Fundamentals

When you begin a protocol involving therapeutic peptides, you are making a profound commitment to your own biology. You are seeking to recalibrate systems that influence your energy, your resilience, and your fundamental sense of self. It is a decision rooted in a desire for optimization and vitality.

A natural and critical question arises from this commitment ∞ how can you be certain that the substance you are introducing into your body is precisely what it is meant to be? Your body is a finely tuned biological instrument, and the quality of any therapeutic agent is paramount.

This question of quality, purity, and identity is where the work of regulatory agencies becomes deeply personal. Their mission is to create a framework of trust, ensuring the biological integrity of these molecules from their source to the moment of administration.

The oversight of compounded peptides is a layered system of checks and balances, managed by several key organizations. Each has a distinct and complementary role, contributing to a comprehensive quality assurance structure. At the federal level, the U.S. Food and Drug Administration (FDA) establishes the foundational rules for which substances can be used in compounding.

The FDA distinguishes between different types of compounding pharmacies, primarily 503A and 503B facilities, each with specific operational and regulatory requirements that directly affect the scale and scope of their work. This federal oversight provides the primary legal architecture for compounding nationwide.

Working in concert with the FDA is the United States Pharmacopeia (USP). The USP is a scientific, non-profit organization that sets exacting standards for the identity, strength, quality, and purity of medicines. For compounded peptides, which are almost always sterile injectable preparations, the standards outlined in USP General Chapter <797> are the authoritative guide.

This chapter details the necessary conditions and practices to prevent contamination and ensure patient safety. It addresses everything from the air quality in the compounding environment to the specific procedures for sterile handling. The USP provides the scientific and procedural bedrock upon which safe compounding is built.

Regulatory agencies establish a multi-layered framework to ensure the biological integrity of compounded peptides, protecting patient health from the source ingredient to the final preparation.

The final layer of direct oversight comes from the State Boards of Pharmacy. These state-level bodies are responsible for licensing and regulating pharmacies within their jurisdiction. They enforce both federal laws, including FDA regulations, and the detailed standards set by the USP.

State board inspectors conduct routine and unannounced visits to compounding pharmacies to verify compliance, examining everything from staff training records and procedural logs to the physical state of the cleanroom facilities. This state-level enforcement translates the federal and scientific standards into daily practice, providing a direct mechanism for accountability.

The Core Principle of Active Ingredient Sourcing

The entire regulatory structure is built upon a single, foundational principle ∞ the quality of the final compounded preparation can be no higher than the quality of its starting components. This is why a significant portion of regulatory focus is on the Active Pharmaceutical Ingredient (API), the pure peptide powder itself.

Regulatory agencies mandate that compounding pharmacies must source their APIs from facilities that are registered with the FDA. This registration signifies that the manufacturer is subject to FDA inspection and must adhere to specific quality standards known as Good Manufacturing Practices (GMP). These practices govern every step of the API production process, from raw material sourcing to final purification and packaging.

When a compounding pharmacy receives a shipment of API, it must be accompanied by a Certificate of Analysis (CoA). This document, provided by the API manufacturer, is a detailed report confirming the identity, purity, and potency of the substance as determined by rigorous analytical testing.

The pharmacy is required to review and maintain these CoAs as proof that their raw materials meet the required specifications. This documentation creates a transparent chain of custody and quality, allowing for traceability from the manufacturer to the individual patient. The system is designed to ensure that the peptide used in your protocol is authentic and free from harmful contaminants before the compounding process even begins.

Understanding the Pharmacy’s Role and Responsibility

A compounding pharmacy operates under a significant weight of professional and ethical responsibility. The pharmacists and technicians who prepare these therapies are highly trained professionals tasked with executing complex procedures with meticulous attention to detail. Their work is a blend of pharmaceutical science and procedural discipline.

Regulatory bodies require that all personnel involved in sterile compounding undergo specialized training in aseptic technique, the set of practices used to prevent microbial contamination. This training is not a one-time event; personnel must demonstrate their proficiency through regular testing and competency assessments.

The pharmacy itself is also required to maintain a state of control over its compounding environment. This involves establishing and following detailed Standard Operating Procedures (SOPs) for every aspect of the operation, from how equipment is cleaned and calibrated to how finished preparations are labeled and stored.

These SOPs are the pharmacy’s internal rulebook, translating external regulations into actionable, repeatable processes. The consistent execution of these procedures is what ensures that every dose prepared meets the same high standards for safety and quality. The regulatory framework, therefore, empowers and obligates the pharmacy to be the ultimate guardian of the peptide’s integrity on its final journey to the patient.

Intermediate

Advancing beyond the foundational understanding of regulatory oversight requires a closer examination of the specific mechanisms and standards that govern the day-to-day operations of a compounding pharmacy. The quality of a sterile peptide preparation is the direct result of a meticulously controlled process, defined in large part by the United States Pharmacopeia (USP).

Specifically, USP General Chapter <797> provides the detailed requirements for compounding sterile preparations, which include the injectable peptides used in hormonal and metabolic health protocols. This chapter is a comprehensive blueprint for minimizing the risk of contamination and ensuring that the final product is safe for patient administration.

The core philosophy of USP <797> is the establishment and maintenance of a controlled sterile environment. This is achieved through a combination of facility design, rigorous personnel procedures, and continuous environmental monitoring. The physical layout of a sterile compounding area is designed to create a series of barriers against contamination.

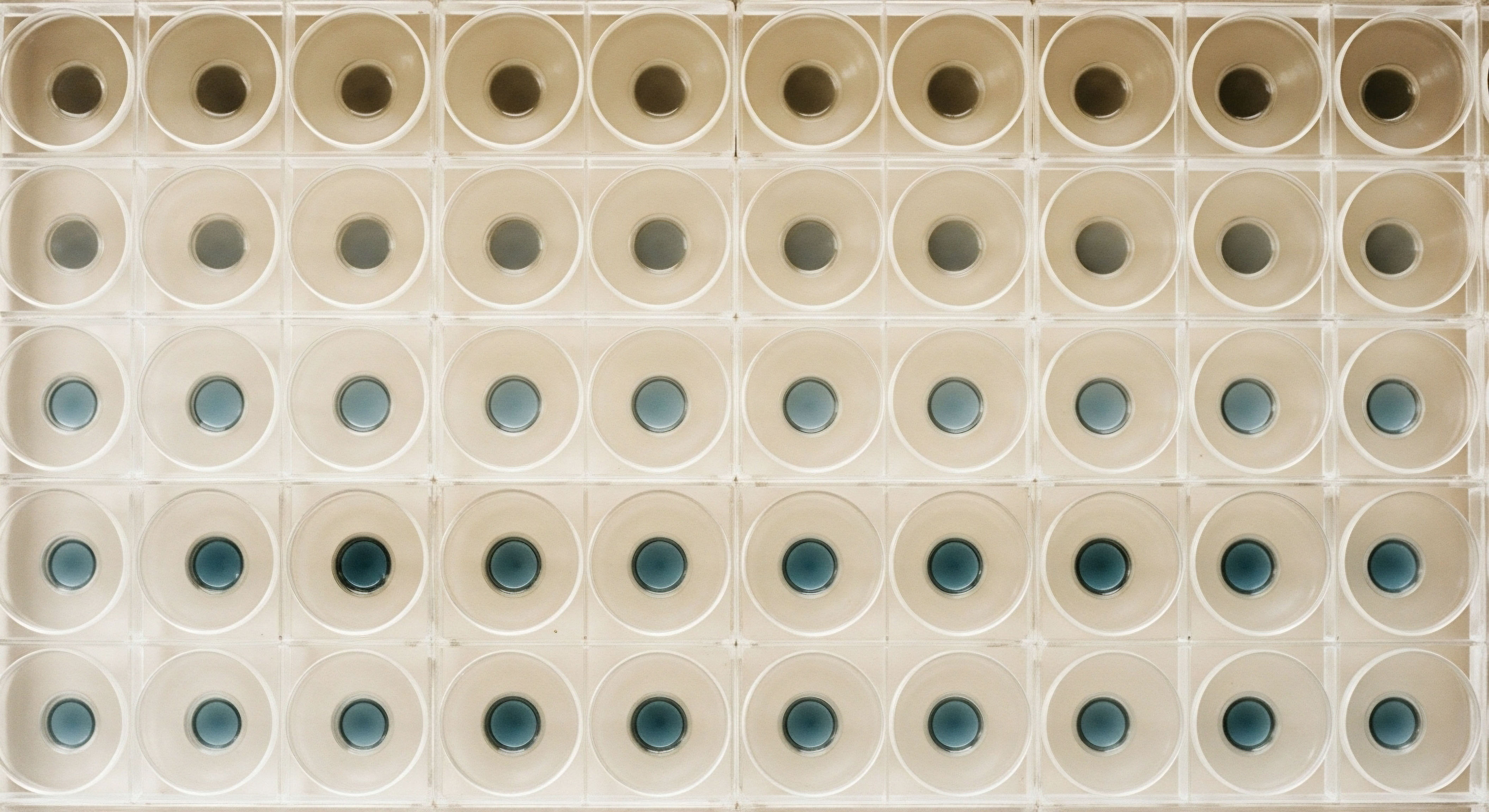

It typically includes an ante-room, where personnel perform hand hygiene and don sterile garb, and a separate cleanroom, or buffer area, where the actual compounding takes place. Within the cleanroom, a primary engineering control, such as a laminar airflow workbench, provides an ISO Class 5 environment, which is an atmosphere containing an extremely low concentration of airborne particles. This controlled airflow continuously sweeps contaminants away from the sterile work area, protecting the integrity of the peptide during handling and preparation.

Distinguishing 503a and 503b Facilities

The U.S. Food and Drug Administration (FDA) provides a critical distinction in the world of compounding that directly impacts how peptides are prepared and distributed. This distinction separates compounding pharmacies into two categories ∞ 503A and 503B facilities. Understanding this difference is essential for appreciating the regulatory landscape and the source of your compounded medications.

A 503A facility is a traditional compounding pharmacy that prepares customized medications for specific patients pursuant to a prescription. These pharmacies are primarily regulated by State Boards of Pharmacy, which enforce USP standards. They are intended to serve the unique needs of individual patients whose clinical requirements cannot be met by commercially available drugs. Because their work is patient-specific, they do not produce large batches of medications in advance of receiving prescriptions.

A 503B facility, also known as an outsourcing facility, is authorized to compound large batches of sterile drugs with or without prescriptions. These facilities must register with the FDA and are held to a higher standard of regulation, known as Current Good Manufacturing Practices (cGMP).

These are the same quality standards that large pharmaceutical manufacturers must follow. 503B facilities are designed to supply sterile medications to hospitals, clinics, and other healthcare providers, providing a source for drugs that are needed in larger quantities than a 503A pharmacy could practically prepare.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Regulation | State Boards of Pharmacy | U.S. Food and Drug Administration (FDA) |

| Quality Standard | USP <795> and <797> | Current Good Manufacturing Practices (cGMP) |

| Prescription Requirement | Required for each specific patient | Can compound without patient-specific prescriptions |

| Batch Production | Small batches for individual patients | Large batches for office use and healthcare systems |

| Federal Registration | Not required to register with FDA | Must register with the FDA as an outsourcing facility |

The FDA Bulks List and Its Impact on Peptide Availability

A central element of the FDA’s regulatory power over compounding is its management of the “bulks list.” For a 503A pharmacy to compound a medication, the active pharmaceutical ingredient (API) must meet one of three criteria ∞ it must be a component of an FDA-approved drug, have a USP or National Formulary monograph, or appear on the FDA’s 503A bulks list. This list contains bulk drug substances that have been nominated for use in compounding and evaluated by the FDA.

The list is divided into categories. Category 1 includes substances that the FDA has determined may be used for compounding, provided all other conditions are met. The agency does not intend to take action against a pharmacy for compounding with these substances. In contrast, Category 2 includes substances that the FDA has found to pose significant safety risks.

The agency has explicitly stated that these substances should not be used in compounding. Many popular peptides, such as BPC-157 and Ipamorelin, have been placed in Category 2, making them ineligible for compounding by 503A pharmacies. This regulatory classification is a primary determinant of which peptide therapies are legally available through traditional compounding channels.

USP Chapter <797> dictates the exacting environmental and procedural controls that compounding pharmacies must follow to ensure the sterility of injectable peptide therapies.

What Are the Procedural Mandates for Sterile Compounding?

USP <797> outlines a series of mandatory procedures designed to build quality into the compounding process. These procedures cover personnel behavior, environmental cleaning, and quality control checks. They represent the practical application of the principles of sterile manufacturing.

- Personnel Training and Garbing ∞ Before entering the cleanroom, personnel must perform a meticulous hand washing and forearm scrubbing routine. They then must don specific personal protective equipment (PPE) in a specific order. This includes shoe covers, a hair net, a face mask, and a sterile, low-particulate gown and gloves. This process, known as garbing, is designed to minimize the shedding of particles and microorganisms from the operator into the sterile environment.

- Aseptic Technique ∞ This is the core skill of sterile compounding. It involves a set of specific manipulations performed to prevent the contamination of sterile surfaces and products. Pharmacists and technicians must handle sterile needles, syringes, and vials in a way that never compromises their sterility. Their proficiency in aseptic technique is regularly evaluated through a procedure called a “media-fill test,” where they compound a sterile growth medium instead of a drug. The resulting preparation is then incubated to see if any microbial growth occurs, providing a direct measure of their technique.

- Environmental Monitoring ∞ A compounding pharmacy must actively monitor the state of its controlled environments. This includes performing regular air and surface sampling to test for microbial contamination. Air samples are collected to count the number of viable microorganisms, while surface samples are taken from critical areas like the airflow hood and countertops. If the microbial counts exceed the limits defined by USP <797>, the pharmacy must take immediate corrective action, which may include a thorough cleaning and re-evaluation of their procedures.

- Cleaning and Disinfection ∞ All surfaces in the ante-room and cleanroom must be cleaned and disinfected daily. This includes floors, walls, and work surfaces. A sporicidal agent must be used weekly or monthly to eliminate bacterial and fungal spores, which are highly resistant to standard disinfectants. Meticulous logs are kept to document that these cleaning procedures are performed consistently and correctly.

Academic

A sophisticated appreciation of compounded peptide quality requires a deep exploration into the analytical chemistry that validates the molecular identity and purity of these complex substances. While regulatory frameworks like those from the FDA and USP establish the procedural and environmental controls for safe compounding, the ultimate assurance of a peptide’s biological integrity rests on empirical, scientific proof.

This proof is primarily derived from advanced analytical techniques, with High-Performance Liquid Chromatography (HPLC) and Mass Spectrometry (MS) serving as the gold standards. These methods provide a quantitative and qualitative “fingerprint” of a peptide, ensuring that the molecule present in the vial is structurally correct and free from impurities that could compromise its therapeutic efficacy or patient safety.

The sourcing of the Active Pharmaceutical Ingredient (API) is the critical starting point for quality. Reputable compounding pharmacies must procure their peptide APIs from FDA-registered manufacturers who adhere to Good Manufacturing Practices (GMP). Each batch of API must be accompanied by a Certificate of Analysis (CoA), a formal document that presents the results of quality control testing.

The data within this CoA, particularly the HPLC and MS results, provides the foundational evidence of the API’s quality. A pharmacy’s due diligence includes scrutinizing this document to confirm that the purity levels meet or exceed established standards, typically greater than 98% for therapeutic peptides.

How Does High Performance Liquid Chromatography Verify Purity?

High-Performance Liquid Chromatography (HPLC) is a powerful analytical technique used to separate, identify, and quantify each component in a mixture. For peptide analysis, its primary function is to determine purity. The process works by pumping a pressurized liquid solvent containing the peptide sample through a column filled with a solid adsorbent material.

The various components in the sample interact with the adsorbent material differently based on their chemical properties, such as polarity and size. These differential interactions cause each component to flow through the column at a different speed.

As the separated components exit the column, they pass through a detector, typically an ultraviolet (UV) detector. Peptides absorb UV light at a specific wavelength due to their peptide bonds. The detector measures this absorption and generates a signal, which is plotted against time to create a chromatogram.

The chromatogram displays a series of peaks, with each peak representing a different component of the sample. The main, largest peak corresponds to the pure peptide, while smaller peaks represent impurities. The area under each peak is proportional to the concentration of that component in the sample.

By calculating the area of the main peptide peak relative to the total area of all peaks, an exact purity percentage can be determined. This method is sensitive enough to detect even trace amounts of contaminants, such as residual solvents from the synthesis process or structurally related impurities like deletion sequences (peptides missing an amino acid).

Advanced analytical methods like HPLC and Mass Spectrometry provide the definitive, scientific proof of a peptide’s molecular identity and purity, forming the bedrock of quality assurance.

Validating Molecular Identity with Mass Spectrometry

While HPLC is exceptional at confirming purity, Mass Spectrometry (MS) is the definitive technique for confirming the peptide’s identity by precisely measuring its molecular weight. After a sample is introduced into the mass spectrometer, it is ionized, meaning the molecules are converted into charged particles.

These ions are then accelerated into a magnetic or electric field, which separates them based on their mass-to-charge ratio (m/z). The detector measures the m/z of the ions and their relative abundance, generating a mass spectrum.

The mass spectrum shows a peak corresponding to the molecular weight of the peptide. This experimentally determined weight is then compared to the theoretical molecular weight, which is calculated based on the peptide’s known amino acid sequence. A match between the experimental and theoretical weights provides extremely strong evidence that the peptide has the correct chemical structure.

This is critically important because even a small error in the synthesis process, such as the substitution of a single amino acid, can alter the peptide’s three-dimensional structure and biological function. MS can detect these subtle but significant structural deviations. Advanced techniques like tandem mass spectrometry (MS/MS) can even be used to sequence the peptide, providing further confirmation of its primary structure.

| Technique | Primary Purpose | Information Provided | Relevance to Patient Safety |

|---|---|---|---|

| High-Performance Liquid Chromatography (HPLC) | Purity Assessment | Quantifies the percentage of the desired peptide and detects impurities. | Ensures the dose contains the correct amount of active drug and is free from potentially harmful contaminants. |

| Mass Spectrometry (MS) | Identity Confirmation | Measures the precise molecular weight of the peptide, confirming its chemical structure. | Guarantees that the administered molecule is the correct therapeutic agent, preventing administration of an incorrect or ineffective substance. |

| Amino Acid Analysis (AAA) | Compositional Verification | Determines the relative quantities of each amino acid in the peptide. | Confirms that the peptide is composed of the correct building blocks in the proper ratios. |

| Endotoxin Testing | Sterility Assurance | Detects the presence of bacterial endotoxins, which can cause fever and inflammation. | A critical safety test for all injectable preparations to prevent pyrogenic reactions. |

What Are the Challenges of the Global API Supply Chain?

The globalization of the pharmaceutical industry means that many APIs, including peptides, are manufactured overseas. This introduces significant complexity into the regulatory oversight process. While the FDA requires foreign API manufacturers that supply the U.S. market to be registered and subject to inspection, the logistical and geopolitical challenges are substantial. A compounding pharmacy must therefore exercise extreme diligence when sourcing APIs internationally.

This due diligence involves more than simply accepting the manufacturer’s CoA at face value. A truly quality-focused pharmacy may engage in supplier qualification programs, which can involve independent, third-party audits of the manufacturing facility to verify compliance with GMP.

They may also perform their own in-house or third-party analytical testing on incoming API batches to independently verify the purity and identity reported on the CoA. This redundant testing provides an essential layer of quality assurance, protecting against the risks of fraudulent documentation or lapses in quality control during manufacturing or transit. The integrity of the entire therapeutic protocol depends on this rigorous, science-backed verification of the foundational ingredient.

- Supplier Verification ∞ Compounding pharmacies must ensure their API supplier is registered with the FDA and has a history of compliance. This involves checking FDA databases and inspection records.

- Certificate of Analysis Scrutiny ∞ The CoA for each API batch must be carefully reviewed to ensure it includes comprehensive testing data, including HPLC for purity and MS for identity, and that the results meet USP specifications.

- Independent Testing ∞ The highest quality assurance standard involves performing or commissioning independent third-party laboratory testing on API batches to verify the manufacturer’s CoA claims. This mitigates risks from the complex global supply chain.

- Documentation and Record-Keeping ∞ Pharmacies must maintain meticulous records of all API purchases, including CoAs and any independent testing results, to ensure traceability and accountability as required by state boards of pharmacy and the FDA.

References

- Fagron Academy. “Industry Update ∞ Interim 503A and 503B Bulks Lists New Revisions.” Fagron Academy, 4 Oct. 2023.

- Alliance for Pharmacy Compounding. “Statement of the Alliance for Pharmacy Compounding ∞ Understanding Law and Regulation Governing the Compounding of Peptide Products.” Alliance for Pharmacy Compounding, 1 Mar. 2024.

- National Association of Boards of Pharmacy. “Compounding Pharmacy Inspections Identify Common Deficiencies.” National Association of Boards of Pharmacy, 4 Dec. 2023.

- Wolters Kluwer. “USP 797 and USP 795 ∞ Creating and Managing a State of Control.” Wolters Kluwer, 2024.

- Alliance for Pharmacy Compounding. “Statement on rules governing compounding, what FDA guidance says about.” Alliance for Pharmacy Compounding, 11 Mar. 2024.

- Vici Health Sciences. “Analytical Testing for Peptide Formulations.” Vici Health Sciences, 2024.

- Donegan, Michael, and Li, Fang. “A Liquid Chromatography-High Resolution Mass Spectrometry for Peptide Drug Quality Control.” Journal of Pharmaceutical and Biomedical Analysis, vol. 148, 2018, pp. 341-350.

- U.S. Food and Drug Administration. “FDA to Compounders ∞ Know Your Bulks and Excipients Suppliers.” FDA.gov, 20 Mar. 2025.

- MedicaPharma. “GMP-Certified APIs For Compounding Pharmacies.” MedicaPharma, 2024.

- Kashyap, Kunal, and Faria, James. “Navigating the Direct Importation of Active Pharmaceutical Ingredients ∞ Compliance Considerations for Compounding Pharmacies.” International Journal of Pharmaceutical Compounding, vol. 29, no. 1, 2025, pp. 6-13.

Reflection

Charting Your Path with Biological Trust

The knowledge of how compounded peptides are regulated provides a framework for confidence. It transforms the abstract concept of ‘quality’ into a concrete system of standards, procedures, and scientific verification. You have seen how the FDA, USP, and State Boards of Pharmacy create a protective architecture, and how analytical science provides the ultimate proof of a peptide’s integrity.

This understanding is a powerful tool. It allows you to engage with your healthcare provider and your compounding pharmacy from a position of informed awareness. You can now ask more specific questions, not just about the intended biological effects of a protocol, but about the sourcing of the materials, the accreditation of the pharmacy, and the quality assurances that stand behind the therapy designed for you.

This journey into your own health is deeply personal. The decision to use targeted therapies is a proactive step toward reclaiming and optimizing your body’s intricate systems. The information presented here is designed to support that step. It provides the logical and scientific foundation for the trust that is essential in any therapeutic partnership.

As you move forward, consider how this knowledge shapes your perspective. Your path to wellness is one you walk in collaboration with professionals who are guided by these very principles of safety, purity, and precision. The ultimate goal is to empower you to build a health strategy that is not only effective but is also one in which you can have complete and justified faith.