Fundamentals

Embarking on a journey to optimize your health often leads to exploring innovative therapies, including peptides. You may feel a sense of hope and anticipation, coupled with a desire for reassurance that these compounds are both effective and safe. This desire for certainty is the very reason regulatory bodies exist.

Their role is to establish a framework of trust between you and the therapies you are considering, ensuring that the product you receive is precisely what it claims to be. It is a silent partnership dedicated to your well-being, translating complex scientific principles into a tangible assurance of quality.

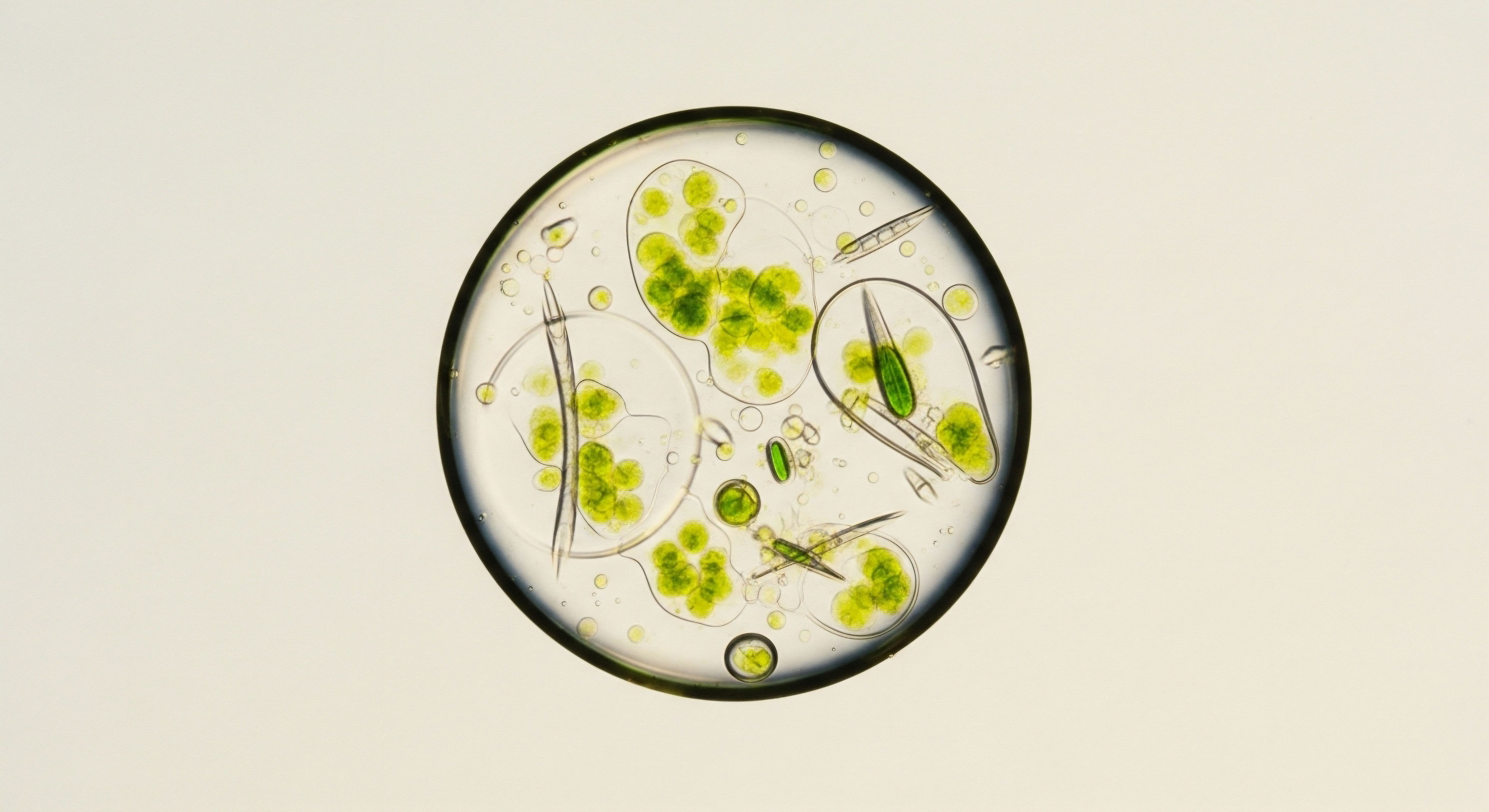

The commitment to quality begins long before a peptide therapeutic reaches you. It originates in the meticulous processes of synthesis and purification, where every step is scrutinized to produce a molecule with the correct sequence and structure. Think of it as a biological blueprint, where even the slightest deviation can alter the intended message.

Regulatory oversight ensures that manufacturers adhere to this blueprint with unwavering consistency, so the therapeutic dialogue within your body occurs as intended. This foundational vigilance is what allows you to focus on your health goals, confident in the integrity of the tools you are using.

Regulatory bodies establish a framework of trust, ensuring that the peptide product you receive is precisely what it claims to be.

Understanding the importance of purity is central to appreciating the regulatory process. A pure peptide product contains only the desired amino acid sequence, free from contaminants or unintended variations that could arise during manufacturing. These impurities, even in minute quantities, can have significant biological consequences.

Therefore, regulatory agencies mandate rigorous testing to identify and quantify any such deviations. This analytical rigor provides a clear picture of the product’s composition, offering a layer of security that is essential for any therapeutic intervention. Your body is a finely tuned system, and the purity of what you introduce into it is paramount.

The Language of Quality Control

In the world of peptide therapeutics, quality control is a language spoken through data. Scientists use sophisticated analytical techniques to characterize each batch of a product, generating a unique fingerprint that attests to its identity and purity. This process is not a mere formality; it is a profound expression of the commitment to patient safety.

The data from these analyses are then compiled into a comprehensive dossier, which is submitted to regulatory authorities for review. This dossier tells the story of the product, from its conception to its final form, providing a transparent account of its quality. It is a testament to the methodical and disciplined approach required to bring a new therapy into clinical practice.

From the Laboratory to You

The journey of a peptide therapeutic from the laboratory to you is a long and exacting one, governed by a series of checkpoints designed to ensure its quality and safety at every stage. This journey is a collaborative effort between manufacturers and regulatory bodies, all working towards the common goal of advancing human health.

The regulations in place are not static; they evolve as our scientific understanding deepens and new technologies emerge. This dynamic process of refinement ensures that the standards for peptide quality remain at the cutting edge of scientific capability. It is a continuous cycle of innovation and oversight, all in service of your health and well-being.

Intermediate

As you deepen your understanding of peptide therapeutics, it becomes clear that ensuring their quality is a highly structured and regulated process. Regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established comprehensive guidelines that manufacturers must follow.

These guidelines are not merely suggestions; they are legally enforceable standards that govern every aspect of a peptide’s lifecycle, from its synthesis to its packaging and distribution. Adherence to these standards is a prerequisite for any peptide therapeutic to be approved for clinical use.

A cornerstone of these regulatory frameworks is the concept of Good Manufacturing Practices (GMP). GMP is a system of quality control that ensures products are consistently produced and controlled according to quality standards. It is a holistic approach that encompasses everything from the training of personnel to the maintenance of equipment and the traceability of raw materials.

For peptide therapeutics, GMP compliance is particularly important due to the complexity of their synthesis and the potential for impurities to arise. By mandating GMP, regulatory bodies ensure that the manufacturing process itself is a key component of quality assurance.

Good Manufacturing Practices are a system of quality control that ensures peptide products are consistently produced and controlled according to stringent standards.

The Chemistry, Manufacturing, and Controls (CMC) section of a regulatory submission is where the scientific evidence of a peptide’s quality is presented. This detailed dossier provides a complete picture of the product, including its chemical properties, the manufacturing process, and the analytical methods used to test it.

The CMC section is meticulously reviewed by regulatory scientists to ensure that the product meets all the required specifications for identity, strength, purity, and quality. It is a critical piece of the regulatory puzzle, providing the data-driven assurance that the product is safe and effective for its intended use.

How Do Regulatory Impurity Thresholds Differ?

One of the more nuanced aspects of peptide regulation is the difference in impurity thresholds between various regulatory agencies. For example, the FDA and EMA have historically had different expectations for the identification and qualification of impurities.

The FDA has often required the identification of any impurity present at a level of 0.1% or higher, while the EMA has traditionally used a threshold of 0.5%. These differences can have significant implications for manufacturers, requiring them to tailor their analytical and manufacturing processes to meet the specific requirements of the region in which they intend to market their product. This highlights the ongoing efforts to harmonize international regulatory standards.

The Role of Reference Standards

Reference standards are highly characterized materials that are used as a benchmark for quality control testing. They are essential for ensuring the accuracy and consistency of the analytical methods used to assess peptide quality. Regulatory bodies and pharmacopeias, such as the United States Pharmacopeia (USP), play a key role in the development and validation of these reference standards.

By providing a common point of reference, these standards help to ensure that peptide products are of a consistent quality, regardless of where they are manufactured. This global system of standards is a testament to the collaborative effort required to safeguard public health.

- FDA (U.S. Food and Drug Administration) This agency’s guidelines are detailed in various documents, including the United States Pharmacopeia (USP). The FDA has recently introduced new chapters, such as USP <1503> and <1504>, which specifically address the quality of synthetic peptides and their starting materials.

- EMA (European Medicines Agency) The EMA provides guidance for the European Union. It has issued draft guidance on the development and manufacture of synthetic peptides, which outlines the specific requirements for products intended for the European market.

- ICH (International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use) The ICH brings together regulatory authorities and the pharmaceutical industry to discuss scientific and technical aspects of drug registration. Its guidelines are widely adopted and help to harmonize regulatory requirements across different regions.

| Aspect | FDA (United States) | EMA (European Union) |

|---|---|---|

| Governing Documents | United States Pharmacopeia (USP), Code of Federal Regulations (CFR) | European Pharmacopoeia (Ph. Eur.), EMA Scientific Guidelines |

| Impurity Identification Threshold | Often 0.1% for specified impurities | Generally 0.5% for specified impurities |

| Starting Material Requirements | Addressed in USP <1504> | Detailed in specific guidance documents |

| Stability Testing | ICH guidelines are followed | ICH guidelines are followed |

Academic

The analytical characterization of peptide therapeutics is a scientifically demanding discipline, requiring a sophisticated array of orthogonal methods to fully elucidate a product’s quality attributes. Regulatory bodies mandate this multi-faceted approach to mitigate the risks associated with the inherent complexity of these molecules.

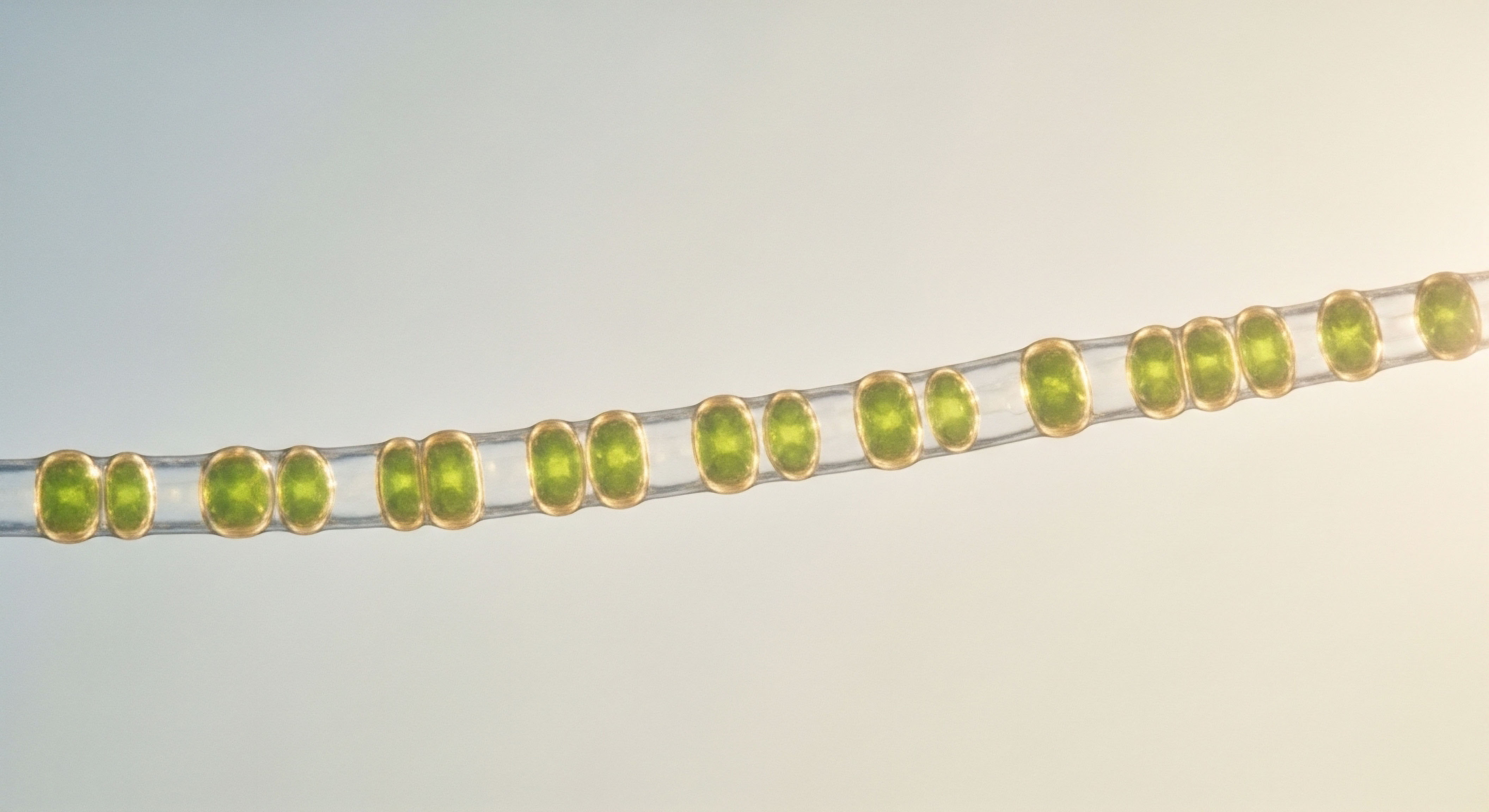

The primary structure, or amino acid sequence, is merely the starting point. Higher-order structures, such as secondary and tertiary conformations, can significantly influence a peptide’s biological activity and immunogenicity. Therefore, techniques like circular dichroism and nuclear magnetic resonance (NMR) spectroscopy are often employed to provide a comprehensive structural profile. This level of detail is essential for establishing a baseline of quality against which all subsequent batches can be compared.

The impurity profile of a peptide therapeutic is a critical quality attribute that receives intense regulatory scrutiny. Impurities can be process-related, such as residual solvents or reagents from the synthesis process, or product-related, such as deletion sequences or diastereomers.

The identification and quantification of these impurities require high-resolution analytical techniques, most notably mass spectrometry (MS) coupled with liquid chromatography (LC-MS). The data generated from these analyses are used to establish a detailed impurity profile for the product, which is then used to set acceptance criteria for batch release. The challenge lies in not only detecting these impurities but also in understanding their potential biological impact.

The analytical characterization of peptide therapeutics requires a sophisticated array of orthogonal methods to fully elucidate a product’s quality attributes.

Immunogenicity, the propensity of a therapeutic to elicit an immune response, is a significant concern for peptide drugs. Even small impurities can act as haptens, triggering an immune reaction that can compromise the safety and efficacy of the product.

Regulatory agencies require a thorough assessment of a product’s immunogenic potential, which often involves a combination of in silico, in vitro, and in vivo studies. The goal is to identify any potential immunogenicity risks and to develop a risk mitigation strategy to manage them. This proactive approach to immunogenicity assessment is a testament to the precautionary principle that underpins modern drug regulation.

What Are the Challenges in Global Harmonization?

Despite the efforts of organizations like the ICH, significant challenges remain in the global harmonization of peptide regulations. As previously noted, differences in impurity thresholds between the FDA and EMA can create complexities for manufacturers seeking to market their products in multiple regions.

These discrepancies often stem from different philosophical approaches to risk assessment and historical precedents. The ongoing dialogue between regulatory agencies is aimed at bridging these gaps and establishing a more unified global framework for peptide regulation. The ultimate goal is to ensure that patients worldwide have access to peptide therapeutics of a consistently high quality, regardless of where they are manufactured or approved.

The Future of Peptide Regulation

The field of peptide therapeutics is rapidly evolving, with new and more complex products entering the development pipeline. This innovation presents both opportunities and challenges for regulatory agencies. The rise of personalized medicine and the development of novel delivery systems will require a more flexible and adaptive regulatory approach.

We can anticipate a future where regulations are more closely tailored to the specific characteristics of each product, moving away from a one-size-fits-all model. This evolution will be driven by advances in analytical science and a deeper understanding of the structure-function relationships of peptide therapeutics. The regulatory landscape of tomorrow will be one of dynamic collaboration, where innovation and patient safety advance hand in hand.

- Solid-Phase Peptide Synthesis (SPPS) This is the most common method for manufacturing synthetic peptides. It involves the sequential addition of amino acids to a growing peptide chain that is attached to a solid support. The process is highly controlled and allows for the synthesis of long and complex peptides.

- Recombinant DNA Technology This method is used to produce peptides in living cells, such as bacteria or yeast. It is particularly useful for producing large quantities of peptides that are identical to their natural counterparts. The purification of recombinant peptides is a critical step to ensure the removal of host cell proteins and other process-related impurities.

- Liquid-Phase Peptide Synthesis (LPPS) This is an older method of peptide synthesis that is still used for the production of some shorter peptides. It involves the synthesis of the peptide in a solution, which can make purification more challenging than with SPPS.

| Technique | Purpose | Information Provided |

|---|---|---|

| Mass Spectrometry (MS) | To determine the molecular weight and sequence of the peptide. | Provides a highly accurate measurement of the peptide’s mass and can be used to identify impurities and modifications. |

| High-Performance Liquid Chromatography (HPLC) | To separate the peptide from impurities. | Generates a chromatogram that shows the purity of the peptide and allows for the quantification of impurities. |

| Nuclear Magnetic Resonance (NMR) Spectroscopy | To determine the three-dimensional structure of the peptide. | Provides detailed information about the peptide’s conformation in solution, which can be important for its biological activity. |

| Amino Acid Analysis (AAA) | To determine the amino acid composition of the peptide. | Confirms that the peptide contains the correct amino acids in the correct ratios. |

References

- Giri, T. Sakharwade, S. Subbappa, P. K. & Sharma, N. (2025). Regulatory Considerations in Synthetic Peptide Characterization ∞ Techniques and Compliance. ResearchGate.

- DLRC Group. (2023, December 20). Synthetic Peptides ∞ Understanding The New CMC Guidelines.

- Parmar, D. (2025, March 20). Impurities in Peptide Drug Substance. TIDES Asia 2025.

- BioPharmaSpec. (2025, June 4). Process-Related Impurities in Peptides ∞ Key Considerations and Analytical Approaches.

- Rathore, A. S. (Ed.). (2019). Regulatory Considerations for Peptide Therapeutics. Royal Society of Chemistry.

Reflection

Your exploration into the world of peptide therapeutics is a personal one, driven by a desire to understand your own biology and to take proactive steps towards a healthier future. The knowledge you have gained about the regulatory landscape is a powerful tool in this journey.

It allows you to ask informed questions and to make choices that are grounded in a clear understanding of the science. This is the foundation of true empowerment in health. As you move forward, consider how this knowledge can shape your conversations with healthcare providers and how it can help you to navigate the ever-evolving world of personalized medicine. Your health journey is unique, and you are now better equipped than ever to be its chief architect.