Fundamentals

When symptoms of imbalance begin to surface ∞ a persistent weariness, a shift in mood, or a subtle but undeniable change in physical vitality ∞ it can feel as though the very blueprint of one’s being is undergoing an unwelcome revision. This experience often prompts a deep introspection, a desire to understand the underlying mechanisms that govern our well-being. Many individuals seek pathways to reclaim their optimal function, recognizing that a generalized approach may not address their unique biological signature. The pursuit of personalized wellness protocols, particularly those involving hormonal recalibration, represents a thoughtful step toward restoring internal equilibrium.

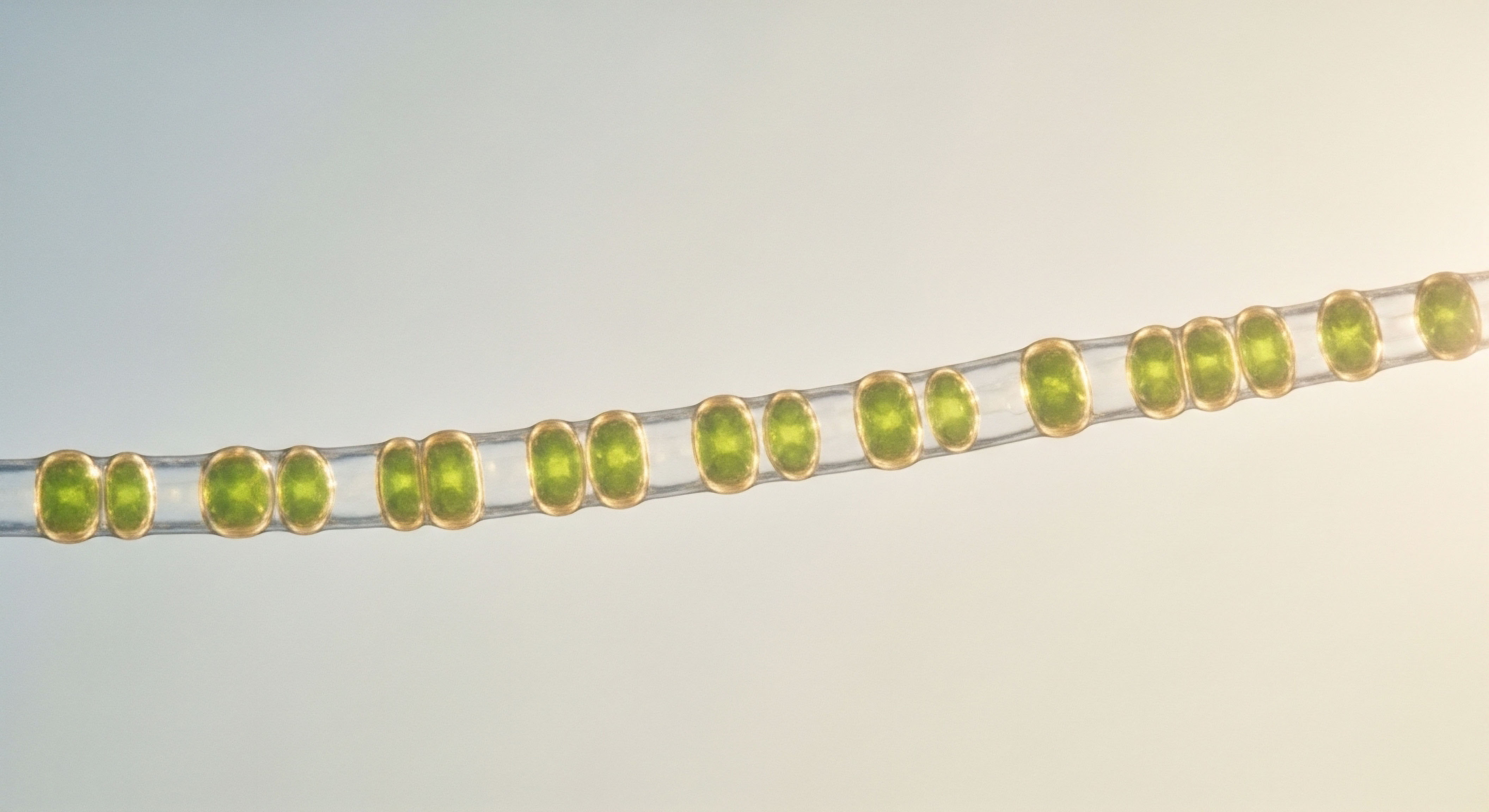

The endocrine system, a complex network of glands and hormones, acts as the body’s internal messaging service, orchestrating countless physiological processes. Hormones, these potent chemical messengers, influence everything from metabolism and energy levels to mood, sleep patterns, and reproductive health. When these messages become garbled or insufficient, the ripple effects can be felt across every system, manifesting as the very symptoms that prompt a search for answers.

Understanding the body’s internal messaging system is the first step toward reclaiming vitality.

For those considering interventions to support hormonal health, the quality and integrity of the pharmaceutical preparations involved become paramount. Whether a therapy involves a topical application, an oral solution, or another form, its purity and precise composition are not merely technical details; they are foundational to its therapeutic effect and, critically, to patient safety. The question of how regulatory bodies ensure this quality, particularly for preparations that are not terminally sterilized, holds significant weight for anyone embarking on a personalized health journey.

In China, the National Medical Products Administration (NMPA) stands as the central authority responsible for safeguarding the quality and safety of drugs, cosmetics, and medical devices. This oversight extends directly to non-sterile pharmaceutical preparations, which, by their nature, require stringent controls to prevent microbial contamination and ensure stability. The NMPA’s framework, supported by the comprehensive standards outlined in the Chinese Pharmacopoeia, provides a critical layer of assurance. This regulatory vigilance aims to ensure that any substance introduced into the body, even in a non-sterile form, meets rigorous standards, thereby protecting the delicate balance of one’s biological systems.

Consider the journey of a pharmaceutical compound from its raw ingredients to its final form. Each step, from sourcing to manufacturing and packaging, carries the potential for variation. For non-sterile preparations, which do not undergo a final sterilization process, the control of microbial load and other contaminants throughout production is exceptionally important.

This is where regulatory guidelines become the guardians of integrity, ensuring that what is intended to restore health does not inadvertently introduce new challenges. The peace of mind that comes from knowing these preparations adhere to strict quality benchmarks allows individuals to focus on their health optimization with greater confidence.

Intermediate

The journey toward hormonal balance often involves specific therapeutic agents, and the integrity of these compounds is directly tied to robust regulatory oversight. In China, the National Medical Products Administration (NMPA) establishes a comprehensive regulatory framework for pharmaceutical products, including those classified as non-sterile preparations. This framework is designed to ensure the safety, efficacy, and quality of medications available to the public.

How Does Regulatory Oversight Shape Pharmaceutical Quality?

The NMPA’s authority stems from the Drug Administration Law of the People’s Republic of China, which mandates strict adherence to quality management standards throughout the entire lifecycle of a drug, from production to distribution and use. For non-sterile preparations, which include a wide array of forms such as oral liquids, topical creams, ointments, and certain compounded solutions, the regulatory focus intensifies on preventing microbial contamination and maintaining chemical stability. These preparations, by definition, do not undergo terminal sterilization, making their manufacturing environment and process controls critically important.

A cornerstone of this regulatory system is the Good Manufacturing Practice for Drugs (GMP), revised in 2010 and continually updated. The GMP guidelines stipulate detailed requirements for pharmaceutical manufacturers, covering everything from facility design and equipment to personnel training and quality control procedures. For non-sterile products, specific manufacturing areas, often designated as Grade D, are required to minimize contamination risks. This systematic approach ensures that each batch of a preparation is consistently produced to meet its registered specifications.

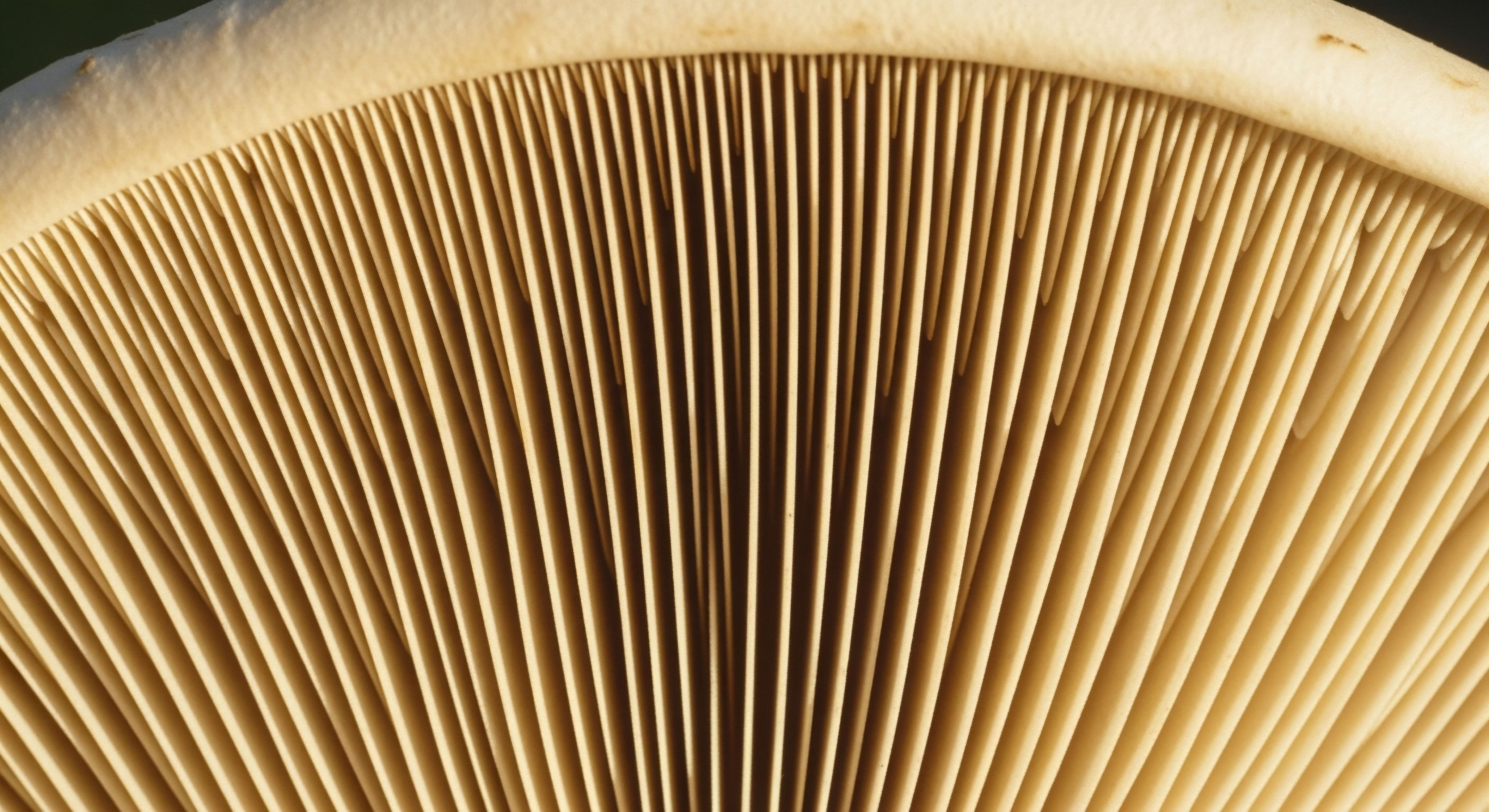

Robust manufacturing practices are essential for the safety of non-sterile pharmaceutical preparations.

The Chinese Pharmacopoeia (ChP) serves as the official compendium of drug standards in China, updated every five years, with the latest edition released in 2020. This authoritative text provides detailed monographs for individual drugs and general chapters outlining testing methods and acceptance criteria. For non-sterile preparations, the ChP includes specific guidelines for microbiological examination, such as methods for microbial enumeration tests (e.g. ChP method 1105) and tests for specified microorganisms (e.g.

ChP method 1106). These tests establish acceptable limits for microbial counts and the absence of certain pathogenic organisms, directly influencing the safety profile of non-sterile compounds.

Regulatory Requirements for Non-Sterile Preparations

The NMPA and the ChP collectively address non-sterile preparations through several key areas ∞

- Microbiological Control ∞ Strict limits are set for the total aerobic microbial count (TAMC) and total yeast and mold count (TYMC), along with requirements for the absence of specific objectionable microorganisms like Escherichia coli or Staphylococcus aureus.

- Quality Management Systems ∞ Manufacturers must establish comprehensive quality management systems that cover all aspects of production, control, release, storage, and distribution to ensure consistent quality.

- Validation of Processes ∞ All manufacturing processes, especially those critical to product quality, must be validated to demonstrate their capability of consistently producing preparations that meet required standards. This includes validation of cleaning procedures and water systems.

- Raw Material Control ∞ Rigorous testing of starting materials and excipients is mandated to prevent contaminants from entering the production stream.

- Personnel Hygiene and Training ∞ Strict protocols for personnel hygiene and ongoing training are enforced to minimize human-related contamination risks.

These regulatory measures are particularly relevant for personalized wellness protocols involving hormonal agents and peptides. Consider the following applications ∞

Testosterone Replacement Therapy (TRT) for Men ∞ While often administered via intramuscular injections (a sterile product), some protocols may involve topical testosterone creams or gels, which are non-sterile preparations. The NMPA’s oversight ensures that these creams, whether commercially produced or compounded, meet standards for active ingredient concentration, stability, and microbial purity. Gonadorelin and Anastrozole, used alongside testosterone, are typically sterile injectables or oral tablets, but their quality control also falls under NMPA scrutiny.

Testosterone Replacement Therapy for Women ∞ Women often utilize lower-dose testosterone, sometimes in subcutaneous injections or topical creams. Progesterone, another vital hormone, may be prescribed as oral capsules or topical creams. The quality of these non-sterile topical or oral preparations is directly influenced by the NMPA’s guidelines for manufacturing and testing. Pellet therapy, while involving a sterile implant, still relies on the quality of the active pharmaceutical ingredient.

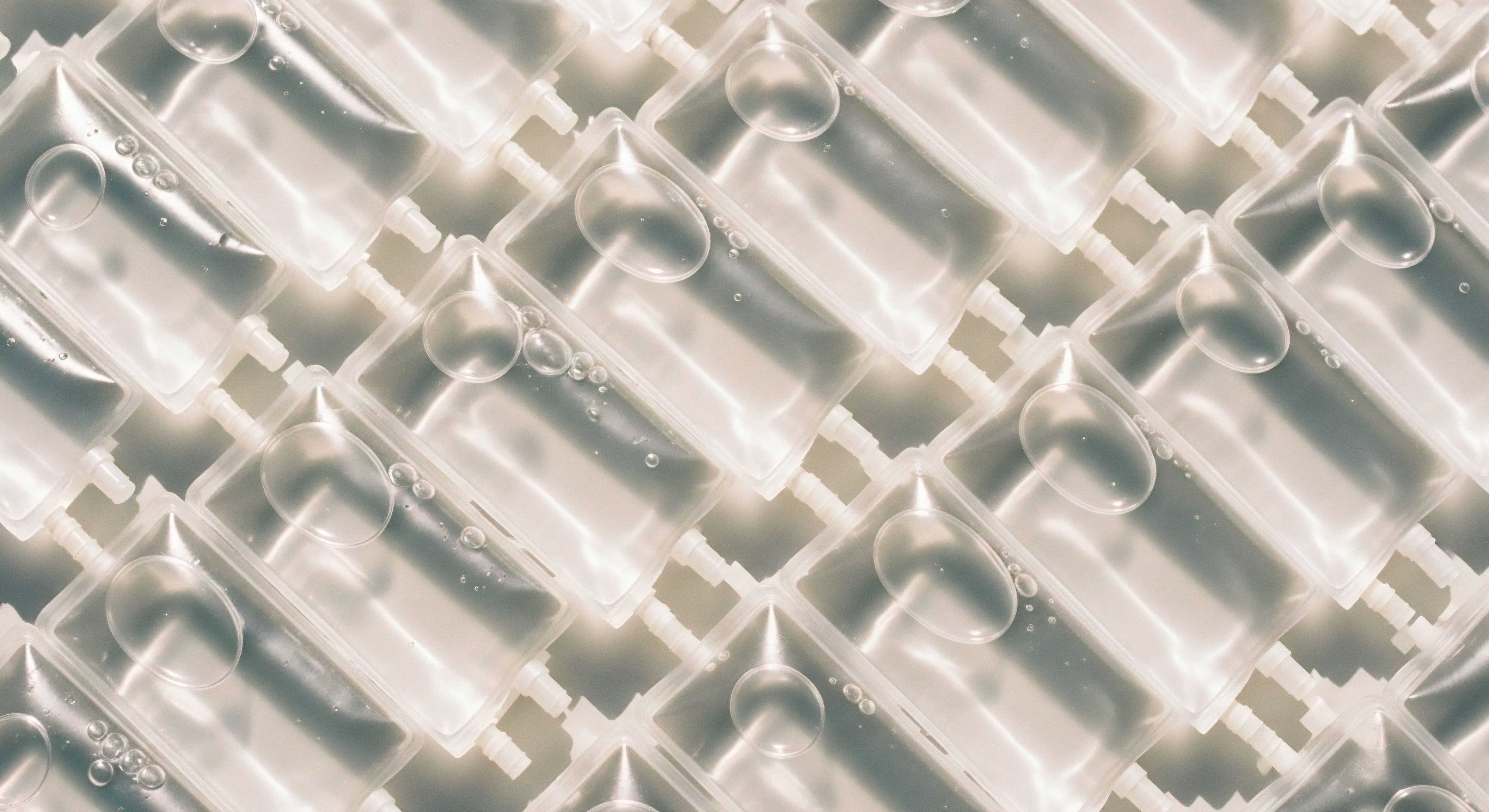

Growth Hormone Peptide Therapy ∞ Peptides like Sermorelin, Ipamorelin/CJC-1295, Tesamorelin, Hexarelin, and MK-677 are often administered via subcutaneous injection after reconstitution from a lyophilized powder. While the final reconstituted solution is sterile, the initial powder and the diluent used for reconstitution must adhere to stringent non-sterile and sterile manufacturing standards, respectively. The NMPA’s regulations ensure the purity and stability of these peptide compounds before reconstitution.

Other Targeted Peptides ∞ Peptides such as PT-141 for sexual health or Pentadeca Arginate (PDA) for tissue repair may also be formulated as non-sterile nasal sprays, oral solutions, or topical applications. The NMPA’s oversight ensures that these diverse non-sterile forms are manufactured under controlled conditions, minimizing risks of contamination and ensuring the stability of the active peptide.

The table below illustrates key quality parameters for non-sterile preparations as influenced by regulatory standards ∞

| Quality Parameter | Regulatory Significance | Impact on Hormonal Therapy |

|---|---|---|

| Microbial Limits | Ensures product safety by controlling bacterial and fungal contamination. | Prevents infections, especially in immunocompromised individuals or those with compromised skin barriers. Contamination can degrade active ingredients. |

| Active Ingredient Assay | Verifies the precise concentration of the therapeutic compound. | Ensures accurate dosing for hormonal balance. Under-dosing leads to insufficient effect; over-dosing causes adverse reactions. |

| pH Value | Maintains stability and compatibility with biological systems, especially for topical or oral solutions. | Affects absorption, comfort, and potential for irritation. Incorrect pH can degrade hormones or peptides. |

| Physical Stability | Assesses consistency in appearance, texture, and separation over time. | Ensures uniform dosing and patient acceptance. Degradation can reduce efficacy. |

| Impurity Profile | Identifies and quantifies unwanted substances from synthesis or degradation. | Minimizes exposure to potentially harmful byproducts that could interfere with endocrine signaling or cause toxicity. |

The meticulous adherence to these regulatory requirements ensures that individuals pursuing personalized hormonal optimization receive preparations that are not only effective but also safe, minimizing the risk of adverse outcomes that could derail their health journey.

Academic

The intricate dance of the endocrine system, with its precise feedback loops and cellular signaling, demands therapeutic interventions of unimpeachable quality. When considering non-sterile pharmaceutical preparations within this context, the regulatory mechanisms in China provide a critical bulwark against potential disruptions to physiological harmony. The National Medical Products Administration (NMPA), in conjunction with the Chinese Pharmacopoeia (ChP), orchestrates a rigorous system designed to ensure that these preparations, whether mass-produced or compounded for individual needs, meet exacting standards.

What Specific Quality Control Measures Govern Non-Sterile Preparations?

The NMPA’s regulatory approach for non-sterile pharmaceutical preparations is deeply rooted in the principles of Good Manufacturing Practice (GMP). The 2010 revision of the GMP for Drugs, which remains foundational, mandates a comprehensive quality management system for all manufacturers. This system extends beyond mere end-product testing; it encompasses every stage of the manufacturing process, from the receipt of raw materials to the final packaging and distribution. The objective is to minimize risks associated with contamination, cross-contamination, and errors in production.

For non-sterile products, the GMP places particular emphasis on environmental controls. Production areas for oral liquids, solid preparations, suppositories, and epidermal products are often required to meet Grade D cleanroom standards. This classification implies specific requirements for air filtration, temperature, humidity, and differential pressures to control airborne particulates and microorganisms. The design and layout of facilities must prevent mix-ups and contamination, ensuring a unidirectional flow of materials and personnel.

A core tenet of GMP, and thus NMPA oversight, is the concept of validation. All critical manufacturing processes, cleaning procedures, and analytical methods must be validated to demonstrate their consistent ability to produce a product meeting predefined quality attributes. For non-sterile preparations, this includes validation of water systems (e.g. purified water used in formulations), equipment cleaning protocols, and the robustness of the manufacturing process itself in controlling microbial ingress. The ChP further supports this with guidelines on the verification and transfer of analytical methods, ensuring consistency in testing across different laboratories.

Rigorous validation of manufacturing processes is a cornerstone of pharmaceutical quality.

Microbiological Integrity and Endocrine Function

The microbiological quality of non-sterile preparations is a paramount concern, directly addressed by specific general chapters in the Chinese Pharmacopoeia. ChP methods 1105 (“Microbiological Examination of Non-sterile Products ∞ Microbial Enumeration Tests”) and 1106 (“Microbiological Examination of Non-sterile Products ∞ Tests for Specified Microorganisms”) establish the procedural requirements for assessing microbial load and detecting objectionable organisms. Method 1107 (“Microbiological Acceptance Criteria of Non-sterile Pharmaceutical Products”) defines the permissible limits for microbial contamination.

These microbiological controls are not arbitrary; they are deeply intertwined with human physiology, particularly the delicate balance of the endocrine system and overall metabolic function. The introduction of excessive microbial load or specific pathogens via a non-sterile preparation can trigger systemic inflammatory responses. Chronic, low-grade inflammation, often initiated by microbial components like endotoxins, can disrupt hormonal signaling pathways.

For instance, inflammatory cytokines can interfere with the hypothalamic-pituitary-gonadal (HPG) axis, affecting the pulsatile release of gonadotropin-releasing hormone (GnRH) from the hypothalamus, and subsequently impacting luteinizing hormone (LH) and follicle-stimulating hormone (FSH) secretion from the pituitary. This cascade can lead to downstream dysregulation of gonadal hormones such as testosterone and estrogen, directly counteracting the goals of hormonal optimization protocols.

Consider the impact on metabolic health. The gut microbiome, a complex ecosystem, plays a significant role in nutrient absorption, immune modulation, and even hormone metabolism. Introducing an imbalanced microbial profile through an oral non-sterile preparation could disrupt this delicate gut ecology, potentially leading to dysbiosis.

Dysbiosis has been linked to insulin resistance, altered thyroid function, and systemic inflammation, all of which can further exacerbate hormonal imbalances and metabolic dysfunction. The NMPA’s strict microbial limits for non-sterile oral preparations therefore serve as a critical barrier against such systemic disruptions.

Pharmacopoeial Standards for Non-Sterile Preparations

The Chinese Pharmacopoeia’s general chapters provide detailed guidance on the assessment of non-sterile products. Key aspects include ∞

- Suitability Testing ∞ Before routine testing, the analytical method’s suitability must be demonstrated in the presence of the product. This ensures that the product’s components do not inhibit microbial growth or interfere with the detection of microorganisms.

- Test Strains ∞ Specific reference strains of microorganisms (e.g. Candida albicans, Aspergillus brasiliensis, Escherichia coli, Staphylococcus aureus, Pseudomonas aeruginosa) are used for growth promotion tests of culture media and for method suitability tests.

- Acceptance Criteria ∞ Different categories of non-sterile products have varying acceptance criteria for microbial counts, reflecting their intended use and route of administration. For example, preparations for oral use might have different limits than those for topical application.

The NMPA also oversees the regulation of Traditional Chinese Medicine (TCM) compound preparations, which often fall under the non-sterile category. While TCM has a distinct theoretical framework, the NMPA has issued guidelines for the clinical development of new TCM compound preparations based on human-use experience, emphasizing the need for evidence to support regulatory decisions. This acknowledges the historical use of these preparations while still seeking to integrate them into a modern quality assurance paradigm.

The table below summarizes critical GMP elements for non-sterile preparations and their physiological implications ∞

| GMP Element | Technical Requirement for Non-Sterile Prep | Physiological Impact if Compromised |

|---|---|---|

| Environmental Control | Grade D cleanroom for production areas, controlled air filtration, temperature, humidity. | Increased microbial load in product, potential for systemic infection, inflammatory response, endocrine disruption. |

| Water System Quality | Purified water standards, regular microbial and chemical testing. | Contamination with endotoxins or chemical impurities, leading to fever, inflammation, or direct toxicity affecting metabolic pathways. |

| Personnel Hygiene | Gowning, hand washing, health monitoring, training on aseptic techniques. | Introduction of human-borne pathogens into the product, leading to infections or adverse immune reactions. |

| Raw Material Testing | Identity, purity, and microbial testing of all incoming ingredients. | Contamination from raw materials, leading to unknown impurities, reduced efficacy, or toxic effects on organ systems. |

| Cleaning Validation | Demonstrated removal of residues and microbial contaminants from equipment. | Cross-contamination between different products, leading to unintended drug exposure or allergic reactions. |

The regulatory landscape in China, with its emphasis on GMP and the detailed standards of the Chinese Pharmacopoeia, creates a robust framework for non-sterile pharmaceutical preparations. This rigorous oversight is not merely bureaucratic; it serves as a fundamental safeguard for patient health, ensuring that the personalized hormonal and peptide therapies individuals pursue are built upon a foundation of quality and safety, thereby supporting the body’s innate capacity for balance and vitality.

References

- Chrousos, George P. “Stress and disorders of the stress system.” Nature Reviews Endocrinology 5, no. 7 (2009) ∞ 374-381.

- Cani, Patrice D. “Human gut microbiome ∞ new therapeutic target in obesity and type 2 diabetes.” Nutrition Reviews 73, no. 1 (2015) ∞ 33-41.

- National Medical Products Administration. “Good Manufacturing Practice for Drugs (2010 Revision).” NMPA, 2011.

- Chinese Pharmacopoeia Commission. “Chinese Pharmacopoeia 2020 Edition.” China Medical Science Press, 2020.

- The US-China Business Council. “China National Medical Products Administration (NMPA).” 2021.

- ECA Academy. “New Chinese GMP rules published in English.” 2012.

- Center for Drug Evaluation, NMPA. “Guideline on Clinical Development of New Drug of Traditional Chinese Medicine Compound Preparations Based on Human use Experience (Final).” NMPA, 2022.

- American Pharmaceutical Review. “Comparison between the Microbiological Testing Methods in the 2015 Chinese Pharmacopeia and the United States.” 2018.

Reflection

As we conclude this exploration, consider the profound implications of understanding your own biological systems. The knowledge gained about regulatory safeguards for pharmaceutical preparations is not merely academic; it is a tool for empowerment. Your health journey is uniquely yours, and recognizing the intricate interplay between external factors, such as medication quality, and internal physiological responses allows for a more informed and proactive approach.

The pursuit of vitality is a continuous process, one that benefits immensely from a partnership with clinical expertise and a deep respect for scientific rigor. This understanding of how quality is maintained, even for non-sterile compounds, provides a foundation of trust. It invites you to consider how each element of your wellness protocol contributes to the larger symphony of your body’s systems, moving you closer to a state of optimal function and sustained well-being.