Fundamentals

Your body’s internal landscape is governed by a precise and elegant language of chemical messengers. When we introduce therapeutic peptides Meaning ∞ Therapeutic peptides are short amino acid chains, typically 2 to 50 residues, designed or derived to exert precise biological actions. into this system, we are adding new words to an ongoing conversation. The immediate question that arises, both for the clinician and for you, is one of authenticity.

How do we ensure the messages we are sending are clear, correct, and free from disruptive noise? This is the central purpose of the rigorous oversight applied to pharmaceutical-grade peptides. The process begins with the foundational principle that what is administered to a patient must be exactly what it purports to be, in its most pure and active form.

Regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) exist to provide a framework of certainty in this complex biochemical world. They establish the standards that transform a synthesized molecule from a laboratory curiosity into a reliable therapeutic tool.

Their guidelines are a multi-layered defense against the potential for harm that could arise from impurities, incorrect sequences, or structural instability. These are not arbitrary rules; they are the codification of decades of scientific understanding about how these molecules behave both in a vial and within the human body. The journey of a peptide from synthesis to syringe is scrutinized at every step to guarantee its identity, potency, and purity are intact.

The Blueprint of a Peptide

Imagine a peptide as a specific key designed to fit a particular lock on the surface of a cell. The sequence of its amino acids ∞ the building blocks of the molecule ∞ determines the shape of that key. If the sequence is wrong, the key will not fit.

If the key is misshapen or cluttered with other molecules, it may fail to work or, worse, jam the lock entirely. Regulatory science, therefore, begins with an exhaustive characterization of the peptide itself. Scientists use sophisticated analytical techniques to confirm that the amino acid sequence is correct, that the molecule has folded into its proper three-dimensional shape, and that it is free from contaminants that could alter its function or provoke an unwanted response from your immune system.

This initial characterization serves as the gold standard for every batch that is subsequently produced. It is the master blueprint against which all future production is measured. This process ensures that the therapeutic signal sent by the peptide is consistent and predictable, allowing for the development of protocols that are both safe and effective.

The commitment to this level of detail is a direct acknowledgment of the profound impact these molecules have on our physiology. It is a commitment to ensuring that when we seek to optimize health, we do so with tools of the highest possible integrity.

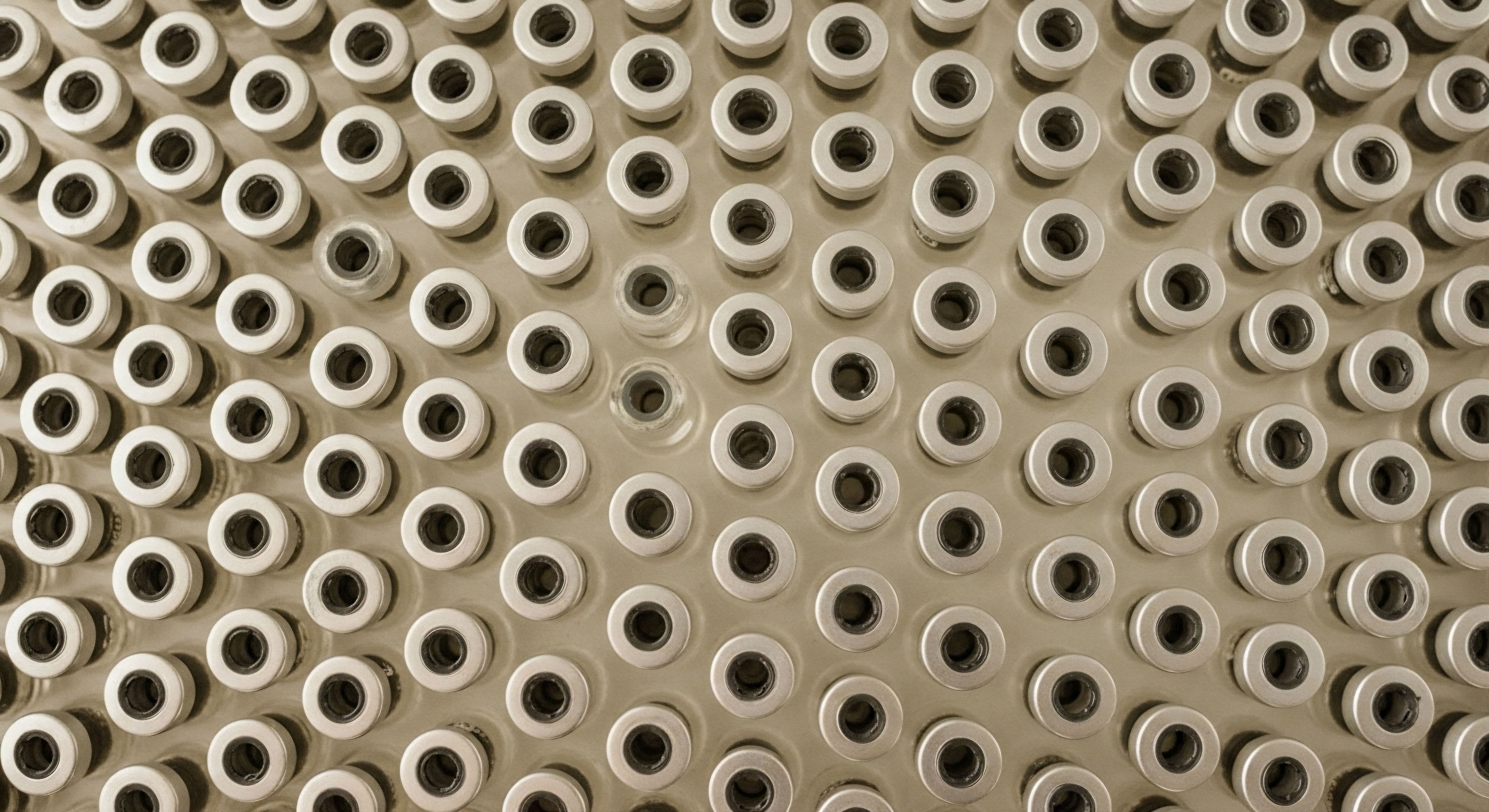

Purity in therapeutic peptides is a direct measure of their safety and reliability as biological messengers.

Why Impurities Matter

The synthesis of a peptide is a complex chemical process, and like any manufacturing process, it can generate byproducts. In the context of peptide therapy, these byproducts are known as impurities. They can take many forms, from small fragments of the intended peptide to residual chemicals from the synthesis itself.

Regulatory guidelines are particularly stringent about identifying and limiting these impurities for two primary reasons. First, an impurity could have its own biological activity, potentially triggering unintended and harmful effects. Second, the immune system Meaning ∞ The immune system represents a sophisticated biological network comprised of specialized cells, tissues, and organs that collectively safeguard the body from external threats such as bacteria, viruses, fungi, and parasites, alongside internal anomalies like cancerous cells. might recognize an impurity as foreign and mount an inflammatory response, which could compromise the therapy’s effectiveness and your overall well-being.

The guidelines set forth by agencies such as the EMA Meaning ∞ EMA, in the context of hormonal health, refers to Estrogen Metabolism Assessment, a detailed evaluation of how the body processes and eliminates estrogen hormones. and the FDA, along with pharmacopoeias like the United States Pharmacopeia (USP), provide specific thresholds for different types of impurities. They require manufacturers to not only detect these substances but also to understand their potential impact.

This deep analytical work provides a comprehensive safety profile for the peptide, ensuring that the therapeutic signal is clean and that the risk of biochemical static is minimized. This meticulous attention to what should not be in the final product is as important as confirming what should be.

Intermediate

The assurance of peptide purity Meaning ∞ Peptide purity defines the percentage of the desired, correctly synthesized peptide molecule in a sample, free from related impurities like truncated sequences or chemical byproducts. transitions from a conceptual necessity to a practical reality through a series of highly specific analytical and manufacturing controls. Regulatory bodies Meaning ∞ Regulatory bodies are official organizations overseeing specific sectors, ensuring adherence to established standards and laws. do not simply request that a peptide be pure; they mandate a comprehensive control strategy that documents and validates purity at every stage of production.

This strategy is a dynamic process, involving a deep understanding of the peptide’s chemistry, its manufacturing pathway, and its stability over time. For those on a journey of hormonal optimization, understanding this process provides a deeper appreciation for the quality inherent in a prescribed therapeutic.

The core of this regulatory expectation lies in the principle of “Quality by Design.” This approach requires the manufacturer to build quality into the product from the very beginning, starting with the raw materials. The amino acids used for synthesis, for instance, must meet their own stringent purity specifications.

The entire manufacturing process, most commonly Solid-Phase Peptide Synthesis Meaning ∞ Solid-Phase Peptide Synthesis (SPPS) is a robust chemical method for creating peptides by sequentially adding amino acid building blocks to a growing chain that is anchored to an insoluble polymeric support, typically a resin bead. (SPPS), is meticulously mapped and its parameters controlled to minimize the formation of impurities from the outset. This proactive approach is a fundamental tenet of modern pharmaceutical manufacturing.

What Are the Key Analytical Tests for Purity?

To confirm the purity of a peptide drug substance, manufacturers employ a battery of sophisticated analytical techniques. Each test provides a different piece of the puzzle, and together they create a high-resolution picture of the final product’s quality. These methods are specified in pharmacopoeial monographs and regulatory guidance documents.

- High-Performance Liquid Chromatography (HPLC) ∞ This is the workhorse of purity analysis. HPLC separates the target peptide from any related impurities, allowing for precise quantification of each. The results are often expressed as a percentage purity, for instance, >99.0%.

- Mass Spectrometry (MS) ∞ This technique provides an exact measurement of the molecular weight of the peptide. It serves as a definitive confirmation of the peptide’s identity and can be used to identify the chemical structures of impurities detected by HPLC.

- Amino Acid Analysis (AAA) ∞ This method verifies that the correct amino acids are present in the correct ratios, confirming the fundamental composition of the peptide chain.

- Water Content ∞ Peptides are often lyophilized (freeze-dried) for stability, and the amount of residual water must be carefully controlled, as excess water can promote degradation. The Karl Fischer titration method is typically used for this measurement.

These tests, among others, form the basis of a Certificate of Analysis, a document that accompanies every batch of a pharmaceutical-grade peptide and attests to its quality and purity. The acceptance criteria for these tests are not arbitrary; they are set based on extensive stability studies and toxicological assessments.

A peptide’s purity profile is established through a suite of orthogonal analytical methods, each providing a unique and essential piece of quality data.

Comparing Regulatory Frameworks

While the goal of ensuring safety and efficacy is universal, the specifics of regulatory frameworks can differ slightly between regions, primarily between the FDA Meaning ∞ The Food and Drug Administration, or FDA, is a federal agency within the U.S. in the United States and the EMA in Europe. These differences are often subtle but reflect evolving scientific consensus and regional approaches to risk management.

For instance, the thresholds for identifying and qualifying unknown impurities may vary. However, international efforts, such as the International Council for Harmonisation (ICH), work to create a unified set of guidelines to streamline the global development of new medicines, including peptides.

The table below outlines some of the key areas of focus for regulatory bodies and the common requirements that manufacturers must meet. This structured approach ensures a consistent standard of quality, regardless of where the peptide is manufactured or intended to be used.

| Regulatory Checkpoint | Purpose | Commonly Required Actions |

|---|---|---|

| Starting Material Control | To ensure the quality of the building blocks of the peptide. | Provide specifications for all raw materials, including amino acid derivatives and reagents. Demonstrate that impurities in starting materials do not carry over into the final product. |

| Process Controls | To minimize the formation of impurities during synthesis and purification. | Define and validate operating ranges for all critical process steps, such as reaction times, temperatures, and purification parameters. |

| Impurity Profiling | To identify and quantify all substances other than the active peptide. | Use validated HPLC methods to separate and quantify impurities. Use Mass Spectrometry to identify the structure of significant impurities. Set acceptance limits for individual and total impurities. |

| Stability Testing | To ensure the peptide remains pure and potent throughout its shelf life. | Conduct long-term and accelerated stability studies under various conditions (e.g. temperature, humidity, light). Monitor purity, potency, and degradation products over time. |

How Are Acceptable Impurity Levels Determined?

The determination of acceptable limits for impurities is a science rooted in toxicology and risk assessment. For impurities that are structurally similar to the main peptide (e.g. a sequence variant), their potential biological activity and immunogenicity are primary concerns. Regulatory bodies often require that any impurity present above a certain threshold (e.g.

0.5%) be identified and, if necessary, “qualified.” Qualification involves conducting studies to demonstrate that the impurity is safe at the level it is found in the product. This might involve dedicated toxicological studies or a robust scientific argument based on its chemical structure and known biological pathways.

This rigorous, data-driven process ensures that the specifications for a peptide product are not just based on manufacturing capability but are fundamentally tied to patient safety. It is a system designed to provide confidence that the therapeutic you receive is not only pure by chemical standards but safe by biological ones.

Academic

The regulatory assurance of peptide purity extends into highly specialized domains of biochemical and immunological science. Beyond the straightforward quantification of impurities lies the complex challenge of assessing the potential for immunogenicity. An immune response to a therapeutic peptide or its contaminants can neutralize the drug’s effect or, in more severe cases, trigger systemic inflammatory reactions.

Consequently, regulatory science in this area is focused on a deep, proactive assessment of immunogenic risk, a process that integrates molecular characterization with predictive in-vitro assays and a thorough understanding of the manufacturing process.

The central scientific issue is that even minute structural variations in a peptide can be recognized by the immune system as foreign. This is particularly true for impurities that arise during synthesis or degradation, such as aggregated forms of the peptide or sequences with minor modifications.

Regulatory agencies, therefore, require a comprehensive risk assessment that considers not only the peptide’s intrinsic properties (its sequence, origin, and similarity to human proteins) but also the extrinsic factors related to its manufacturing and clinical use. This systems-level view is essential for ensuring the long-term safety and viability of peptide therapeutics.

The Immunogenicity Conundrum of Peptide Impurities

The potential for a peptide-related impurity to provoke an immune response is a function of its ability to be processed by antigen-presenting cells (APCs) and subsequently displayed to T-lymphocytes. This complex biological cascade is the initiating event for most immunogenic reactions.

An impurity might be more immunogenic than the parent peptide if its structure is more readily taken up by APCs or if it forms a novel epitope that the immune system has not been tolerized to. This is a significant concern for regulatory bodies, as even a seemingly minor impurity could have disproportionate immunological consequences.

To address this, advanced analytical methods Meaning ∞ Analytical Methods refer to systematic, standardized procedures employed in scientific and clinical laboratories to identify, quantify, and characterize biological substances or processes. are employed to characterize the full spectrum of impurities. Techniques like two-dimensional liquid chromatography combined with high-resolution mass spectrometry can provide a granular view of the impurity profile. Once identified, the immunogenic potential of specific impurities can be evaluated using sophisticated in-silico tools and in-vitro assays.

These assays may involve exposing human immune cells to the impurity and measuring markers of T-cell activation. This proactive, science-based approach to immunogenicity assessment is becoming an integral part of the regulatory submission for new peptide drugs.

The immunogenic risk of a therapeutic peptide is a composite of its intrinsic molecular properties and the extrinsic factors of its production and administration.

Higher-Order Structure and Purity

For many peptides, biological activity is contingent upon a specific three-dimensional conformation, often referred to as its higher-order structure. Purity, in this context, is not just about the absence of chemical contaminants; it is also about the presence of the correctly folded, active molecule. Aggregation, where peptide molecules clump together, is a common and critical issue. Aggregates can represent a loss of potency and are often associated with an increased risk of immunogenicity.

Regulatory guidelines mandate the use of analytical techniques capable of characterizing these higher-order structures. The table below details some of these methods and their specific applications in defining the structural integrity of a peptide product.

| Analytical Technique | Principle of Operation | Information Provided |

|---|---|---|

| Circular Dichroism (CD) Spectroscopy | Measures the differential absorption of left- and right-circularly polarized light. | Provides information on the secondary structure of the peptide (e.g. alpha-helix, beta-sheet content). Useful for assessing conformational integrity. |

| Size-Exclusion Chromatography (SEC) | Separates molecules based on their hydrodynamic radius. | Detects and quantifies soluble aggregates and oligomers, which are critical impurities that can impact safety and efficacy. |

| Dynamic Light Scattering (DLS) | Measures fluctuations in scattered light intensity due to particle motion. | Provides information on the size distribution of particles in a solution, including aggregates and sub-visible particles. |

| Nuclear Magnetic Resonance (NMR) Spectroscopy | Probes the magnetic properties of atomic nuclei. | Can provide a detailed, atom-level map of the peptide’s three-dimensional structure in solution. |

The integration of these advanced analytical methods into the regulatory framework reflects a mature understanding of peptide science. It acknowledges that the true purity of a biological drug is a composite of its chemical identity, its structural integrity, and its immunological silence. This comprehensive approach is what underpins the safety and reliability of modern peptide therapies, providing a robust foundation for their use in personalized wellness protocols.

The establishment of qualification thresholds for impurities is a cornerstone of this academic approach. As outlined in draft EMA guidelines and Ph. Eur. monographs, there is a clear, risk-based rationale for setting limits.

For instance, the general threshold of 1.0 mg/day for total daily intake of an uncharacterized impurity provides a conservative safety margin, derived from principles established for small molecule drugs but adapted for the unique considerations of peptides. This quantitative approach moves the discussion of purity from a qualitative ideal to a measurable and enforceable standard, grounded in toxicological and immunological principles.

References

- De Spiegeleer, B. et al. “Regulatory Guidelines for the Analysis of Therapeutic Peptides and Proteins.” Journal of Peptide Science, vol. 31, no. e70001, 2025.

- De Spiegeleer, B. et al. “Quality specifications for peptide drugs ∞ A regulatory-pharmaceutical approach.” Journal of Peptide Science, vol. 15, no. 10, 2009, pp. 683-96.

- DLRC Group. “Synthetic Peptides ∞ Understanding The New CMC Guidelines.” DLRC Group Website, 20 Dec. 2023.

- Duncan, Katharine. “CMC Regulatory Experiences and Expectations for Peptides.” USP Presentation, 2024.

- Lepsy, C. “Assessing the Safety of Peptide-Related Impurities in Support of Commercial Control Strategy Development.” USP Presentation, 26 Nov. 2024.

Reflection

You have now seen the intricate systems and scientific rigor that stand behind the concept of peptide purity. This knowledge transforms the conversation about therapeutic protocols. It moves from a simple question of “what does this do?” to a more profound appreciation of “what is this, precisely?” The layers of regulatory oversight, from the fundamental blueprint of an amino acid sequence to the sophisticated analysis of immunological risk, are all in service of one goal ∞ ensuring the message sent to your body is the one intended.

This understanding is the first step on any path toward proactive wellness. The next is to consider how this foundation of quality and precision applies to your own unique biological system. The journey is personal, but the science that makes it possible is universal.