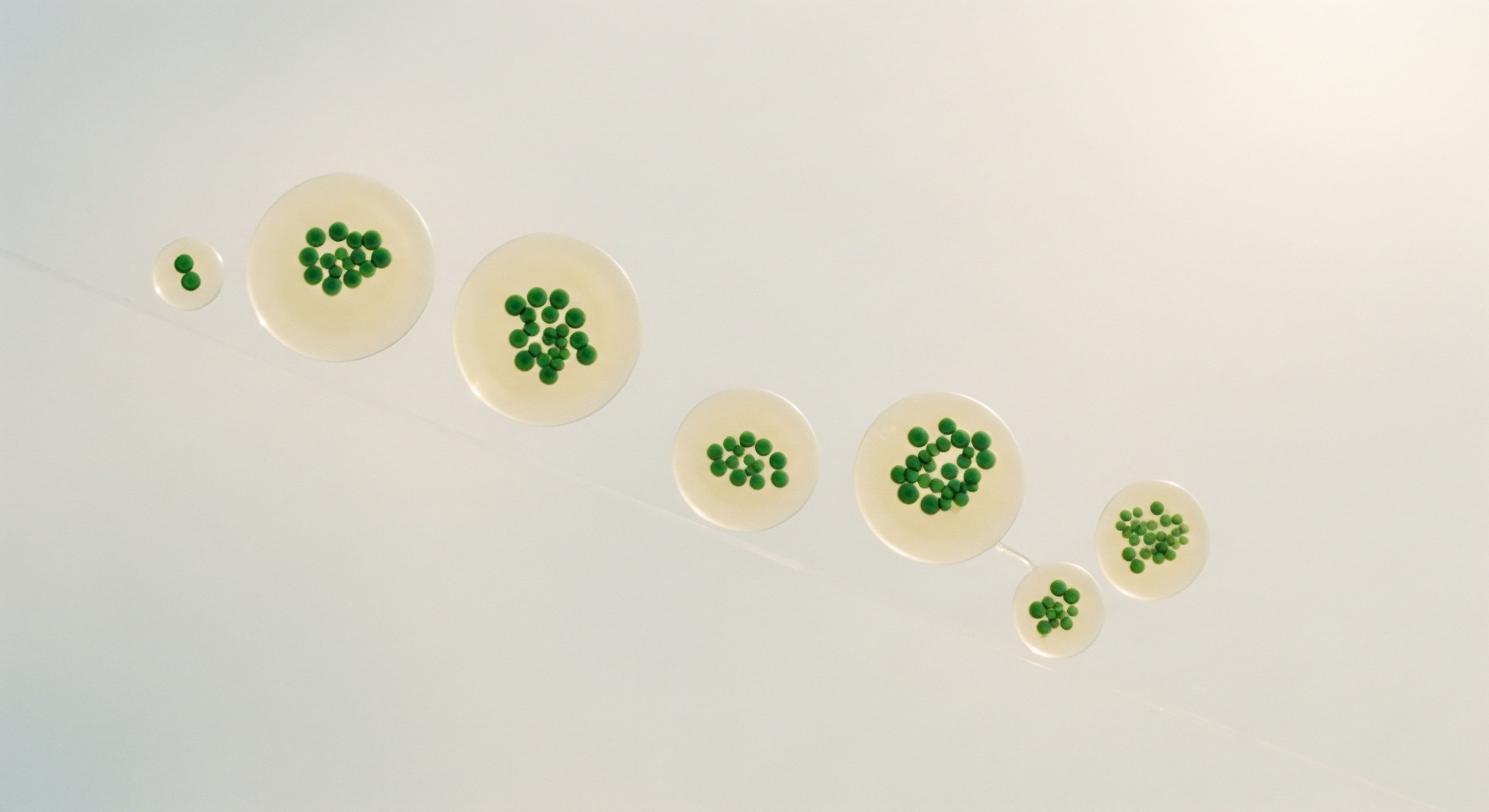

Sterility, as defined by the absence of viable microorganisms, is a foundational requirement. The more subtle and challenging threat in sterile preparations comes from endotoxins. Endotoxins are lipopolysaccharides (LPS), structural components of the outer membrane of Gram-negative bacteria.

These molecules are shed when bacteria die and lyse, and because Gram-negative bacteria are ubiquitous in environments like water and air, endotoxin contamination is a persistent risk in any compounding process. Even if a final preparation is successfully sterilized, killing all bacteria, the heat-stable endotoxin molecules can remain.

Why is this critically important for peptide therapies? The human immune system has evolved a hyper-vigilant detection system for LPS. Toll-like receptor 4 (TLR4), present on the surface of immune cells like macrophages and monocytes, is a pattern recognition receptor that specifically binds to the lipid A portion of the endotoxin molecule.

This binding event acts as a powerful biological alarm, initiating a potent pro-inflammatory cascade. Even picogram-per-milliliter concentrations of endotoxin in the bloodstream can trigger the release of a storm of cytokines, including Tumor Necrosis Factor-alpha (TNF-α), Interleukin-1 (IL-1), and Interleukin-6 (IL-6).

For a patient using peptides to optimize health, reduce inflammation, or improve metabolic function, an endotoxin-contaminated injection can produce the exact opposite of the desired effect. The clinical presentation of an endotoxin response can range from localized injection site redness and swelling to systemic symptoms like fever, chills, myalgia, and malaise, which can be easily mistaken for a viral illness or an unrelated condition.

In severe cases, high endotoxin loads can lead to septic shock, a life-threatening condition of systemic inflammation and cardiovascular collapse. This is why USP <797> mandates endotoxin testing for certain categories of compounded sterile preparations. State Boards of Pharmacy, in their inspections, verify that pharmacies are either using sterile, pyrogen-free ingredients or are performing the necessary tests, such as the Limulus Amebocyte Lysate (LAL) assay, on their final products to ensure they do not exceed established endotoxin limits.

Molecular Fidelity the Challenge of Peptide Impurities

Beyond sterility and pyrogenicity lies the question of the active pharmaceutical ingredient (API) itself. The therapeutic effect of a peptide like Sermorelin, a 29-amino-acid fragment of growth hormone-releasing hormone (GHRH), depends on its precise amino acid sequence and three-dimensional structure, which allow it to bind perfectly to the GHRH receptor in the pituitary gland. Any deviation in this structure can render the peptide ineffective or, in some cases, cause unintended biological effects.

Solid-phase peptide synthesis (SPPS), the method used to create most therapeutic peptides, is a complex, multi-step chemical process. Despite technological advancements, it is not perfect. Several types of impurities can be introduced:

- Deletion Sequences ∞ An amino acid is missed during a coupling cycle, resulting in a shorter, incomplete peptide chain.

- Truncation Sequences ∞ The peptide chain is capped and stops growing prematurely.

- Insertion Sequences ∞ An amino acid is unintentionally added twice.

- Diastereomeric Impurities ∞ The chirality of an amino acid is inverted during the synthesis process, altering the peptide’s 3D structure.

These impurities can have significant consequences. A deletion or truncation sequence might fail to bind to the target receptor at all, resulting in a product with low potency. The patient would experience a lack of therapeutic effect, believing the therapy itself has failed, when in fact the compounded product was substandard.

More concerning is the potential for an impurity to act as a competitive antagonist, binding to the receptor without activating it, thereby blocking the action of the correct peptide molecule. This is a level of quality control that is exceptionally difficult for a State Board of Pharmacy to directly assess during a routine inspection. They cannot perform mass spectrometry on every batch of peptides a pharmacy compounds.

Instead, their oversight relies on a system of proxies and documentation. The board will:

- Verify Supplier Credentials ∞ The inspector will check that the pharmacy is purchasing its peptide APIs from reputable suppliers who provide a Certificate of Analysis (CofA) for each batch. This CofA should detail the purity of the peptide (typically determined by High-Performance Liquid Chromatography, or HPLC), its identity (confirmed by Mass Spectrometry), and its endotoxin content.

- Review Compounding Records ∞ The inspector will examine the Master Formulation Record and the individual Compounding Record for a given preparation. This documentation should show that the pharmacist used the correct calculations and procedures to reconstitute and dilute the API, minimizing the chance for error.

- Assess Potency Testing Protocols ∞ For certain preparations, particularly those made in larger batches or stored for longer periods, the pharmacy may be required to send samples to a third-party analytical lab for potency testing. The inspector reviews these lab reports to ensure the final product contains the amount of peptide specified on the label.

The following table details the potential failures in peptide quality and the corresponding regulatory checks performed by state boards:

| Point of Failure | Potential Consequence for Patient | State Board of Pharmacy Verification Method |

|---|---|---|

| Microbial Contamination | Localized or systemic infection, sepsis. | Inspection of cleanroom (USP <797>), personnel technique, and review of sterility test results. |

| Endotoxin (LPS) Contamination | Fever, inflammation, malaise, septic shock. | Review of ingredient sourcing (pyrogen-free) and review of LAL endotoxin testing results. |

| Peptide Impurities (e.g. deletions) | Lack of efficacy, failed therapeutic cycle. | Review of API supplier Certificate of Analysis (CofA), which should include HPLC purity data. |

| Incorrect Potency (Dose) | Sub-therapeutic effect or exaggerated side effects. | Audit of compounding records and calculations; review of third-party potency testing reports. |

This academic perspective reveals that ensuring compounded peptide quality is a multi-faceted challenge. State Boards of Pharmacy serve as the critical auditors of a complex system of process controls and documentation. While they may not analyze the peptides directly, their enforcement of USP standards and their scrutiny of a pharmacy’s sourcing and quality control records are the most effective tools available to protect patients.

Their work ensures that the highly specific, potent, and delicate molecular messengers that form the basis of modern peptide therapy can be administered with a high degree of confidence in their safety and integrity.

References

- Gudeman, J. Jozwiakowski, M. Chollet, J. & Randell, M. (2013). Potential Risks of Pharmacy Compounding. Drugs in R&D, 13(1), 1 ∞ 8.

- The Pew Charitable Trusts. (2016). State Oversight of Drug Compounding. The Pew Charitable Trusts.

- U.S. Food and Drug Administration. (2018). Compounding and the FDA ∞ Questions and Answers. FDA.gov.

- Kastango, E. S. & Bradshaw, B. D. (2014). USP Chapter <797> ∞ The new testament for sterile compounding. International Journal of Pharmaceutical Compounding, 8(4), 263-269.

- Brandenburg, K. Hein, M. Schromm, A. B. & Gutsmann, T. (2019). Biophysical Mechanisms of Endotoxin Neutralization by Cationic Amphiphilic Peptides. Biophysical Journal, 116(3), 59a.

- Allen, L. V. (2013). The Art, Science, and Technology of Pharmaceutical Compounding. American Pharmacists Association.

- National Academies of Sciences, Engineering, and Medicine. (2020). The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of the Evidence. National Academies Press.

- Parenteral Drug Association (PDA). (2012). Technical Report No. 3 ∞ Validation of Dry Heat Processes Used for Sterilization and Depyrogenation.

- United States Pharmacopeial Convention. (2019). General Chapter <800> Hazardous Drugs ∞ Handling in Healthcare Settings.

- Tita, B. Morganti, P. & Tita, D. (2011). Compounded non-sterile preparations and United States Pharmacopeia (USP) chapter 795. Clinics in Dermatology, 29(3), 269-278.

Reflection

Your Path Forward

The knowledge you now possess about the systems governing peptide quality is itself a form of therapeutic empowerment. You began this inquiry seeking to understand an external process of regulation, and in doing so, you have sharpened your own internal tools for navigating your health.

The journey to reclaim your body’s vitality is deeply personal, yet it occurs within this larger ecosystem of science, medicine, and oversight. The regulations, the cleanrooms, the chemical analyses ∞ they all exist in service of the biological conversation you are trying to have with your own body.

As you move forward, consider how this understanding shapes your dialogue with your physician and your pharmacist. Let it inform your questions, guide your choices, and solidify your confidence as an active, educated participant in your own wellness protocol. Your biology is unique; your path to optimizing it should be built on a foundation of trust and clarity.