Fundamentals

Your personal wellness journey is a process of profound self-discovery, driven by a desire to restore your body’s intended state of vitality. When you consider incorporating therapeutic peptides, you are seeking a precise tool to communicate with your own biological systems.

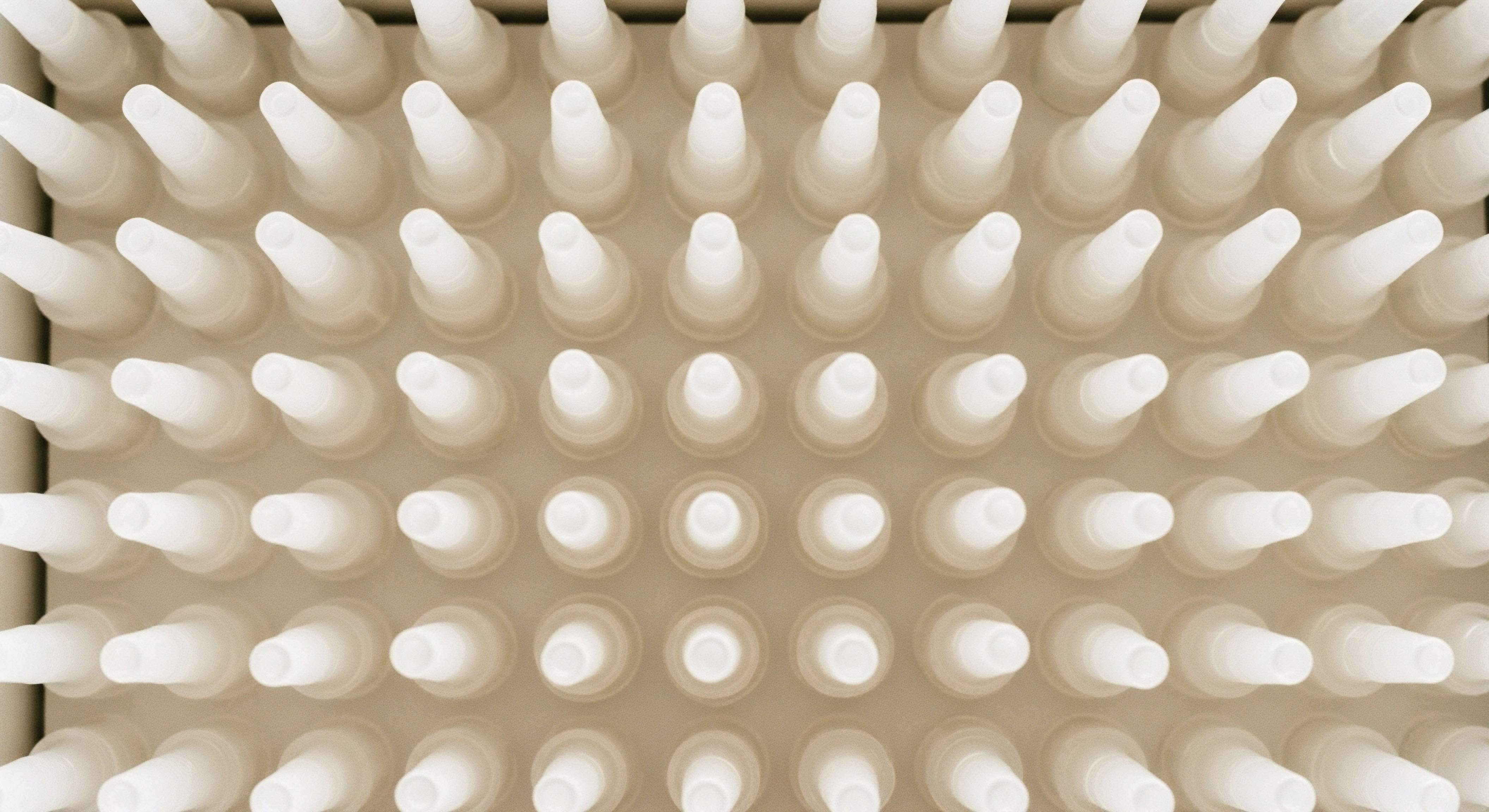

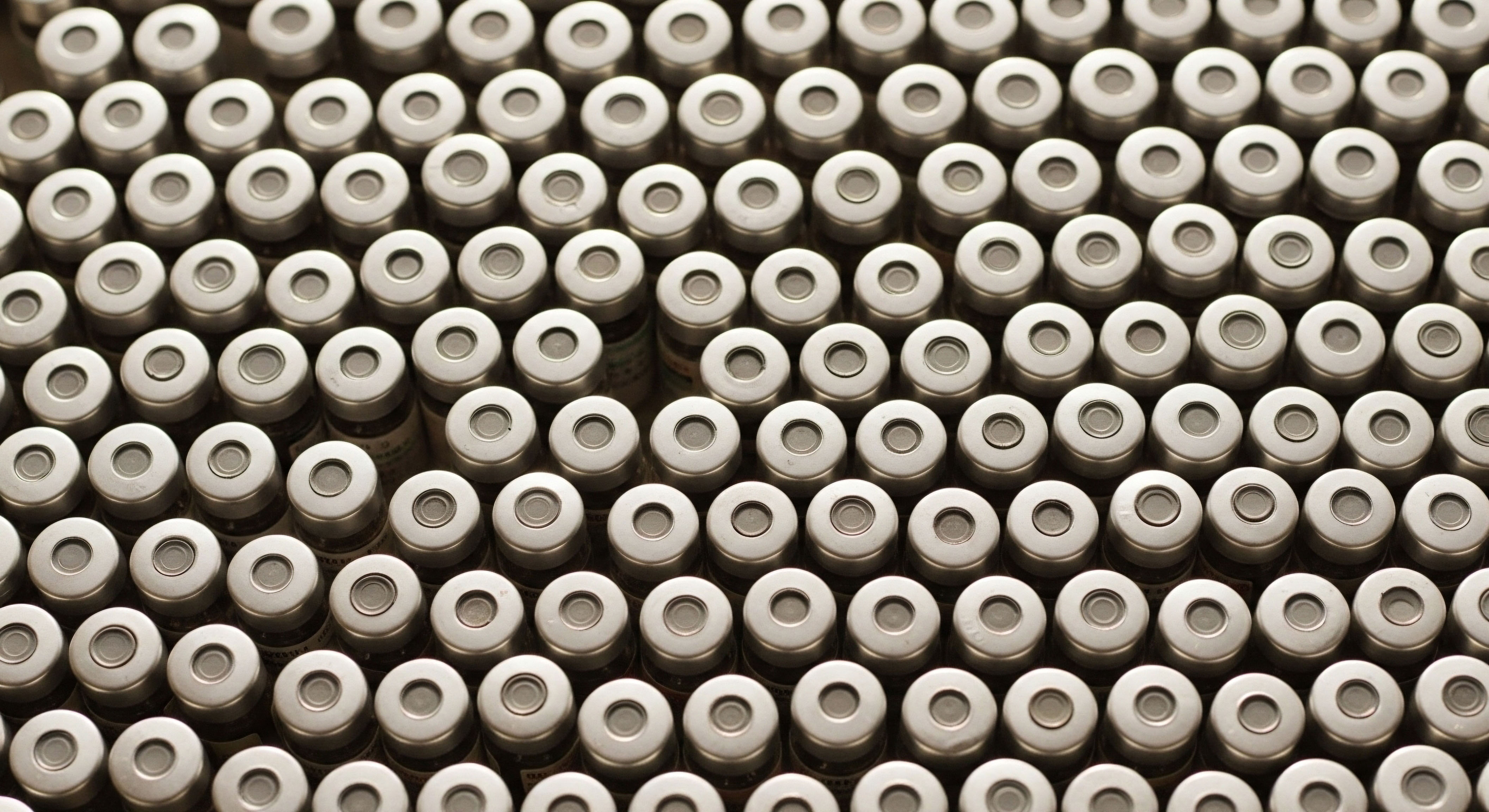

You hold a small vial, often containing a lyophilized powder, that represents a potential key to unlocking improved function. The question of its origin, its purity, and the systems that govern its creation are directly linked to your personal health outcome. The contents of that vial are a set of instructions for your cells. Ensuring those instructions are clear, accurate, and free from disruptive errors is the foundational principle of safe and effective therapy.

The Biological Reality of a Peptide

A therapeutic peptide is a short chain of amino acids, designed to mimic or influence a specific process in your body. Think of it as a key, crafted to fit a particular lock on a cell’s surface.

When the correct key (the peptide) fits the lock (the receptor), it sends a signal that can help regulate metabolism, support tissue repair, or modulate inflammation. The efficacy of this entire process depends on the structural integrity of that key. If the key is misshapen, broken, or if the vial contains a multitude of incorrect keys, the intended signal becomes garbled. These incorrect keys are impurities, and they represent a significant variable in your therapeutic outcome.

These are not benign, inactive substances. Impurities can be fragments of the intended peptide, altered versions created during synthesis, or contaminants from the manufacturing environment. Each one has the potential to interact with your biology in unintended ways, from provoking an immune response to simply failing to produce the desired effect. Your body is an exquisitely sensitive system, and introducing substances of unknown quality creates an unpredictable biological environment.

The physical substance you use is a direct molecular instruction to your cells; its purity determines the clarity of that instruction.

What Does Quality Control Mean for You?

For any substance intended for human use, a system of quality control is meant to guarantee that what is on the label is what is in the product. This system, known as Good Manufacturing Practice (GMP), is a set of rigorous standards that covers every step of production, from the sourcing of raw materials to the final packaging.

GMP is designed to ensure the identity, strength, quality, and purity of drug products. It is the framework that provides confidence that each vial contains the correct molecule at the correct dose, free from harmful contaminants.

The challenge within the global peptide market arises from the fact that not all peptides are produced under these stringent GMP guidelines. Many are synthesized and sold for “research use only,” a designation that exempts them from the rigorous quality control required for human therapeutics.

This creates a landscape where products with the same name can have vastly different levels of purity and safety. The regulatory gaps are the spaces where these non-GMP products can enter the supply chain, often sourced from international manufacturers with inconsistent oversight. Understanding this distinction is the first step in taking control of your wellness protocol and ensuring the tools you use are built for their intended purpose.

- Identity ∞ Does the vial contain the exact amino acid sequence of the peptide you intend to use?

- Purity ∞ What percentage of the vial’s contents is the active peptide, versus synthesis-related impurities or other contaminants?

- Potency ∞ Is the peptide present in the correct concentration and biologically active form to produce a therapeutic effect?

- Safety ∞ Is the product free from harmful substances like endotoxins, heavy metals, or residual solvents from the manufacturing process?

Intermediate

Navigating the world of peptide therapy requires an understanding of the regulatory structures that differentiate a pharmaceutical-grade product from a substance of unknown origin. The gaps in global quality control are not abstract policy issues; they are practical realities that directly influence the safety and reliability of the peptides available to you.

These gaps exist in the seams between different types of suppliers, varying national regulations, and the specific legal classifications of peptide substances themselves. Acknowledging these realities allows you to make informed decisions and prioritize sources that adhere to the highest standards of quality and safety.

Pharmaceutical Grade versus Compounded Preparations

The U.S. Food and Drug Administration (FDA) provides a clear pathway for the approval of new drugs, including peptides. This process is exhaustive, demanding extensive data on safety, efficacy, and manufacturing quality. When a peptide is an FDA-approved drug (like Tesamorelin for lipodystrophy), it has undergone this rigorous scrutiny. The manufacturing facilities are subject to regular GMP inspections, and each batch must meet precise specifications for purity and consistency.

A different pathway exists for compounding pharmacies. These facilities create personalized medications for specific patient needs. They are primarily regulated by state boards of pharmacy, but the FDA has authority over the bulk ingredients they use. Compounding pharmacies are divided into two main types, 503A and 503B, with different levels of oversight.

- 503A Pharmacies ∞ These are traditional compounding pharmacies that prepare medications for individual patients based on a prescription. They are not required to adhere to full GMP standards, but must follow guidelines set by the U.S. Pharmacopeia (USP), such as USP 795 for non-sterile compounding and USP 797 for sterile compounding. They can only compound with bulk substances that are components of an FDA-approved drug, have a USP monograph, or are on an FDA-approved list.

- 503B Outsourcing Facilities ∞ These facilities can produce larger batches of compounded drugs without a prescription for each patient. In exchange for this ability, they must register with the FDA and adhere to full cGMP standards, similar to a pharmaceutical manufacturer. This provides a higher level of quality assurance.

The regulatory gap widens when peptides are sourced from suppliers that operate outside of these frameworks, particularly those selling products labeled as “research use only.” These materials are not intended for human consumption, and their manufacturers are not held to any pharmaceutical quality standard. The active pharmaceutical ingredient (API) may be sourced from international labs with little to no transparency or oversight, leading to a high risk of impurities, incorrect dosages, or even the presence of entirely different substances.

The regulatory designation of a peptide’s source dictates the level of quality control applied to its production.

How Do International Sourcing Gaps Affect Quality?

A significant portion of the raw peptide material available globally originates from overseas manufacturers where regulatory oversight can be inconsistent. Without a harmonized international standard for peptide API production, the quality can vary dramatically. A compounding pharmacy in the U.S. must ensure its API is sourced from an FDA-registered facility, even if that facility is overseas.

This provides a layer of accountability. However, suppliers that operate in the “research use only” market have no such obligation. They may source the cheapest available material to maximize profit, with little concern for the rigorous analytical testing required to ensure patient safety.

This creates a bifurcated market. On one side, you have a regulated supply chain where API quality is a primary concern. On the other, you have a gray market where cost is the main driver and quality is an unknown variable. The inability of a typical consumer to distinguish between these sources is a central challenge.

Key Differences in Peptide Sourcing

| Source Type | Regulatory Oversight | Purity Standard | Risk of Impurities |

|---|---|---|---|

| FDA-Approved Pharmaceutical | Full FDA cGMP inspection and approval | Extremely high, with defined specifications | Very Low |

| 503B Compounding Facility | FDA registration and cGMP compliance | High, follows cGMP standards | Low |

| 503A Compounding Pharmacy | State Board of Pharmacy and USP standards | Variable, follows USP guidelines | Moderate |

| “Research Use Only” Supplier | None for human use | Unknown and unverified | High to Very High |

Why Are Some Peptides Not Eligible for Compounding?

The legal status of a peptide further complicates the regulatory landscape. For a 503A pharmacy to compound a peptide, the bulk substance must meet specific criteria. Many popular peptides do not appear on the FDA’s approved lists, making them ineligible for legal compounding.

Furthermore, as of March 2020, some peptides, like HCG and Tesamorelin, were reclassified as biologics. A biologic is a complex molecule derived from living organisms, and 503A pharmacies are prohibited from compounding them. This legislative shift removed certain well-known peptides from the compounding market, pushing some demand toward unregulated channels. These regulatory nuances create openings for disreputable suppliers to market products that legitimate pharmacies cannot, preying on the gap between patient demand and regulated supply.

Academic

A comprehensive evaluation of peptide quality extends beyond regulatory compliance into the domain of analytical chemistry. The gaps in global peptide quality control are ultimately measurable at a molecular level. For the individual on a personalized wellness protocol, the difference between a therapeutic outcome and a potential adverse event is determined by the precise biochemical composition of the product they administer.

The sophisticated instrumentation used in pharmaceutical quality control is the definitive tool for closing the information gap, providing an unbiased assessment of a peptide’s identity, purity, and safety. The absence of such rigorous analysis in a product’s supply chain represents a failure of quality assurance.

The Analytical Cornerstone High-Performance Liquid Chromatography

High-Performance Liquid Chromatography (HPLC) is the universally accepted method for determining the purity of a synthetic peptide. This technique separates the components of a mixture based on their chemical properties. In simplified terms, the peptide sample is dissolved in a solvent and forced under high pressure through a column packed with a special material.

Different molecules in the sample travel through the column at different speeds, depending on their size, charge, and affinity for the column material. A detector at the end of the column records each component as it emerges, producing a chromatogram ∞ a graph with peaks representing each separated substance.

The largest peak should correspond to the target peptide. All other peaks represent impurities. The purity is calculated by comparing the area of the main peak to the total area of all peaks. A properly developed HPLC method can separate the target peptide from closely related impurities, such as deletion sequences (where an amino acid is missing) or truncated sequences.

A purity level of 99% or higher is the standard for clinical-grade peptides. Products sold for “research” may have purities of 95% or lower, with the remaining percentage composed of unknown and potentially problematic substances.

Advanced analytical methods provide the definitive, objective measure of a peptide’s quality, revealing what regulatory paperwork alone cannot.

Confirming Molecular Identity with Mass Spectrometry

While HPLC is excellent for assessing purity, Mass Spectrometry (MS) is essential for confirming the peptide’s identity. This technique measures the mass-to-charge ratio of ionized molecules, allowing for the precise determination of a molecule’s weight. A peptide has a specific, calculated molecular weight based on its amino acid sequence.

MS analysis confirms that the main peak from the HPLC is, in fact, the correct peptide. It is a powerful tool that can detect even subtle changes in molecular structure, such as the oxidation of a single amino acid, which could alter the peptide’s biological function. The combination of HPLC and MS (LC-MS) provides an unambiguous profile of a peptide product, confirming both its purity and its identity.

What Are the Dangers of Unseen Impurities?

Regulatory gaps allow for the distribution of products that have not undergone rigorous analytical testing. This exposes the end-user to several classes of process-related impurities, each with distinct physiological risks.

| Impurity Type | Origin | Potential Biological Consequence |

|---|---|---|

| Deletion/Truncated Sequences | Errors during solid-phase peptide synthesis (SPPS). | May have no activity, reduced activity, or could act as an antagonist, blocking the receptor from the intended peptide. |

| Residual Solvents | Chemicals used during synthesis and purification (e.g. acetonitrile, trifluoroacetic acid). | Can be toxic at certain concentrations and may cause irritation or allergic reactions at the injection site. |

| Endotoxins (Pyrogens) | Contaminants from the cell walls of gram-negative bacteria. | Can trigger a potent inflammatory and immune response, leading to fever, chills, and other systemic symptoms. |

| Heavy Metals | Contamination from manufacturing equipment or raw materials. | Can be toxic and may catalyze the degradation of the peptide, reducing its stability and shelf-life. |

How Can Chiral Integrity Be Compromised?

A more subtle, yet critical, aspect of peptide quality is chiral integrity. Amino acids (except glycine) exist in two mirror-image forms, or enantiomers ∞ the “L” form and the “D” form. Biologically active peptides are almost exclusively composed of L-amino acids.

During synthesis, some L-amino acids can be inadvertently converted to their D-form, a process called racemization. This creates a peptide with the correct sequence and mass but the wrong three-dimensional shape. A peptide with compromised chiral integrity will have reduced or no biological activity because it can no longer bind correctly to its target receptor. Specialized analytical techniques are required to detect this, and they are rarely employed by low-grade suppliers.

The Economic Barrier to Quality

The primary reason these analytical tests are not universally performed is economic. The equipment for HPLC and MS is expensive to purchase and maintain, and it requires highly trained personnel to operate and interpret the results. For a manufacturer focused on producing low-cost “research” peptides, investing in a comprehensive quality control program is not a priority.

The regulatory gaps allow them to bypass these essential steps. This economic reality means that the responsibility for verifying quality often falls to the compounding pharmacy or, ultimately, to the informed consumer who must choose their source wisely. The price of a peptide often reflects the level of quality control invested in its production. An unusually low price may be an indicator that these critical analytical verification steps have been skipped.

References

- Ge, Y. and G. Jia. “Quality control in peptide manufacturing ∞ Specifications for GMP peptides.” Polypeptide Laboratories, 2011.

- Kumar, P. et al. “Analytical techniques for peptide-based drug development ∞ Characterization, stability and quality control.” International Journal of Science and Research Archive, vol. 12, no. 1, 2024, pp. 3140-3159.

- Frier Levitt Attorneys at Law. “Regulatory Status of Peptide Compounding in 2025.” Frier Levitt, 3 Apr. 2025.

- Proclinical. “Ensure Safe & Effective Peptide Drugs ∞ Mastering GMP Compliance for Quality Control.” Proclinical, 11 Apr. 2024.

- BioPharmaSpec. “Process-Related Impurities in Peptides ∞ Key Considerations and Analytical Approaches.” BioPharmaSpec, 4 June 2025.

- Alliance for Pharmacy Compounding. “Understanding Law and Regulation Governing the Compounding of Peptide Products.” APC, 1 Mar. 2024.

- Donegan, M. and M. E. P. B. de Lemos. “Liquid Chromatography-High Resolution Mass Spectrometry for Peptide Drug Quality Control.” Journal of the American Society for Mass Spectrometry, vol. 26, no. 6, 2015, pp. 962-969.

Reflection

You began this exploration seeking to understand how distant regulatory policies might impact your personal health objectives. The journey has revealed that the quality of a therapeutic peptide is not an abstract concept but a tangible, molecular reality. The knowledge you have gained is a powerful tool.

It transforms you from a passive recipient into an active, informed participant in your own wellness protocol. Your body is your most valuable biological system. The questions you now know how to ask ∞ about sourcing, purity, and analytical verification ∞ are the most important ones you can bring to any conversation about your health. This understanding is the foundation upon which a truly personalized and effective therapeutic path is built, empowering you to move forward with clarity and confidence.