Fundamentals

When you begin a protocol involving therapeutic peptides, you are placing immense trust in the microscopic molecules designed to recalibrate your body’s internal communication systems. This trust is not abstract; it is a deeply personal reliance on the purity and integrity of what you introduce into your system.

The body, in its intricate wisdom, operates on a language of precise chemical signals. A therapeutic peptide is designed to speak this language fluently. Regulatory agencies, therefore, function as the guardians of this language, ensuring every syllable, every molecular word, is articulated correctly. Their evaluation of peptide manufacturing quality is a profound commitment to your biological safety and the efficacy of your personal wellness journey.

The entire system of oversight is built upon a foundational principle known as Good Manufacturing Practice, or GMP. Think of GMP as the non-negotiable rules of grammar for creating a therapeutic substance. These are not mere suggestions; they are a comprehensive set of regulations that dictate every step of the production process, from the initial sourcing of raw materials to the final sterile packaging.

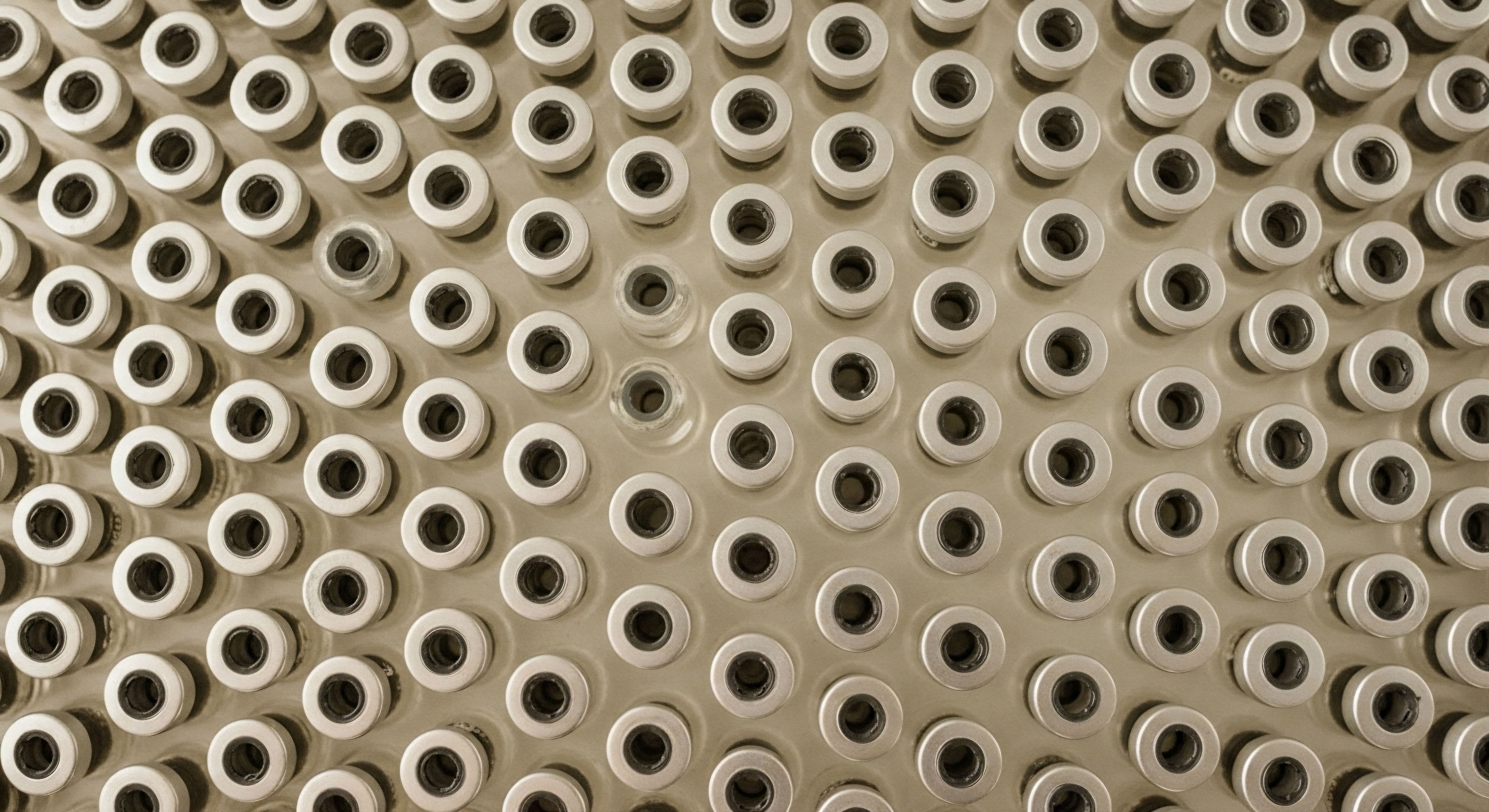

For you, the end-user, this means that the peptide you administer has been produced in a facility that is clean, with equipment that is meticulously maintained, and by personnel who are rigorously trained. The process is designed to be consistent, ensuring that the vial you use today is identical in its composition and purity to the one you will use months from now. This consistency is the bedrock of a predictable and effective therapeutic response.

The Blueprint of Identity and Purity

At the heart of regulatory evaluation is a simple yet powerful question ∞ is the peptide what it claims to be, and is it free from contaminants? To answer this, agencies like the U.S. Food and Drug Administration (FDA) require manufacturers to establish a detailed “fingerprint” for their product.

This involves a battery of tests designed to confirm the peptide’s identity, purity, strength, and potency. Imagine a key meant to fit a specific lock in your body ∞ a cellular receptor. The identity tests confirm that the key has the right shape.

The purity tests ensure there are no other, incorrect keys mixed in that could block the lock or fit other, unintended locks, causing unwanted effects. Strength and potency assessments confirm that the key is strong enough to turn the lock and initiate the desired biological message.

A regulatory agency’s primary role is to ensure the peptide you receive is precisely the molecule intended, free from anything that could dilute its effect or cause harm.

This meticulous validation is what separates a pharmaceutical-grade therapeutic from a research chemical. The former comes with a guarantee of quality, a documented history of its creation, and accountability at every stage. This documented journey, often called a batch record, provides complete traceability, allowing every single vial to be tracked from its origin to your hands. This creates a powerful chain of custody that underpins the safety and reliability of your chosen protocol.

Intermediate

Advancing beyond the foundational principles of Good Manufacturing Practice (GMP), the regulatory evaluation of peptide manufacturing incorporates a sophisticated framework known as a Quality Management System (QMS). A QMS is the operational brain of a manufacturing facility, an integrated system that ensures quality is built into the process at every stage, rather than being an afterthought checked only at the end.

It is a proactive and dynamic process of risk identification and mitigation. For peptide therapeutics, where even minute structural variations can alter biological activity, this systematic approach is paramount. The FDA provides specific guidance for synthetic peptides, focusing on Chemistry, Manufacturing, and Controls (CMC), which serves as the core dossier of evidence that a manufacturer must present to prove its process is under control.

This CMC information details the entire lifecycle of the peptide. It includes the precise sequence of amino acids, the methods used for synthesis and purification, and the analytical procedures for characterization. Regulatory bodies scrutinize this information to understand not just the final product, but the potential for impurities to arise during production.

They are concerned with deletion sequences (where an amino acid is missing), insertion sequences (an extra amino acid), and modifications like deamidation or oxidation, all of which can occur during complex chemical synthesis and can impact the peptide’s efficacy and safety. A robust QMS anticipates these risks and implements controls to prevent them.

What Is the Role of Analytical Method Validation?

A critical component of the QMS is the validation of all analytical methods used for quality control. It is one thing to perform a test; it is another to prove the test itself is reliable, accurate, and reproducible. Regulatory agencies require manufacturers to demonstrate that their testing methods can consistently detect what they are supposed to detect. For peptides, High-Performance Liquid Chromatography (HPLC) is a universally applied technique for determining purity.

Method validation for HPLC would involve demonstrating the following:

- Specificity ∞ The method can distinguish the target peptide from potential impurities and degradation products.

- Linearity ∞ The test results are directly proportional to the concentration of the peptide over a given range.

- Accuracy ∞ The method provides results that are close to the true value.

- Precision ∞ The method yields similar results when repeated on the same sample multiple times.

- Robustness ∞ The method remains reliable even with small, deliberate variations in its parameters, simulating the minor fluctuations of real-world use.

This validation ensures that when a manufacturer states a peptide is 99% pure, that number is scientifically meaningful and trustworthy. This level of detail provides regulators with the confidence that the manufacturer can reliably produce a high-quality product from one batch to the next, a concept known as lot-to-lot consistency.

The Quality Management System translates the philosophy of quality into a set of concrete, enforceable, and verifiable actions within the manufacturing process.

Comparing Key Quality Control Tests

Regulatory agencies mandate a suite of tests to create a comprehensive quality profile for a peptide. Each test provides a different piece of the puzzle, and together they confirm the product’s suitability for therapeutic use.

| Quality Attribute | Primary Analytical Technique | Purpose in Regulatory Evaluation |

|---|---|---|

| Identity | Mass Spectrometry (MS), Amino Acid Analysis (AAA) | Confirms the peptide has the correct molecular weight and amino acid composition, verifying its fundamental structure. |

| Purity | High-Performance Liquid Chromatography (HPLC) | Separates the target peptide from impurities, ensuring the dose is not contaminated with by-products from the synthesis process. |

| Potency/Strength | Bioassay or Ligand-Binding Assay | Measures the specific biological activity of the peptide, confirming it can effectively interact with its target receptor or enzyme. |

| Sterility & Endotoxins | Microbial Culture, Limulus Amebocyte Lysate (LAL) Test | Ensures the product is free from microbial contamination and bacterial endotoxins, which is critical for injectable therapeutics. |

Academic

The regulatory evaluation of peptide manufacturing quality at its most sophisticated level moves into the realm of physicochemical characterization and impurity profiling. From a systems-biology perspective, a therapeutic peptide is an exogenous signaling molecule intended to interface with an endogenous network, such as the Hypothalamic-Pituitary-Gonadal (HPG) axis or metabolic pathways regulated by GLP-1.

The bioactivity of this molecule is exquisitely dependent on its three-dimensional conformation and chemical integrity. Therefore, regulatory bodies like the FDA and EMA demand a profound level of molecular scrutiny that goes far beyond simple purity assessments. The “Guidance for Industry for the Submission of Chemistry, Manufacturing, and Controls Information for Synthetic Peptide Substances” is the foundational document, but its interpretation requires a deep understanding of protein chemistry and analytical science.

The core challenge in peptide manufacturing is the inherent heterogeneity of solid-phase peptide synthesis (SPPS), the dominant production method. While highly efficient, SPPS can introduce a constellation of related impurities that are structurally similar to the active pharmaceutical ingredient (API).

These can include diastereomers (arising from racemization of an amino acid’s chiral center), truncated sequences, or sequences with protecting groups that failed to cleave. Such impurities may possess altered or even antagonistic biological activity, or they could be immunogenic. Regulatory agencies, therefore, require manufacturers to not only quantify the total purity (typically via HPLC) but also to identify and characterize impurities that are present above a certain threshold (e.g. 0.1%).

How Do Regulators Assess Impurity Profiles?

The process of impurity profiling is a forensic investigation into the manufacturing process. It requires orthogonal analytical methods, meaning multiple techniques that measure the same attribute through different physical principles. This approach provides a more complete picture and reduces the risk of an impurity being missed by a single method.

For instance, a peptide’s purity might be assessed by both Reverse-Phase HPLC (RP-HPLC) and Capillary Electrophoresis (CE). While RP-HPLC separates based on hydrophobicity, CE separates based on charge-to-mass ratio, potentially revealing impurities that co-elute with the main peak in the HPLC chromatogram.

A complete characterization package for a peptide provides a molecular signature that assures regulators of its identity, purity, and functional integrity.

Advanced techniques are employed to elucidate the exact structure of these impurities. Liquid Chromatography-Mass Spectrometry (LC-MS) is a workhorse, coupling the separation power of HPLC with the mass-detection capability of MS to determine the molecular weight of an impurity, often providing enough information to deduce its identity.

For definitive structural confirmation, particularly for complex cases, Tandem Mass Spectrometry (MS/MS) or Nuclear Magnetic Resonance (NMR) spectroscopy may be required. This level of analysis demonstrates to regulators a manufacturer’s deep understanding of their own process and their ability to control it.

The Criticality of Stability and Potency Assays

A peptide’s quality is not static; it must be maintained throughout its shelf life. Regulatory agencies thus place enormous emphasis on stability testing. This involves storing the peptide drug product under various conditions (e.g. different temperatures and humidity levels) and testing it at predetermined intervals.

The goal is to detect any degradation products that may form over time and to establish a scientifically justified expiration date. These stability studies must use validated, stability-indicating methods capable of separating the intact peptide from its degradation products.

Potency assays represent the ultimate measure of a peptide’s quality, as they assess its biological function. A peptide can be 100% pure by HPLC but have zero potency if its conformation is incorrect or it has degraded in a way that affects its ability to bind to its target receptor.

Potency is typically measured using a cell-based bioassay that quantifies a specific biological response, such as cAMP production in response to a GLP-1 receptor agonist. The acceptance criteria for potency are stringent, ensuring that each batch of the product will elicit the intended physiological effect in the patient. This functional confirmation is the final and most important piece of evidence for a regulatory agency, connecting the chemical structure of the molecule to its therapeutic purpose.

| Advanced Characterization Method | Information Provided | Regulatory Significance |

|---|---|---|

| Tandem Mass Spectrometry (MS/MS) | Provides fragmentation patterns that can elucidate the precise amino acid sequence of the peptide and its impurities. | Offers definitive structural confirmation of identity and helps identify unknown impurities for safety assessment. |

| Nuclear Magnetic Resonance (NMR) | Gives detailed information about the three-dimensional structure and conformation of the peptide in solution. | Crucial for understanding higher-order structure, which directly relates to biological activity and stability. |

| Circular Dichroism (CD) Spectroscopy | Assesses the secondary structure (e.g. alpha-helix, beta-sheet content) of the peptide. | Used to demonstrate conformational consistency between batches and to monitor structural integrity during stability studies. |

| Size-Exclusion Chromatography (SEC) | Separates molecules based on size, detecting the presence of aggregates. | Aggregation is a critical quality attribute, as aggregates can reduce efficacy and potentially cause immunogenicity. |

References

- Fosgerau, K. & Hoffmann, T. (2015). Peptide therapeutics ∞ current status and future directions. Drug discovery today, 20(1), 122-128.

- International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use. (2000). ICH Harmonised Tripartite Guideline Q7 ∞ Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients.

- Lau, J. L. & Dunn, M. K. (2018). Therapeutic peptides ∞ Historical perspectives, current development trends, and future directions. Bioorganic & medicinal chemistry, 26(10), 2700-2707.

- U.S. Food and Drug Administration. (1994). Guidance for Industry ∞ Submission of Chemistry, Manufacturing, and Controls Information for Synthetic Peptide Substances.

- Shirzadi, S. (2010). Quality Considerations for Peptide Manufacturing Processes. BioPharm International, 23(3).

- Rastogi, A. et al. (2022). Peptide Therapeutics ∞ A New Wave of Innovative Medicines. Journal of Medicinal Chemistry, 65(7), 5271-5301.

- Vlieghe, P. Lisowski, V. Martinez, J. & Khrestchatisky, M. (2010). Synthetic therapeutic peptides ∞ science and market. Drug discovery today, 15(1-2), 40-56.

Reflection

Calibrating Your Internal Systems

The journey into personalized wellness protocols is one of profound self-discovery. The knowledge of how regulatory agencies ensure the quality of a therapeutic peptide is more than an academic exercise; it is a tool for empowerment. It transforms you from a passive recipient of a therapy into an informed participant in your own health.

Understanding the meticulous processes of identity verification, purity analysis, and potency testing provides a framework for appreciating the precision required to communicate with your body’s endocrine and metabolic systems. This knowledge serves as a foundation, allowing you to ask more insightful questions and make decisions grounded in a deeper understanding of the science that supports your goals.

The path forward involves continuing this dialogue, both with trusted clinical advisors and with your own body, as you learn to interpret its signals with ever-increasing clarity.