Fundamentals

Your body’s inner world operates on a language of exquisite precision. It is a constant, flowing dialogue between systems, conducted by molecular messengers that carry instructions from one cell to another. When we feel a loss of vitality, a decline in function, or a sense of disharmony within ourselves, it often points to a disruption in this internal communication.

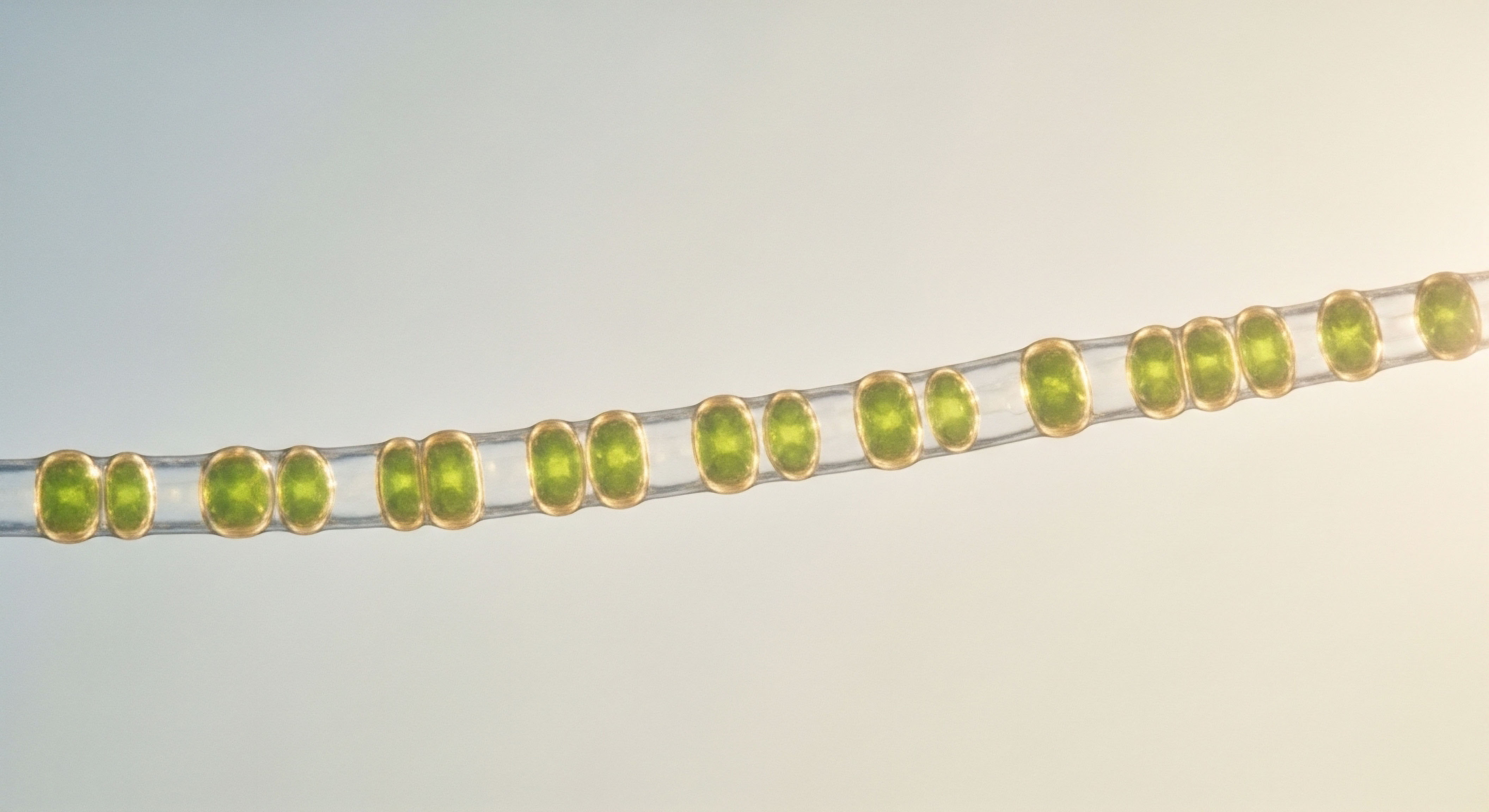

The journey toward reclaiming your well-being begins with understanding this language. Peptides, in this context, are short chains of amino acids, the very building blocks of proteins. They are a fundamental part of your biology, acting as signals that direct a vast array of physiological processes, from tissue repair to metabolic regulation.

When we consider using peptides as therapeutic agents, we are essentially learning to speak the body’s native tongue. The goal is to introduce a specific, well-defined message to correct a deficiency or enhance a function. For this intervention to be both safe and effective, regulatory bodies like the U.S.

Food and Drug Administration (FDA) must have absolute confidence in the identity and purity of the message being sent. This is where the structure of a peptide compound becomes the central character in its story of approval. The regulatory pathway for a peptide is a meticulous process of verification, ensuring the molecule you receive is precisely the molecule that was designed and tested. It is a framework built to protect you, grounded in the unchangeable principles of chemistry and biology.

The Foundational Definition in a Regulatory Context

From a regulatory perspective, the identity of a therapeutic molecule determines the path it must travel to gain approval. The FDA establishes a clear distinction based on size ∞ a polymer of amino acids Meaning ∞ Amino acids are fundamental organic compounds, essential building blocks for all proteins, critical macromolecules for cellular function. with a sequence of 40 or fewer is defined as a peptide. Molecules exceeding this length are classified as proteins.

This distinction is substantive because it dictates whether the compound is reviewed as a New Drug Application Meaning ∞ The New Drug Application, or NDA, is a formal submission by a pharmaceutical sponsor to a national regulatory authority, like the U.S. (NDA), typical for chemically synthesized molecules, or a Biologics License Application (BLA), reserved for larger, more complex biological products. Peptides reviewed under the NDA pathway are scrutinized with a focus on their chemical attributes, a process known as Chemistry, Manufacturing, and Controls (CMC).

The CMC documentation is the comprehensive dossier that details every aspect of the peptide’s molecular life. It provides regulators with a complete blueprint of the compound. This includes its exact amino acid sequence, its three-dimensional shape, its purity profile, and the methods used to produce it consistently. Each element of this blueprint is a critical data point that informs the agency’s assessment of the drug’s quality, which is inextricably linked to its safety and efficacy in your body.

A peptide’s regulatory journey begins with its precise structural definition, as this determines the specific approval pathway it must follow.

How Does Molecular Size Shape the Regulatory View?

The size of a peptide directly influences its biological behavior and the analytical methods required to characterize it. Shorter peptides, such as a dipeptide (two amino acids) or a tripeptide, have a structural simplicity that allows for straightforward chemical synthesis and analysis.

Their smaller size generally corresponds to a lower risk of eliciting an unwanted immune response, a phenomenon known as immunogenicity. As the chain of amino acids lengthens, the molecule’s complexity grows exponentially. Longer peptides can fold into specific secondary and tertiary structures, like helices and sheets, which are essential for their biological function.

This structural complexity presents a greater challenge for manufacturing and characterization. The potential for errors in the sequence or for the formation of impurities increases with each added amino acid. Consequently, regulatory scrutiny intensifies for larger peptides. The FDA requires extensive data to confirm that every batch produced has the correct primary sequence and has folded into the correct higher-order structure.

Any deviation could alter the peptide’s interaction with its target receptor in the body, potentially rendering it ineffective or, in some cases, harmful. The regulatory framework is designed to be proportional; the more complex the structure, the more rigorous the demonstration of control required.

Intermediate

Understanding the fundamental importance of a peptide’s structure opens the door to a more detailed appreciation of its regulatory journey. This next level of insight moves from the ‘what’ to the ‘how’ ∞ how do specific structural attributes and modifications translate into concrete requirements during the FDA’s review?

Every decision made during a peptide’s design, from altering a single amino acid to attaching a larger molecule, has direct consequences for the data package that must be submitted for approval. The regulatory process is a systematic evaluation of these choices, designed to quantify their impact on the compound’s behavior within the human body.

This scrutiny is centered on a core principle ∞ a therapeutic peptide Meaning ∞ A therapeutic peptide is a short chain of amino acids, typically 2 to 50 residues, designed to exert a specific biological effect for disease treatment or health improvement. must be a known entity. Its identity, purity, strength, and quality must be consistent from the first preclinical study to the last dose administered to a patient. Structural modifications are often introduced to enhance a peptide’s therapeutic properties, such as extending its half-life or improving its stability.

These modifications, while beneficial, introduce new layers of complexity that demand a more sophisticated level of analytical characterization and a more thorough assessment of potential risks, particularly immunogenicity.

The Central Role of Chemistry Manufacturing and Controls

The Chemistry, Manufacturing, and Controls (CMC) section of a New Drug Application (NDA) is the bedrock of a peptide’s regulatory submission. It is here that the sponsor must prove to the FDA that they have complete mastery over the product.

This involves a granular description of the manufacturing process, comprehensive characterization of the drug substance, and a robust strategy for ensuring batch-to-batch consistency. For peptides, this is a particularly demanding task due to their inherent complexity compared to traditional small-molecule drugs.

The control strategy for a peptide therapeutic encompasses several key domains:

- Starting Materials ∞ The quality of the raw ingredients, including the individual amino acid derivatives used in synthesis, must be rigorously controlled. For any unusual or custom-synthesized amino acids, regulators may request detailed information about their own manufacturing process and impurity profiles.

- Manufacturing Process ∞ The method of synthesis, most commonly Solid-Phase Peptide Synthesis (SPPS), must be described in detail. This includes every step of the process, from the coupling of each amino acid to the final cleavage and purification of the peptide. Controls at each step are necessary to minimize the formation of impurities.

- Characterization ∞ The final peptide product must be exhaustively characterized. This goes beyond simply confirming the amino acid sequence. It involves a battery of analytical tests to determine its physicochemical properties, identify and quantify all impurities, and, where relevant, confirm its higher-order structure.

- Specifications ∞ A set of specifications, which are critical quality attributes with defined acceptance criteria, must be established for the release of each batch. These include tests for identity, purity, assay (potency), and specific impurities.

Structural Modifications and Their Regulatory Impact

Native peptides often have limitations as therapeutic agents, such as rapid degradation by enzymes in the body, leading to a very short half-life. To overcome these challenges, chemists employ various structural modifications. While these changes can dramatically improve a peptide’s pharmacokinetic profile, they also add significant complexity to the regulatory submission.

Consider the following modifications and their implications:

- Cyclization ∞ Creating a cyclic structure by linking the ends of the peptide chain or forming a bond between amino acids in the middle of the sequence can make the peptide more resistant to enzymatic degradation. From a regulatory standpoint, this introduces a new covalent bond that must be precisely characterized. The FDA will require data confirming the exact location of the cyclization and demonstrating that this structure is formed consistently in every batch.

- PEGylation ∞ The attachment of a polyethylene glycol (PEG) chain is a common strategy to increase a peptide’s size, which slows its clearance by the kidneys and extends its circulation time. This creates what is known as a peptide conjugate. The regulatory challenge here is twofold. First, the point of attachment of the PEG chain to the peptide must be controlled. Second, the PEG material itself is a polymer with a distribution of different chain lengths. The submission must characterize this distribution and ensure its consistency.

- Use of Unnatural Amino Acids ∞ Substituting a standard amino acid with a synthetic or D-amino acid can block cleavage by specific enzymes. The FDA requires that these non-standard building blocks be thoroughly characterized as starting materials. Their incorporation into the final peptide must be verified, and any unique impurities resulting from their use must be identified and assessed.

Structural modifications enhance a peptide’s therapeutic potential but concurrently increase the burden of proof required by regulators to ensure quality and consistency.

The following table illustrates how these modifications add layers of analytical complexity, directly influencing the depth of the CMC data required for regulatory approval.

| Structural Feature | Simple Linear Peptide (e.g. Sermorelin) | Complex Modified Peptide (e.g. a PEGylated Peptide) |

|---|---|---|

| Primary Structure | Verification of the amino acid sequence using methods like mass spectrometry and amino acid analysis. | Verification of the amino acid sequence plus confirmation of the specific site of modification (e.g. where the PEG chain is attached). |

| Manufacturing | Standard Solid-Phase Peptide Synthesis (SPPS) with defined purification steps. | SPPS followed by a separate conjugation step to attach the modifying group. This additional step requires its own set of controls and validation. |

| Impurities | Focus on peptide-related impurities like deletion sequences or truncated fragments from the synthesis process. | Includes all standard peptide impurities, plus new impurities related to the modification, such as peptides with the PEG chain on the wrong amino acid or unreacted peptide. |

| Pharmacokinetics | Typically has a shorter half-life. The pharmacokinetic profile is relatively straightforward to characterize. | Has a longer half-life due to the modification. The absorption, distribution, metabolism, and excretion (ADME) profile is more complex and requires extensive study. |

| Immunogenicity Risk | Risk is primarily related to the peptide’s sequence and any synthesis-related impurities. | Risk is multifactorial, arising from the peptide sequence, the modifying group (PEG itself can be immunogenic), and new impurities formed during conjugation. |

What Is the Regulatory Concern with Immunogenicity?

Immunogenicity is the propensity of a therapeutic to trigger an immune response Meaning ∞ A complex biological process where an organism detects and eliminates harmful agents, such as pathogens, foreign cells, or abnormal self-cells, through coordinated action of specialized cells, tissues, and soluble factors, ensuring physiological defense. in the body, leading to the formation of anti-drug antibodies Meaning ∞ Anti-Drug Antibodies, or ADAs, are specific proteins produced by an individual’s immune system in response to the administration of a therapeutic drug, particularly biologic medications. (ADAs). This is a paramount safety concern for all biological drugs, including peptides. The primary structure of a peptide is a key determinant of its potential to be recognized as foreign by the immune system.

Certain amino acid sequences can bind to Major Histocompatibility Complex (MHC) molecules on immune cells, initiating a cascade that results in ADA production.

From a regulatory perspective, the immunogenicity risk Meaning ∞ Immunogenicity risk denotes the potential for an administered therapeutic agent, especially biologics or certain hormone preparations, to trigger an undesirable immune response. must be thoroughly assessed and managed. This involves a multi-tiered approach:

- Risk Assessment ∞ Early in development, sponsors use computational tools and in vitro assays to predict the immunogenic potential of the peptide sequence and any impurities. This helps to identify and mitigate risks before clinical trials begin.

- Clinical Assessment ∞ During clinical trials, patients are routinely monitored for the presence of ADAs. The development of validated assays to detect these antibodies is a regulatory requirement.

- Impact Analysis ∞ If ADAs are detected, their impact must be evaluated. Regulators need to know if the antibodies affect the drug’s pharmacokinetics (e.g. by clearing it from the body faster), its efficacy (e.g. by neutralizing its activity), or cause adverse events (e.g. allergic reactions).

Every aspect of the peptide’s structure, from its amino acid sequence Meaning ∞ The amino acid sequence is the precise, linear order of amino acids linked by peptide bonds, forming a polypeptide chain. to the impurities generated during its manufacture, contributes to its immunogenicity profile. Therefore, the comprehensive structural characterization demanded by the CMC process is also a foundational element of the safety assessment required for approval.

Academic

The regulatory evaluation of a therapeutic peptide is a deeply scientific discipline, predicated on the analytical deconstruction of its molecular architecture. At this level of examination, the conversation moves beyond general principles to the specific, quantitative evidence required to establish a molecule’s identity and purity with an exceptionally high degree of confidence.

The dialogue between a drug sponsor and a regulatory agency is conducted through data ∞ data from sophisticated analytical techniques designed to interrogate every conceivable structural attribute and potential variant of the peptide. The approval pathway is, in essence, a process of systematic risk mitigation, where structural uncertainty is progressively eliminated through rigorous scientific validation.

This process is guided by a risk-based approach, where the intensity of regulatory scrutiny is directly proportional to the peptide’s structural complexity and its intended clinical application. A synthetic peptide intended for a short-term indication may have a different set of expectations than a complex, modified peptide conjugate designed for chronic administration.

The core task for the sponsor is to build an unassailable scientific argument, supported by orthogonal analytical methods, that the manufacturing process yields a consistent product whose quality attributes are well-understood and controlled within clinically justified limits.

Advanced Analytical Characterization for Structural Elucidation

Demonstrating control over a peptide’s structure requires a suite of advanced analytical technologies. A single method is insufficient; regulators expect the use of multiple, orthogonal techniques that provide complementary information. This creates a comprehensive and robust picture of the molecule.

Primary Structure and Molecular Weight

The foundation of a peptide’s identity is its primary structure ∞ the linear sequence of its amino acids. Confirming this sequence with absolute certainty is a primary regulatory requirement.

- Mass Spectrometry (MS) ∞ High-resolution mass spectrometry is the cornerstone of peptide analysis. It provides an extremely accurate measurement of the peptide’s molecular weight, serving as a primary confirmation of its identity. Tandem mass spectrometry (MS/MS) involves fragmenting the peptide within the instrument and analyzing the masses of the fragments. This allows for the direct sequencing of the peptide, confirming the amino acid order and identifying the precise locations of any modifications.

- Amino Acid Analysis (AAA) ∞ This classical biochemical technique involves hydrolyzing the peptide into its constituent amino acids and then quantifying the amount of each one. The resulting amino acid ratio is compared to the theoretical ratio based on the intended sequence. This provides complementary evidence of the peptide’s composition and can help in accurately determining its concentration.

Higher-Order Structure (HOS)

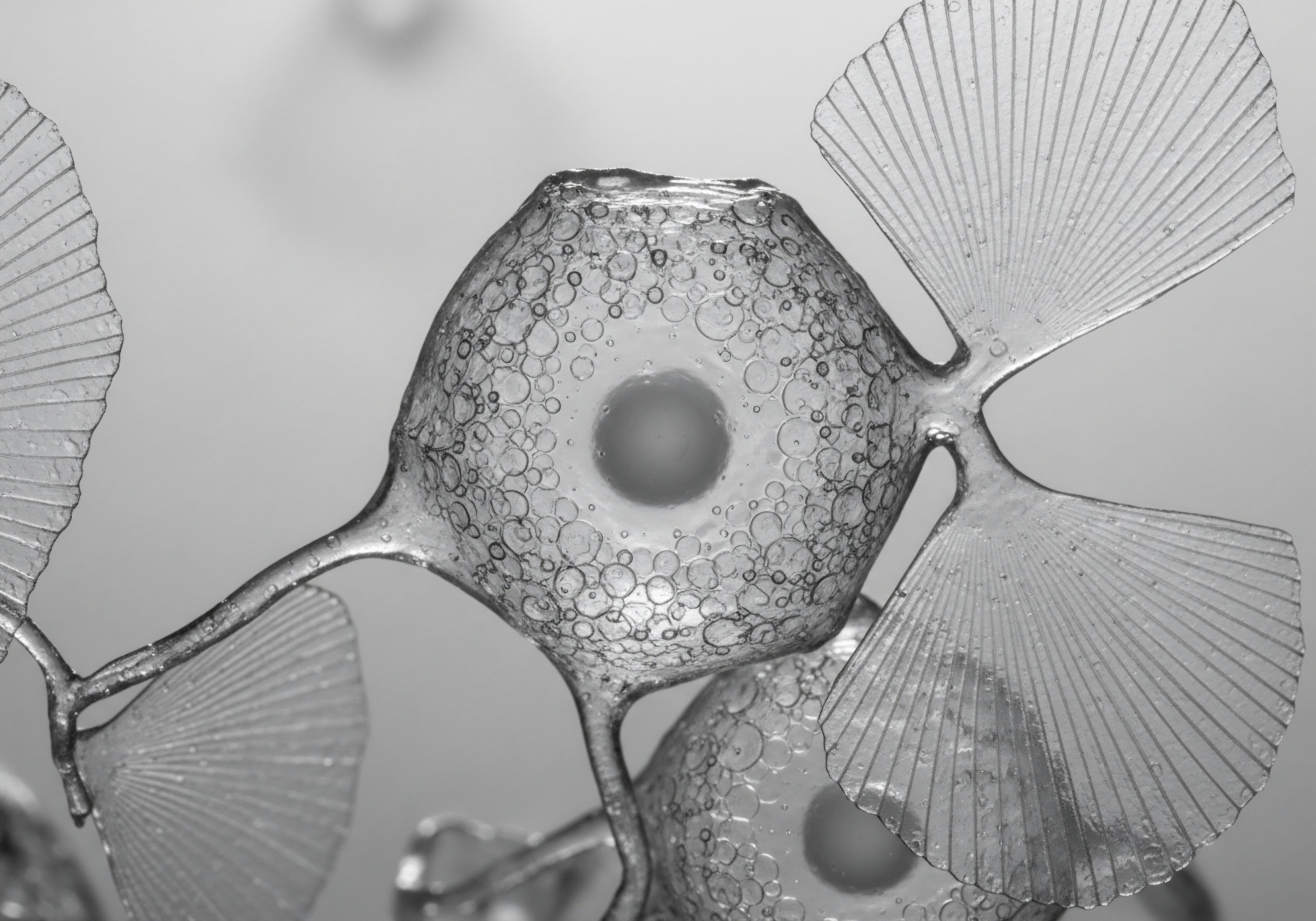

For many peptides, biological activity is dependent on their specific three-dimensional conformation. While the FDA does not typically mandate a bioassay for peptides in the same way it does for large proteins, providing data on higher-order structure Meaning ∞ Higher-order structure refers to the precise three-dimensional organization of biological macromolecules, such as proteins and nucleic acids, beyond their linear sequence. can be a critical part of the control strategy, especially for more complex peptides.

- Circular Dichroism (CD) Spectroscopy ∞ CD spectroscopy is highly sensitive to the secondary structure of peptides. It measures the differential absorption of left- and right-circularly polarized light. The resulting spectrum can reveal the relative proportions of alpha-helices, beta-sheets, and random coil structures, confirming that the peptide is folded correctly.

- Nuclear Magnetic Resonance (NMR) Spectroscopy ∞ NMR provides the most detailed atomic-level information about a peptide’s three-dimensional structure in solution. While technically demanding, 2D-NMR experiments can be used to solve the complete solution structure of a peptide, confirming folding and the spatial relationships between different amino acids.

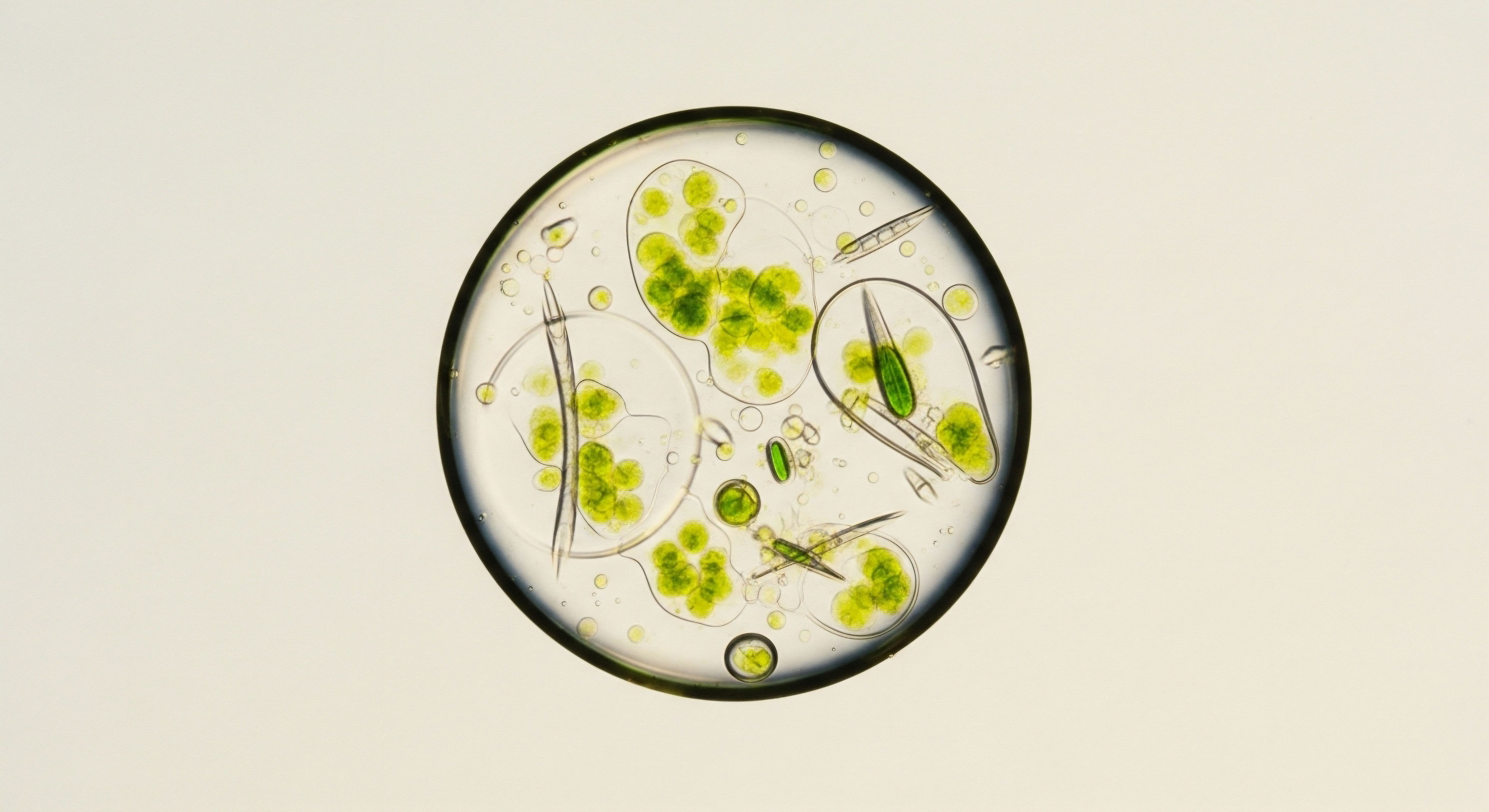

The Taxonomy of Impurities and Regulatory Expectations

The FDA’s guidance on peptide quality emphasizes the critical importance of characterizing and controlling impurities. The agency expects that any impurity present at a level of 0.10% or greater be identified. In cases where an impurity poses a significant potential risk, such as being a potent immunogen, it may need to be evaluated even at lower levels. The manufacturing process, particularly SPPS, can generate a characteristic spectrum of peptide-related impurities Meaning ∞ Peptide-related impurities are chemical entities within a peptide product not the intended active peptide molecule. that must be meticulously profiled.

The regulatory approval of a peptide hinges on a comprehensive impurity profile, as these molecular variants can directly impact the therapeutic’s safety and efficacy.

The following table provides a detailed overview of common peptide-related impurities, their origins, and their significance from a regulatory perspective.

| Impurity Type | Description and Origin | Potential Impact and Regulatory Concern |

|---|---|---|

| Deletion Sequences | Peptide chains that are missing one or more amino acids from the intended sequence. This occurs due to incomplete coupling during SPPS. | These impurities may have altered or no biological activity. In some cases, they could act as antagonists at the target receptor. Their presence reduces the overall potency of the drug substance. |

| Truncated Sequences | Peptides that are shorter than the full-length product, typically missing amino acids at one of the ends. This can result from premature termination of the synthesis. | Similar to deletion sequences, these reduce potency. Regulators require strict limits on these impurities to ensure consistent dosing and effect. |

| Insertion Sequences | Peptide chains that contain one or more extra amino acids. This is often caused by the double addition of an amino acid during a single coupling cycle. | An inserted amino acid can dramatically alter the peptide’s structure and function. It could also create a new, potent immunogenic epitope, making this a significant safety concern. |

| Deamidation Products | The chemical conversion of an asparagine (Asn) or glutamine (Gln) residue into aspartic acid or glutamic acid, respectively. This is a common degradation pathway. | Deamidation introduces a negative charge, which can alter the peptide’s structure, stability, and binding affinity. It is a critical quality attribute to monitor during stability studies. |

| Oxidation Products | The oxidation of susceptible amino acids, most commonly methionine (Met) and tryptophan (Trp). This can be caused by exposure to air or oxidizing agents. | Oxidation can inactivate the peptide or alter its pharmacokinetic profile. Stability testing under stress conditions is required to understand these degradation pathways. |

| Diastereomers | Impurities that arise from the racemization (conversion from L-form to D-form) of an amino acid during synthesis. | The presence of a D-amino acid in a sequence intended to contain only L-amino acids can change the peptide’s conformation and make it resistant to normal enzymatic degradation, altering its PK/PD profile. |

Why Is a Risk-Based Approach to Immunogenicity Assessment Necessary?

The clinical evaluation of immunogenicity is resource-intensive. Therefore, regulatory agencies encourage a science- and risk-based approach to determine the necessary level of assessment. This involves integrating information from various sources to build a holistic view of a product’s potential immunogenicity.

The assessment strategy involves several tiers of investigation:

- In Silico Analysis ∞ The amino acid sequences of the peptide and all identified impurities are screened against databases of known T-cell epitopes. Computational algorithms predict the binding affinity of these sequences to various MHC class II alleles, providing a preliminary risk score.

- In Vitro Assays ∞ For peptides with predicted risk, in vitro experiments can provide more direct evidence. MHC binding assays measure the physical interaction between a peptide and purified MHC molecules. Cell-based T-cell activation assays use blood cells from a diverse pool of human donors to see if the peptide or its impurities can stimulate an immune response.

- Product Attribute Analysis ∞ The physicochemical properties of the product are also considered. For example, the propensity of a peptide to aggregate is a major risk factor, as aggregates can be highly immunogenic. The presence of impurities that can act as adjuvants, such as those that stimulate the innate immune system, is also a critical consideration.

The data from these non-clinical studies inform the design of the clinical immunogenicity monitoring plan. If the pre-clinical assessment indicates a low risk, routine ADA monitoring in later-stage trials may be sufficient.

If a higher risk is identified, more intensive monitoring, including assessments for neutralizing antibodies and detailed pharmacokinetic/pharmacodynamic impact analysis, will be required from the earliest stages of clinical development. This tiered, evidence-based approach ensures that patient safety is protected while using development resources efficiently.

References

- Duncan, Katharine. “CMC Regulatory Experiences and Expectations for Peptides.” USP Workshop on Peptide and Oligonucleotide Therapeutics, 2024.

- FDA. “Guidance on Clinical Pharmacology for Peptide Drugs.” Dec. 2023.

- “Regulatory Considerations for Peptide Therapeutics.” ResearchGate, 2021.

- “Immunogenicity of therapeutic peptide products ∞ bridging the gaps regarding the role of product-related risk factors.” Frontiers in Immunology, 2023.

- “What Are the FDA Requirements for Peptide Characterization?” Avomeen, 2025.

- Diao, L. and B. Meibohm. “Pharmacokinetics and pharmacokinetic-pharmacodynamic correlations of therapeutic peptides.” Clinical Pharmacokinetics, vol. 52, no. 10, 2013, pp. 855-68.

- “Scientific and Regulatory Considerations for Assessment of Immunogenicity Risk for Generic Peptide and Oligonucleotide Drug Products.” FDA, 2024.

- “Chemistry, Manufacturing, and Controls ∞ Regulatory Considerations Through Clinical Development.” FDA, 2023.

Reflection

The Molecular Contract of Trust

The journey of a therapeutic peptide from a concept in a laboratory to a tool for wellness is paved with an immense volume of scientific data. This rigorous process of structural characterization and validation is far more than a bureaucratic requirement. It is a molecular contract between the developer, the regulator, and you.

It is the tangible evidence that underpins the trust you place in a therapy. Each peak on a chromatogram, each fragment in a mass spectrum, and each data point from a stability study contributes to a singular assurance ∞ the molecule is precisely what it claims to be, and it will remain so until the moment of its use.

Understanding this deep scientific diligence offers a new perspective. It reframes the regulatory pathway as a silent, dedicated partner in your health journey. The complexities of peptide structure, the challenges of manufacturing, and the potential for impurities are all managed through a system designed for your protection.

The knowledge gained here is a tool of empowerment. It allows you to see beyond the name of a therapy to the intricate science that ensures its quality. Your path to vitality is personal, and it is supported by this unwavering commitment to molecular integrity.