Fundamentals

You have arrived at this point in your health journey through a process of careful consideration and a commitment to understanding your own biology. When you decide to incorporate a therapy like a specific peptide, you are taking a definitive step toward optimizing your body’s intricate systems.

This decision brings with it a critical question, one that speaks to the very foundation of any therapeutic protocol ∞ “What is the precise composition of the substance I am introducing into my body?” This inquiry into purity and the nature of impurities forms the bedrock of safety and efficacy. Understanding how regulatory frameworks approach this question reveals the profound difference between a mass-produced, approved pharmaceutical and a personalized, compounded preparation.

At the highest level, two parallel systems of medical oversight exist. The first is the world of commercially approved drugs, governed by the Food and Drug Administration (FDA). This pathway is designed for medications intended to be manufactured on a massive scale, identical from one batch to the next, and prescribed to a wide population.

The second is the realm of compounding pharmacies, which create patient-specific formulations based on a physician’s prescription. Their regulatory structure, guided by the United States Pharmacopeia (USP) and state boards of pharmacy, is designed to ensure safety and quality for individualized medicine.

The core distinction lies in the purpose ∞ one system regulates standardized products for the population, the other oversees customized preparations for the individual.

What Constitutes an Impurity in a Peptide

An impurity is any component within the final therapeutic substance that is not the intended peptide molecule itself. In the context of complex molecules like peptides, these are rarely inert substances. They are often structurally similar variants of the active peptide that arise during the complex chemical synthesis process. These are known as process-related or drug-related impurities.

Consider the synthesis of a peptide as assembling a specific chain of amino acids in a precise order. An impurity could be a chain with a missing amino acid (a deletion sequence) or one with an incorrect amino acid (a substitution).

It could also be a fragment of the intended peptide or a version where a chemical modification occurred during manufacturing or storage. Each of these variations creates a new molecule with its own potential biological signature. It might be inactive, it might have a reduced effect, or it could potentially interact with your body’s systems in an unintended way. This is why the characterization and control of impurities are central to the safety conversation.

The Roles of the FDA and USP

To navigate this landscape, it is helpful to understand the primary roles of the two main governing bodies in the United States. Their functions are distinct yet complementary, creating a web of standards that touches every medication you might encounter.

- The Food and Drug Administration (FDA) is a federal agency responsible for protecting public health by ensuring the safety, efficacy, and security of human and veterinary drugs, biological products, and medical devices. The FDA’s most visible role is its rigorous drug approval process, which involves extensive clinical trials to prove a new drug is both safe and effective for its intended use before it can be marketed to the public.

- The United States Pharmacopeia (USP) is a non-governmental, scientific organization that sets standards for the identity, strength, quality, and purity of medicines, food ingredients, and dietary supplements. These standards are published in the U.S. Pharmacopeia ∞ National Formulary (USP-NF). While the USP is not a government agency, its standards are often integrated into U.S. law and are enforced by the FDA. Compounding pharmacies, for instance, are required to adhere to specific USP chapters, such as USP General Chapter <797> for sterile preparations.

The interaction between these two organizations defines the landscape of pharmaceutical quality. The FDA sets the high bar for new drug approval, while the USP provides the essential, enforceable playbook for maintaining quality across a wide range of medical products, including the compounded peptides central to many personalized wellness protocols.

Intermediate

As we move deeper into the regulatory mechanics, the distinction between approved drugs and compounded peptides becomes clearer, revealing two fundamentally different philosophies of quality control. The framework for conventional pharmaceuticals is built on exhaustive pre-market analysis and standardized limits. The world of compounded therapies, by contrast, relies on process standards and the quality of raw ingredients to ensure patient safety. This divergence is rooted in the inherent molecular nature of the substances themselves.

Impurity Thresholds for Approved Drugs

The primary guidance for impurities in new, chemically synthesized drug substances (often called “small molecules”) comes from the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH). Specifically, the ICH Q3A guideline establishes a clear, tiered system for addressing impurities based on the maximum daily dose (MDD) of the drug. This system creates a globally recognized standard for pharmaceutical manufacturers.

The thresholds are built around three key actions:

- Reporting Threshold ∞ The level at which an impurity must be reported in a company’s regulatory submission to the FDA.

- Identification Threshold ∞ The level at which the manufacturer must identify the chemical structure of the impurity.

- Qualification Threshold ∞ The level at which the manufacturer must conduct safety studies (toxicology) to justify the presence of the impurity.

These thresholds provide a predictable, data-driven framework. However, the ICH Q3A guidance explicitly excludes certain classes of drugs, including peptides, oligonucleotides, and biological/biotechnological products. The reason for this exclusion is the profound structural complexity of these molecules compared to traditional chemical drugs. Their potential to cause an immune reaction (immunogenicity) requires a more nuanced, case-by-case evaluation.

| Maximum Daily Dose | Reporting Threshold | Identification Threshold | Qualification Threshold |

|---|---|---|---|

| ≤ 2 g/day | 0.05% | 0.10% or 1.0 mg/day (whichever is lower) | 0.15% or 1.0 mg/day (whichever is lower) |

| 2 g/day | 0.03% | 0.05% | 0.05% |

How Are Approved Peptides Regulated?

Since peptides fall outside the standard ICH Q3A guidelines, the FDA evaluates them on a case-by-case basis. This approach acknowledges their unique biological properties. For certain highly purified synthetic peptides seeking approval as generic drugs, the FDA has provided draft guidance suggesting that any new impurity exceeding 0.10% should be identified, and the total level of new impurities should not surpass 0.50%.

This demonstrates a much tighter control compared to the general thresholds for small molecules, reflecting a heightened awareness of the potential risks associated with peptide-related impurities.

The regulatory path for approved peptides is individualized, focusing intensely on the manufacturing process and the potential for immunogenic impurities.

The Compounding Pharmacy Framework 503a versus 503b

Compounded peptides exist within a separate regulatory space, governed primarily by state boards of pharmacy and USP standards. Within this space, there are two types of facilities with very different operational and regulatory requirements.

A 503A Compounding Pharmacy prepares medications based on a prescription for a specific patient. These pharmacies are regulated by state boards and must comply with USP chapters like <795> for non-sterile compounding and <797> for sterile compounding. Their focus is on the safe preparation of individualized medicines.

A 503B Outsourcing Facility is a designation created to bridge the gap between traditional compounding and industrial drug manufacturing. These facilities can produce large batches of compounded drugs with or without prescriptions. In exchange for this broader scope, they must register with the FDA and adhere to Current Good Manufacturing Practices (cGMP), the same quality system that applies to pharmaceutical manufacturers. This imposes a much higher level of process control, testing, and documentation.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Regulation | State Boards of Pharmacy, USP Chapters | FDA, Current Good Manufacturing Practices (cGMP) |

| Prescription Requirement | Required for each specific patient | Can compound without patient-specific prescriptions |

| Scale of Production | Patient-specific batches | Large-scale batches (“for office use”) |

| Quality Standard | USP <795> / <797> | cGMP (21 CFR Parts 210 & 211) |

| Active Ingredient Sourcing | Must have a USP monograph or be on an FDA-approved list | Must meet higher quality and testing standards |

For a person using a compounded peptide, the distinction is significant. A peptide sourced from a 503B facility has been produced under federally inspected manufacturing conditions that more closely mirror those of a pharmaceutical company.

The responsibility for ensuring purity in the compounding world rests heavily on the pharmacy’s adherence to these standards and their diligence in sourcing high-quality Active Pharmaceutical Ingredients (API) from reputable, FDA-registered suppliers. The Certificate of Analysis (CofA) provided by the API manufacturer is a critical document, attesting to the identity and purity of the bulk substance before it is compounded into a final preparation.

Academic

The regulatory divergence between approved pharmaceuticals and compounded peptides is not a matter of arbitrary policy. It is a direct consequence of their molecular biology and the sophisticated analytical science required to ensure their safety. The central concern that shapes the entire regulatory approach for peptides is immunogenicity ∞ the potential for a therapeutic molecule or its related impurities to provoke an unwanted immune response.

This biological reality necessitates a far more rigorous and individualized assessment than what is applied to conventional small-molecule drugs.

The Specter of Immunogenicity

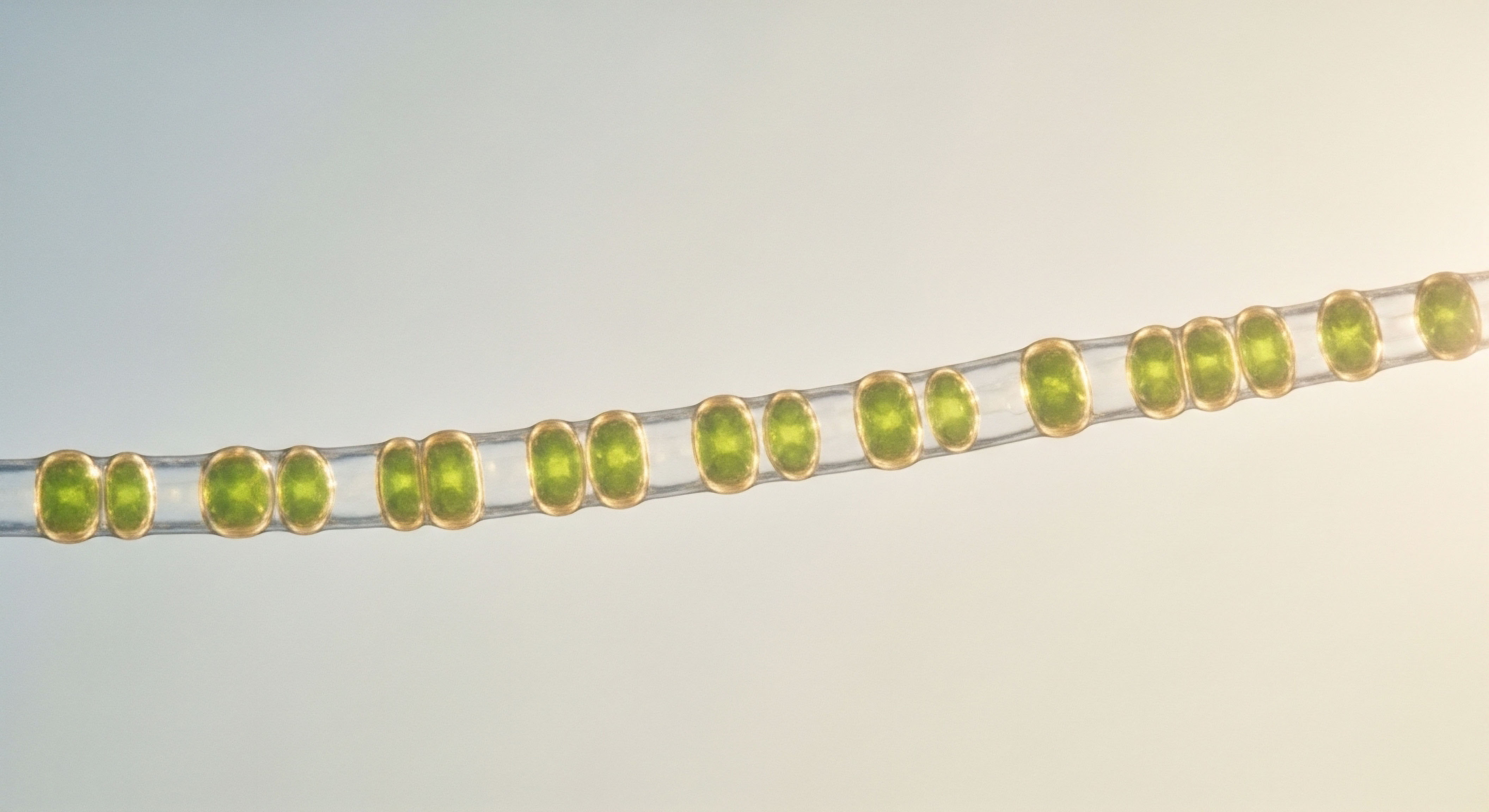

Your immune system is exquisitely tuned to identify and neutralize foreign entities. It does this by recognizing specific molecular shapes and sequences. An approved therapeutic peptide is designed to mimic an endogenous molecule, performing a specific biological function without triggering this defense mechanism. However, even a minute alteration in its amino acid sequence or structure, as might be found in a process-related impurity, can be sufficient for the immune system to recognize it as “non-self.”

The consequences of an immune response to a peptide therapeutic can range from benign to severe:

- Neutralizing Antibodies ∞ The immune system may generate antibodies that bind to the therapeutic peptide, rendering it ineffective. The patient would experience a loss of response to the therapy.

- Cross-Reactivity ∞ This is a more significant concern. Antibodies generated against an impurity might also recognize and attack the native, endogenous hormone the peptide was designed to supplement. This could lead to a new, iatrogenic deficiency or autoimmune condition.

- General Immune Activation ∞ In some cases, the response can be less specific, leading to hypersensitivity reactions or other inflammatory conditions.

Because of this risk, the FDA’s case-by-case evaluation of a new peptide drug involves a deep analysis of the manufacturing process to understand all potential impurities. The goal is to ensure that the final product is not only pure in a general sense but also free from specific, structurally-related impurities that pose an immunogenic risk.

This stands in stark contrast to small-molecule drugs, where the primary safety concern for impurities is typically direct toxicity, which can often be predicted by chemical structure and assessed in standard toxicological models.

What Does Case-By-Case Impurity Assessment Truly Involve?

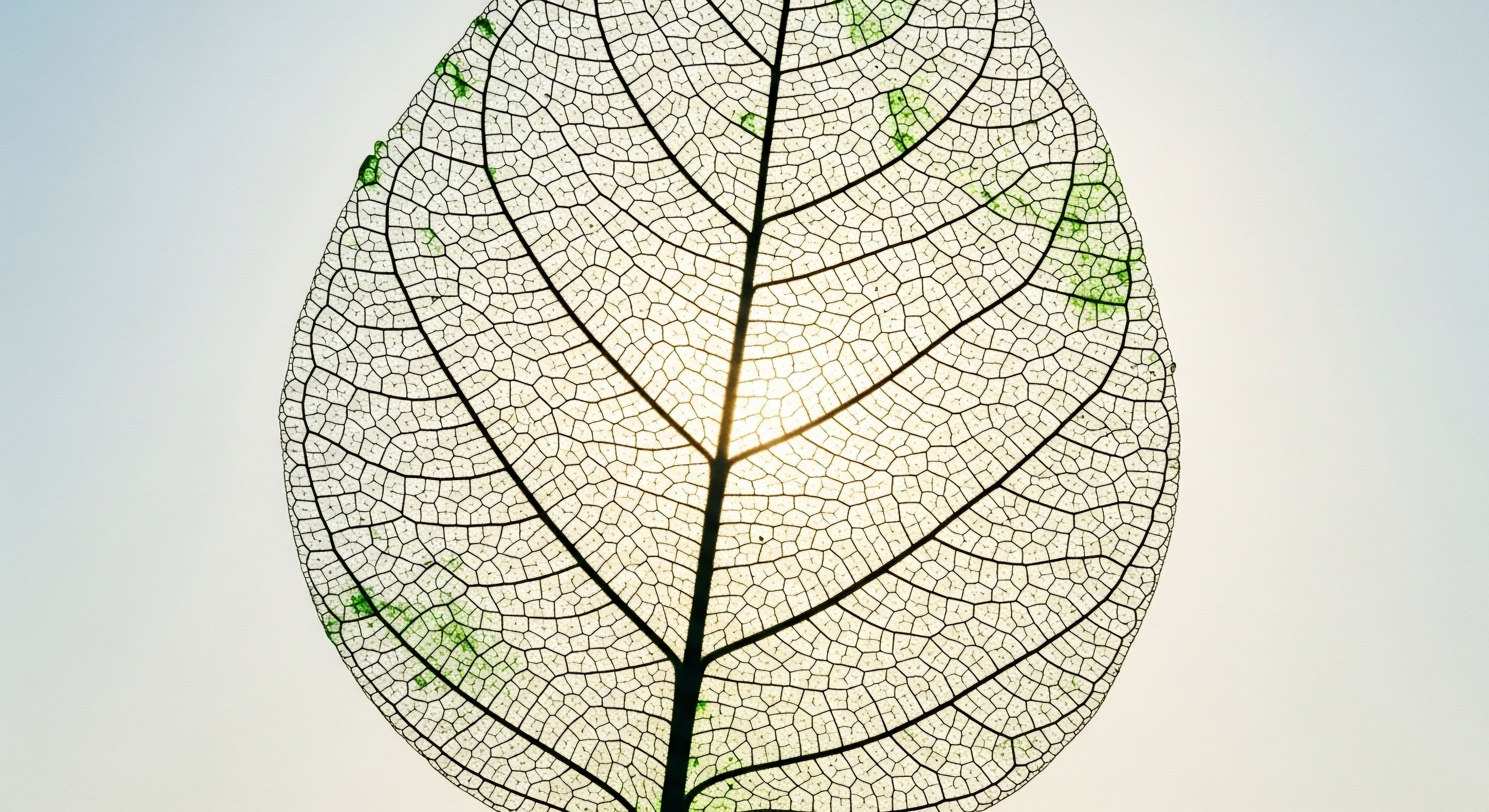

When the FDA assesses a new peptide for market approval, it scrutinizes the entire manufacturing process, from starting materials to final product. This Chemistry, Manufacturing, and Controls (CMC) review is exhaustive. The manufacturer must demonstrate a profound understanding and control over their process.

They must show that they can consistently produce the peptide with a well-defined and minimal impurity profile. This involves using multiple, highly sensitive analytical techniques, known as orthogonal methods, to build a complete picture of the product’s purity. Techniques like high-performance liquid chromatography (HPLC), mass spectrometry (MS), and amino acid analysis are used in combination to confirm the peptide’s identity, sequence, and purity, and to characterize any detectable impurities.

How Does the Risk Profile Differ for Compounded Peptides?

In the compounding setting, this exhaustive, product-specific pre-market review does not occur. Instead, the system relies on adherence to process standards (USP <797>) and the quality of the starting materials. The responsibility for safety shifts from the manufacturer’s deep characterization of a specific product to the compounding pharmacy’s diligence in sourcing and handling the Active Pharmaceutical Ingredient (API).

A compounding pharmacy must source its API from an FDA-registered facility. This API arrives with a Certificate of Analysis (CofA), a document that reports the purity and identity of the bulk substance. However, the level of detail on a typical CofA for a bulk peptide may not match the extensive impurity profile dossier required for an FDA-approved drug.

The regulatory framework for compounded peptides emphasizes procedural integrity and raw material quality as the primary mechanisms for ensuring patient safety.

This creates a different risk management paradigm. The safety of a compounded peptide is contingent on the quality of the entire supply chain and the operational excellence of the pharmacy. A 503B outsourcing facility, operating under cGMP, provides a higher degree of quality assurance due to its federally mandated process controls and more extensive testing requirements.

For the prescribing physician and the patient, understanding the source of the compounded peptide, especially whether it originates from a 503A or a 503B facility, becomes a critical component of the overall risk assessment. The regulatory system for compounded peptides is built on a foundation of trust in professional standards, process controls, and supply chain integrity, a sharp contrast to the molecule-specific, data-intensive approval process for commercial drugs.

References

- Tiwari, Anita. “CMC Regulatory Experiences and Expectations for Peptides.” U.S. Food and Drug Administration, 9 Apr. 2021.

- Pack, Brian, et al. “Assessing the Safety of Peptide-Related Impurities in Support of Commercial Control Strategy Development.” USP, 26 Nov. 2024.

- International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use. “ICH Harmonised Tripartite Guideline ∞ Impurities in New Drug Substances Q3A(R2).” 25 Oct. 2006.

- Frier Levitt. “Regulatory Status of Peptide Compounding in 2025.” Frier Levitt Attorneys at Law, 3 Apr. 2025.

- Duncan, Katharine. “CMC Regulatory Experiences and Expectations for Peptides.” USP Presentation, 2023.

- U.S. Food and Drug Administration. “Guidance for Industry ∞ ANDAs for Certain Highly Purified Synthetic Peptide Drug Products That Refer to Listed Drugs of rDNA Origin.” FDA, 2021.

- Vici Health Sciences. “Analytical Testing for Peptide Formulations.” Vici Health Sciences, 2024.

- European Medicines Agency. “ICH Q3A(R2) Impurities in New Drug Substances.” EMA, 1 Oct. 2006.

- United States Pharmacopeia. “USP General Chapter <1078> Good Manufacturing Practices for Bulk Pharmaceutical Excipients.” USP-NF.

- United States Pharmacopeia. “USP General Chapter <467> Residual Solvents.” USP-NF, 27 Sep. 2019.

Reflection

You have now traveled through the complex terrain of pharmaceutical regulation, from the broad frameworks down to the molecular level. This knowledge serves a distinct purpose. It transforms you from a passive recipient of a therapy into an active, informed participant in your own wellness protocol. The journey through the science of purity and the architecture of oversight is designed to equip you with a new lens through which to view your choices.

The path to optimizing your health is deeply personal, and the therapies you choose are components of that unique journey. This understanding of impurity thresholds and regulatory pathways is not meant to create apprehension. It is meant to build confidence. It provides you with the language and the concepts to engage in a more meaningful dialogue with your clinician.

It empowers you to ask discerning questions about the source and quality of your treatments, transforming your role in the patient-physician relationship into a true partnership.

Consider this knowledge a foundational element of your personal health strategy. The true power of personalized medicine lies not only in the specific molecules prescribed but in the quality and precision with which those molecules are delivered. Your continued health journey is one of ongoing learning and proactive engagement. The understanding you have gained here is a vital tool, enabling you to navigate your path with greater clarity, assurance, and a profound sense of ownership over your biological destiny.

Glossary

food and drug administration

united states pharmacopeia

compounded peptides

international council for harmonisation

ich q3a

immunogenicity

certain highly purified synthetic

compounding pharmacy

current good manufacturing practices

503b outsourcing facility

certificate of analysis

active pharmaceutical ingredient

503b outsourcing