Fundamentals

Beginning a personalized wellness protocol is a significant step, one that rests on a foundation of trust. You are placing your confidence in a specific set of molecules, whether it is Testosterone Cypionate to recalibrate your endocrine system, Anastrozole to manage estrogen, or a therapeutic peptide like Sermorelin to optimize cellular function.

You trust that these compounds will interact with your unique biology to restore vitality. The question of how regulatory standards influence compounding pharmacy quality is, at its core, a question of how we honor that trust. These standards are the silent, rigorous guardians of your protocol, ensuring the substance you introduce into your body is precisely what it claims to be.

The entire framework of compounding pharmacy regulation is built to answer one fundamental question ∞ is this medication safe and effective for the patient? To address this, two primary organizations establish the guardrails. The United States Pharmacopeia (USP) is a scientific organization that sets standards for the identity, strength, quality, and purity of medicines.

Concurrently, the Food and Drug Administration (FDA) provides federal oversight, particularly for larger-scale operations. These bodies work to ensure that the medication you receive is consistent, unadulterated, and performs as expected within your physiological systems.

The Two Pillars of Compounding Standards

Within the USP’s extensive guidance, two chapters form the bedrock of daily compounding practices. Each one governs a different type of preparation you might encounter on your health journey.

First, USP General Chapter <795> addresses non-sterile compounding. This applies to medications that are taken orally or applied topically, such as capsules, creams, or oral tablets like Anastrozole. The chapter outlines requirements for the compounding environment, personnel training, and the quality of the ingredients used. It ensures that the oral medications supporting your hormonal therapy are prepared in a clean, controlled manner to deliver the correct dose without introducing contaminants.

Second, and of particular importance for many hormonal and peptide protocols, is USP General Chapter <797> for sterile preparations. Any substance injected into the body, from Testosterone Cypionate to Ipamorelin, must be sterile. This means it must be completely free of microbial contaminants like bacteria or fungi.

USP <797> establishes far more stringent requirements for air quality, facility design, and personnel garbing to prevent contamination that could lead to serious infection. These regulations are a direct acknowledgment of the vulnerability of the body’s internal environment and a commitment to protecting it.

The primary function of regulatory standards is to transform the science of personalized medicine into a safe, reliable, and consistent therapeutic experience for the patient.

Understanding these foundational rules is the first step in appreciating the complex ecosystem of quality control that underpins your treatment. These are not arbitrary regulations; they are a scientifically derived set of procedures designed to protect your health journey at the most fundamental level. They ensure that the potent molecules intended to optimize your biology are the only molecules in the preparation.

Intermediate

Moving beyond the foundational principles, we can examine the specific, tangible practices that regulatory standards mandate within a compounding pharmacy. These are the day-to-day actions and environmental controls that directly translate written rules into a safe, high-quality medication.

For anyone on an injectable protocol involving Testosterone, Gonadorelin, or peptides like CJC-1295, the protocols dictated by USP <797> are of paramount importance. These standards address the critical risks associated with sterile compounding, chiefly the prevention of microbial contamination and the assurance of correct dosage.

The Controlled Sterile Environment

A pharmacy’s sterile compounding area is a meticulously engineered space designed to minimize the introduction of contaminants. This involves a suite of rooms with specific environmental controls. The air itself is subject to rigorous standards, classified according to ISO (International Organization for Standardization) criteria, which measure the number of particles per cubic meter of air.

Compounding must occur within a Primary Engineering Control (PEC), such as a laminar airflow hood, which maintains ISO 5 air quality. This device provides a constant flow of HEPA-filtered air over the workspace, sweeping away potential contaminants and creating a protected zone where vials and syringes can be handled safely.

Personnel entering these areas must follow strict procedures to avoid bringing in contaminants from the outside world. This involves more than simply washing hands; it is a systematic process of garbing.

- Hand Hygiene ∞ This begins with a thorough washing of hands and forearms, followed by the application of a persistent antimicrobial scrub.

- Gowning ∞ Personnel don specific, low-particulate garments in a particular order, including shoe covers, hair and beard covers, face masks, and sterile gowns.

- Sterile Gloves ∞ Sterile gloves are the final layer, donned carefully to avoid touching any non-sterile surfaces. These gloves are regularly sanitized with sterile 70% isopropyl alcohol throughout the compounding process.

How Do We Verify Quality and Safety?

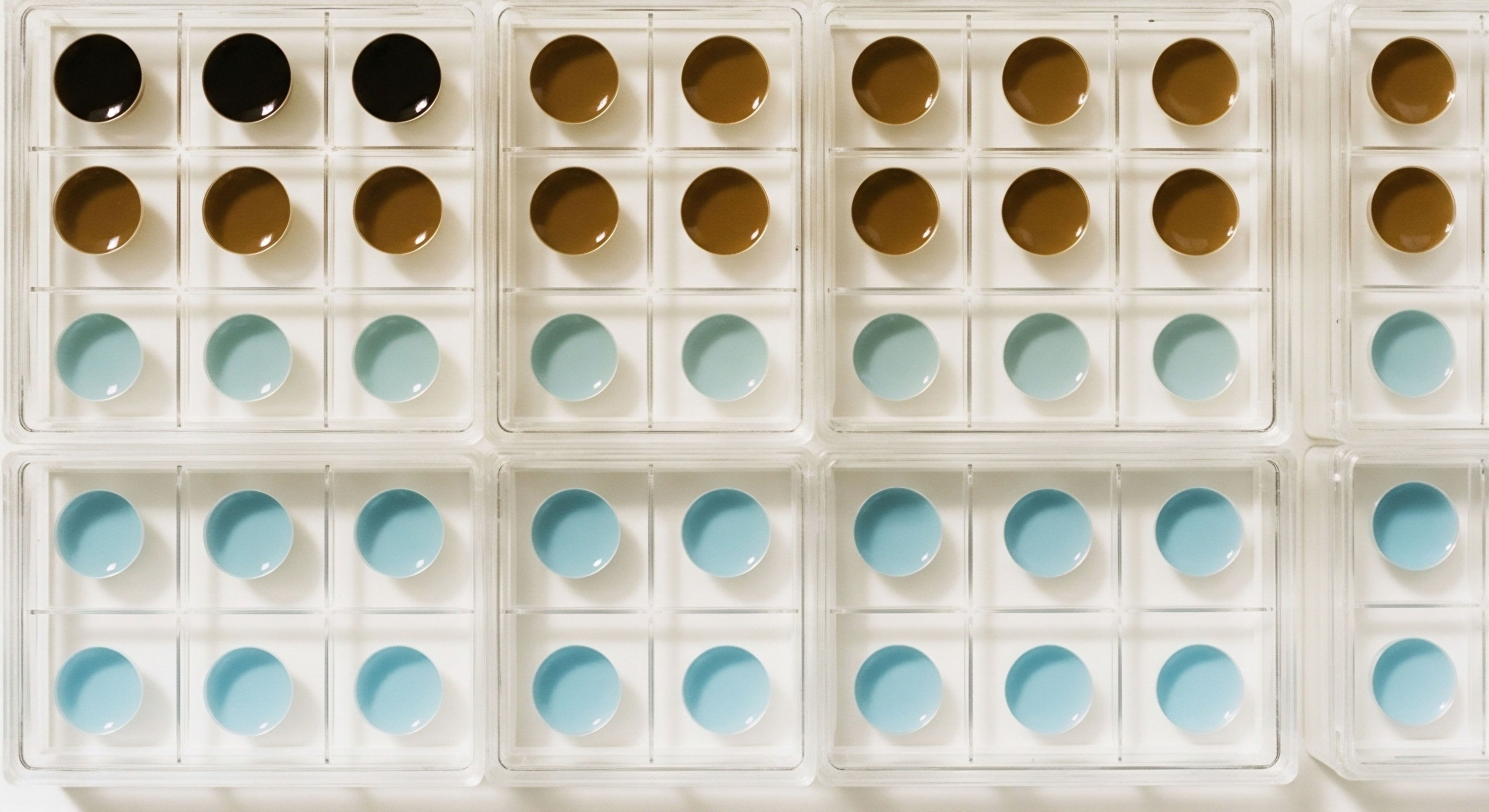

A compounded medication’s quality rests on three pillars ∞ its potency, its sterility, and its purity. Regulatory standards require pharmacies to have robust quality assurance programs to verify each of these components through objective testing.

- Potency Testing ∞ This answers the question, “Does the medication contain the correct amount of the active ingredient?” A pharmacy must be able to prove that a vial of Testosterone Cypionate labeled as 200mg/mL actually contains that specific concentration. The gold standard for this analysis is High-Performance Liquid Chromatography (HPLC), an analytical technique that separates and quantifies the components in a sample. This ensures you are administering the precise dose prescribed for your physiological needs.

- Sterility Testing ∞ This answers the question, “Is the medication free from microbial contamination?” Samples of a compounded preparation are sent to a lab where they are incubated in growth media. If no bacteria or fungi grow over a specified period, the batch is confirmed to be sterile. This is a direct check against the risk of injection-site or systemic infection.

- Endotoxin Testing ∞ This is a further step for sterile preparations. Endotoxins are toxic substances left behind by certain types of bacteria, even if the bacteria themselves have been killed. They can cause fever and severe inflammatory reactions. Testing specifically for endotoxins is another layer of protection for injectable therapies.

Regulatory compliance is demonstrated through meticulous documentation and validated testing, which together provide objective proof of a compounded preparation’s quality.

These intermediate steps show how regulatory guidelines are put into action. They create a system of overlapping safeguards, from the air the pharmacist breathes to the gloves they wear to the analytical tests that verify the final product. It is a system designed to ensure that the therapeutic molecules you rely on are delivered with the highest degree of safety and accuracy.

| Feature | USP <795> (Non-Sterile) | USP <797> (Sterile) |

|---|---|---|

| Primary Goal | Ensure quality and minimize contamination of oral and topical medications. | Prevent harm from microbial contamination in injectable medications. |

| Typical Preparations | Capsules (Anastrozole), Creams, Oral Solutions | Injections (Testosterone, Peptides), IV Admixtures |

| Environment | A designated, clean, and orderly space, separate from sterile areas. | ISO-classified cleanroom suite with positive pressure ante-rooms and ISO 5 PECs. |

| Personnel Garb | Gloves required; gowns and masks may be used based on the preparation. | Full head-to-toe garbing including sterile gloves, gowns, masks, and shoe covers. |

| Quality Testing Focus | Potency, purity, and physical characteristics of the final preparation. | Sterility, potency, and freedom from endotoxins. |

Academic

A sophisticated understanding of compounding quality requires moving beyond the standards set by USP and into the domain of federal regulatory structure and enforcement. The landscape of compounding pharmacy oversight in the United States is bifurcated, a direct result of historical events that necessitated clearer lines of authority.

This division is primarily defined by sections 503A and 503B of the Federal Food, Drug, and Cosmetic (FD&C) Act. The distinction between pharmacies operating under these two sections has profound implications for the scale of production, regulatory burden, and the quality systems they must implement.

The Genesis of a Dual System the 503a and 503b Distinction

The modern framework was shaped by the 2012 New England Compounding Center (NECC) fungal meningitis outbreak, which was linked to contaminated sterile steroid injections and resulted in significant patient harm. This event exposed a regulatory gap where a large-scale compounding operation was functioning more like a drug manufacturer without adhering to the same stringent standards. In response, Congress passed the Drug Quality and Security Act (DQSA), which clarified the FDA’s authority and created the two distinct categories of compounders.

A 503A facility is what most people consider a traditional compounding pharmacy. These pharmacies are licensed by state boards of pharmacy and are permitted to compound medications based on the receipt of a valid, patient-specific prescription. While they are expected to comply with USP chapters <795> and <797>, their primary regulator is the state.

The FDA retains authority to inspect 503A facilities, typically for cause, such as in response to a complaint or if there is evidence of insanitary conditions or production at a scale that mimics manufacturing.

A 503B facility, also known as an “outsourcing facility,” is a different entity altogether. These facilities voluntarily register with the FDA and are permitted to compound large batches of sterile drugs without patient-specific prescriptions, which can then be sold to healthcare providers for “office use.” Because they operate more like manufacturers, 503B facilities are held to a higher standard.

They must comply with Current Good Manufacturing Practices (CGMP), which are the same extensive regulations that conventional pharmaceutical manufacturers must follow. This includes more rigorous process validation, stability testing, and quality control systems than what is outlined in USP <797> alone.

What Is the Impact of CGMP on Quality Assurance?

For a 503B outsourcing facility, adherence to CGMP represents a significant elevation in quality assurance protocols. This is particularly relevant for clinics and patients who use office-stocked supplies of medications like Testosterone Cypionate or peptide therapies. CGMP requires a systems-based approach to quality.

- Process Validation ∞ A 503B facility must prove through extensive documentation and testing that its specific compounding process consistently produces a product of a certain quality. This goes beyond testing a single batch; it validates the entire manufacturing line.

- Stability-Indicating Methods ∞ While a 503A pharmacy might conduct a simple potency test, a 503B facility must use a validated stability-indicating assay. An HPLC method, for example, must be proven to separate the active pharmaceutical ingredient (API) from any potential degradants, impurities, or excipients. This is critical for establishing a scientifically sound beyond-use date (BUD).

- Environmental Monitoring ∞ CGMP requires a more frequent and comprehensive program of environmental monitoring, including both viable (microbial) and non-viable (particulate) air sampling, as well as surface sampling, to ensure the production environment remains in a state of control.

The regulatory classification of a compounding pharmacy dictates the specific quality system it must follow, directly influencing the level of validation and testing applied to its products.

This dual system creates a tiered approach to quality assurance. While a properly managed 503A pharmacy adhering to USP standards provides safe and effective medications for individual patients, a 503B facility provides an additional layer of regulatory scrutiny aligned with large-scale manufacturing. For the end user, understanding where their compounded medication originates provides deep insight into the specific regulatory framework governing its quality.

| Attribute | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Regulation | State Boards of Pharmacy | Food and Drug Administration (FDA) |

| Prescription Requirement | Required for each specific patient. | Not required; can compound for office use. |

| Guiding Quality Standard | USP <795> / <797> | Current Good Manufacturing Practices (CGMP). |

| FDA Registration | Not required. | Voluntary, but required to operate as an outsourcing facility. |

| Adverse Event Reporting | Reporting requirements vary by state. | Mandatory reporting of serious adverse events to the FDA. |

| Scale of Production | Limited to patient-specific quantities. | Permitted to produce large batches. |

References

- United States Pharmacopeial Convention. “General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations.” USP-NF, 2023.

- United States Pharmacopeial Convention. “General Chapter <795> Pharmaceutical Compounding ∞ Nonsterile Preparations.” USP-NF, 2023.

- U.S. Food and Drug Administration. “Compounding Laws and Policies.” FDA.gov, 2024.

- Kupiec, Thomas C. et al. “Stability Versus Potency Testing ∞ The Madness is in the Method.” International Journal of Pharmaceutical Compounding, vol. 12, no. 1, 2008, pp. 50-53.

- U.S. Food and Drug Administration. “Current Good Manufacturing Practice (CGMP) Regulations.” FDA.gov, 2024.

- McDermott Will & Emery. “FDA Publishes Proposed Rule on 503A and 503B Compounding.” JDSupra, 5 Apr. 2024.

- Kastango, Eric S. “Basics of compounding ∞ considerations for implementing United States pharmacopeia chapter 797 pharmaceutical compounding-sterile preparations, part 7 ∞ microbial contamination risk levels, 12-hour use, and immediate use.” International Journal of Pharmaceutical Compounding, vol. 12, no. 3, 2008, pp. 252-7.

- Bharti, Amber, et al. “HPLC Method Development and Validation for the Quantification of Related Impurities in Testosterone Cypionate Active Pharmaceutical Ingredient.” International Journal of Pharmacy and Pharmaceutical Research, vol. 56, no. 1, 2022.

Reflection

The architecture of regulatory standards, from USP chapters to FDA oversight, constructs a vital system of checks and balances. This knowledge does more than simply explain a process; it transforms your relationship with your own therapeutic protocol. You are now equipped with a deeper awareness of the meticulous care required to prepare your personalized medications.

This understanding shifts your position from that of a passive recipient to an informed participant in your health journey. The science of hormonal optimization is a collaborative process between you, your clinician, and the pharmacy that prepares your treatment. Your comprehension of the quality standards that bind this collaboration together is a powerful asset.

It allows you to ask more precise questions and engage with your providers on a more substantive level, ensuring the path you walk toward vitality is built upon a foundation of verifiable quality and mutual confidence.

Glossary

testosterone cypionate

compounding pharmacy

regulatory standards

food and drug administration

your health journey

sterile compounding

microbial contamination

quality assurance

potency testing

outsourcing facility

503b facility

current good manufacturing practices