Fundamentals

You stand at a threshold, seeking to reclaim a level of vitality that feels like it is slipping away. The body’s subtle shifts ∞ the fatigue that settles deeper, the slowing of recovery, the muted sense of well-being ∞ have led you here, to an investigation of the body’s own signaling molecules.

You have heard of peptides, these keys to cellular function, and you are considering how they might unlock a more optimized state of being. This is a profound and personal starting point, one grounded in the felt sense of your own biology. Your body is communicating a need, and your role is to learn its language.

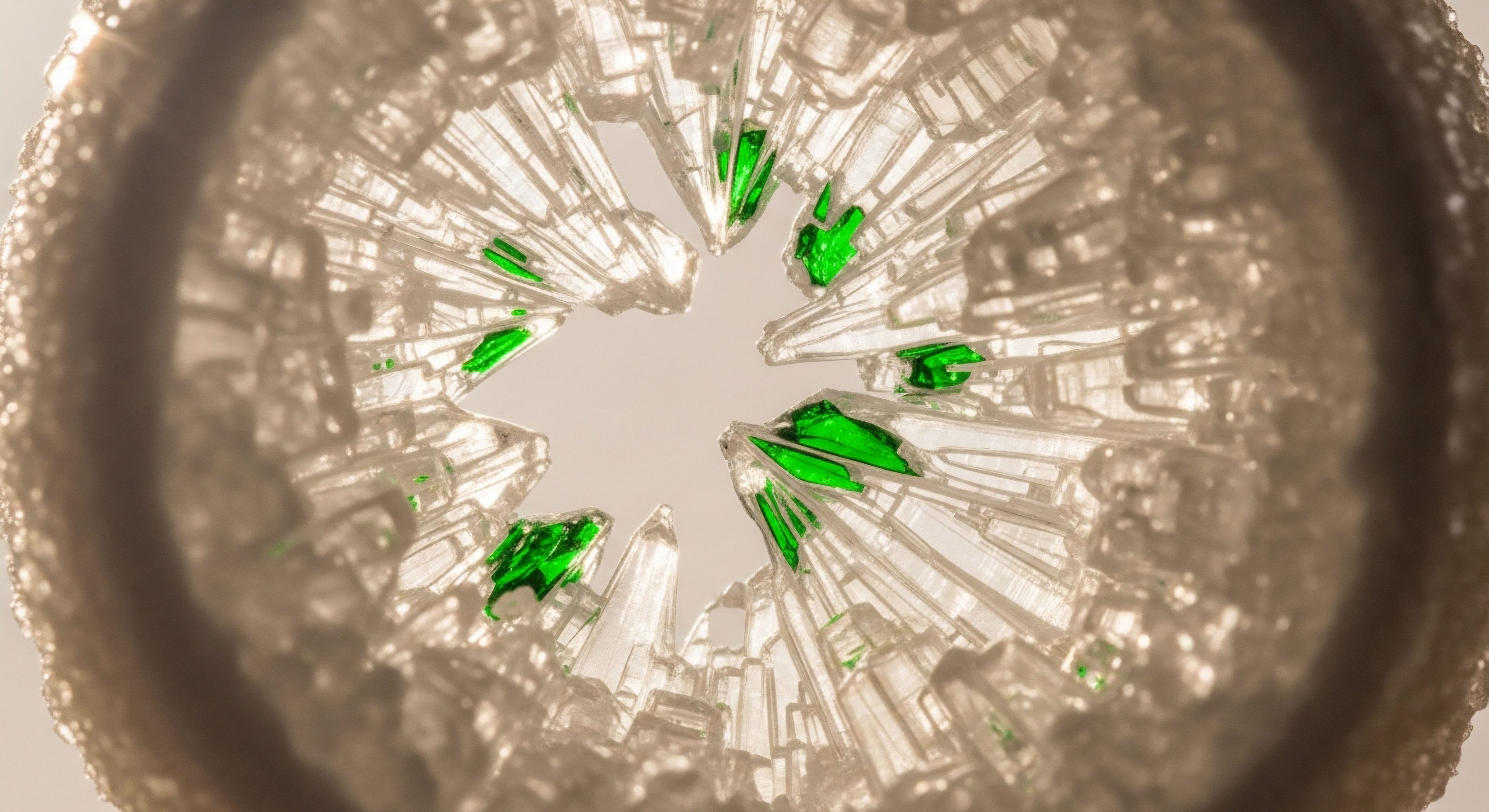

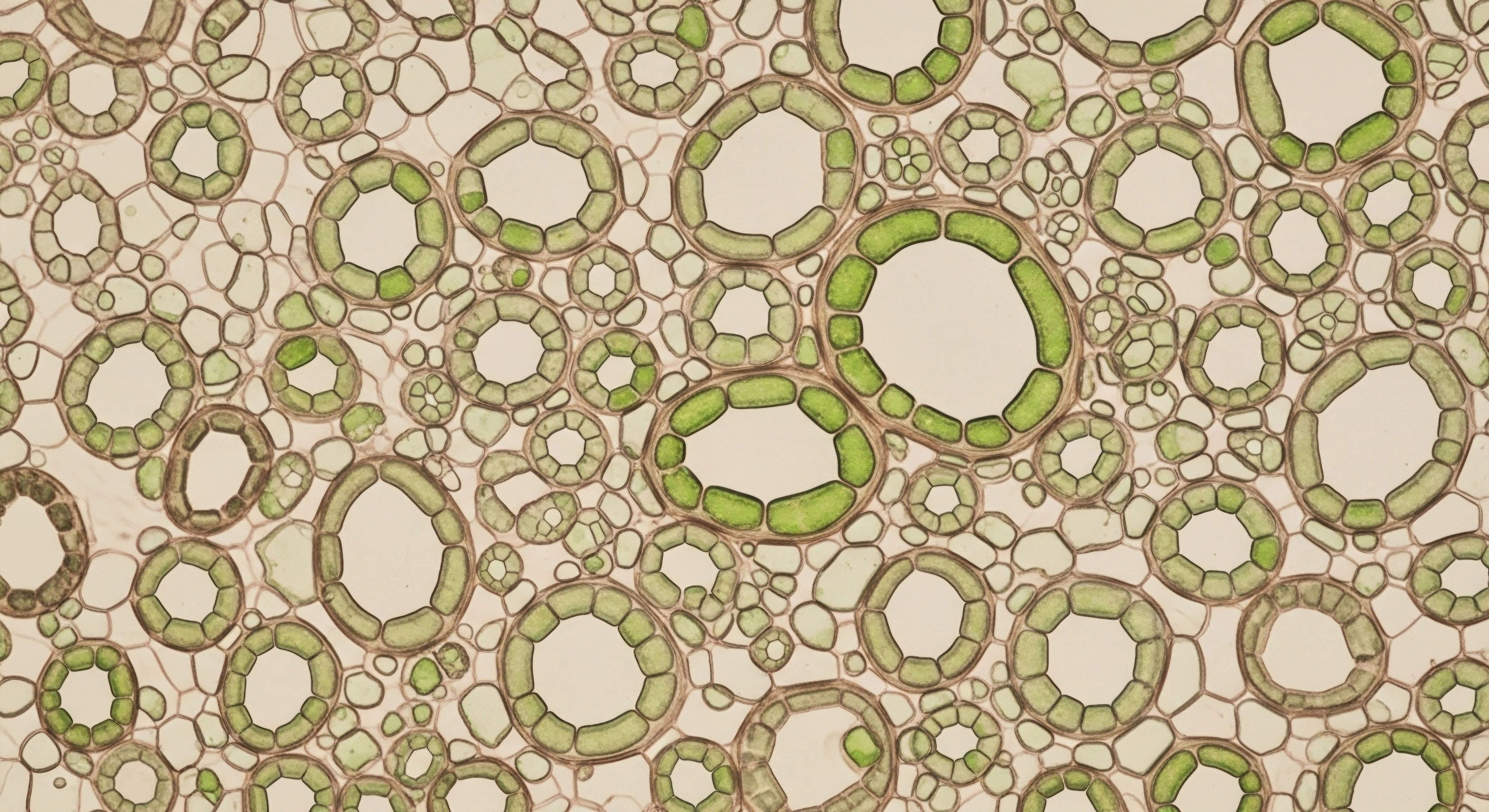

The therapeutic promise of a peptide is contained entirely within its molecular structure. Think of it as a key, precision-engineered to fit a specific lock on the surface of a cell. When the key turns, a message is delivered, initiating a cascade of events that can regulate metabolism, orchestrate healing, or modulate inflammation.

The sequence of amino acids Meaning ∞ Amino acids are fundamental organic compounds, essential building blocks for all proteins, critical macromolecules for cellular function. in the peptide chain, its length, and its three-dimensional shape all contribute to its unique identity and function. This structure is the source of its power. A peptide designed to stimulate growth hormone release, for instance, works because its shape mimics the body’s own signaling molecules, fitting perfectly into the pituitary gland’s receptors.

The biological function of a peptide is a direct consequence of its precise molecular architecture.

The Molecule and Its Origin Story

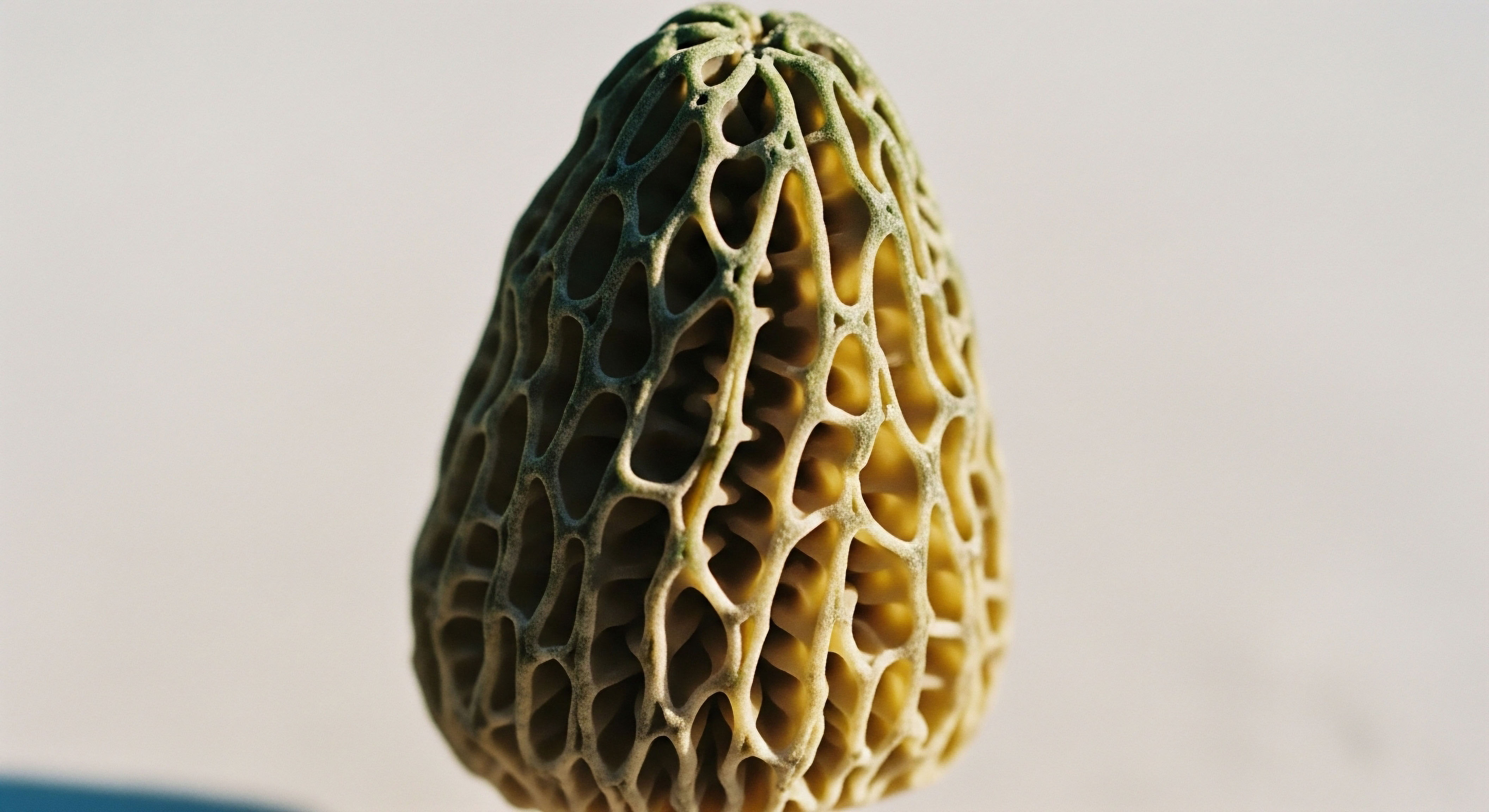

Every therapeutic molecule has an origin story, a journey from raw materials to a final, purified form. The manufacturing process is this origin story. It dictates the final integrity of the peptide key. A meticulous, controlled synthesis creates a key that is clean, correctly shaped, and free of imperfections.

An uncontrolled or poorly documented process can produce a key that is misshapen, contaminated with residual chemicals, or mixed with a host of other failed keys. Such a product may fail to deliver its message, or worse, it may transmit a garbled signal that leads to unintended biological consequences.

This is why regulatory scrutiny of peptide manufacturing Meaning ∞ Peptide manufacturing is the controlled chemical synthesis of short amino acid chains, peptides, for pharmaceutical or research applications. is so rigorous. Agencies like the Food and Drug Administration Meaning ∞ The Food and Drug Administration (FDA) is a U.S. (FDA) are tasked with a singular, critical mission ∞ to ensure the key that reaches the patient is the exact key it purports to be. Their oversight is a validation of the peptide’s molecular integrity.

They examine the entire manufacturing process, from the sourcing of raw amino acids to the final sterile vial, to confirm that the product is pure, potent, and safe. The regulations are the guardians of the molecule’s promise, ensuring that the quest for vitality is built on a foundation of verified science and safety.

What Defines Quality in Peptide Synthesis?

The quality of a peptide is not a subjective measure; it is a quantifiable reality defined by specific analytical metrics. Purity is the measure of how much of the final product is the desired peptide sequence, as opposed to fragments or failed sequences.

Identity confirms that the amino acid sequence is correct and in the proper order. Potency measures the biological activity of the peptide, its ability to effectively turn the lock. The absence of contaminants, from manufacturing solvents to bacterial endotoxins, is another critical quality attribute.

Each of these parameters is a direct reflection of the manufacturing method employed. A sophisticated process yields a product that meets these high standards, while a lesser process introduces variables that compromise them. Understanding this connection empowers you to ask the right questions about the therapies you are considering, transforming you from a passive recipient to an informed participant in your health journey.

Intermediate

As we move from the conceptual to the clinical, the focus sharpens onto the specific methodologies that build peptides and the regulatory frameworks that govern them. The journey of a peptide from a chemical blueprint to a therapeutic agent is one of immense complexity.

The choice of manufacturing pathway ∞ be it chemical synthesis Meaning ∞ Chemical synthesis refers to the deliberate construction of complex chemical compounds from simpler precursor molecules through controlled reactions. or recombinant biotechnology ∞ profoundly influences the final product’s profile, including its purity, potential impurities, and, consequently, the level of regulatory examination it must undergo. Each method presents a unique set of challenges and advantages, directly impacting the safety and efficacy of protocols like Testosterone Replacement Therapy (TRT) or Growth Hormone Peptide Therapy.

Regulatory bodies are not assessing these methods in a vacuum. They are applying a consistent set of principles outlined in international guidelines, such as those from the International Council for Harmonisation Meaning ∞ The International Council for Harmonisation (ICH) is a global initiative uniting regulatory authorities and pharmaceutical industry associations. (ICH). These guidelines provide a global standard for pharmaceutical quality.

For peptides, this means a manufacturer must provide a comprehensive data package that validates the product’s identity, purity, and stability. The FDA’s recent shift in enforcement, moving from a focus on website marketing claims to a direct examination of the manufacturing supply chain, underscores this principle. The agency is intensifying its scrutiny of how these molecules are made, demanding transparency and demonstrable quality control at every step.

A Tale of Two Syntheses Recombinant Vs Chemical

The production of therapeutic peptides generally follows one of two major pathways. Understanding their fundamental differences is key to appreciating the regulatory nuances that apply to each. Recombinant DNA technology Meaning ∞ Recombinant DNA Technology involves the precise manipulation of genetic material to combine DNA sequences from different biological sources, creating novel genetic constructs that can be introduced into host cells for specific purposes. uses living systems, like bacteria or yeast, as miniature factories.

Scientists insert the genetic code for the desired peptide into these host cells, which then produce the molecule as part of their natural biological processes. This method is particularly effective for producing larger peptides and proteins. Chemical synthesis, most commonly Solid-Phase Peptide Synthesis Meaning ∞ Solid-Phase Peptide Synthesis (SPPS) is a robust chemical method for creating peptides by sequentially adding amino acid building blocks to a growing chain that is anchored to an insoluble polymeric support, typically a resin bead. (SPPS), builds the peptide one amino acid at a time in a controlled, sequential chemical reaction.

This method offers precise control over the sequence and allows for the incorporation of non-natural amino acids, which can enhance a peptide’s stability or function.

| Attribute | Recombinant DNA Technology | Solid-Phase Peptide Synthesis (SPPS) |

|---|---|---|

| Primary Application | Large peptides and proteins (typically > 40 amino acids). | Small to medium-sized peptides (typically < 40 amino acids). |

| Key Advantage | Biological system produces the correctly folded, complex structure. Cost-effective for large molecules at scale. | High purity, precise sequence control, and ability to incorporate modified amino acids. |

| Common Impurities | Host-cell proteins, DNA/RNA from the host organism, endotoxins, and variants with incorrect folding. | Truncated or deleted sequences, residual chemical reagents and solvents, and side-reaction byproducts. |

| Regulatory Focus | Demonstrating complete removal of host-cell contaminants and ensuring proper protein folding and activity. | Characterizing and quantifying synthesis-related impurities and ensuring removal of toxic chemical residues. |

How Do Regulators Verify a Peptide’s Molecular Fingerprint?

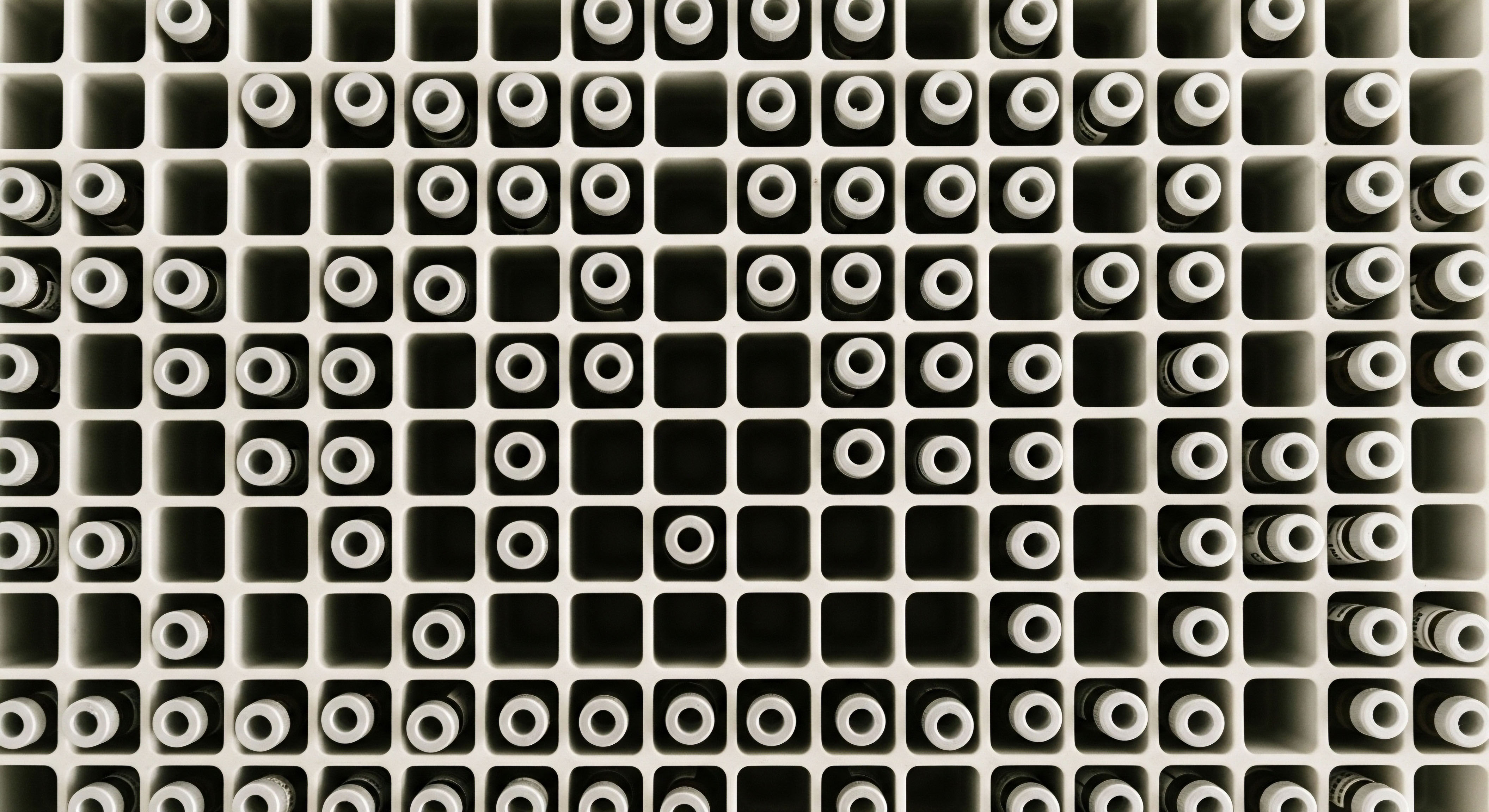

To ensure a peptide’s integrity, regulators require manufacturers to employ a suite of sophisticated analytical techniques. These methods serve to create a detailed “molecular fingerprint” of the product, confirming it matches the intended design. The FDA provides guidance on these validation methods, ensuring that the data submitted is reliable and accurate.

One of the primary tools is High-Performance Liquid Chromatography (HPLC). In this technique, the peptide product is dissolved in a liquid and passed through a column under high pressure. The column contains material that interacts differently with the main peptide and any impurities, causing them to separate and emerge at different times.

The result is a chromatogram, a graph that shows a large peak for the pure peptide and smaller peaks for any impurities, allowing for precise quantification of purity.

Following separation, Mass Spectrometry Meaning ∞ Mass Spectrometry is a sophisticated analytical technique identifying and quantifying molecules by measuring their mass-to-charge ratio. (MS) is used to confirm identity. This technique acts like a molecular scale, measuring the precise mass of the peptide molecules. The measured mass is compared to the theoretical mass calculated from its amino acid sequence. A match provides powerful evidence that the correct molecule has been synthesized.

Advanced techniques like tandem mass spectrometry (LC-MS/MS) can even be used to fragment the peptide and verify the sequence of amino acids in the chain, offering the highest level of structural confirmation.

Regulatory agencies mandate a suite of analytical tests to confirm a peptide’s identity, purity, and potency before it can be deemed safe for clinical use.

This rigorous, multi-step verification process is the bedrock of patient safety. It ensures that when a clinician prescribes a therapy like Sermorelin to support growth hormone function or PT-141 for sexual health, the molecule being administered has been verified to be what it claims to be, free from contaminants that could undermine the therapeutic goal or introduce unforeseen risks.

Academic

A deeper examination of the nexus between peptide manufacturing and regulatory science reveals a landscape of profound chemical and biological complexity. The regulatory imperative extends far beyond the simple confirmation of sequence and purity. It delves into the subtle, often invisible, universe of process-related impurities, stereoisomeric integrity, and the potential for immunogenicity.

These are the factors that distinguish a well-characterized therapeutic agent from a substance with unknown biological potential. For peptides, which are often structurally similar or identical to endogenous signaling molecules, even minute deviations introduced during manufacturing can have significant physiological consequences.

The FDA and European Medicines Agency (EMA) have both articulated the importance of controlling for impurities that arise from the manufacturing process itself. These are not just failed peptide sequences but can include residual solvents, reagents, and catalysts used during synthesis.

For peptides produced via recombinant methods, the challenges involve removing all traces of host-cell proteins (HCPs) and nucleic acids, as these biological macromolecules can trigger immune responses in patients. The regulatory expectation is that a manufacturer not only detects and quantifies these impurities but also understands their origin and demonstrates their consistent removal to well-below established safety thresholds.

What Are the Unseen Risks in Peptide Synthesis?

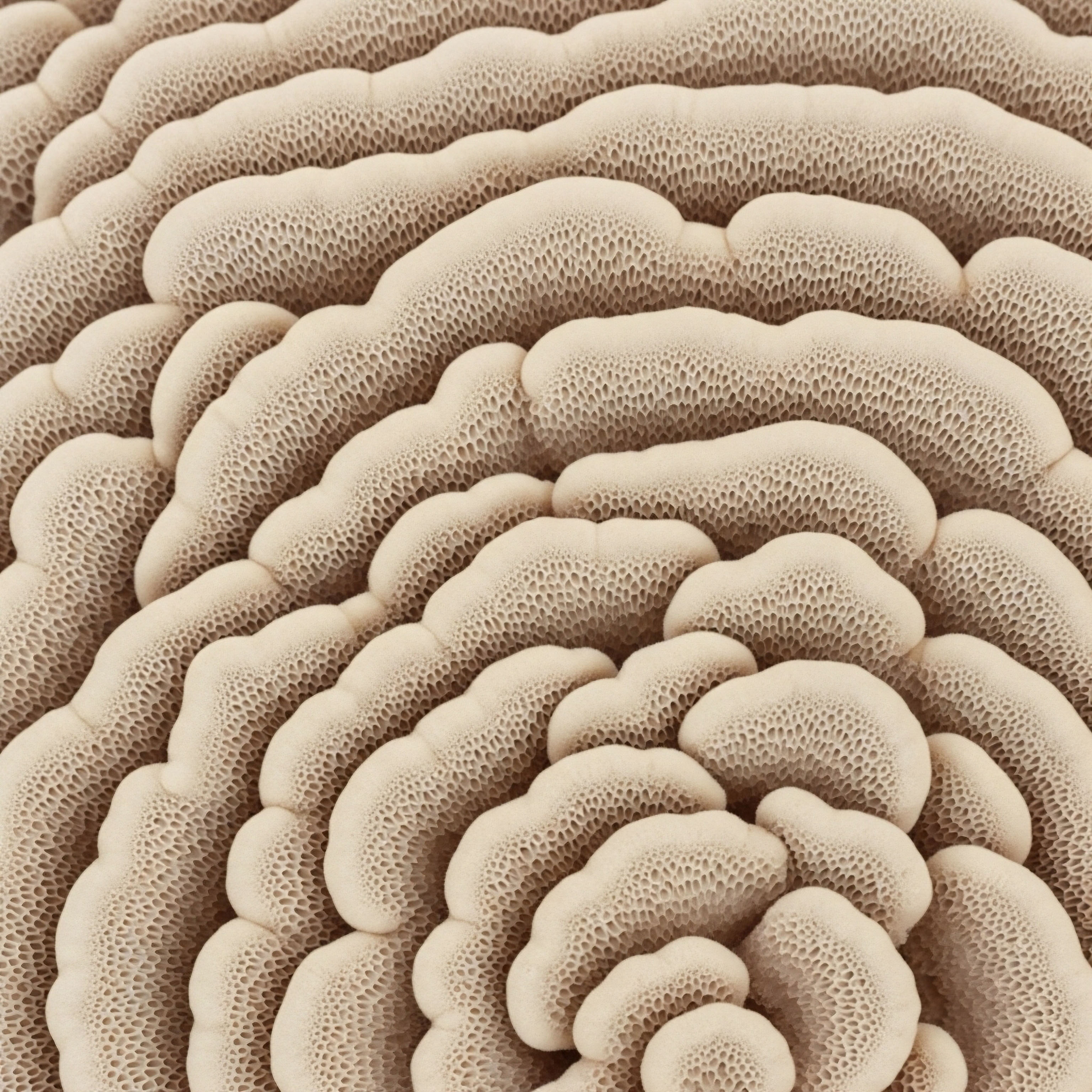

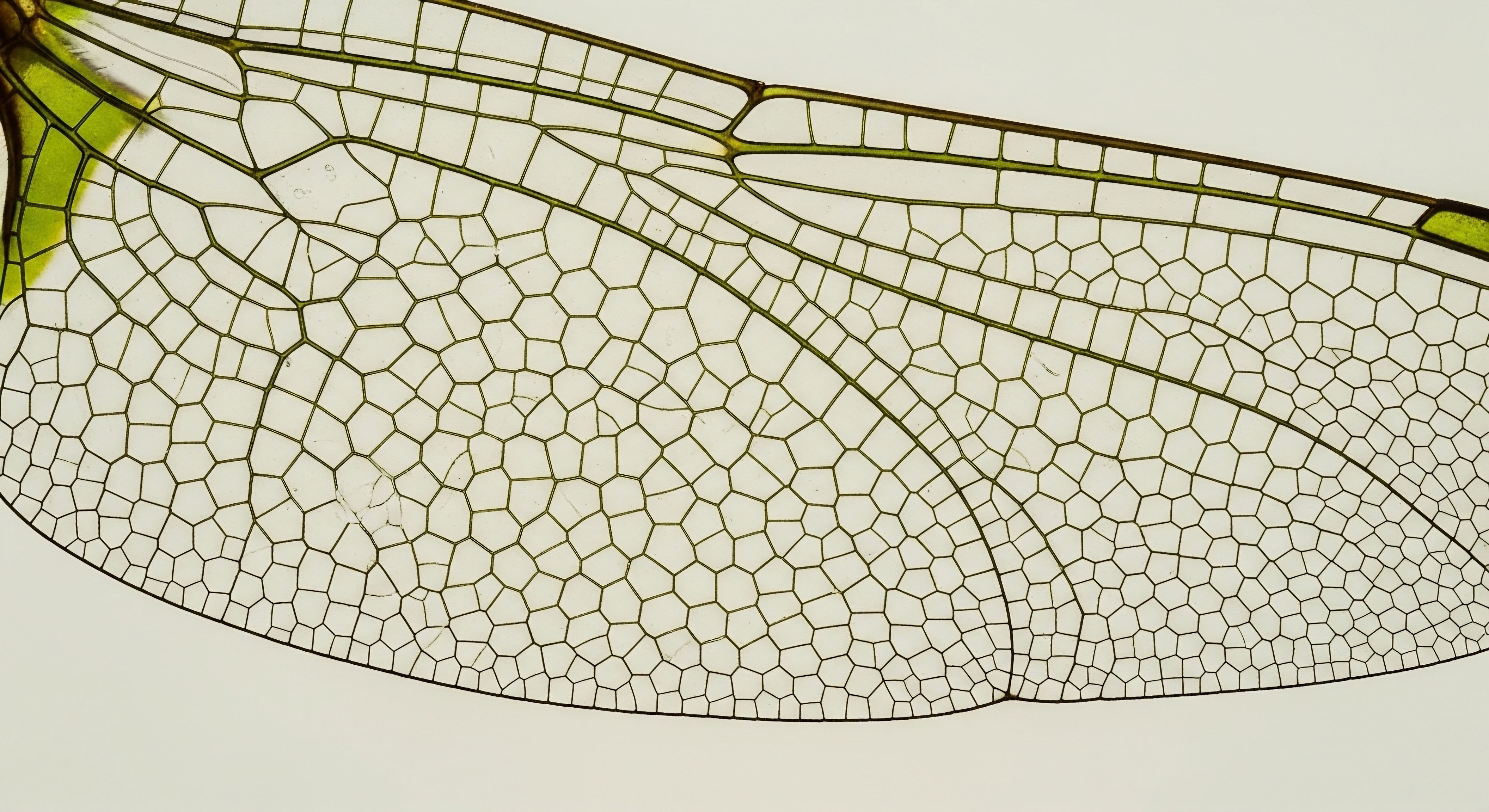

The structural complexity of peptides gives rise to potential impurities that are particularly challenging to detect and control. One of the most critical considerations is stereoisomeric integrity. Amino acids (with the exception of glycine) are chiral molecules, existing in left-handed (L) and right-handed (D) forms.

Biological systems almost exclusively use L-amino acids. During chemical synthesis, however, harsh conditions can cause some amino acids to flip their orientation, a process called racemization. The presence of even a small percentage of a D-amino acid in a peptide designed to be composed entirely of L-amino acids can dramatically alter its three-dimensional shape.

This change can reduce or eliminate its binding affinity for its target receptor or, more concerningly, cause it to interact with other receptors in unintended ways. Advanced chromatographic methods, such as chiral chromatography, are required to separate and quantify these stereoisomeric impurities, a step that is essential for ensuring the biological fidelity of the final product.

- Process-Related Impurities ∞ These contaminants originate directly from the manufacturing workflow. For synthetic peptides, this includes chemicals like trifluoroacetic acid (TFA), which is commonly used in purification, or coupling reagents that were not fully removed. For recombinant peptides, this category is dominated by host-cell proteins and endotoxins from the bacterial cell wall, which can cause inflammatory reactions.

- Product-Related Impurities ∞ These are molecules that are structurally similar to the desired peptide. This includes deletion sequences (where an amino acid is missing), truncated sequences (where the chain is incomplete), and aggregation (where peptide molecules clump together). These impurities are particularly difficult to separate and can compete with the active drug for its receptor, acting as antagonists.

- Contaminants from Container Systems ∞ A frequently overlooked source of impurities is the final container closure system. Chemicals can leach from the glass vial, rubber stopper, or plastic syringe over time, contaminating the sterile peptide solution. Regulatory agencies now require extensive extractable and leachable studies to ensure the long-term stability and purity of the product throughout its shelf life.

The Challenge of Bioequivalence for Generic Peptides

As many foundational peptide drugs come off patent, the development of generic versions presents a unique regulatory challenge. For simple small-molecule drugs, demonstrating bioequivalence might involve showing that the generic drug reaches the same concentration in the bloodstream over the same period as the brand-name drug.

For complex peptides, this is insufficient. Due to their intricate structures and potential for a multitude of minor variations, the FDA requires a much more comprehensive demonstration that the generic product is, for all practical purposes, identical to the original.

Ensuring the molecular and biological identity of a peptide is a foundational requirement for its safe and effective clinical application.

This involves using a battery of advanced analytical techniques to show that the generic peptide has the same primary sequence, the same higher-order structures (how it’s folded), and the same impurity profile as the reference product. Even then, clinical studies may be required to ensure that these analytical similarities translate to identical safety and efficacy profiles in the human body.

This high bar exists because regulators understand that with peptides, the process defines the product. Two peptides made by two different processes may be analytically similar yet behave differently in a biological system. This principle protects patients by ensuring that a generic peptide therapy has undergone the same rigorous characterization as the innovative drug it seeks to replace, guaranteeing the continuity of care and the integrity of the therapeutic promise.

| Impurity Type | Potential Source | Primary Analytical Method | Clinical Significance |

|---|---|---|---|

| Stereoisomers (D-forms) | Chemical synthesis (racemization). | Chiral Chromatography, NMR Spectroscopy. | Reduced potency, altered receptor binding, potential for off-target effects. |

| Host-Cell Proteins (HCPs) | Recombinant DNA manufacturing. | Enzyme-Linked Immunosorbent Assay (ELISA), Mass Spectrometry. | High potential for immunogenicity, leading to allergic reactions or loss of efficacy. |

| Aggregates | Manufacturing, formulation, and storage. | Size-Exclusion Chromatography (SEC), Dynamic Light Scattering (DLS). | Reduced solubility, increased immunogenicity, and potential for causing blockages. |

| Leachables | Container closure systems (vials, stoppers). | Gas Chromatography-Mass Spectrometry (GC-MS), Liquid Chromatography-Mass Spectrometry (LC-MS). | Introduction of potentially toxic or reactive chemicals into the final product. |

References

- Cohen, Jeff, and Caitlin A. Koppenhaver. “The FDA Is Expanding Its Oversight ∞ Research Use Only Peptide Businesses Should Be Watching Manufacturing Closely.” Florida Healthcare Law Firm, 2023.

- U.S. Food and Drug Administration, Center for Drug Evaluation and Research (CDER). “Draft Guidance on ANDAs for Certain Highly Purified Synthetic Peptide Drug Products That Refer to Listed Drugs of rDNA Origin.” Federal Register, 2021.

- U.S. Food and Drug Administration. “Impact Story ∞ Developing the Tools to Evaluate Complex Drug Products ∞ Peptides.” FDA.gov, 5 Feb. 2019.

- International Council for Harmonisation. “ICH Harmonised Tripartite Guideline Q6B ∞ Specifications ∞ Test Procedures and Acceptance Criteria for Biotechnological/Biological Products.” 1999.

- European Medicines Agency (EMA). “Guideline on the quality of synthetic peptides.” Committee for Medicinal Products for Human Use (CHMP), 2012.

Reflection

The Dialogue between Promise and Process

You began this inquiry with a personal need, a desire to align your biological function with your wellness goals. The exploration of peptide manufacturing and its regulatory landscape transforms this desire into a more profound understanding. The journey of a molecule, from its conception in a laboratory to its precise action within your body, is a narrative of immense technical and biological precision. This knowledge provides a new lens through which to view your health.

It shifts the conversation from one of simple solutions to one of informed partnership. The quality of a therapeutic agent is not an abstract concept; it is the physical foundation upon which your results will be built.

This awareness equips you to engage in a more meaningful dialogue with your clinical provider, to ask questions that move beyond “what does it do?” to “how is its integrity ensured?”. The path to optimizing your body’s intricate systems is a personal one, and it begins with the foundational wisdom that the promise of any therapy is inseparable from the process that creates it.