Fundamentals

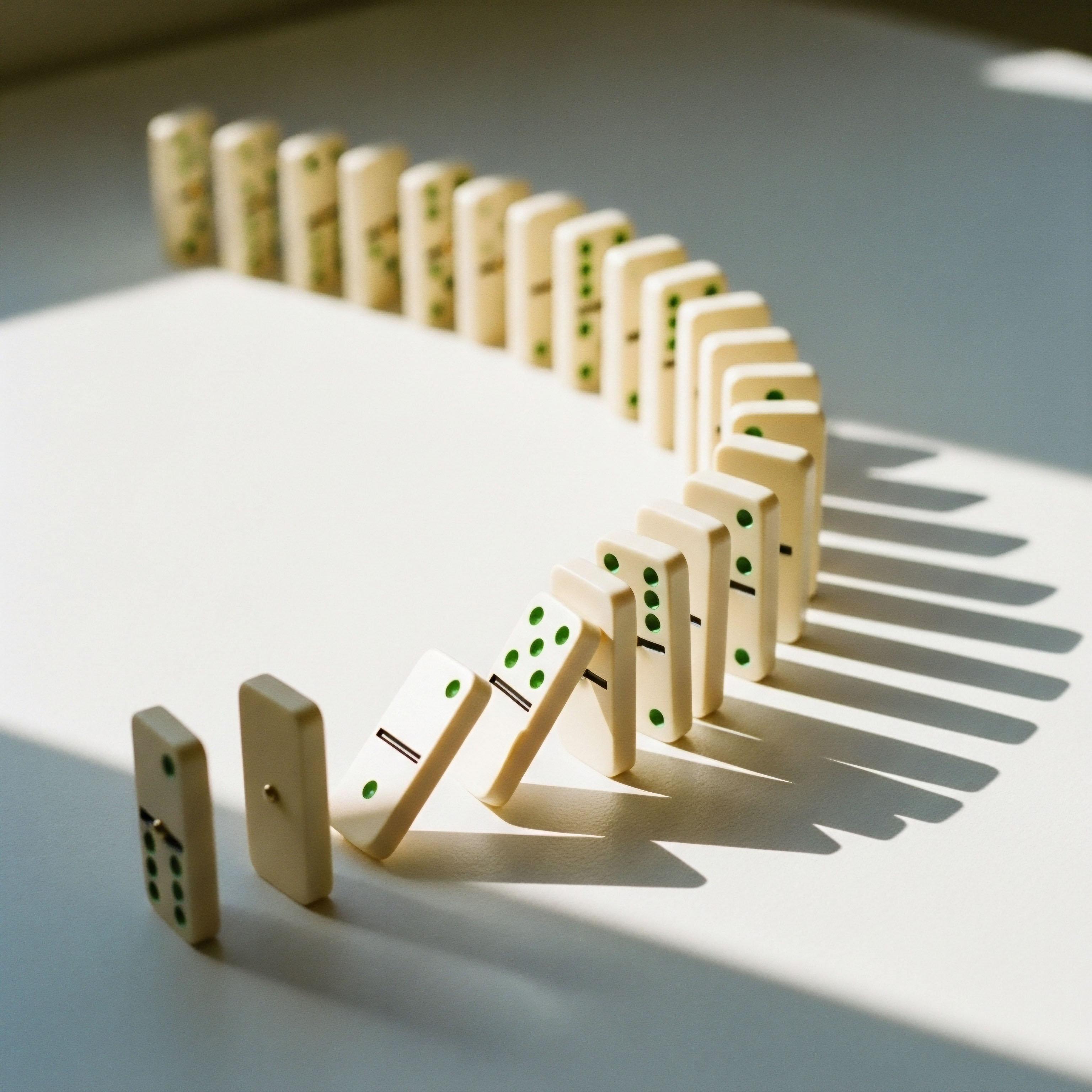

Your body’s internal communication relies on exquisite precision. Think of peptides as specific keys, crafted to fit particular locks within your cells to initiate critical processes like healing, metabolic regulation, and hormone production. When you consider a therapeutic peptide protocol, you are introducing a powerful set of keys into this intricate system.

The origin and purity of these keys become profoundly important. The standards governing a peptide’s creation directly translate to its ability to interact correctly with your physiology. A flawlessly synthesized peptide communicates its intended message clearly. A poorly constructed one, laden with impurities or structural errors, may fail to fit the lock, or worse, jam it entirely, sending confusing signals that your body must then manage.

This is the human element of manufacturing science. The discussion of regional standards is a conversation about biological trust. It addresses the foundational query of whether the molecule you introduce into your system is a perfect copy of the intended messenger or a distorted version.

Your cells do not differentiate based on a product’s label or cost; they respond to molecular structure. Therefore, understanding the landscape of manufacturing quality is the first step in ensuring a therapeutic partnership with your own biology, one built on the molecular integrity of the agents you employ to guide it.

A peptide’s manufacturing origin dictates its purity, which directly impacts its interaction with your body’s cellular signaling pathways.

The Language of Purity and Potency

In the world of biochemistry, “purity” and “potency” are terms with precise meanings that have direct consequences for your health. Purity refers to the percentage of the product that is the correct, intended peptide sequence. Potency, on the other hand, describes the biological activity or strength of that peptide.

A high-purity product might have low potency if the molecules, though correctly sequenced, are folded improperly or degraded. Conversely, a potent but impure product contains a high concentration of active molecules alongside a significant number of contaminants.

These contaminants can include:

- Deletion Sequences ∞ Truncated versions of the peptide that are missing one or more amino acids.

- Residual Solvents ∞ Chemicals used during the synthesis process that have not been fully removed.

- Endotoxins ∞ Toxins released from bacteria that can cause inflammatory reactions.

Each of these impurities introduces a variable that your system must interpret. The goal of rigorous manufacturing standards is to minimize these variables, delivering a clear, singular message to your cells. This molecular precision is the bedrock of any effective and safe peptide therapy.

Intermediate

Navigating the world of therapeutic peptides requires an understanding of the regulatory frameworks that ensure their safety and efficacy. These systems, established by governmental bodies, create a clear distinction between peptides intended for pharmaceutical use and those sold for research purposes. The primary global arbiters of quality are the U.S.

Food and Drug Administration (FDA) and the European Medicines Agency (EMA). Both agencies mandate adherence to Good Manufacturing Practices (GMP), a set of stringent guidelines that control every aspect of production, from the raw materials to the final sterile product.

GMP standards are the operational blueprint for creating a pharmaceutical-grade product. They ensure that each batch of a peptide is produced and controlled consistently, guaranteeing its identity, strength, quality, and purity. Peptides manufactured outside of this GMP framework, often labeled as “for research use only,” do not have the same quality assurance.

Their production may lack the rigorous testing, documentation, and process validation required for human administration, leading to significant variability in purity and the potential presence of harmful contaminants.

Good Manufacturing Practices (GMP) provide a universal standard for producing pharmaceutical-grade peptides, ensuring batch-to-batch consistency and purity.

How Do Regulatory Frameworks Compare Globally?

While the FDA and EMA represent the gold standard, the global regulatory landscape is a mosaic of varying requirements. The principles of GMP are largely harmonized through the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), but regional implementation and oversight differ.

A product manufactured under GMP in an FDA-inspected facility offers a high degree of certainty regarding its quality. The requirements in other regions may be less stringent, creating a spectrum of quality across the global market.

This table provides a simplified comparison of these regulatory environments:

| Regulatory Body | Region | Key Standard | Primary Focus |

|---|---|---|---|

| FDA (Food and Drug Administration) | United States | US GMP (21 CFR Parts 210/211) | Ensures safety and efficacy for drugs marketed in the U.S. through rigorous facility inspections and process validation. |

| EMA (European Medicines Agency) | European Union | EudraLex Volume 4 (EU GMP) | Centralized authorization procedure for medicines, ensuring consistent standards across all EU member states. |

| Other Regions | Varies | National GMP or ICH Adoption | Standards can vary widely. Some countries have robust national agencies, while others may have less developed oversight. |

| Unregulated/Research | Global | None (Typically) | Products are not intended for human use; no mandatory quality control, purity, or safety standards are enforced. |

What Distinguishes Pharmaceutical Grade from Research Grade?

The distinction between pharmaceutical-grade and research-grade peptides is defined by the manufacturing process and its accompanying documentation. It is a difference in process, oversight, and certainty.

- Pharmaceutical Grade (GMP) ∞ This grade signifies that the peptide was produced in a facility compliant with GMP standards. Every step, from synthesis to purification and packaging, is validated and documented. The final product undergoes extensive testing for purity, potency, sterility, and the absence of contaminants like endotoxins. This process provides the traceability and quality assurance necessary for clinical use.

- Research Grade ∞ These peptides are intended for laboratory experiments (in vitro or in vivo animal studies). While some research-grade peptides may have high purity, the manufacturing process lacks the stringent controls and validation of GMP. There is no guarantee of lot-to-lot consistency, and testing for contaminants relevant to human safety is not required. The purity stated on the label may not be verified by an independent regulatory body.

Academic

The biological consequence of varying peptide manufacturing standards extends deep into the domains of immunology and toxicology. A therapeutic peptide is designed to function as a precise signaling molecule. Its efficacy is predicated on its structural integrity, specifically its primary amino acid sequence and, in some cases, its higher-order conformation.

Deviations from this intended structure, which are more prevalent in non-GMP manufacturing, can create molecules that the body may recognize as foreign or dysfunctional. These deviations are not inert; they are biologically active contaminants with potential physiological ramifications.

At the molecular level, impurities in peptide preparations can be categorized based on their origin and structure. These include sequence variants (e.g. deletions, insertions), chemically modified forms (e.g. oxidation, deamidation), and process-related impurities (e.g. residual solvents, reagents, host cell proteins).

From a clinical perspective, the most concerning of these are impurities that can provoke an immune response or exhibit off-target biological activity. For instance, an aggregated peptide or one with a minor sequence modification could be recognized by antigen-presenting cells, potentially leading to the development of anti-drug antibodies. Such an immune response can neutralize the therapeutic effect of the peptide or, in rare cases, trigger broader autoimmune reactions.

What Is the Immunological Impact of Peptide Impurities?

The immunogenicity of a therapeutic peptide is a critical safety parameter influenced heavily by its purity and the presence of aggregates. Even small amounts of structurally altered peptides can break immunological tolerance. The solid-phase peptide synthesis (SPPS) process, while efficient, can generate a range of closely related impurities that are difficult to separate during purification.

If these impurities persist in the final product, they act as neoantigens. The immune system may mount a response, leading to reduced efficacy as neutralizing antibodies clear the therapeutic peptide from circulation. This phenomenon underscores why regulatory bodies like the FDA and EMA place such a strong emphasis on the characterization and control of impurities.

The presence of molecular impurities in a peptide preparation can trigger an unintended immune response, compromising both safety and therapeutic efficacy.

The following table details common process-related impurities and their potential physiological consequences, illustrating the direct link between manufacturing standards and patient outcomes.

| Impurity Class | Description | Potential Physiological Consequence |

|---|---|---|

| Sequence Variants | Peptides with deleted or incorrect amino acids due to errors in the synthesis cycle. | Can have altered binding affinity for the target receptor, act as an antagonist, or be immunogenic. |

| Peptide Aggregates | Clumps of peptide molecules formed due to improper folding or storage conditions. | Highly associated with increased immunogenicity and can lead to injection site reactions. |

| Endotoxins (Lipopolysaccharides) | Components of bacterial cell walls that are potent immune stimulants. | Can cause systemic inflammation, fever, and other adverse reactions even at very low concentrations. |

| Residual Solvents/Reagents | Chemicals used in synthesis and purification that are not completely removed. | May have direct toxic effects on cells and tissues, depending on the specific chemical and its concentration. |

Therefore, the stringent validation and control limits mandated by GMP are not bureaucratic hurdles. They are essential safeguards designed to minimize the introduction of immunogenic and toxic components. The analytical methods used in GMP facilities, such as high-performance liquid chromatography (HPLC) and mass spectrometry, are validated to ensure they can detect and quantify these specific impurities, providing a level of safety and predictability that is absent in less regulated manufacturing environments.

References

- U.S. Food and Drug Administration. “Guidance for Industry ∞ Chemistry, Manufacturing, and Controls Information for Synthetic Peptide Substances.” 1994.

- European Medicines Agency. “Guideline on the Development and Manufacture of Synthetic Peptides.” 2023.

- White, P. & Collins, J. Peptide Synthesis and Applications. Humana Press, 2013.

- “Quality control in peptide manufacturing ∞ specifications for GMP peptides.” Polypeptide Group, 2008.

- International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use. “ICH Harmonised Tripartite Guideline Q7A ∞ Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients.” 2000.

- Vlieghe, P. et al. “Synthetic Therapeutic Peptides ∞ Science and Market.” Drug Discovery Today, vol. 15, no. 1-2, 2010, pp. 40-56.

- Eon-Duval, A. et al. “Quality and regulatory requirements for peptide-based pharmaceuticals.” Peptide Science, vol. 98, no. 2, 2012, pp. 81-97.

Reflection

You stand at the intersection of profound biological knowledge and personal responsibility. The information regarding peptide manufacturing standards provides you with a new lens through which to view your health journey. It transforms the abstract concept of ‘quality’ into a tangible set of criteria with direct implications for your body’s intricate signaling network.

This understanding is a tool, empowering you to ask more precise questions and make more informed decisions. The path to optimizing your vitality is built upon a foundation of such knowledge, where each choice is a conscious step toward aligning your actions with your biological truth. How will this deeper appreciation for molecular integrity shape the next phase of your wellness protocol?