Fundamentals

You stand at a threshold, holding a vial that contains a sequence of amino acids, a peptide. This small molecule represents a potential recalibration of your body’s internal communication network. Perhaps you are seeking the restorative effects of Sermorelin on sleep and cellular repair, or the metabolic precision of Ipamorelin.

Your goal is tangible ∞ to reclaim a sense of vitality, to feel your body functioning with the efficiency and resilience you know it possesses. This personal objective is the very reason the microscopic contents of that vial are subject to a level of scrutiny that is both immense and profoundly necessary. The journey to hormonal optimization begins with an absolute, unshakeable confidence in the quality of the therapeutic agents being introduced into your system.

Regulatory bodies like the U.S. Food and Drug Administration (FDA) approach the oversight of peptides with a deep understanding of their power. These molecules are not blunt instruments; they are precision keys designed to fit specific locks within your cells.

An oversight in their manufacture could create a key that fits the wrong lock, or one that breaks off, jamming a critical biological process. Therefore, the monitoring of peptide quality during clinical trials is a foundational process, ensuring that the agent being studied is exactly what it purports to be, and nothing else.

This process is governed by a comprehensive framework known as Good Manufacturing Practice (GMP). Think of GMP as the non-negotiable operating system for pharmaceutical production. It dictates every variable, from the sterility of the environment and the training of the personnel to the rigorous documentation of every single step. It ensures that the peptide you receive in month six of a trial is identical in every meaningful way to the one you received on day one.

The Three Pillars of Peptide Quality

Within the GMP framework, regulatory agencies focus on three core attributes that define the quality of a therapeutic peptide. Understanding these pillars allows you to appreciate the immense scientific effort that underpins the safety and efficacy of these treatments.

- Identity ∞ This is the most fundamental question ∞ Is the peptide what we say it is? Scientists use sophisticated techniques to confirm the exact sequence of amino acids. For a peptide like CJC-1295, which is designed to stimulate growth hormone release, confirming its precise structure is the first step in guaranteeing its biological function. A single incorrect amino acid could render it inert or, worse, cause an unintended effect.

- Purity ∞ This pillar addresses the question ∞ What else is in the vial? Purity analysis is a meticulous search for any substance that is not the intended peptide. These substances, called impurities, can arise from the complex chemical synthesis process. They might be residual solvents, leftover reagents, or even slightly malformed versions of the peptide itself. Regulatory bodies set stringent limits on these impurities because they represent unknown variables that could impact safety and efficacy.

- Potency ∞ This attribute measures the biological activity of the peptide. Potency answers the question ∞ How well does it work? A peptide can have perfect identity and purity but lack potency if it has folded incorrectly or degraded. For a therapeutic like PT-141, used for sexual health, a potency assay would measure its ability to bind to and activate its target melanocortin receptors. This ensures that each batch of the drug produces the desired biological effect at a consistent dose.

These three pillars form the basis of the Chemistry, Manufacturing, and Controls (CMC) data that a company must submit to regulators. This extensive dossier is the complete biography of the peptide, detailing its life story from raw chemical precursors to the final, sterile product. It is this rigorous, data-driven narrative that allows regulatory scientists to confidently approve a peptide for investigation in humans, providing a foundation of safety upon which all clinical trials are built.

The meticulous process of regulatory oversight ensures that every dose of a therapeutic peptide is a precise and reliable biological signal.

Intermediate

For any therapeutic peptide to advance into clinical trials, its developers must present a comprehensive data package to regulatory authorities like the FDA or the European Medicines Agency (EMA). This submission, specifically the Chemistry, Manufacturing, and Controls (CMC) section, provides a microscopic view of the product’s quality.

It is a scientific mandate that demonstrates a complete mastery over the manufacturing process. The goal is to prove that the peptide is consistently produced to meet exacting standards of identity, purity, strength, and quality. This is where the abstract principles of GMP translate into concrete analytical data.

The entire regulatory framework is built upon a risk-based approach. Scientists from agencies like the FDA’s Center for Drug Evaluation and Research (CDER) evaluate the potential risks associated with a given peptide product. They consider its complexity, its intended clinical use, and the specific patient population.

For instance, a peptide like Gonadorelin, used in testosterone replacement therapy (TRT) protocols to maintain testicular function, directly interacts with the sensitive Hypothalamic-Pituitary-Gonadal (HPG) axis. An impurity in Gonadorelin could disrupt this delicate feedback loop, so the standards for its purity are exceptionally high. The regulatory review is a dynamic process of identifying potential hazards and ensuring that the manufacturer has implemented effective controls to mitigate them.

What Are the Core Analytical Requirements for Peptides?

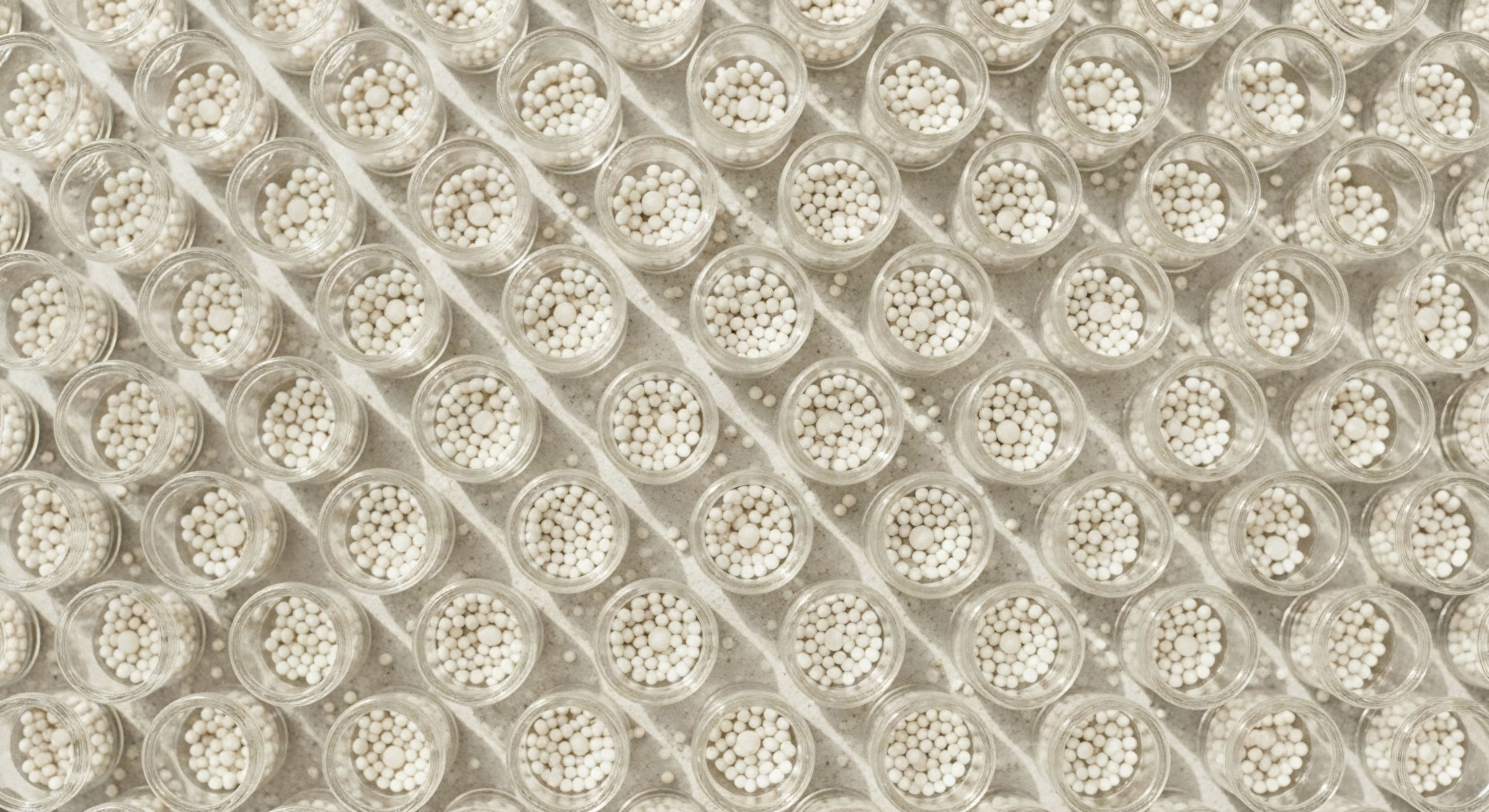

To satisfy regulatory bodies, manufacturers must conduct a battery of tests to characterize their peptide product fully. These tests fall into several key categories, each providing a different layer of information about the molecule’s integrity. The selection of tests is guided by publications from the International Council for Harmonisation (ICH), which provides a unified set of standards accepted by the FDA, EMA, and other global agencies.

| Quality Attribute | Purpose | Common Analytical Methods |

|---|---|---|

| Identity | Confirms the correct amino acid sequence and structure. | Mass Spectrometry (MS), Amino Acid Analysis (AAA), Peptide Mapping |

| Purity & Impurities | Quantifies the percentage of the desired peptide and identifies any process-related or product-related impurities. | High-Performance Liquid Chromatography (HPLC), Gas Chromatography-Mass Spectrometry (GC-MS) for residual solvents. |

| Potency (Activity) | Measures the specific biological effect of the peptide. | In vitro cell-based assays, receptor binding assays. |

| Quantity | Ensures the correct amount of peptide is present in each vial. | HPLC with UV detection, AAA. |

| Sterility & Endotoxins | Confirms the absence of microbial contamination and bacterial endotoxins, which can cause severe immune reactions. | Sterility testing (USP <71>), Limulus Amebocyte Lysate (LAL) test for endotoxins. |

Process-Related Impurities a Central Focus

Regulatory agencies pay special attention to impurities that originate from the manufacturing process itself. These are distinct from product-related impurities (like a degraded form of the peptide). Process-related impurities include residual solvents, reagents, and catalysts used during chemical synthesis.

For example, solvents like acetonitrile or dichloromethane are common in peptide synthesis but must be removed to extremely low levels in the final product. Agencies refer to ICH Q3C guidelines, which set specific limits for different classes of solvents based on their toxicity.

Another critical area is the control of raw materials. The quality of the final peptide is dependent on the quality of its building blocks. Regulatory guidelines require manufacturers to have robust supplier qualification programs and to test incoming raw materials, including the amino acids themselves.

This prevents the introduction of impurities at the very start of the process. For peptides produced via recombinant DNA technology, this extends to controlling for host cell proteins and DNA, which are biological contaminants from the production system.

Regulatory bodies require a complete analytical dossier that demonstrates total control over the peptide’s manufacturing process and final composition.

How Do Regulatory Agencies Approach Stability Testing?

A peptide’s quality must be maintained throughout its entire shelf life. To ensure this, regulatory bodies mandate rigorous stability testing programs. These studies expose the peptide to various environmental conditions over time to see how it holds up.

- Long-Term Stability ∞ The peptide is stored at its recommended storage condition (e.g. refrigerated) and tested at regular intervals (e.g. 3, 6, 9, 12, 24 months) to establish its shelf life.

- Accelerated Stability ∞ The peptide is stored at elevated temperatures and humidity to speed up potential degradation. This data helps predict the long-term stability profile and is critical for assessing what might happen if the product is temporarily exposed to suboptimal conditions during shipping.

- Stress Testing ∞ The peptide is intentionally exposed to harsh conditions like extreme pH, high temperatures, and intense light. This helps identify likely degradation pathways and informs the development of a stable formulation and appropriate packaging.

The data from these stability studies are a crucial part of the CMC package. For a man on a TRT protocol that includes weekly injections of Testosterone Cypionate and twice-weekly injections of Gonadorelin, or for an athlete using Ipamorelin/CJC-1295, the assurance that these peptides remain stable and potent from the first dose to the last is a direct result of this exhaustive regulatory requirement.

Academic

The regulatory evaluation of a therapeutic peptide is a deeply scientific discipline grounded in analytical chemistry and molecular biology. The core objective is to characterize the drug substance and drug product with such precision that any potential risk to a patient is identified and systematically mitigated.

At the academic level of inquiry, we move beyond the categories of “purity” and “identity” and into the specific molecular attributes that define them. The central challenge lies in the inherent complexity of peptides. Unlike small-molecule drugs, peptides are large, conformationally flexible, and susceptible to a wide array of chemical and physical modifications. This complexity demands a multi-faceted analytical approach, where orthogonal methods are used to build a complete and unambiguous picture of the molecule.

The Specter of Immunogenicity from Peptide Impurities

A primary concern for regulators, especially with synthetic peptides intended to be analogues of endogenous human proteins, is the risk of immunogenicity. An immune response to a therapeutic peptide can neutralize its effect or, in a more severe scenario, lead to cross-reactivity against the body’s own natural hormone.

This risk is directly linked to the purity profile of the peptide. Even minute quantities of impurities that are structurally related to the main peptide can be sufficient to trigger an immune response.

Consider a growth hormone secretagogue like Tesamorelin, prescribed for lipodystrophy. Its sequence is precisely defined. During synthesis, however, side reactions can occur, leading to a population of related but structurally distinct impurities:

- Truncated Sequences ∞ Peptides missing one or more amino acids from either end.

- Deletion Sequences ∞ Peptides with an internal amino acid missing.

- Modified Sequences ∞ Peptides where an amino acid side chain has undergone oxidation, deamidation, or another chemical change.

- Aggregation ∞ Multiple peptide molecules clumping together, which is a potent trigger for an immune response.

The FDA has issued specific guidance for synthetic peptides that reference a product originally derived from recombinant technology. This guidance states that the risk of immunogenicity from the generic synthetic product should not differ from that of the original. This places an immense burden on the manufacturer to demonstrate an exceptionally high degree of purity and to characterize every detectable impurity. Advanced analytical techniques are the only way to meet this high standard.

Advanced Analytical Characterization Techniques

High-Performance Liquid Chromatography (HPLC) is the workhorse for purity analysis, but its power is magnified when coupled with high-resolution mass spectrometry (HRMS). This combination allows for the separation of impurities from the main peptide and their subsequent identification based on their precise mass.

| Technique | Application in Regulatory Science | Specific Information Gained |

|---|---|---|

| LC-MS/MS (Liquid Chromatography-Tandem Mass Spectrometry) | Primary structure confirmation and impurity identification. | Fragments the peptide and its impurities to determine their exact amino acid sequence, allowing for pinpoint identification of modifications or sequence errors. |

| Ion-Mobility Spectrometry (IMS) | Analysis of peptide conformation and aggregation state. | Separates molecules based on their size and shape (collisional cross-section), providing information about the peptide’s three-dimensional structure and detecting aggregates that other methods might miss. |

| Circular Dichroism (CD) Spectroscopy | Assessment of secondary structure (alpha-helices, beta-sheets). | Provides a global signature of the peptide’s folded state. Changes in the CD spectrum during stability studies can indicate conformational degradation, which often precedes loss of potency. |

| Multi-Angle Light Scattering (MALS) | Absolute measurement of molar mass and detection of aggregates. | When coupled with size-exclusion chromatography (SEC), MALS can accurately quantify the presence of dimers, trimers, and higher-order aggregates in a sample. |

Case Study the Challenge of Stereoisomers

A particularly difficult analytical challenge is the detection of stereoisomers, specifically the presence of D-amino acids in a peptide that should only contain L-amino acids (the building blocks of natural proteins). The EMA guideline on synthetic peptides highlights this risk.

A D-amino acid has the same chemical formula and mass as its L-counterpart, making it invisible to standard mass spectrometry. However, its different 3D orientation can alter the peptide’s structure, function, and immunogenic potential. Detecting these requires specialized chiral chromatography methods that can separate molecules based on their stereochemistry.

For a protocol like the post-TRT fertility stimulation regimen involving Tamoxifen and Clomid, which are themselves complex molecules, ensuring the purity of an adjunctive peptide like Gonadorelin down to the stereoisomeric level is a component of ensuring predictable biological outcomes.

The regulatory mandate for peptide quality necessitates the use of advanced, orthogonal analytical techniques capable of detecting subtle molecular variations that could have significant physiological consequences.

Ultimately, the academic rigor applied by regulatory bodies serves a deeply humanistic purpose. By demanding this level of detailed molecular characterization, agencies like the FDA and EMA ensure that when a physician prescribes a peptide therapy, from Testosterone Cypionate for hormonal balance to Pentadeca Arginate (PDA) for tissue repair, they are working with a known and defined entity.

This scientific certainty is what translates a sequence of amino acids in a vial into a reliable and safe therapeutic intervention, allowing patients to pursue their health goals with confidence in the science that underpins their treatment.

References

- “Ensure Safe & Effective Peptide Drugs ∞ Mastering GMP Compliance for Quality Control.” CordenPharma, 11 April 2024.

- Gausepohl, H. and J. Eichler. “Regulatory Guidelines for the Analysis of Therapeutic Peptides and Proteins.” Journal of Peptide Science, vol. 31, no. 3, 2025, p. e70001.

- Gausepohl, H. and J. Eichler. “Regulatory Guidelines for the Analysis of Therapeutic Peptides and Proteins.” National Center for Biotechnology Information, U.S. National Library of Medicine, 8 February 2025.

- “Process-Related Impurities in Peptides ∞ Key Considerations and Analytical Approaches.” BioPharmaSpec, 4 June 2025.

- Al-Sabbagh, A. and J.P. Faustino. “Chapter 1 ∞ Regulatory Considerations for Peptide Therapeutics.” RSC Drug Discovery Series, Royal Society of Chemistry, 28 August 2019.

Reflection

The journey through the science of regulatory oversight reveals a profound commitment to your safety and the integrity of your personal health protocol. The knowledge that every therapeutic peptide, whether it is for hormonal optimization, metabolic recalibration, or cellular repair, undergoes such an exhaustive and sophisticated evaluation process is itself a form of empowerment.

This intricate system of checks and balances, from Good Manufacturing Practice to advanced mass spectrometry, exists to ensure that the biological message you introduce into your body is clear, precise, and predictable.

This understanding now becomes a part of your toolkit. It informs your conversations with your clinician and shapes the standards you hold for your own wellness path. As you move forward, consider how this principle of quality extends beyond the vial.

Think about the source of your therapies, the expertise of the professionals guiding you, and the data you use to track your own progress. The science of regulation provides a powerful model for your own health journey ∞ one built on diligence, precision, and an unwavering commitment to quality as the foundation for achieving your highest potential.

Glossary

amino acids

ipamorelin

regulatory bodies

peptide quality

good manufacturing practice

therapeutic peptide

gonadorelin

stability testing

tesamorelin