Fundamentals

You find yourself in a place of profound self-awareness, listening intently to the subtle signals your body has been sending. Perhaps it is a persistent fatigue that sleep does not seem to touch, a shift in your mood and cognitive sharpness, or a sense that your internal vitality has diminished.

This journey inward has likely led you to explore the intricate world of hormonal health and the potential of peptide therapies to restore your system’s equilibrium. As you stand at this threshold, considering a protocol that involves molecules like Sermorelin, Testosterone, or Ipamorelin, a foundational question arises from a place of deep personal responsibility ∞ how can you be certain that these compounds are precisely what they claim to be? How is their quality, the very essence of their ability to safely interact with your biology, truly ensured?

This question moves far beyond academic curiosity. It is a deeply personal inquiry into the trust you place in the therapeutic tools designed to recalibrate your health. The answer resides within the meticulous and systematic world of regulatory oversight, a framework designed to protect your biological integrity.

Regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) function as the ultimate stewards of pharmaceutical quality. Their purpose is to establish and enforce a set of universal standards that every manufacturer must meet. This ensures that the peptide you receive is a well-defined therapeutic agent, capable of eliciting a predictable and beneficial physiological response.

Regulatory oversight provides a structured, scientific framework to guarantee that a peptide compound is safe, pure, and potent for its intended biological purpose.

At the heart of this framework lies a concept known as Good Manufacturing Practices, or GMP. GMP is a comprehensive philosophy of production, a set of stringent principles governing every single step of the manufacturing process. It covers the physical facility, the training of the personnel, the validation of the equipment, and the meticulous documentation of every action taken.

Think of GMP as the master blueprint for creating a therapeutic peptide. It ensures that every batch, whether it is the first or the thousandth, is produced with the exact same process controls, resulting in a consistent and reliable final product. This consistency is paramount.

When you begin a protocol, your clinical team is titrating your dose based on the assumption that 10 units of a peptide today is biologically identical to 10 units next month. GMP is the system that makes this assumption a clinical reality.

The Building Blocks of Quality

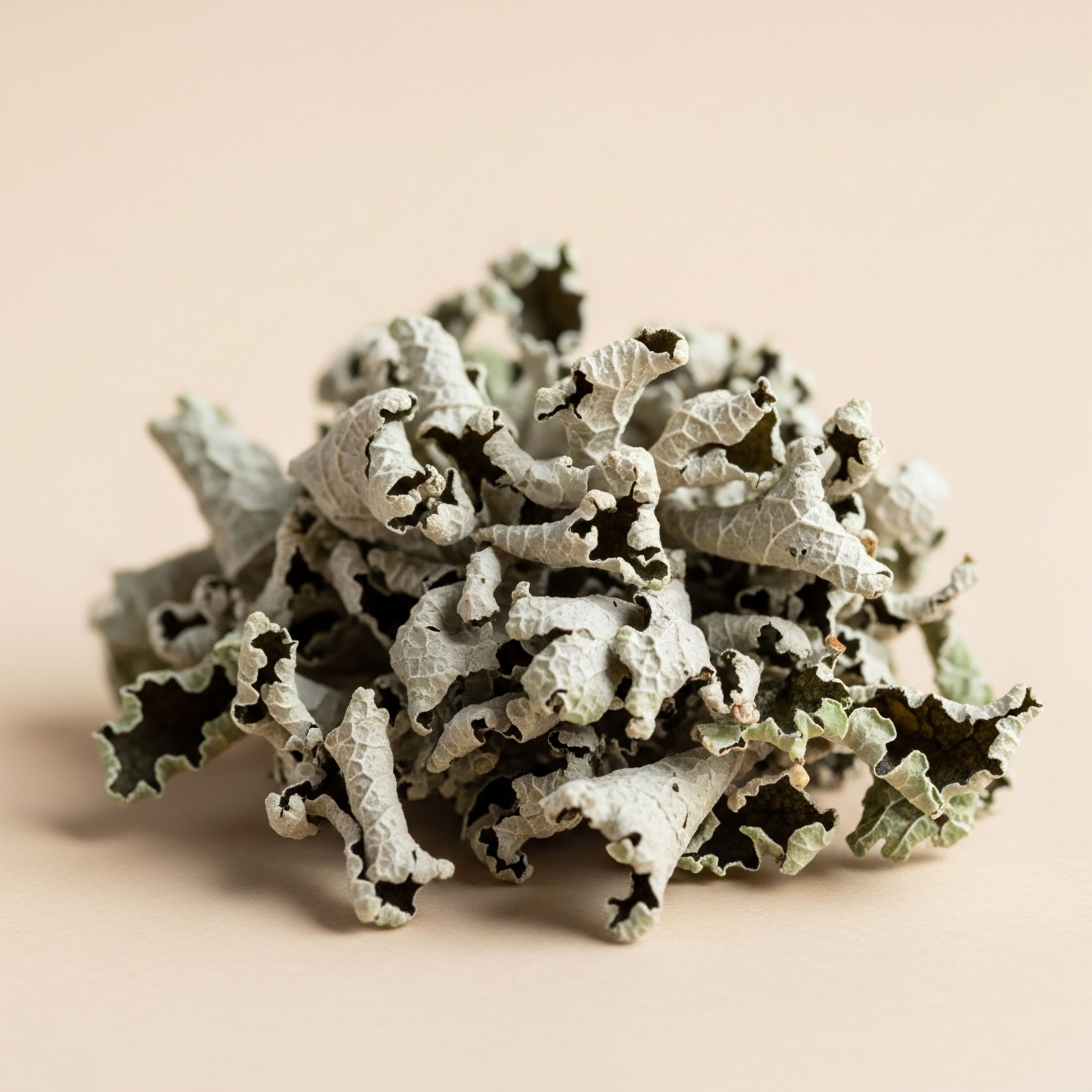

The entire process begins long before the complex synthesis of a peptide chain. It starts with the fundamental raw materials, primarily the amino acids that serve as the building blocks for the final molecule. Regulatory bodies mandate that manufacturers must verify the quality and purity of these starting materials with exacting precision.

Each batch of amino acids must be tested for its identity and purity, ensuring that no contaminants or incorrect stereoisomers (mirror-image molecules) are introduced at the very beginning of the process. This initial step is a critical control point. Introducing a low-quality or impure raw material would inevitably compromise the integrity of the final peptide, creating a cascade of potential issues that could alter its function and safety profile within your body.

Defining a Molecule’s Identity

Once the manufacturing process is complete, the resulting peptide compound undergoes a battery of analytical tests designed to confirm its core attributes. The first and most fundamental of these is identity. The manufacturer must prove, unequivocally, that the molecule they have created is the intended peptide.

For instance, if the goal was to synthesize Tesamorelin, a 44-amino-acid chain, the manufacturer must provide definitive evidence that the final product has that exact sequence and structure. This is achieved through sophisticated analytical techniques that function like a molecular fingerprinting system, confirming that the compound’s structure matches the established reference standard.

This confirmation is the bedrock of therapeutic trust. It assures you and your clinician that the molecule being introduced into your system is the one that has been studied and clinically validated to produce a specific effect, such as supporting the natural release of growth hormone.

The Critical Importance of Purity and Potency

Beyond its basic identity, a peptide’s quality is defined by its purity and potency. Purity refers to the percentage of the active pharmaceutical ingredient (API) in the final product compared to any impurities. During chemical synthesis, it is virtually impossible to achieve 100% purity.

Small amounts of closely related but structurally different molecules, known as impurities, can be formed. Regulatory bodies mandate strict limits on these impurities. Manufacturers must not only quantify the total amount of impurities but also identify their structures, especially if they exceed certain thresholds.

This is because a structurally similar impurity could still interact with your body’s receptors, potentially leading to a weakened therapeutic effect, an unexpected side effect, or even an immunogenic reaction. Ensuring high purity means you are receiving a clean signal, a clear message to your endocrine system, without the biological noise of unwanted molecules.

Potency, in turn, is the measure of the peptide’s biological activity. It answers the question ∞ does the molecule actually perform its intended function at the cellular level? For a peptide like Gonadorelin, used to support the hypothalamic-pituitary-gonadal (HPG) axis, a potency assay would measure its ability to stimulate the pituitary gland.

This is a functional validation of the molecule’s quality. It confirms that the peptide not only has the correct structure but also folds into the correct three-dimensional shape required to bind to its target receptor and initiate the desired biological cascade.

Regulatory agencies require manufacturers to establish and meet potency specifications, ensuring that each dose of the medication delivers a reliable and quantifiable therapeutic effect. This systematic assurance of identity, purity, and potency is how regulatory bodies transform a synthesized chemical into a trusted therapeutic tool, providing you with the confidence to embark on your journey toward renewed vitality.

Intermediate

As you become more familiar with the landscape of hormonal optimization, your questions naturally evolve. You begin to look past the foundational assurances of quality and seek to understand the specific mechanisms of regulatory enforcement. How do agencies like the FDA translate the philosophy of Good Manufacturing Practices (GMP) into a concrete, auditable set of requirements for a peptide manufacturer?

The answer lies in a critical component of any drug application known as the Chemistry, Manufacturing, and Controls (CMC) section. The CMC dossier is the master document where a manufacturer provides the complete scientific and technical evidence that they can consistently produce a high-quality peptide. It is the rulebook they write for themselves, which is then rigorously audited and approved by the regulatory authority.

The CMC section details every facet of the production lifecycle. It begins with the characterization of the starting materials, including the amino acids and reagents used in the synthesis. It describes the entire manufacturing process in granular detail, outlining each chemical reaction, purification step, and in-process control.

Think of these in-process controls as quality checkpoints along the production line. At various stages, samples are taken and tested to ensure the process is running as expected, allowing for adjustments to be made before the final product is complete. This proactive approach to quality management is a hallmark of the GMP framework.

The CMC section also contains the full suite of analytical methods used to test the final peptide for identity, purity, potency, and stability, along with the validation data proving those methods are accurate and reliable. Finally, it establishes the formal specifications, which are the set of criteria that a batch of the peptide must meet to be released for clinical use.

The Role of Pharmacopoeias in Setting Standards

While the CMC provides the specific details for one particular product, the broader standards for peptide quality are established in official pharmacopoeias. The United States Pharmacopeia (USP) and the European Pharmacopoeia (Ph. Eur.) are legally recognized compendiums of standards for medicines.

These are not static textbooks; they are dynamic scientific documents developed by independent experts, including scientists from academia, industry, and regulatory agencies. They provide general chapters and specific monographs that outline the expected quality attributes for different types of drugs.

For synthetic peptides, which occupy a unique space between traditional small-molecule drugs and larger biologics, dedicated chapters have been developed to address their specific challenges. For example, USP General Chapter <1503>, “Quality Attributes of Synthetic Peptide Drug Substances,” provides a detailed overview of the critical quality attributes that need to be controlled, with a strong focus on the impurity profile.

These pharmacopoeial standards serve as a baseline for regulators and manufacturers, creating a shared understanding of what constitutes a quality peptide compound.

The CMC dossier is a manufacturer’s detailed promise of quality, while pharmacopoeias provide the universal language and standards for defining it.

Advanced Analytical Techniques the Tools of Quality Verification

To meet the stringent requirements of the CMC and pharmacopoeial standards, manufacturers employ a sophisticated arsenal of analytical technologies. These instruments allow scientists to visualize and quantify the molecular attributes of a peptide with incredible precision. The two most powerful and widely used techniques in peptide quality control are High-Performance Liquid Chromatography (HPLC) and Mass Spectrometry (MS).

- High-Performance Liquid Chromatography (HPLC) is the workhorse for assessing peptide purity. In an HPLC system, the peptide sample is dissolved in a liquid and pumped under high pressure through a column packed with a solid material (the stationary phase). Because different molecules in the sample have different chemical affinities for the stationary phase, they travel through the column at different speeds. This separates the main peptide from process-related impurities and degradation products. As the separated molecules exit the column, they pass through a detector, which generates a signal for each component. The result is a chromatogram, a graph showing a series of peaks. The largest peak typically represents the pure peptide, while smaller peaks represent impurities. The area of each peak is proportional to the amount of that substance, allowing for precise quantification of the peptide’s purity. For many peptide protocols, such as TRT for women where doses are very small (e.g. 10-20 units weekly), ensuring this high level of purity is essential for accurate and safe administration.

- Mass Spectrometry (MS) is a technique used to measure the precise mass of a molecule. It is the ultimate tool for confirming a peptide’s identity. In a mass spectrometer, the peptide molecules are given an electrical charge and then accelerated through a magnetic or electric field. The field deflects the molecules according to their mass-to-charge ratio. By measuring this deflection, the instrument can determine the molecular weight of the peptide with extraordinary accuracy. This experimental mass is then compared to the theoretical mass calculated from the peptide’s amino acid sequence. A match provides definitive confirmation of the peptide’s identity. High-resolution mass spectrometry can also be used to identify unknown impurities by providing their exact mass, which gives crucial clues to their chemical structure.

How Do Regulators Define an Acceptable Impurity?

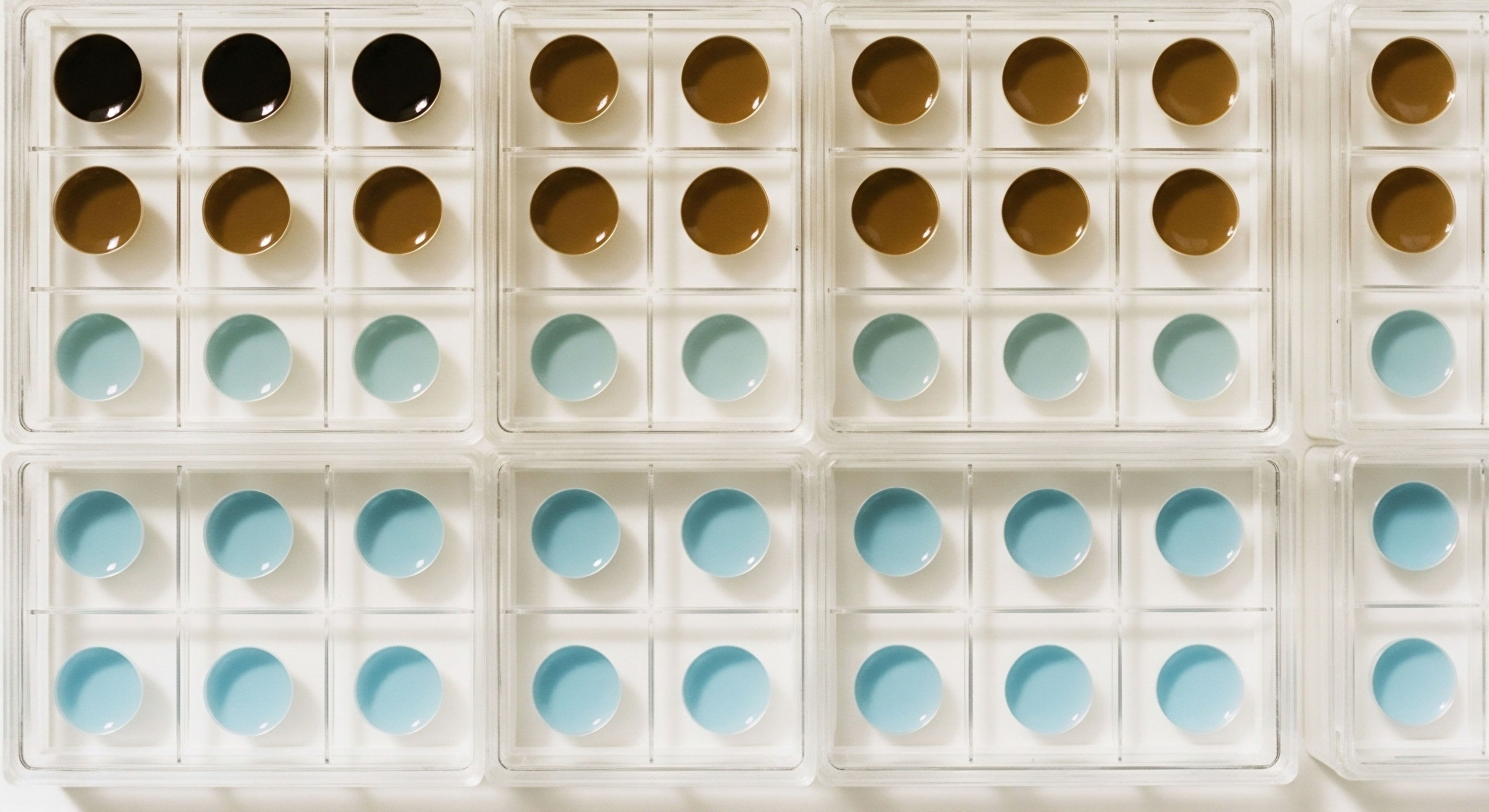

The control of impurities is arguably the most complex aspect of peptide regulation. Regulatory agencies have established specific thresholds for impurities. The European Pharmacopoeia, for instance, sets the identification threshold for impurities in synthetic peptides at 0.5%. This means any single impurity present at or above this level must be structurally identified.

The qualification threshold, often around 1.0%, is the level above which an impurity must be assessed for its biological safety. The FDA, on the other hand, often takes a case-by-case approach and may require immunogenicity risk assessment for any new impurity found at a level above 0.10% when comparing a generic peptide to a reference drug.

This meticulous focus on impurities stems from the understanding that even a small structural change can alter a peptide’s biological function or, in a worst-case scenario, trigger an adverse immune response. This is particularly relevant for therapies involving peptides designed to mimic endogenous hormones, where maintaining a high-fidelity signal is the entire point of the intervention.

| Technique | Primary Purpose | Information Provided | Relevance to Patient Safety |

|---|---|---|---|

| HPLC | Purity Assessment | Quantifies the percentage of the active peptide versus impurities. | Ensures the dose contains the correct amount of the active drug and minimizes exposure to potentially harmful or inactive substances. |

| Mass Spectrometry (MS) | Identity Confirmation | Measures the exact molecular weight of the peptide, confirming its chemical formula. | Guarantees that the correct molecule is being administered, preventing the use of incorrect or structurally flawed compounds. |

| Amino Acid Analysis (AAA) | Composition Verification | Determines the relative amounts of each amino acid in the peptide. | Confirms that the peptide is built from the correct amino acid building blocks in the correct ratios. |

| Circular Dichroism (CD) | Structural Conformation | Analyzes the peptide’s secondary structure (e.g. alpha-helices, beta-sheets). | Verifies that the peptide is folded correctly, which is essential for its biological activity and receptor binding. |

Academic

A sophisticated understanding of peptide quality control requires a perspective rooted in systems biology. The regulatory frameworks established by bodies like the FDA and EMA are designed to manage the intricate interplay between a synthetic therapeutic agent and the complex, dynamic environment of the human body.

From this academic viewpoint, a peptide is an information-dense molecule designed to interface with a specific biological network, such as the Hypothalamic-Pituitary-Gonadal (HPG) axis in the case of Gonadorelin or Testosterone Replacement Therapy (TRT). Regulatory science, therefore, is the discipline of ensuring the fidelity of that information transfer.

Any deviation in the peptide’s structure, purity, or stability represents a potential corruption of the intended signal, with consequences that can range from a loss of efficacy to significant adverse events.

Synthetic peptides present a unique regulatory challenge because they exist at the interface of small-molecule drugs and large-molecule biologics. They are large enough to have complex structural features and the potential for immunogenicity, like a protein, yet they are often produced via chemical synthesis, like a small molecule.

This has led to a regulatory landscape where guidance from both worlds is often applied. Key international guidelines, such as those from the International Council for Harmonisation (ICH), frequently exclude peptides from their scope, necessitating the development of specific standards like those found in the USP and Ph. Eur. This nuanced position requires manufacturers to conduct a deep and thorough characterization of their product, going far beyond what might be required for a simpler chemical entity.

What Are the Regulatory Implications of Peptide Conjugation?

The drive to improve the therapeutic properties of peptides, particularly their short in-vivo half-lives, has led to the development of advanced conjugation strategies. For example, in some long-acting Growth Hormone Releasing Hormone (GHRH) analogues like certain versions of CJC-1295, a reactive maleimidopropyl group is attached to the peptide.

This group allows the peptide to form a covalent bond with albumin in the bloodstream, dramatically extending its duration of action. From a regulatory perspective, this conjugation adds a significant layer of complexity. The CMC submission must now characterize both the peptide and the linker, as well as the final conjugated product.

Regulators will require data demonstrating the consistency of the conjugation reaction, the specific site of attachment on the peptide, and the stability of the resulting peptide-albumin conjugate. Furthermore, the potential for the linker itself or any byproducts of the conjugation reaction to introduce toxicity or immunogenicity must be thoroughly evaluated. This deep dive into molecular engineering is essential to ensure the safety and predictability of these advanced therapeutic agents.

The regulatory assessment of a peptide is a deep analysis of its molecular integrity, aimed at guaranteeing it sends a clear and precise signal to the body’s complex biological networks.

Immunogenicity a Central Concern in Peptide Regulation

A primary concern for regulators, especially with larger or modified peptides, is the risk of immunogenicity. This is the potential for the therapeutic peptide to be recognized as foreign by the patient’s immune system, leading to the development of anti-drug antibodies (ADAs). The presence of ADAs can have several negative consequences.

They can neutralize the therapeutic effect of the peptide by binding to it and preventing it from reaching its target receptor. They can also accelerate the clearance of the peptide from the body. In rare cases, if the therapeutic peptide is very similar to an endogenous protein, the ADAs could cross-react with the body’s own protein, leading to an autoimmune response.

The risk of immunogenicity is significantly increased by the presence of impurities, particularly those that are structurally related to the peptide or form aggregates. Aggregates are clumps of peptide molecules that can be highly immunogenic. For this reason, regulatory agencies require manufacturers to implement sensitive analytical methods to detect and control aggregates, such as Size-Exclusion Chromatography (SEC).

They also require a comprehensive immunogenicity risk assessment based on the peptide’s sequence, structure, origin (e.g. human vs. non-human sequence), and the patient population. This focus on immunogenicity underscores the deep biological thinking that informs modern regulatory science.

How Does Manufacturing Method Influence the Final Impurity Profile?

The specific method used to manufacture a peptide has a profound impact on the types and quantities of impurities that are generated. The most common method for producing synthetic peptides is Solid-Phase Peptide Synthesis (SPPS). In SPPS, the peptide is built one amino acid at a time while it is anchored to a solid resin support.

While highly efficient, the repetitive nature of SPPS can lead to a characteristic set of process-related impurities. Understanding this impurity profile is a key expectation of regulatory bodies. They expect the manufacturer to demonstrate a deep understanding of their own process and to have implemented controls to minimize these byproducts. The final purification steps, typically involving one or more rounds of HPLC, are designed to remove these impurities to meet the strict specifications for the final active pharmaceutical ingredient.

| Impurity Type | Description | Potential Biological Impact | Primary Detection Method |

|---|---|---|---|

| Deletion Sequences | An amino acid is missing from the peptide chain due to an incomplete coupling reaction. | Can lead to a completely inactive or weakly active peptide. May have altered receptor binding. | HPLC, Mass Spectrometry (MS) |

| Insertion Sequences | An extra amino acid is incorporated into the chain, often due to incomplete removal of a temporary protecting group. | Alters the structure and likely the function of the peptide. Potential for immunogenicity. | HPLC, Mass Spectrometry (MS) |

| Truncated Sequences | The peptide chain synthesis stops prematurely, resulting in shorter fragments. | These are typically inactive but contribute to overall impurity levels. | HPLC |

| Deamidation Products | The side chain of an asparagine or glutamine residue is hydrolyzed, converting it to aspartic or glutamic acid. | Introduces a negative charge, which can alter the peptide’s structure, stability, and biological activity. | Ion-Exchange HPLC, MS |

| Oxidation Products | Amino acids like methionine or cysteine are oxidized during synthesis or storage. | Can significantly reduce or eliminate biological activity. | Reversed-Phase HPLC, MS |

| Racemization | An L-amino acid (the natural form) flips to its D-amino acid (mirror image) stereoisomer during a coupling reaction. | Can dramatically alter the peptide’s 3D structure and its ability to bind to the target receptor. | Chiral Chromatography, HPLC-MS |

The rigorous analysis and control of these manufacturing-derived impurities is a non-negotiable aspect of gaining regulatory approval. It represents the pinnacle of quality control, where advanced analytical chemistry and a deep understanding of protein biochemistry converge to ensure the safety and efficacy of peptide therapeutics.

For the individual on a personalized wellness protocol, this academic-level scrutiny is what provides the ultimate confidence that their therapy is built on a foundation of molecular precision, designed to restore function and vitality without introducing unnecessary biological risk.

References

- Thürmer, R. “Regulatory Perspective on Synthetic Peptides in Europe.” Peptide Therapeutics ∞ Strategy and Tactics for Chemistry, Manufacturing and Controls, edited by V. Srivastava, The Royal Society of Chemistry, 2019, pp. 31-68.

- Duncan, Katharine. “FDA’S Katharine Duncan on CMC Expectations for Therapeutic Peptides.” IPQ.org, 21 May 2024.

- United States Pharmacopeial Convention. “General Chapter, 〈1503〉 Quality Attributes of Synthetic Peptide Drug Substances.” USP-NF, 2021.

- Rogstad, Sarah, et al. “Modern analytics for synthetically derived complex drug substances ∞ NMR, AFFF ∞ MALS, and MS tests for glatiramer acetate.” Analytical and Bioanalytical Chemistry, vol. 407, no. 29, 2015, pp. 8647 ∞ 8659.

- Bunger, et al. “Control Strategies for Synthetic Therapeutic Peptide APIs – Part I ∞ Analytical Consideration.” Polypeptide, 2015.

- De-stress, Hitesh, et al. “Analytical techniques for peptide-based drug development ∞ Characterization, stability and quality control.” International Journal of Science and Research Archive, vol. 12, no. 1, 2024, pp. 3140-3159.

- “Chapter 1 ∞ Regulatory Considerations for Peptide Therapeutics.” Peptide Therapeutics ∞ Strategy and Tactics for Chemistry, Manufacturing and Controls, The Royal Society of Chemistry, 2019, pp. 1-30.

- “The Impact of European Pharmacopeia Regulations for Peptides During the Change of Manufacturer at Late Phase.” Almac Group, 2021.

- Cain, et al. “Development and Regulatory Challenges for Peptide Therapeutics.” International Journal of Toxicology, vol. 39, no. 6, 2020, pp. 1091581820977846.

- “Good Manufacturing Practice (GMP) standards are essential in peptide manufacturing. ” NEX Bio, 20 February 2025.

Reflection

The knowledge of the rigorous, multi-layered process that underpins the quality of a therapeutic peptide offers a powerful perspective. It transforms the conversation from one of uncertainty to one of informed dialogue. Understanding the roles of GMP, the CMC dossier, and advanced analytical methods provides you with a new lens through which to view your own health journey.

This is the architecture of trust, built from scientific precision and a deep respect for biological integrity. This understanding becomes a tool, enabling you to engage with your clinical team on a more profound level, to ask insightful questions, and to move forward with the quiet confidence that comes from knowing the immense care invested in the molecules designed to support your body’s return to balance.

Your path to optimized health is a personal one, and this knowledge serves as a critical checkpoint on that map, empowering you to proceed with clarity and assurance.