Fundamentals

You have arrived at a significant point in your personal health investigation. The feelings of fatigue, the subtle shifts in your body’s performance, and the search for renewed vitality have led you here, to the world of therapeutic peptides.

This is a space of immense potential, a place where we can use the body’s own signaling language to encourage healing, optimize function, and reclaim a sense of well-being. As you stand at this threshold, you are met with a foundational choice that will define the very nature of your protocol.

The question of how quality control standards differ between compounded and pharmaceutical-grade peptides is an inquiry into the core philosophy of your approach to wellness. This decision speaks to the level of precision, safety, and predictability you demand from the therapeutic signals you introduce into your biological systems.

Understanding this distinction begins with appreciating the elegant role of peptides themselves. Within the complex symphony of your physiology, hormones act as long-range messengers, traveling through the bloodstream to orchestrate major bodily functions. Peptides, in contrast, are often the local, highly specific couriers.

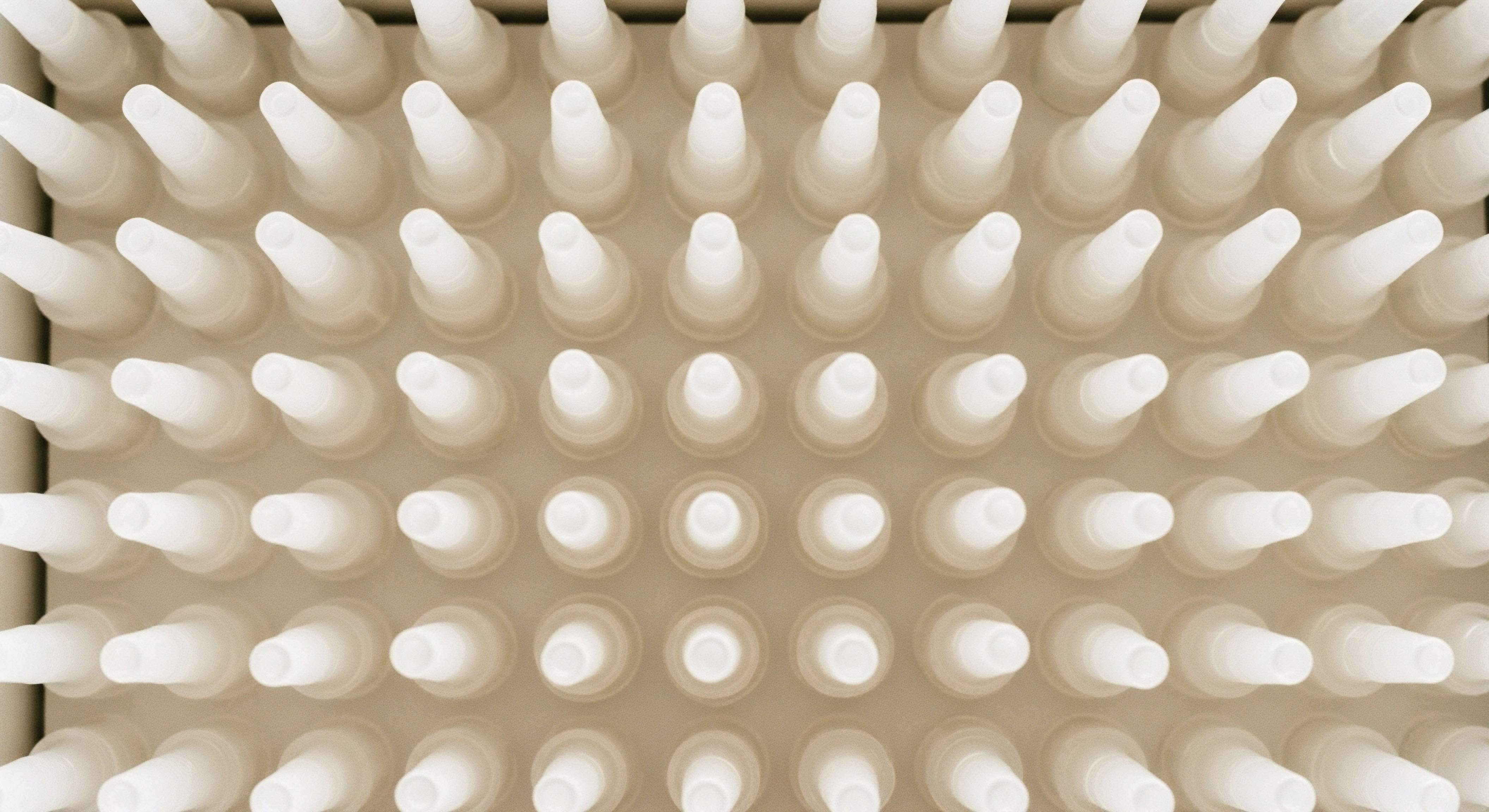

These short chains of amino acids deliver precise instructions to nearby cells, governing processes like tissue repair, inflammation response, and the release of other hormones. When we use a therapeutic peptide like Sermorelin or Ipamorelin, we are introducing a specific, targeted instruction into this system.

The goal is to prompt a natural response, such as encouraging the pituitary gland to release more of your own growth hormone. The absolute purity and structural integrity of that instructional molecule is paramount. A flawed message can be an ineffective one, or worse, a misunderstood one, leading to unintended consequences.

The Pharmaceutical-Grade Pathway

The first path is that of the pharmaceutical-grade peptide. This represents the highest level of regulatory scrutiny and standardization in medicine. A peptide that earns this designation has undergone an exhaustive journey overseen by national regulatory bodies, such as the U.S. Food and Drug Administration (FDA).

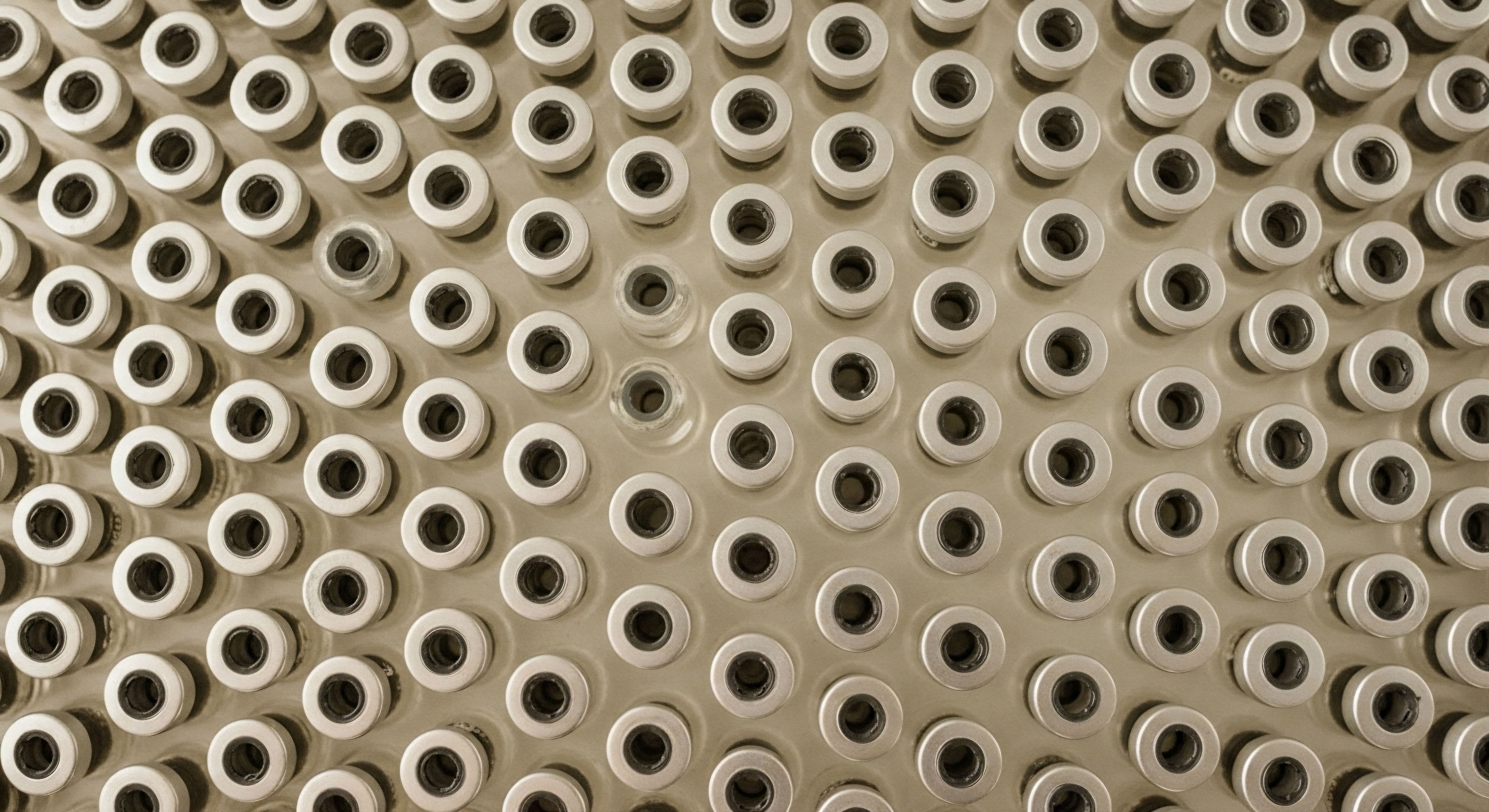

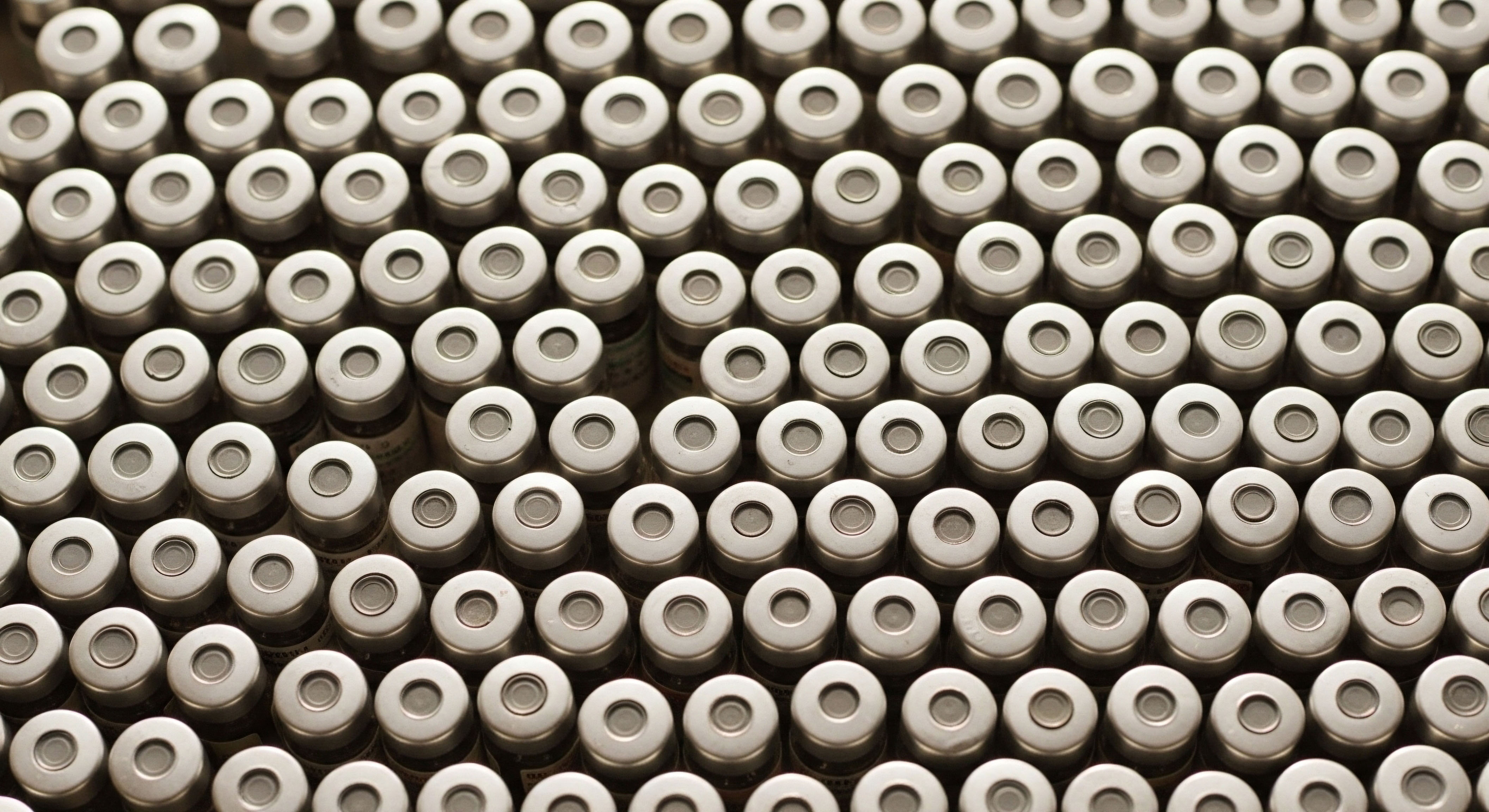

This process is designed to produce a product that is uniform, predictable, and validated by extensive clinical data. Every aspect of its creation, from the initial chemical synthesis to the final sterile vial, is governed by a set of protocols known as Current Good Manufacturing Practices (CGMP). These regulations ensure that the peptide you receive is precisely what it claims to be, at the exact concentration specified, and free from contaminants.

The development of a pharmaceutical-grade peptide involves years of research and multi-phase clinical trials to establish its safety and efficacy for a specific medical condition. The manufacturer must prove that the product consistently produces the desired therapeutic effect in human subjects and that its potential risks are well-understood and documented.

The quality control is relentless, with every batch being tested for identity, purity, potency, and sterility. This pathway provides a universal benchmark of quality, a standard against which all other sources are measured. It is a system built on population-level data and designed for mass-market consistency.

The Compounded Peptide Pathway

A second, distinct path is that of the compounded peptide. Compounding is a cornerstone of personalized medicine, a practice where a licensed pharmacist combines or alters ingredients to create a medication tailored to the unique needs of an individual patient.

This is done based on a prescription from a licensed physician who has determined that a commercially available drug is not the optimal treatment for their patient. For instance, a patient may require a specific dosage not available on the market, or they may have an allergy to a non-active ingredient in a mass-produced drug.

Compounded peptides are regulated, but by a different framework. In the United States, this oversight comes from state Boards of Pharmacy and adherence to standards set by the United States Pharmacopeia (USP).

For injectable peptides, the critical standard is USP General Chapter <797>, which outlines the stringent requirements for preparing sterile medications. This includes specifications for the cleanroom environment, the handling procedures to prevent microbial contamination, and the testing of the final product. Reputable compounding pharmacies source their active pharmaceutical ingredients (APIs) ∞ the raw peptide powder ∞ from FDA-registered facilities.

They then conduct their own testing on the final preparations, often through third-party analytical labs, to verify potency, sterility, and the absence of harmful endotoxins. This pathway prioritizes physician-led customization and direct therapeutic flexibility for individual patient care.

A pharmaceutical-grade peptide is a product of standardized, large-scale manufacturing for proven applications, while a compounded peptide is a personalized preparation created by a pharmacist for a specific patient’s needs.

Your choice between these sources directly impacts the therapeutic signals you send to your body. One represents a universally validated message, rigorously tested and confirmed on a large scale. The other represents a personalized message, crafted under specific guidelines to meet the precise requirements of your unique physiology as determined by your clinician.

Both paths, when pursued correctly, operate within regulated medical systems designed to protect patient safety. The key is understanding which system aligns with your specific health goals and the level of customization your protocol requires.

| Aspect | Pharmaceutical-Grade Peptides | Compounded Peptides |

|---|---|---|

| Governing Body | National regulatory agencies (e.g. FDA) | State Boards of Pharmacy and the United States Pharmacopeia (USP) |

| Primary Purpose | Mass-market production of a standardized, approved drug | Patient-specific medication created on-demand per a prescription |

| Testing Focus | Large-scale clinical trials for safety and efficacy for a specific indication | End-product testing for potency, sterility, and endotoxins per batch |

| Patient Access | Prescription for an FDA-approved indication | Prescription based on a physician’s judgment for a specific patient’s needs |

| Regulatory Standard | Current Good Manufacturing Practices (CGMP) | USP General Chapters (e.g. <797> for sterile preparations) |

Intermediate

To truly grasp the distinction between pharmaceutical and compounded peptides, we must move beyond the regulatory frameworks and into the meticulous, scientific processes that define their quality. The difference is tangible, existing in the chemistry of the molecules and the environments where they are prepared.

This deeper understanding is essential for anyone embarking on a therapeutic protocol, as it reveals the ‘how’ and ‘why’ behind the safety and efficacy of these powerful signaling molecules. Your body’s endocrine system is a network of exquisite sensitivity, and the quality of the peptides you introduce determines whether you are providing a clear, productive signal or a garbled, potentially disruptive one.

The Rigor of Current Good Manufacturing Practices

Pharmaceutical-grade peptides are born from a culture of extreme process control defined by Current Good Manufacturing Practices (CGMP). This is a comprehensive system mandated by the FDA that controls every facet of drug manufacturing. The objective of CGMP is to ensure that a drug is produced to a consistent, verifiable standard of identity, strength, quality, and purity. It is a proactive system designed to build quality into the product at every step.

The journey begins with the raw materials. The active pharmaceutical ingredient (API) and any other components must be sourced from qualified vendors and rigorously tested upon arrival to confirm their identity and purity. Throughout the manufacturing process, meticulous records are kept in a master batch record, documenting every action, every measurement, and every piece of equipment used.

The environment itself is controlled, with specific standards for air quality, temperature, and humidity to prevent cross-contamination or degradation. Finally, the finished product undergoes a battery of tests. High-Performance Liquid Chromatography (HPLC) is used to confirm its purity and quantify any impurities. Mass spectrometry validates its molecular weight and structure.

Sterility testing ensures it is free from microbes, and Limulus Amebocyte Lysate (LAL) testing confirms it is free of endotoxins, which are fever-inducing substances from bacteria. This entire process creates a product with a known, stable, and reproducible profile, validated by extensive data.

The Precision of USP Sterile Compounding

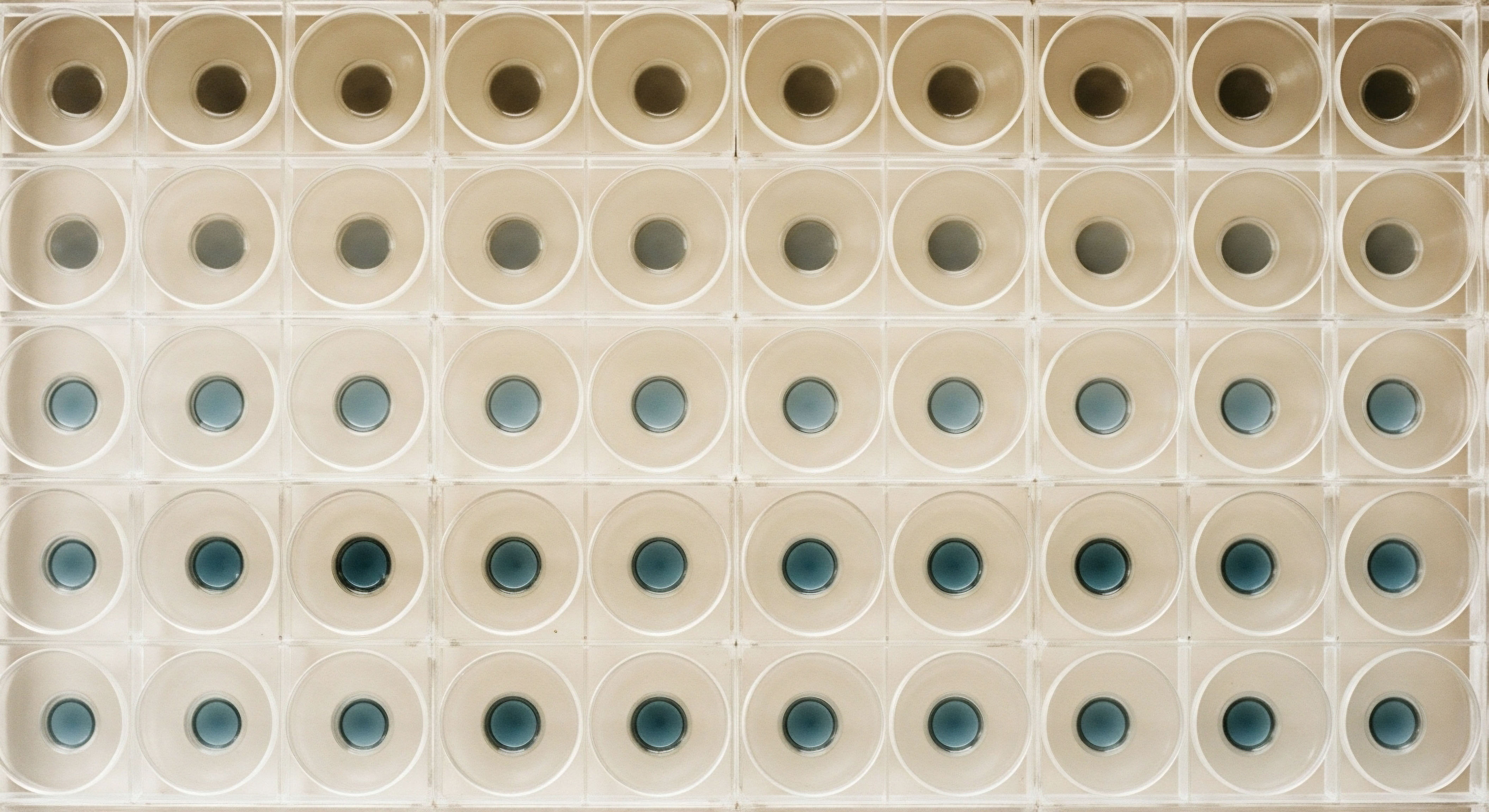

Compounded peptides, particularly those intended for injection, operate under a different yet equally critical set of standards, primarily USP General Chapter <797>. This chapter provides the foundation for preventing patient harm that could result from microbial contamination, excessive endotoxins, or variability in the strength of sterile preparations. The focus of USP <797> is on the environment, personnel, and procedures used by the pharmacist to prepare a sterile product from its constituent ingredients.

A compounding pharmacy that prepares sterile peptides must do so within a certified cleanroom. This is a controlled environment with filtered air and surfaces that are regularly sanitized to maintain a state of microbial control. Pharmacists and technicians must undergo specialized training in aseptic techniques ∞ procedures designed to prevent contamination ∞ and demonstrate their proficiency through regular testing.

They source their peptide APIs from FDA-registered facilities, which provides an initial layer of quality assurance. Once a batch of peptide vials is prepared for a group of patients, a reputable compounding pharmacy will send samples from that specific batch to a third-party analytical laboratory.

This lab performs tests for potency (to ensure correct dosage), sterility, and endotoxin levels, providing a Certificate of Analysis (CoA) for that batch. This process ensures that the personalized medication meets critical safety standards before it is dispensed to the patient.

The CGMP for pharmaceuticals is a system designed to mass-produce a verifiably identical product, whereas USP <797> for compounding is a system designed to safely prepare a customized medication for an individual.

What Are the Practical Risks of Unregulated Peptides?

A third category exists outside of these two regulated medical pathways. This is the gray market of online vendors who sell peptides labeled as “research chemicals” or “not for human use.” This labeling is a deliberate tactic to circumvent all regulatory oversight from both the FDA and state boards of pharmacy. These products are not subject to CGMP or USP standards, and their quality is completely unverified. Engaging with this market introduces significant and unpredictable risks into your health protocol.

- Purity and Identity Failures ∞ Without regulatory oversight, there is no guarantee that the substance in the vial is the correct peptide. The synthesis process may have been incomplete, resulting in a product containing truncated or incorrect amino acid sequences. These malformed molecules will fail to bind to the correct cellular receptors, rendering them ineffective and introducing unknown variables into your system.

- Dangerous Contaminants ∞ The product may contain residual solvents, heavy metals, or other byproducts from a poorly controlled manufacturing process. These contaminants can be toxic and place a significant burden on the body’s detoxification systems.

- Incorrect Potency ∞ A vial from an unregulated source may contain significantly more or less peptide than advertised. Too little, and the protocol is useless. Too much, and you risk an exaggerated biological response and a greater potential for adverse effects.

- Lack of Sterility and Endotoxins ∞ Injecting a non-sterile product can lead to serious localized or systemic infections. The presence of endotoxins can trigger a severe inflammatory cascade, causing fever, chills, and other dangerous symptoms. There is no requirement for these vendors to perform sterility or endotoxin testing.

Choosing a source for therapeutic peptides is a decision that directly influences the safety and potential success of your health optimization strategy. The regulated pathways of pharmaceutical manufacturing and legitimate medical compounding are designed with patient safety as their primary objective. They provide verifiable data and professional oversight, ensuring the signals you send to your body are the ones you intend.

| QC Parameter | Pharmaceutical-Grade (CGMP) | Compounded (USP <797>) | Unregulated “Research” Supplier |

|---|---|---|---|

| Regulatory Oversight | FDA and other national bodies | State Boards of Pharmacy | None |

| Prescription Required | Yes | Yes | No |

| Purity & Identity Guarantee | Guaranteed through multi-stage testing and clinical trials | Verified by sourcing API from FDA-registered facilities; final product testing | None; high risk of impurities and incorrect molecules |

| Potency Assay | Required and validated to be within a narrow range | Tested per batch by a third-party lab for verification | Not guaranteed; can be highly variable and inaccurate |

| Sterility Testing | Mandatory for all injectable products | Mandatory for all sterile preparations; tested per batch | Not required; high risk of microbial contamination |

| Endotoxin Limit Testing | Mandatory for all injectable products | Tested per batch to ensure safety | Not required; high risk of pyrogenic reactions |

Academic

An academic exploration of peptide quality control moves beyond regulatory compliance and into the realm of molecular biology and systems physiology. The central issue becomes one of informational integrity. A therapeutic peptide is a molecule designed to convey a precise message to a specific receptor within a complex biological system.

The quality of that peptide ∞ its purity, sequence, and three-dimensional structure ∞ determines the clarity and fidelity of that message. Any deviation can corrupt the signal, leading to a spectrum of outcomes ranging from therapeutic nullity to unintended off-target activity and systemic disruption.

Molecular Fidelity in Peptide Synthesis

The vast majority of therapeutic peptides are created using a process called Solid-Phase Peptide Synthesis (SPPS). This brilliant chemical technique involves building the peptide one amino acid at a time while it is anchored to a solid resin bead. While SPPS is highly efficient, it is an imperfect process.

Each step of adding a new amino acid (a coupling cycle) carries a small risk of failure. Over the course of synthesizing a peptide of 15, 29, or even 40 amino acids, these small probabilities can compound, leading to a heterogeneous final product.

The resulting impurities are not random chemicals; they are often closely related to the target peptide itself. Common variants include:

- Deletion Sequences ∞ An amino acid is missed during a coupling cycle, resulting in a shorter, incorrect peptide chain.

- Truncated Sequences ∞ The synthesis process stops prematurely, creating an incomplete fragment of the target peptide.

- Insertion Sequences ∞ An amino acid is inadvertently added twice.

- Diastereomers ∞ The chirality of an amino acid is flipped during synthesis, altering the peptide’s three-dimensional shape.

These closely related impurities are particularly challenging because they may share similar chemical properties with the correct peptide, making them difficult to separate during purification. Advanced analytical techniques are required to ensure molecular fidelity.

High-Performance Liquid Chromatography (HPLC) is used to assess purity by separating molecules based on their chemical characteristics, while Mass Spectrometry (MS) is essential to confirm that the primary molecule has the correct mass, which corresponds to its amino acid sequence. A pharmaceutical-grade reference standard, a batch of peptide that has been exhaustively characterized to be as close to 100% pure and correct as possible, is the ultimate benchmark for these analytical tests.

How Do Impurities Affect the Hypothalamic Pituitary Axis?

The consequences of molecular infidelity become profoundly clear when we consider the delicate feedback loops of the endocrine system, such as the Hypothalamic-Pituitary-Gonadal (HPG) axis or the Growth Hormone (GH) axis. Let’s consider the use of a Growth Hormone Releasing Hormone (GHRH) analogue like Sermorelin or CJC-1295. The therapeutic goal is to mimic the body’s natural GHRH, bind to GHRH receptors on the pituitary gland, and stimulate the synthesis and release of endogenous growth hormone.

If the administered peptide is of low purity and contains a significant percentage of deletion or truncated sequences, several negative outcomes can occur. These variant peptides may have a weak affinity for the GHRH receptor, failing to trigger a signal and thus producing no therapeutic effect.

A more problematic scenario arises if these impurities can bind to the receptor without activating it. In this case, they act as competitive antagonists, occupying the receptor sites and blocking the body’s own natural GHRH, as well as any full-length therapeutic peptide, from binding. This could paradoxically lead to a reduction in growth hormone signaling.

Furthermore, the concept of “peptide content” is distinct from “peptide purity.” A vial may be tested via HPLC and show 99% purity, meaning 99% of the peptide-related material is the correct sequence. However, the total peptide content could be low, with the majority of the vial’s mass consisting of salts (like trifluoroacetate, a remnant of synthesis) and water.

A vial advertised as 10mg might only contain 6mg of the actual peptide. A pharmaceutical-grade product or a high-quality compounded preparation will have undergone analysis to assign an accurate peptide content value, ensuring that dosing is precise and the therapeutic effect is predictable.

Without this level of characterization, a clinical protocol is built on a foundation of uncertainty, making it impossible to distinguish between a non-response due to individual biology and a non-response due to a substandard product.

The introduction of poorly characterized peptides into the body is an uncontrolled experiment, risking not only the absence of benefit but the active disruption of sensitive homeostatic systems.

The systemic implications extend to the immune system. The body is adept at recognizing foreign or malformed proteins. The introduction of peptides with significant impurities could potentially trigger an immune response, leading to the development of anti-drug antibodies.

These antibodies could neutralize the therapeutic peptide, rendering it ineffective, and in a worst-case scenario, they could cross-react with the body’s own endogenous hormones, creating a state of acquired autoimmune deficiency. This underscores the absolute necessity of the stringent quality control measures employed in both pharmaceutical manufacturing and high-quality sterile compounding. The goal of these therapies is to gently guide and recalibrate biological function, an objective that demands the highest possible fidelity in the tools we use.

References

- “Peptides Purchased Online vs Compounding Pharmacies ∞ What’s the Difference?” Empower Pharmacy, 6 Jan. 2020.

- “The Role of Peptide Reference Standards in Pharmaceutical Quality Control.” CymitQuimica, 6 Mar. 2025.

- “Is Peptide Sciences A Compounding Pharmacy? Unpacking The Truth.” Inside Bodybuilding, 2 Jul. 2025.

- “Compounding Pharmacies Vs Online Peptide Suppliers.” Joi + Blokes, 22 Feb. 2022.

- P. De-Ping, et al. “Reference Standards to Support Quality of Synthetic Peptide Therapeutics.” Journal of Pharmaceutical Sciences, vol. 112, no. 6, 2023, pp. 1535-1549, doi:10.1016/j.xphs.2023.03.022.

Reflection

You have now examined the intricate details that separate peptides born of standardized industrial science from those crafted for individual biology. This knowledge does more than simply answer a question; it equips you with a framework for making one of the most critical decisions in your health protocol.

The path you choose is a direct reflection of your personal commitment to a process that is transparent, accountable, and aligned with the precise needs of your body. This is the moment to look inward and consider your own philosophy of care.

Are you seeking a well-established, universally validated intervention, or does your journey require a level of customization that only a physician-led, compounded protocol can provide? The information you have absorbed is the first and most vital step. It transforms you from a passive recipient of care into an active, informed participant in your own wellness journey.

The next step involves a conversation, a partnership with a clinician who understands this landscape and can help you apply this knowledge to your unique biological context. The ultimate goal is to move forward with confidence, knowing that every choice you make is a deliberate step toward reclaiming your vitality and function, without compromise.

Glossary

quality control

therapeutic peptide

ipamorelin

growth hormone

current good manufacturing practices

cgmp

compounded peptides

from fda-registered facilities

good manufacturing practices

high-performance liquid chromatography

compounding pharmacy

endotoxin testing

peptide quality control

peptide synthesis

sermorelin