Fundamentals

Your body operates as an intricate, responsive system, a finely tuned orchestra where hormones act as the conductors. A subtle shift in the level of a single hormone ∞ a molecule of testosterone, a pulse of progesterone ∞ can alter your energy, mood, and cognitive function.

You have lived this reality; you have felt the profound effects of minute biological variances within your own system. This lived experience is the perfect lens through which to understand a parallel universe of precision ∞ the world of biologic medicines and the immense regulatory scrutiny they undergo.

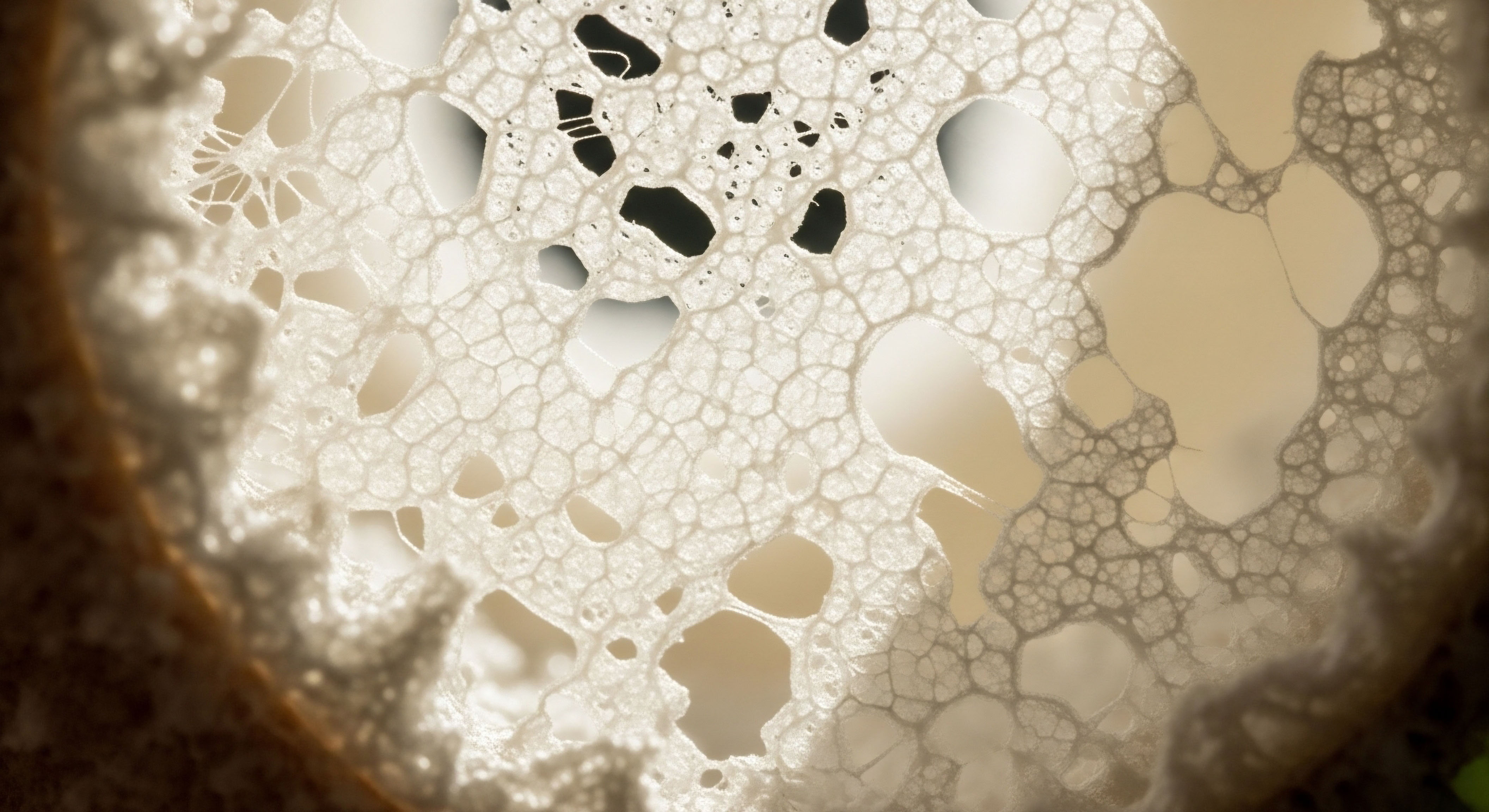

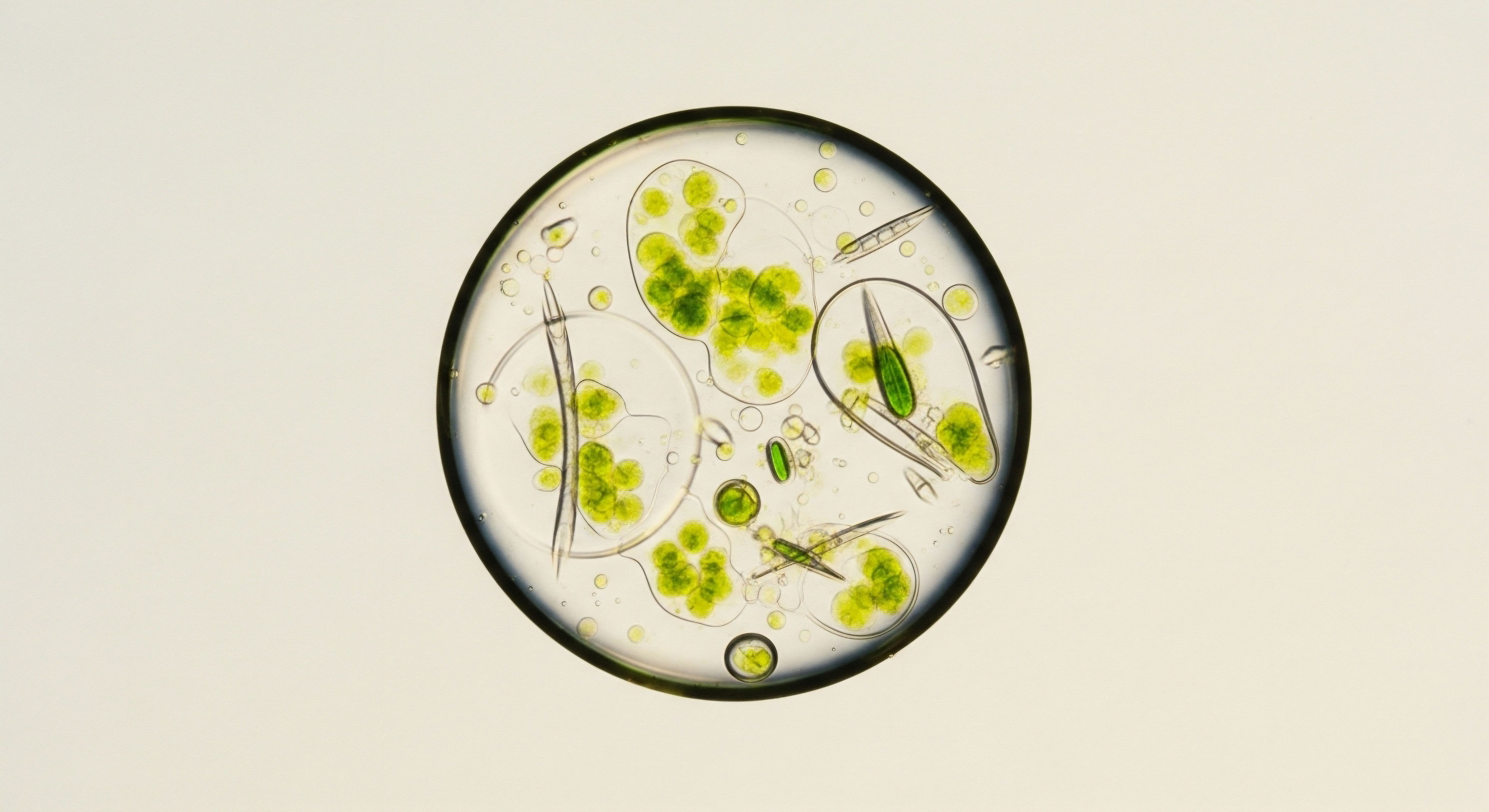

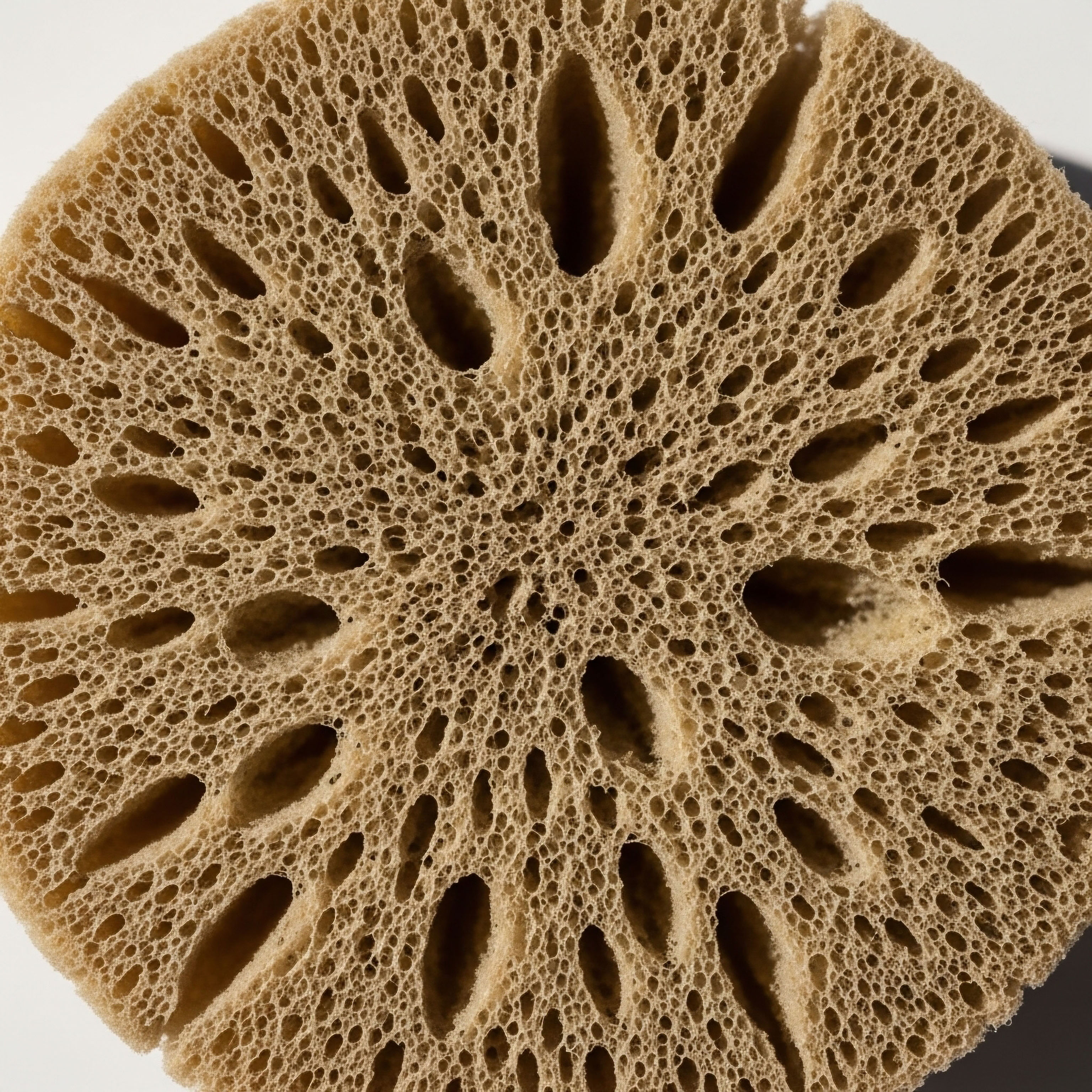

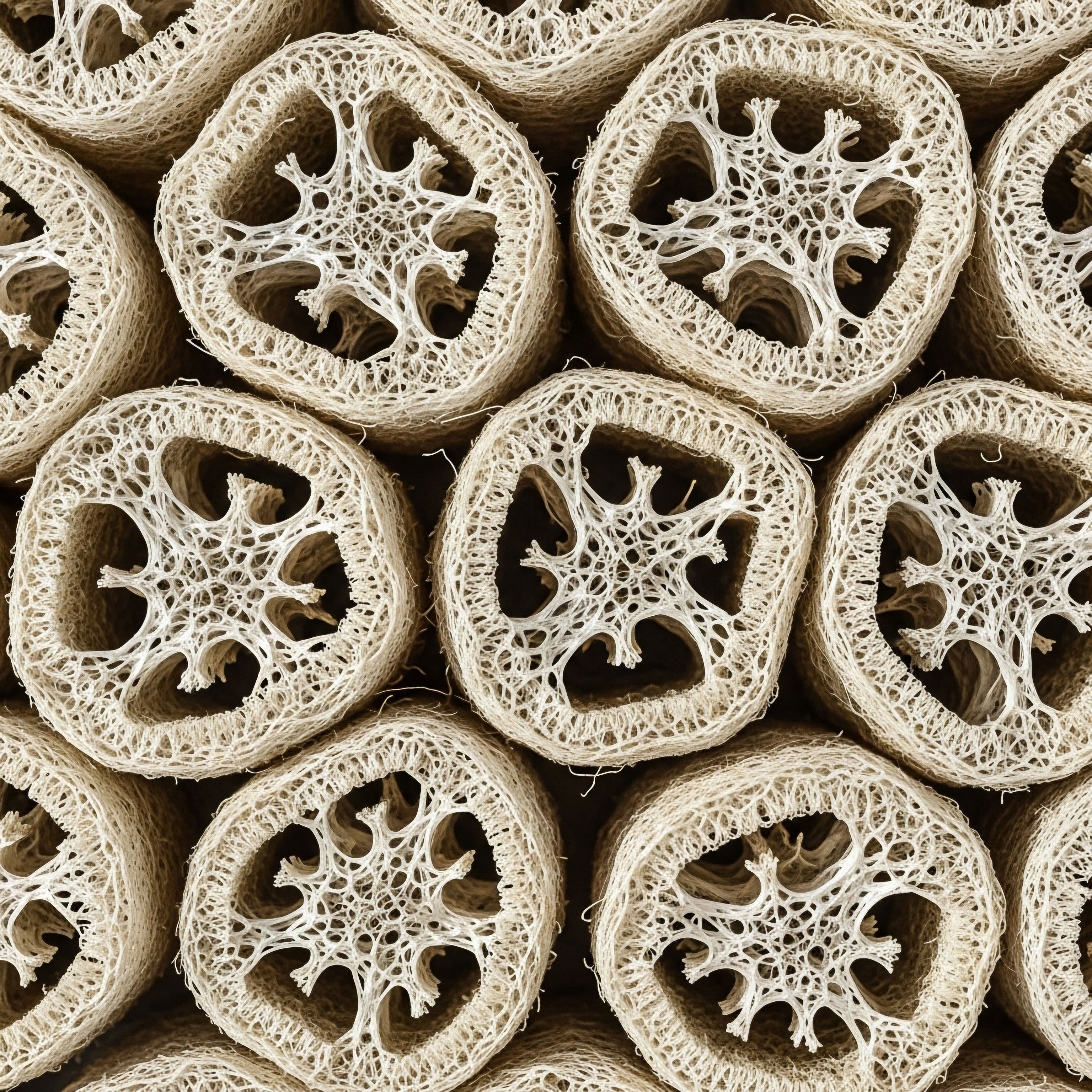

Biologics are complex therapeutic agents derived from living organisms. Think of peptides like Sermorelin, which encourages your body’s own growth hormone production, or even the bioidentical testosterone used in hormonal optimization protocols. These are sophisticated molecules, far more intricate than simple chemical drugs. Their structure is their function.

A tiny, imperceptible fold in a protein chain or a slight alteration in a complex sugar attachment can change how that molecule interacts with your cells. This is why manufacturing them is a matter of extreme precision. The process itself defines the final product.

The Body as the Ultimate Proving Ground

When you feel the fatigue of low testosterone or the cognitive fog of fluctuating estrogen, you are experiencing the downstream effects of subtle molecular changes. Your cellular receptors are exquisitely sensitive. They are designed to recognize and respond to specific hormonal keys.

A slightly misshapen key may not fit the lock, or it may fit poorly, sending a muddled signal or no signal at all. This sensitivity you feel is precisely why regulatory bodies like the U.S. Food and Drug Administration (FDA) apply such a rigorous standard to the manufacturing of biologics.

The regulatory framework governing biologics is built upon the biological principle that structure dictates function, a reality you experience daily in your own health journey.

A manufacturing variance refers to any change in the established process for creating a biologic. This could be a modification to the cell line used to produce the protein, a new piece of purification equipment, or even a change in the physical location of a manufacturing step.

Each alteration, no matter how small, carries the potential to change the final molecule’s structure and, consequently, its safety and effectiveness within your body. The regulatory approval process is the mechanism designed to safeguard this consistency. It ensures the therapeutic molecule you receive today is functionally identical to the one you received last month and the one that was proven effective in clinical trials.

Why Is the Approval Process so Rigorous for Biologics?

The creation of a biologic is a delicate dance of cellular biology and biochemical engineering. The process involves living cells, which have inherent variability. Controlling this process to produce a consistent product batch after batch is a monumental scientific challenge. The FDA’s role is to ensure that manufacturers have mastered this challenge.

They require extensive data, known as Chemistry, Manufacturing, and Controls (CMC) information, that acts as a detailed blueprint of the entire production. This blueprint is the baseline against which all future changes are measured. Any deviation from this approved process requires justification and, in many cases, pre-approval, because even a minor shift could have significant biological consequences for the person receiving the therapy.

Intermediate

Understanding the regulatory oversight of biologics manufacturing moves from the conceptual to the practical when we examine how changes are categorized and managed. For anyone on a personalized wellness protocol involving therapeutic peptides or hormone therapies, this system offers a reassuring parallel to the adjustments made in their own clinical journey.

The FDA classifies post-approval manufacturing changes into a tiered system based on their potential to impact the product’s quality, safety, or efficacy. This framework validates the core principle of personalized medicine ∞ that every adjustment must be considered, measured, and justified.

These regulatory tiers provide a logical structure for managing change, ensuring the level of scrutiny matches the level of risk. This process is a dialogue between the manufacturer and the regulatory agency, with the patient’s well-being as the silent, central focus. Each category of change has a specific reporting requirement, a protocol that must be followed to ensure continued approval and market access.

A Clinical Parallel to Regulatory Oversight

The way regulators handle manufacturing variances mirrors the way a clinician manages a patient’s hormonal health protocol. A change in your life ∞ increased stress, altered diet, a new fitness regimen ∞ can necessitate a change in your protocol. A clinician’s response is tiered, just like the FDA’s. This alignment between macro-level regulation and micro-level clinical care is powerful. It shows a consistent, science-based approach to managing complex biological systems, whether in a bioreactor or in your body.

The table below draws a direct comparison between the FDA’s reporting categories for manufacturing changes and the corresponding adjustments a clinician might make to a personal hormone optimization plan.

| FDA Reporting Category | Description of Manufacturing Change | Clinical Analogue in Personalized Medicine |

|---|---|---|

| Annual Report | A minor change with minimal potential to affect product quality, such as a slight tightening of an existing quality control specification. The change is implemented and documented in a yearly report to the FDA. | A minor lifestyle observation, like noting improved sleep patterns after starting a magnesium supplement, which is documented in the patient’s chart at their next regular follow-up. |

| Changes Being Effected in 30 Days (CBE-30) | A moderate change, like a minor adjustment to the manufacturing process. The manufacturer must notify the FDA 30 days before distributing the product made with the new process. | A planned dosage adjustment, such as slightly increasing weekly Testosterone Cypionate based on recent lab work showing suboptimal levels. The change is made with a clear clinical rationale and follow-up is scheduled. |

| Changes Being Effected-0 (CBE-0) | A moderate change that can be implemented immediately upon the FDA’s receipt of the supplement, often related to ensuring product sterility or safety. | An immediate protocol adjustment due to a patient-reported side effect, like adding Anastrozole to a TRT protocol to manage rising estrogen levels. The action is taken promptly to ensure patient well-being. |

| Prior Approval Supplement (PAS) | A major change with significant potential to affect the product’s identity, strength, quality, purity, or potency. This includes changes to the manufacturing facility or fundamental process steps. The change cannot be implemented until the FDA formally approves the supplement. | A complete recalibration of a therapeutic protocol, such as transitioning a patient from weekly TRT injections to a fertility-stimulating protocol involving Gonadorelin and Clomid, which requires a full clinical reassessment. |

The Language of Consistency Chemistry Manufacturing and Controls

The foundation of this entire regulatory structure is the Chemistry, Manufacturing, and Controls (CMC) data submitted in the original Biologics License Application (BLA). The CMC section is an exhaustive document detailing every aspect of production.

It includes the precise specifications of the raw materials, the genetic makeup of the cell line, the exact parameters of the fermentation and purification processes, and the analytical tests used to confirm the final product’s quality. This CMC package is the biologic’s fingerprint. When a manufacturer proposes a change, they must demonstrate how it affects this fingerprint and provide data to show that the final product remains consistent and safe.

The meticulous CMC documentation for a biologic serves the same purpose as your comprehensive health record and lab history, providing a stable baseline against which all changes are measured.

Academic

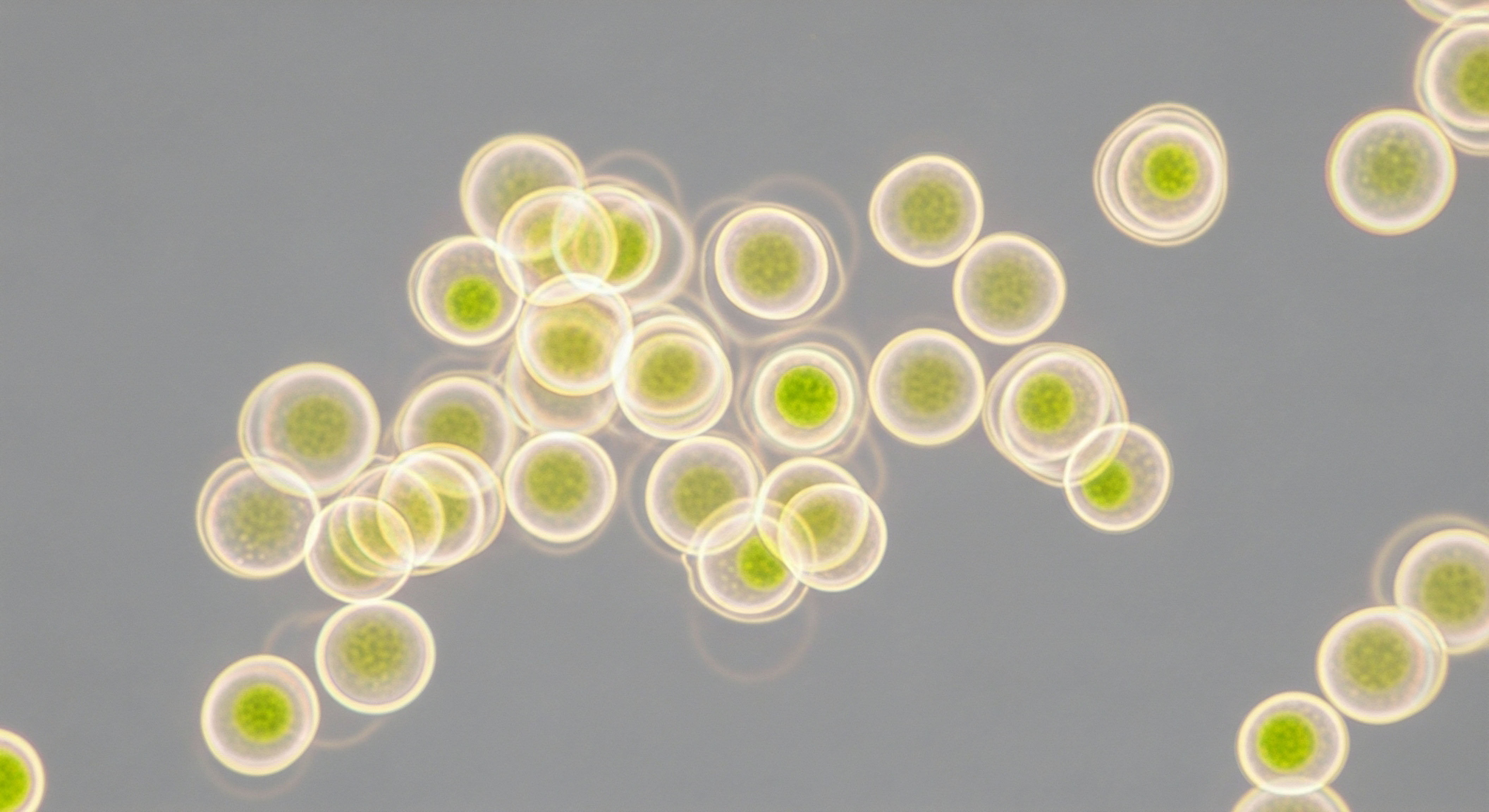

At the most sophisticated level of regulatory science, the assessment of manufacturing variances centers on a critical concept ∞ comparability. When a manufacturer alters any part of their approved process, they must scientifically demonstrate that the resulting biologic is highly similar, in molecular and functional terms, to the product made using the pre-change process.

This is accomplished through a formal “comparability study,” a rigorous exercise that generates data to confirm that the change has not negatively impacted the product’s quality attributes. This process is the bedrock of regulatory trust and directly ensures that the patient experience remains consistent and predictable.

A comparability analysis is a multi-faceted investigation. It examines the biologic from numerous angles, using advanced analytical techniques to create a high-resolution portrait of the molecule. The goal is to prove that any physicochemical or biological differences between the pre-change and post-change product are clinically irrelevant. For a person whose well-being depends on the precise signaling of a therapeutic peptide like Ipamorelin or a hormone like testosterone, this scientific diligence is paramount.

What Does a Comparability Analysis Truly Measure?

The depth of a comparability analysis reflects the complexity of the biologic itself. The investigation goes far beyond simply confirming the correct protein sequence. It assesses a suite of critical quality attributes (CQAs) that can be influenced by manufacturing conditions. These attributes are the very features that dictate how the biologic will behave in the human body, from its stability in the vial to its interaction with a target receptor on a cell surface.

The following list outlines key areas assessed in a comprehensive comparability study:

- Physicochemical Properties ∞ This involves using techniques like mass spectrometry to confirm the exact molecular weight and amino acid sequence. It also includes methods like chromatography to analyze the product for impurities or variants, such as oxidized or clipped forms of the protein, which could reduce efficacy or cause unwanted immune reactions.

- Structural Integrity ∞ The biologic’s three-dimensional structure, including its secondary and tertiary folding, is essential for its function. Techniques like circular dichroism are used to confirm this higher-order structure is maintained. Any variance in the folding could render the biologic inactive or even immunogenic.

- Post-Translational Modifications ∞ Many biologics, especially complex proteins, have sugar molecules attached to them in a process called glycosylation. These glycan profiles can be critical for the molecule’s stability, half-life, and receptor-binding affinity. Manufacturing changes can alter these patterns, so detailed analysis is required to ensure they remain consistent.

- Biological Activity ∞ This is the ultimate functional test. A cell-based bioassay is used to measure the biologic’s ability to elicit a specific, desired response in a controlled laboratory setting. For a growth hormone secretagogue like Sermorelin, this might involve measuring its ability to stimulate growth hormone release from pituitary cells. This confirms the molecule works as intended.

The Clinical Significance of Analytical Rigor

Each data point in a comparability study has a direct line to clinical outcomes. A seemingly minor variance detected in a lab can have major implications for a patient. The table below connects specific analytical tests used in these studies to their direct relevance in a clinical or physiological context, illustrating the profound connection between manufacturing science and human health.

| Analytical Technique | Attribute Measured | Direct Clinical or Physiological Relevance |

|---|---|---|

| Mass Spectrometry | Confirms the precise molecular mass and identifies any modifications or degradants. | Ensures the fundamental identity of the therapeutic molecule is correct, preventing the administration of an incorrect or degraded substance that could be ineffective or harmful. |

| High-Performance Liquid Chromatography (HPLC) | Separates the main product from process-related impurities and product variants. | Guarantees the purity of the dose, minimizing the patient’s exposure to potentially immunogenic or inactive molecular variants that could cause side effects or reduce therapeutic benefit. |

| Circular Dichroism Spectroscopy | Assesses the higher-order (secondary and tertiary) protein structure. | Confirms the molecule is correctly folded, which is essential for its ability to bind to the correct biological receptor (e.g. the growth hormone secretagogue receptor for Ipamorelin) and initiate a signal. |

| Cell-Based Bioassay | Measures the specific biological activity or potency of the molecule. | Provides direct evidence that the biologic can produce its intended physiological effect, ensuring that a 1mg dose provides 1mg worth of functional activity in the body. |

This level of detailed analysis ensures that when a manufacturer refines their process, the change is an improvement or a necessary adaptation that does not compromise the product’s established safety and efficacy profile. It is a scientific commitment to consistency that allows clinicians and patients to trust the therapeutic agents they rely on for optimizing health, managing chronic conditions, and reclaiming vitality.

References

- U.S. Food and Drug Administration. “Chemistry, Manufacturing, and Controls Changes to an Approved Application ∞ Certain Biological Products.” Guidance for Industry, June 2021.

- U.S. Food and Drug Administration. “Draft Guidance on Postapproval Manufacturing Changes for Biologics.” August 2017.

- Regulatory Affairs Professionals Society (RAPS). “FDA Drafts Guidance on Postapproval Manufacturing Changes for Biologics.” August 8, 2017.

- “New FDA guidance on biological manufacturing changes.” European Pharmaceutical Review, 25 August 2017.

- Regulatory Compliance Associates Inc. “FDA Publishes Updated Biologics Guidance.” 2021.

Reflection

Your Biology Is Your Story

You began this exploration with an intimate understanding of variance. You know how a subtle internal shift can rewrite your daily experience. The journey through the world of biologics manufacturing and regulatory science offers a new vocabulary for this understanding. The same principles of precision, consistency, and structural integrity that govern the creation of these advanced therapies apply directly to the complex, living system that is your body.

The meticulous attention given to a single protein’s fold or a minor change in a production environment validates your own sensitivity. It affirms that these small details matter profoundly. This knowledge is a tool. It equips you to view your own health journey not as a series of disconnected symptoms, but as a coherent system that can be understood and optimized.

Your path forward involves applying this same rigorous yet respectful attention to your own biology, recognizing that personalized wellness is the ultimate expression of understanding and honoring variance.

Glossary

growth hormone

food and drug administration

therapeutic peptides

hormone optimization

biologics license application

regulatory science

comparability study

critical quality attributes

glycosylation